Professional Documents

Culture Documents

Project Profile On Fly Ash Building Products

Uploaded by

banavaram10 ratings0% found this document useful (0 votes)

0 views12 pagesfdsfs gfhgfjhn

Original Title

Fly

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfdsfs gfhgfjhn

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

0 views12 pagesProject Profile On Fly Ash Building Products

Uploaded by

banavaram1fdsfs gfhgfjhn

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

PROJECT PROFILE ON

FLY ASH BUILDING PRODUCTS

PRODUCT : FLY ASH BUILDING PRODUCTS

NIC PRODUCT CODE : 320901009: BRICKS

32091500X: HIGH STRENGTH BRICKS

QUALITY STANDARDS : IS:12894-1990:

Specn. for Fly ash Lime Bricks.

IS:4139-1989:

Specn. for Calcium Silicate Bricks

PRODUCTION CAPACITY : QUANTITY: 18 LAKHS BRICKS

(PER ANNUM) VALUE : Rs.26.1 Lakhs.

MONTH & YEAR

OF PREPARATION : MARCH, 2010

PREPARED BY : G&C DIVISION

MSME-DEVELOPMENT INSTITUTE

GOVT. OF INDIA, MINISTRY OF MSME

111 & 112, B.T.ROAD, KOLKATA- 700 108.

TEL. 2577-0595,0596,0597,0598.

A. INTRODUCTION

Fly ash based building products are manufactured by using

Major percentage of fly ash generated from Thermal Power stations and plants like (i)

NTPC, Farakka, (ii) Kolaghat Thermal Power Station, (iii) DSP, Durgapur. ((iv)

NALCO, Orissa (v) RSP, Rourkela, etc. and many Paper Mills , Aluminium

Industries, who uses Boiler & captive power plant produces bulk quantity of Fly Ash

in the Eastern Region of our country. Other raw materials used along with Fly Ash are

lime and calcined gypsum. FAL-G Bricks are popular out of all building products can

be manufactured with low investment in comparison to Fly ash lime bricks and Clay

fly ash bricks. Other building products are Fly Ash concrete blocks , solid & hollow

types , Fly Ash low cement concrete, Fly Ash castable & many other low moisture Fly

Ash ready-mix. At present FAL-G building bricks technology is much popular in

State Andhra Pradesh and Orissa who have accepted this eco-friendly technology

being inspired and encourages by the Govt. authority and promotional agencies like

Fly Ash Mission, IREDA, and different Environmental Programme of State Govt. .

FAL-G bricks do not lose strength unduly even upon socked in water

continuously. Hence plastering is optional rather than necessity. Well cured Fal-G

bricks absorb 4-12% water only. On account of less water absorption, rationalisation

of plastering and mortar, a finished Fal-G brick wall is lighter and cheaper in

comparison to finished clay brick wall. Fal-G bricks can be made to order with

engineering properties comparable to cement concrete befitting for specialized

applications such as canal liming, dam construction, water tanks etc.

The Fal-G mix is nothing but a slow setting pozzolana cement mix. The process

is same as making cement in cement factories where clay and lime stones are burnt

with coal and gypsum is mixed and ground to make cement. When fly ash, hydrated

lime powder and gypsum are mixed and ground in a pan mixer the resulting mixture

acts as slow setting pozzolana cement and thus a cement bonding property is

attained in the said mixture. Sand or crushed stone dust may be added to bring down

the cost of mix.

The above mix is pressed with lower moisture cement in a brick press, specially

and indigenously designed to give high pressure load at slow rate, in the order of 350

kg./sq. inch.

Thus Fal-G bricks are the substitute to common burnt clay bricks which every

class of people can easily accept for constructional activities.

B. MARKET

There are around 25 FAL-G bricks manufacturing units functioning in the state

of Orissa and many more prospective entrepreneurs are going for the said project. As

the production of building bricks in the state and country, as well

falls far below the market demand due to increase in constructional activities and

standard of living of the countrymen, the shortfall is likely to increase in manifold.

