Professional Documents

Culture Documents

Trick Flow Camshaft Degreeing Kit: Instructions For

Uploaded by

ROYALOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trick Flow Camshaft Degreeing Kit: Instructions For

Uploaded by

ROYALCopyright:

Available Formats

Instructions for

Trick Flow Camshaft Degreeing Kit

TFS-90000

Thank you for purchasing this Trickflow Camshaft of finding out where your valves are opening and closing in

Degreeing Kit. In addition to checking camshaft timing and relation to the crankshaft position. By degreeing the cam,

piston to valve clearance, you will find many other uses for you will be able to detect and compensate for errors in valve

the indicator and magnetic base: checking flywheel run out, timing. These errors can be due to variations in the

crankshaft endplay, and ring gear backlash are just a few machining of the timing set, the crank keyway position, or the

examples. If you're someone who likes to save money by cam itself.

doing things yourself, this kit will pay for itself many times

over. Getting Started

Learning to use the kit correctly will help to take some of There are two basic methods of degreeing camshafts. One

the mystery out of valvetrain operation, so please read all locates the theoretical centerline of the #1 intake lobe. The

instructions first. Make sure to check the contents of your other locates the opening and closing points of the #1 intake

kit. If you have any questions, please call or text line at (330) valve or lifter at a specified amount of lift - usually .050”. We

630-1555. are going to use a combination of both and adjust the intake

centerline if needed to make sure the opening and closing

Parts List points or where they should be.

2 Low tension checking springs Most modern cam lobes are asymmetrical by design, so

1 Wire pointer relying on theoretical centerline position alone is not good

1 TDC stop (head on engine type) enough. Relying on centerline alone will also miss a lobe that

1 11” Degree wheel is either too big or too small. In other words, centerline tells

3 Adapter bushings you nothing about any variation of the opening and closing

1 Flat washer ramps of the lobe. Depending on the amount of variation,

1 Magnetic base you can either split the difference or set either the intake

1 Dial indicator opening or closing point as it specified position. Keep in mind

the point at which the intake valve closes has an obvious

1 Carrying case

effect on cylinder pressure.

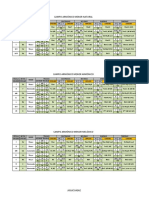

The table below describes the basic effects of advancing or

Why Should I Degree My Camshaft?

retarding a camshaft.

Valve opening and closing points are what give an engine a

specific performance curve. Degreeing a cam is the only way

General Effects of Advancing or Retarding a Camshaft

Performance Piston to Valve Clearance Valve Timing

Shifts power curve down Intake Valve loses All timing events occur sooner

Advancing the Cam approximately 200 RPM Exhaust Valve gains

for a 4 degree change

Shifts power curve up Intake Valve gains All timing events occur later

Retarding the Cam approximately 200 RPM Exhaust Valve loses

for a 4 degree change

Note: The 200 RPM shift in the power curve is an approximate figure for most high

performance street/strip engines.

TFS-INS-90000 Rev.0 10/13/15

Basic Degreeing Procedure (with heads on engine) 7. Be sure to check the accuracy of your adjustment by

turning the degree wheel from stop to stop again.

Note: references to clockwise and counterclockwise or based You should have an equal amount of travel on each

on a person facing the front of the engine side of TDC.

1. Install the checking springs on the #1 cylinder. If you 8. Place a solid lifter of the type that matches your cam

do not wish to remove the existing valve springs you on the #1 intake lobe. Install the appropriate

can degree the cam directly off a solid lifter. Make pushrod and rocker on the same valve. If an

sure the specs on the cam card are taken from the adjustable pushrod is available, use it; you can make

lifter also. If they are taken at the valve, divide the it longer to compensate for the shorter mechanical

valve lift by the specified rocker ratio to get the lifter and keep the geometry the same.

correct tappet lift. Since we have included the

checking springs, the rest of the instructions were 9. Place the dial indicator and magnetic base on the

referred to degreeing the cam from the valve. cylinder head. If you have aluminum cylinder heads

you need to mount a piece of steel on the valve

2. Install the new cam and adjustable timing set per cover mounting holes for the magnetic base too

manufacturer’s instructions. Make sure both lobes attached to. Preload the dial indicator a little more

for the #1 cylinder are free of any thick assembly than your maximum valve lift, and be sure the point

lube that may throw off your readings. After the on the dial indicator is resting on the valve spring

degreeing procedure, re-lubricate the lobes. retainer and in alignment with the travel of the