Hence there is a promising market potential for Fly Ash based building bricks,

however, the quality and cost have to be maintained at par with the conventional red

clay burnt building bricks. There is also vast scope on use of Fly ash bricks in cyclone

devastated areas of the state.

India needs around 60 billion bricks every year that would exhaust 180 million

tones of tap soil, making barren 7500 hectares of fertile land. To overcome this

problem the use of Fal-G bricks is the need of the hour. People have started realizing

the importance of use and application of Fal-G bricks. Hence in all modern civil

engineering constructional activities Fal-G bricks will occupy a key position.

As the manufacture of clay fly ash bricks and lime fly ash bricks need higher

investment, the manufacture of Fal-G bricks can be well accepted by small scale

entrepreneurs.

Since 60% of countrys electricity comes from coal based power station, the

country has a huge stock of fly ash amounting to 60 million tones annually. Despite

all the efforts present scenario is not too encouraging as only 5% of countrys total

ash has been consumed in different sectors.

Considering the gravity of the situation of disposal of fly ash, which is

hazardous, both the central and State Governments and R&D organizations have been

constantly finding out appropriate means for best utilization of fly ash. Fal-G bricks is

the outcome of the developmental works done by Institute of Solid Waste Research &

Ecological Balance (INSWAREB), Visakhapatnam.

The need of the hour is to find wealth from wastage and eco-friendly

technologies for our progress and prosperity.

With the rise in population and increase in constructional activities considering

the improvement in the standard of living the demand for building bricks is increasing

day by day.

C. BASIS AND PRESUMPTION

1. The unit will work 300 working days in a year on two shifts basis and will

be able to utilize its full capacity utilization after one year of regular

production. However, the efficiency of capacity utilization has been

considered as 80%.

2. Labour and wages will be as per the prescribed minimum wages.

3. The rate of interest for both the fixed and working capital has been

considered as 17%.

4. Margin money of around 25% of the project cost has to be arranged by the

entrepreneur.

5. Operative period of the project has been considered as 10 years considering

technology obsolescence rate and period of repayment of loan.

6. the cost of land, construction cost, cost of machinery and equipment, etc. has

been considered as per the prevailing market rate and as per quotation of

machinery obtained.

7. The unit has to be situated in close proximity to the deposit/availability of

fly ash and lime. However, calcined gypsum has to be procured from Tamil

Nadu or Rajasthan.

The unit will also use lime sludge and phosphor-gypsum within the

permissible limit.

D. IMPLEMENTATION SCHEDULE

The regular commencement of production will take around six months after

availability of finance from financial Institution.

i) Survey for collection of data in respect of

Demand, availability of power, water and

Raw materials, etc. 0-1

st

month

ii) Preparation of Project document regn. 1

st

2

nd

month

iii) Financial assistance 2

nd

4

th

month

iv) Selection of site and development of land 3

rd

4

th

month

v) Power and water tie up for availability -do-

vi) Construction of building and shed 4

th

6

th

month

vii) Purchase of Machinery & equipment 4

th

6

th

month

viii) Procurement of raw materials &

recruitment of personnel . 7

th

8

th

month

ix) Trial production 9

th

month.

E. TECHNICAL ASPECTS

1) Process of Manufacture :

Process of manufacture of Fal-G bricks involve the following stages of

operations.

i) Proportioning and mixing of batch materials such as fly ash, lime, calcined

gypsum, sand and water.

ii) Shaping of bricks in the press.

iii) Drying of green bricks over wooden pallets.

iv) Curing of the bricks by spraying/sprinkling water for 10 to 15 days.

v) Sorting, inspection and quality control tests prior to sale.