valve. This will reduce any geometric error in the

3. Install the degree wheel on the front of the valve lift measurements.

crankshaft using the balancer bolt and the aluminum

bushings. Attach the pointer at a convenient 10. Rotate the engine clockwise until you reach the

location, usually a bolt near the water pump. Align point of maximum lift. Start slowing down as the

the pointer so that it is aimed directly at the center needle slows down. When the needle stops moving

of the wheel and the tip is close to the edge of the you have reached the point of maximum lift. Double

wheel. check the indicator probe to see if it is still touching

the valve spring retainer. If you did not preload the

4. Bring the #1 piston close to top dead center (TDC) on indicator enough the probe will be resting in the air.

the compression stroke (both valves closed). That will stop the movement of the needle, but the

Without moving the crank, adjust the degree wheel cam won't be at max lift.

so that the pointer is at the TDC mark on the wheel.

This is just to get you close to position. 11. If everything is OK, turn the face of a dial indicator to

zero. Turn the crank until you reach .050” before

5. Turn the crank shaft ¼- turn counterclockwise to max lift and mark the position on the wheel.

lower the piston, then, install the piston stop in the Continue turning the crank until a needle indicates

#1 spark plug hole. Screw the center post on the .050” after max lift and record the reading. Add the

stop all the way in. Gently turn the crank clockwise two readings together and divide by two. For

until the piston hits the stop and record the reading. example:

Turn the crankshaft in the opposite direction until

the piston comes back up and hits the stop, then 150° on one side

record that reading. +66° on the other = 216°

216° ÷ 2 = 108°

6. If your original TDC estimation was correct, you'll

have equal amount of travel on either side of TDC 12. This result (108° in our example) will be the point of

(34° BTDC and 34° ATDC, for example). In most cases maximum lift, which is the theoretical intake

you'll have unequal readings such as 38° BTDC and centerline. If you're within 1° of the specification on

30° ATDC. In this case, just split the difference and the cam card, you're all set. If you're further off than

adjust the degree wheel without moving the crank. that, you must adjust the cam’s position and repeat

Here is an example: 38° - 30° = 8° ÷ 2 = 4° the degreeing procedure. If you got a smaller

number the cam is advanced and would need to be

retarded. Say in our example the cam came out at

106° instead of 108°. That means it is advanced and

TFS-INS-90000 Rev.0 10/13/15

you would need to retard it 2°. Getting a larger Note: When checking opening and closing points,

number than what is on the cam card means that look at the cam card to see if the .050” lift is

the cam is retarded. In our example, getting 110° measured at the lifter or the valve. If it is measured

reading for a cam spaced at 108° indicates the cam is at the lifter, you need to multiply the lift figure by

2° retarded, so you would have to advance it 2°. your rocker ratio since you are measuring at the

valve.

13. Once the intake centerline is correct, check the

opening and closing points of the #1 intake valve at 15. Set up the indicator, lifter, and proper pushrod on

.050” lift. Preload the indicator as before and turn the exhaust lobe of the #1 cylinder for a quick check

the crank in the same direction until the valve closes. of maximum lift, lobe center, and opening and

The needle will stop moving since it will be on the closing points.

heel of the lobe. Set the indicator face to zero, and

slowly turn the crank until the needle just starts to 16. Now that the cam is correctly positioned, remove

rise as the valve opens. Turn very slowly until the your checking equipment and recoat the #1 lobes

needle reads .050” of valve lift. Record the reading and lifter with your camshaft manufacturer’s

on the degree wheel, and turn the crank and count recommended break-in lube. Replace the checking

the revolutions of the needle from .050” open until springs with the originals and assemble the

the valve reaches maximum lift. At that point the remainder of the engine. Pay close attention to

needle will momentarily stop, then change direction. getting the engine ready to start immediately after

the key is turned. Put a timing light on the #1 plug

14. Continue turning the crank as the valve closes and wire and have fuel system primed and ready to flow.

the needle makes the same number of turns until Quick start-up and proper cam break-in is essential.

the valve is at .050” before being fully closed. Make sure to follow all of your cam manufacturer’s

Record the reading on the degree wheel, and break-in instructions to get the maximum

compare both readings to the specifications on the performance life possible out of your camshaft.

cam card. Again, if they are within 1° you are fine. If

not, the cam position will need to be adjusted.

Follow your timing set instructions on making any

adjustment. Re-check after you are done.

TFS-INS-90000 Rev.0 10/13/15

Ultimate Bolt-On Performance Lifetime Warranty

Trick Flow Specialties cylinder head castings are backed by a lifetime warranty. If a cylinder head casting fails to provide the

original purchaser with complete satisfaction, Trick Flow Specialties will repair or replace it free of charge — guaranteed!

Moreover, the valves, valve guides, valve seats, valve job, valve springs, valve spring retainers, valve locks, rocker arm studs, guideplates, and valve

stem seals included on assembled Trick Flow Specialties cylinder heads are warranted to the original purchaser to be free from defects in materials

and workmanship for a period of two years from the date of purchase. All other Trick Flow Specialties products are warranted to be free from

defects in materials and workmanship for a period of 90 days. There are no mileage limitations.

Extent of Warranty

Customers who believe they have a defective product should return it to the dealer from which they purchased or ship it freight prepaid to Trick Flow

Specialties along with proof of purchase and a complete description of the problem. If a thorough inspection indicates defects in materials or

workmanship, our sole obligation is to repair or replace the product.

This warranty is only if the product is properly installed, subjected to normal use and service, did not fail due to owner negligence or misuse, and has

not been altered or modified.

Trick Flow Specialties warranties do not cover any installation or removal costs.

Trick Flow Specialties is not liable for consequential damages for breach of contract of any warranty in excess of the purchase price of the product

sold.

PROPOSITION 65 WARNING

This product may contain one or more substances or chemicals known to the state of California to cause cancer, birth defects or other

reproductive harm.

TRICK FLOW SPECIALTIES

285 West Avenue

Tallmadge, Ohio 44278

Telephone: (330) 630-1555

TFS-INS-90000 Rev.0 10/13/15

You might also like

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Why Is It That ImportantDocument2 pagesWhy Is It That Importantkozaro 678No ratings yet

- Valve/Tappet Clearance Valve/Tappet Clearance: ! CautionDocument2 pagesValve/Tappet Clearance Valve/Tappet Clearance: ! CautionVenkatNo ratings yet

- Valve Adjustment ProcedureDocument1 pageValve Adjustment ProcedureKim Tuazon SantosNo ratings yet

- ValveadjustmentprocedureDocument1 pageValveadjustmentprocedureHilton JoriNo ratings yet

- Ramel LP FinalDocument7 pagesRamel LP FinalRamel RaymousNo ratings yet

- Waukesha F11gsi - Valve Clearence - CompressionDocument2 pagesWaukesha F11gsi - Valve Clearence - Compressionnicol_sg100% (1)

- Mantenimiento ShaferDocument12 pagesMantenimiento ShaferMauricio RoldanNo ratings yet

- Calibracion de Valvulas Perkins 400Document3 pagesCalibracion de Valvulas Perkins 400nolram23No ratings yet

- Tilt CylinderDocument7 pagesTilt Cylinderluis tocoraNo ratings yet

- Ajuste de ValvulasDocument5 pagesAjuste de ValvulasAlejandro ValenzuelaNo ratings yet

- 08 Testing&Adjustment Tier3 Engine - 1602Document23 pages08 Testing&Adjustment Tier3 Engine - 1602gustavo333martinsNo ratings yet

- Rotary Vane: Maintenance and Service ManualDocument12 pagesRotary Vane: Maintenance and Service Manualjorge lopez100% (1)

- Ajuste Valve Perins 1104Document5 pagesAjuste Valve Perins 1104josel204No ratings yet

- Adjust Valve C9Document3 pagesAdjust Valve C9JebrodNo ratings yet

- Null MOTORDocument215 pagesNull MOTORAditya JoglekarNo ratings yet

- Rollmaster: High Performance Timing Chain Sets Degreeing in Your CamshaftDocument2 pagesRollmaster: High Performance Timing Chain Sets Degreeing in Your Camshafttito titoNo ratings yet

- Valve Adjustment E7Document16 pagesValve Adjustment E7malcolm stewartNo ratings yet

- Calibracion de Valvulas.Document3 pagesCalibracion de Valvulas.Enso RosalesNo ratings yet

- Emissionized Engine Timing With LUCAS Fuel InjectionDocument5 pagesEmissionized Engine Timing With LUCAS Fuel InjectionKevin HarrisNo ratings yet

- Engine Valve Lash - Inspect AdjustDocument3 pagesEngine Valve Lash - Inspect AdjustRay CapriNo ratings yet

- EFC ActuatorDocument4 pagesEFC ActuatorRonald BoocNo ratings yet

- Solex Adj ProcedureDocument6 pagesSolex Adj Procedureprivate 2No ratings yet

- Valve Adjustment ProcedureDocument24 pagesValve Adjustment ProcedureRoel Bautista100% (1)