Fly ash, lime, calcined gypsum, sand and aggregate are the raw materials

Required for making fly ash bricks and blocks. The raw materials of brick mix in

desired proportion (ash 60-65%) Lime, 20-25% and calcined gypsum 10% by weight)

are blended intimately in dry or wet form in a suitable blender/mixer. The wet brick

mix is fed into the machine mould. The vibration is given for a while the mould is

again fed. The stripper head is pressed and vibration is given simultaneously for

about 10 seconds. The mould is lifted and four bricks produced pallet is removed and

kept on the platform for air drying.

The next day the bricks produced on the previous day are put in the stack. The

stack is formed with much care to see that curing water and air for drying reaches to

every brick. After 3 days warm water aon small quantity is poured in the stacked

bricks without any pressure. After 5 days hot water is sprinkled on the brick stack for

2 times a day. The bricks stack after each watering are immediately covered with

black PVC sheets. The bricks are then left in the stack for drying for 7 days. The

bricks are ready for dispatch after 22 days from the date of manufacture. The

compressive strength of the bricks produced from the brick mix and manufacturing

process suggested herein would be 80 Kg./cm

2

to 110 kg./cm.

2

2) Quality Specifications :

Bureau of Indian Standards formulated specifications for clay fly ash bricks,

lime fly ash bricks, common burnt clay bricks and calcium silicate bricks which can

be referred to as regards to the quality of Fal-G bricks.

IS: 12894:1990 Specification for Fly Ash Lime bricks.

IS:13757:1976 Specification for Burnt clay fly ash building

Bricks.

IS:4137:1989 Specification for calcium silicate bricks.

IS:3102:1976 Classification of burnt clay solid bricks.

The other relevant BIS specifications are :

IS:3812:1981 Specification for Fly Ash for use as

Pozzolana and admixture.

IS:712:1984 Specification for Building limes.

IS:3495(Pt.I)1976 Methods of tests of burnt clay building bricks.

For production of good quality fly ash bricks the quality of Fly Ash should be

as follows :

i) Moisture content of fly ash should not exceed 5% .

ii) Visual appearance of fly ash should be of light steel grey or smoky grey

colour.

iii) Unburnt carbon content in the fly ash be around 5% .

The typical physical requirement of Fal-G bricks as per customers

specifications is as follows :

a) Compressive strength 60-250 kg/cm.

2

b) Water absorption 5-12%

c) Density 1.5 gms./c.c.

3) Production capacity per annum

a) Quantity : 18 lakh bricks.

b) Value : Rs. 26.1 lakhs.

4) Approximate Motive Power : 60 H.P.

5) Pollution control needs :

Workmen working with Fly Ash and at the mixing area are to be provided with

protective equipment like dust masks and safety goggles.

6) Energy Conservation Needs :

The management has to be vigilant in ensuring higher productivity by the best

utilization of man and machine hours. Periodic checks over working stages,

functioning of machinery and their preventive maintenance and timely repair etc. will

help in energy conservation.

F. FINANCIAL ASPECTS :

Fixed Capital :

1. Land: 0.5 acre Rs. 1,25,000/-

Building/Shed :

Work Shed: 100 Sq. Mtr. @ Rs. 1500/-

Per Sq. Mtr. Rs. 1,50,000/-

Office & Store: 20 Sq. Mtr. @ Rs.2500/-

Per Sq. Mtr. Rs. 50,000/-

Tube well with over head tank, pipe line

and other civil construction including

Boundary and Gate etc. Rs. 60,000/-

Rs. 2,60,000/-

2. Machinery & Equipment :

i) Brick press(semi-automatic) with 7.5 H.P.

Motor and 500 bricks/hr.cap. and complete

with all accessories . 1(One) Set Rs. 1,85,000/-

ii) Pan mixer with 7.5 HP motor, 150 Kg.Cap.

& complete with all accessories 1(One)Set Rs. 85,000/-

iii) Hydraulic Pellet Truck, 500 Kgs. Cap. 2(Two)

Sets Rs. 45,000/-

iv) Wheel barrows : 250 Kgs. Cap. 2(Two) Sets Rs. 10,000/-

v) Wooden pellets(3x2 size, 6 bricks cap.