- 102 112 Disc Brake Adjustments - OBS 102 075 Monitor E 128Document11 pages102 112 Disc Brake Adjustments - OBS 102 075 Monitor E 128Tomas Enrique Ramirez GomezNo ratings yet

- Ip Fegv S4901Document2 pagesIp Fegv S4901diego martinezNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- Edelbrock Camshaft 7102Document5 pagesEdelbrock Camshaft 7102v-techNo ratings yet

- Starting and ReversingDocument55 pagesStarting and ReversingMeghanath AdkonkarNo ratings yet

- Valveadjustment PDFDocument2 pagesValveadjustment PDFNacer MalekNo ratings yet

- AC4 - AC5 Horizntal Series ManualDocument8 pagesAC4 - AC5 Horizntal Series ManualDaniel RibeiroNo ratings yet

- Repair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetorDocument5 pagesRepair Guides - Carbureted Fuel System - Rochester 2se - E2se CarburetoreducsalNo ratings yet

- C4.4 Valve LashDocument2 pagesC4.4 Valve LashTom CleggNo ratings yet

- Fuel PumpDocument4 pagesFuel PumpRajesh Kumar100% (2)

- Beamex PGL Manual ENGDocument16 pagesBeamex PGL Manual ENGbiotech666No ratings yet

- Circuit Setter ManualDocument4 pagesCircuit Setter ManualAnonymous 7xHNgoKE6eNo ratings yet

- BandasDocument116 pagesBandasJhon GuerraNo ratings yet

- Yella Terra Roller Rocker Geometry GuideDocument1 pageYella Terra Roller Rocker Geometry GuideDave BournNo ratings yet

- Isuzu Truck Workshop Manual UBS Page 1535Document1 pageIsuzu Truck Workshop Manual UBS Page 1535GIORGI KUKHALEISHVILINo ratings yet

- Engine Valve Lash - Inspect/AdjustDocument4 pagesEngine Valve Lash - Inspect/AdjustHrvoje ŠkaricaNo ratings yet

- Camshaft AdvanceDocument5 pagesCamshaft Advancejameel babooramNo ratings yet

- Valve and Valve AdjustmentsDocument18 pagesValve and Valve Adjustmentsgillian marbebeNo ratings yet

- Rt500 1 Service AdjustmentsDocument29 pagesRt500 1 Service AdjustmentsjulianmataNo ratings yet

- Mep Oral AnswersDocument28 pagesMep Oral AnswersAshjo Gamer100% (1)

- Manual For Steering Gear. 1 To 4 Rudders (2014)Document12 pagesManual For Steering Gear. 1 To 4 Rudders (2014)RomanNo ratings yet

- Manual Progr BrakeDocument4 pagesManual Progr BrakeGerchu GTNo ratings yet

- C11 Valves and InjDocument7 pagesC11 Valves and Injraymon1191No ratings yet

- Valve Clearance AdjustmentDocument14 pagesValve Clearance AdjustmentHazem NouhNo ratings yet

- 12-Mounting, Starting Up and Operating InstructionDocument19 pages12-Mounting, Starting Up and Operating InstructionGrisha Mari KosoyanNo ratings yet

- Camshaft / Lifters / Lube Kit CATALOG # 3702 General InstructionsDocument4 pagesCamshaft / Lifters / Lube Kit CATALOG # 3702 General InstructionsFREDDYJIMENEZNo ratings yet

- Ajuste Valvula 3176CDocument3 pagesAjuste Valvula 3176CAdelio RamirezNo ratings yet

- Timing ExerciceDocument12 pagesTiming Exercicehector eduardo moya benavidesNo ratings yet

- Farm Power PracticalDocument5 pagesFarm Power PracticalSaliha SattiNo ratings yet

- Finding Top Center Position For No. 1 PistonDocument14 pagesFinding Top Center Position For No. 1 PistonTuan Anh100% (1)

- 1955 Seagrave Model 530-BH ManualsDocument129 pages1955 Seagrave Model 530-BH Manualsbones333100% (3)

- Removing Distributor AssemblyDocument2 pagesRemoving Distributor Assemblyzelalem mamoNo ratings yet

- Exp 5Document6 pagesExp 5Aryan KumarNo ratings yet

- Posiwell Double Block Bleed Gate ValveDocument10 pagesPosiwell Double Block Bleed Gate ValvefadzilharmanNo ratings yet

- Ignition HTMDocument7 pagesIgnition HTMjorge Angel LopeNo ratings yet

- CV Carb TuningDocument7 pagesCV Carb Tuningmark_dayNo ratings yet

- Simple ReceiptDocument5 pagesSimple ReceiptROYALNo ratings yet

- Howards2016 17 Mid PDFDocument360 pagesHowards2016 17 Mid PDFROYALNo ratings yet

- Hi PerformanceDocument44 pagesHi Performancerobertoperez525No ratings yet

- Honda Ignitor - Diagnose and Repair PDFDocument7 pagesHonda Ignitor - Diagnose and Repair PDFROYALNo ratings yet

- Hi PerformanceDocument44 pagesHi Performancerobertoperez525No ratings yet

- Sinclair EP LetterDocument2 pagesSinclair EP LetterROYALNo ratings yet

- SCSI Transmission Signal and Cable Length: SummaryDocument1 pageSCSI Transmission Signal and Cable Length: SummaryROYALNo ratings yet

- Iamt Driver Installation Guide: Holder1 - Ebiztabstripnoform2 - Tab DriverDocument9 pagesIamt Driver Installation Guide: Holder1 - Ebiztabstripnoform2 - Tab DriverROYALNo ratings yet

- GT-6 OmDocument84 pagesGT-6 OmKrunoslav DobričevićNo ratings yet

- Expungement Power Point VersionDocument60 pagesExpungement Power Point VersionROYALNo ratings yet

- General Product Guide: Printed in Japan 1804-02E 195 (LI) 0.5KDocument25 pagesGeneral Product Guide: Printed in Japan 1804-02E 195 (LI) 0.5KROYALNo ratings yet

- UGMS Users Manual PDFDocument44 pagesUGMS Users Manual PDFROYALNo ratings yet

- Spot Thermal Camera: See The Heat°™ - Speed Electrical TroubleshootingDocument2 pagesSpot Thermal Camera: See The Heat°™ - Speed Electrical TroubleshootingjamelNo ratings yet

- F GHJETRDocument2 pagesF GHJETRROYALNo ratings yet

- EA8300 - UG - International Lyksys Ea8300 Router PDFDocument810 pagesEA8300 - UG - International Lyksys Ea8300 Router PDFROYALNo ratings yet

- EllenDocument2 pagesEllenROYALNo ratings yet

- Universal PCI Smart Serial Board Quick Installation Guide: CP-114UL Series /CP-114UL-I SeriesDocument4 pagesUniversal PCI Smart Serial Board Quick Installation Guide: CP-114UL Series /CP-114UL-I SeriesROYALNo ratings yet

- User Manual: EAZ0077L00D Rev. ADocument187 pagesUser Manual: EAZ0077L00D Rev. AROYALNo ratings yet

- Universal Joint Specs2 PDFDocument1 pageUniversal Joint Specs2 PDFROYALNo ratings yet

- Smart Sensor Transmitter: Operator ManualDocument39 pagesSmart Sensor Transmitter: Operator ManualROYALNo ratings yet

- Sum-Carb Rebuild Adjust PDFDocument8 pagesSum-Carb Rebuild Adjust PDFROYALNo ratings yet

- txp4 200 PDFDocument64 pagestxp4 200 PDFROYALNo ratings yet

- Universal Joint Application Chart PDFDocument1 pageUniversal Joint Application Chart PDFROYALNo ratings yet

- V8 Speed & Resto Shop Project Car Planner - 314.783.8325Document5 pagesV8 Speed & Resto Shop Project Car Planner - 314.783.8325ROYALNo ratings yet

- Spot Thermal Camera: See The Heat°™ - Speed Electrical TroubleshootingDocument2 pagesSpot Thermal Camera: See The Heat°™ - Speed Electrical TroubleshootingjamelNo ratings yet

- User Caution For CPU Cooler Installation On LGA775 CPU Card PDFDocument2 pagesUser Caution For CPU Cooler Installation On LGA775 CPU Card PDFROYALNo ratings yet

- Universal Joint Application Chart PDFDocument1 pageUniversal Joint Application Chart PDFROYALNo ratings yet

- Vacuum PipingDocument8 pagesVacuum PipingCesar Muñoz OssesNo ratings yet

- Sinclair EP LetterDocument2 pagesSinclair EP LetterROYALNo ratings yet

- Weight Seal Model AKG Koyo FAG SKF IRB D D B C KG Bearing No. Dimension (MM)Document1 pageWeight Seal Model AKG Koyo FAG SKF IRB D D B C KG Bearing No. Dimension (MM)Mehdi MansourianNo ratings yet

- Registru1Piese DaewooDocument34 pagesRegistru1Piese DaewoonicnicnicNo ratings yet

- Gc20e-5 Sb1133e04Document612 pagesGc20e-5 Sb1133e04GORD67% (3)

- Air Vantage 500 Kubota: Parts List ForDocument28 pagesAir Vantage 500 Kubota: Parts List Fordadang prayogoNo ratings yet

- Montacarga HYUNDAI 50D-9SA PDFDocument8 pagesMontacarga HYUNDAI 50D-9SA PDFdanielaNo ratings yet

- B767 - Daily (Freighter) CZZ-N524Document11 pagesB767 - Daily (Freighter) CZZ-N524Belisario Sergio Llacchas rodasNo ratings yet

- Sistema Hco EJC 145 (Colores)Document92 pagesSistema Hco EJC 145 (Colores)JorgeNo ratings yet

- ATF ReferenciaDocument26 pagesATF ReferenciaAaron CabreroNo ratings yet

- Ape Diesel D125 D180 Manual 20100402Document30 pagesApe Diesel D125 D180 Manual 20100402Binh le ThanhNo ratings yet

- Manual Alarma ChevyDocument20 pagesManual Alarma ChevyGerman Ocampo0% (1)

- Documents - Pub - Citroen v4105 Diagnostics List Diagnosis Profesional Citroen v4105 DiagnosticsDocument71 pagesDocuments - Pub - Citroen v4105 Diagnostics List Diagnosis Profesional Citroen v4105 DiagnosticssavecodocjNo ratings yet

- VSS1 Setting Guide English ASM 000 09-0 PZ464-00130-00 PZ464-00131-00 PDFDocument9 pagesVSS1 Setting Guide English ASM 000 09-0 PZ464-00130-00 PZ464-00131-00 PDFBruce LyndeNo ratings yet

- Disc CouplingDocument6 pagesDisc CouplingPrestoneKNo ratings yet

- GaN & SiC Power Semiconductors - Why These Devices Are Gaining Popularity - NewsDocument15 pagesGaN & SiC Power Semiconductors - Why These Devices Are Gaining Popularity - NewsAmanuel Amare GebrekidanNo ratings yet

- Everything About Warstilla EngineDocument212 pagesEverything About Warstilla Enginesoldatosa100% (10)

- Home Repair Kits: Drivemaster Standard Parts ListDocument2 pagesHome Repair Kits: Drivemaster Standard Parts Listjuan carlosNo ratings yet

- All Supplier: Order DeliveryDocument6 pagesAll Supplier: Order Deliverydasih mindasariNo ratings yet

- F01 Energy ManagementDocument34 pagesF01 Energy ManagementPhan VănNo ratings yet

- Agri MonoblocDocument2 pagesAgri Monoblockeeprocking9777No ratings yet

- B2B Tyre Industry FinalDocument50 pagesB2B Tyre Industry FinalSwapnil LilkeNo ratings yet

- Owner'S ManualDocument36 pagesOwner'S ManualEric LaqueilleNo ratings yet

- Nirmal Bang Paint Sector Update 010920Document87 pagesNirmal Bang Paint Sector Update 010920Vishnu KanthNo ratings yet

- Optra Functional Specifications: EngineDocument2 pagesOptra Functional Specifications: EngineMahmoud El-MeghenyNo ratings yet

- Campos Armónicos Menores - EbDocument1 pageCampos Armónicos Menores - Ebvladimir morales brown100% (2)

- RockShox Front Suspension SpecificationsDocument25 pagesRockShox Front Suspension SpecificationsNicky KiloNo ratings yet

- Kubota Tecnical ReportDocument72 pagesKubota Tecnical ReporthumbertoNo ratings yet

- Molylube Extreme Pressure High Viscosity GreaseDocument2 pagesMolylube Extreme Pressure High Viscosity GreaseGilmer Williams Cáceres BenaventeNo ratings yet

- 2021 Rules Enduring Racing Langley SpeedwayDocument4 pages2021 Rules Enduring Racing Langley SpeedwayMARKNo ratings yet

- d11r BrochureDocument24 pagesd11r Brochurerrodriguez405No ratings yet

- Actuator TypeDocument18 pagesActuator TypelinhphamNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsFrom EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersRating: 4.5 out of 5 stars4.5/5 (2)

- Grid-Scale Energy Storage Systems and ApplicationsFrom EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNo ratings yet

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)