And 72 bricks / pellet) 50 Nos. Rs. 20,000/-

vi) Installation & electrification Rs. 30,000/-

vii) Weighing machine, platform type

and of 100 Kgs. Cap. 1(One) Set Rs. 20,000/-

viii) Office equipment & furniture L.S. Rs. 21,000/-

Rs. 4,15,000/-

3. Pre-operative expenses Rs. 15,000/-

Rs. 4,30,000/-

Total fixed capital : (1+2+3)= Rs. 8,15,000/-

4. Working Capital (P.M.)

(i) Personnel (P.M.) :

1. Manager 1 (One) @ Rs.3000/- p.m. Rs. 3,000/-

2. Supervisor-2(Two) @ Rs.2500/-p.m. Rs. 5,000/-

3. Machine operators 2(Two) @ Rs.2000/-p.m. Rs. 4,000/-

4. Skilled workers 4(Four) @ Rs.1800/- p.m. Rs. 7,200/-

5. Un-skilled workers 10(Ten) @ Rs.1200/-p.m. Rs 12,000/-

6. Watchman-cum-peon 2(Two) @ Rs.1000/-p.m. Rs. 2,000/-

Rs. 33,200/-

Perquisite @ 15% Rs. 5,000/-

Rs. 38,200/-

(ii) Raw materials (P.M.) :

1. Fly ash 150 MT @ Rs.120/- per MT Rs.18,000/-

2. Sand/Crushed stone

dust 200 MT @ Rs.80/- MT Rs. 16,000/-

3. Lime(Slaked) 20MT @ Rs.1700/per MT Rs. 34,000/-

4. Lime sludge 20MT @ Rs.800/- per MT Rs. 16,000/-

5. Calcined gypsum 10MT @ Rs.2300/- per MT Rs. 23,000/-

6. Phospho-gypsum 10MT @ Rs.800/- per MT Rs. 8,000/-

Rs. 1,15,000/-

(iii) Utilities (P.M.) :

1. Power Rs. 7500/-

2. Water Rs. 300/-

Rs. 7800/-

(iv) Other Contingent Expenses (P.M.) :

a) Postage and stationery Rs. 300/-

b) Telephone Rs. 600/-

c) Consumable Stores Rs. 600/-

d) Repair and maintenance Rs. 1000/-

e) Transport and traveling expenses Rs. 2000/-

f) Advertisement and publicity Rs. 1000/-

g) Insurance Rs. 500/-

h) Miscellaneous Rs. 1000/-

Rs. 7000/-

Hence, total Recurring Expenses per month =Rs.1,68,000/-

5. Total Capital Investment :

a) Total fixed capital Rs. 8,15,000/-

b) Working Capital (on one month basis) Rs. 1,68,000/-

Rs. 9,83,000/-

G. MACHINERY UTILISATION :

The pressing and curing of bricks are the bottleneck operations and the

anticipated utilization of major facilities has been considered as 80% .

H. FINANCIAL ANALYSIS :

I. Cost of Production (Per year) :

i) Total recurring expenditure Rs.20,16,000/-

ii) Depreciation on bldg./shed @ 5% Rs. 13,000/-

iii) Depreciation on machinery & equipt. @10% Rs. 36,500/-

iv) Depreciation on fixtures & office equipment Rs. 10,000/-

& furniture.

v) Interest on total investment @ 17% Rs. 1,67,100/-

2. Sales turnover per year : Rs. 22,42,600/-

By sale of 18 lakhs bricks @ Rs.1450/- per1000 bricks Rs. 26,10,000/-

3. Net profit per year :

H.2 - H.1 = Rs.3,67,400/-

4. Net Profit Ratio :

Profit x 100 = 3,67,400 x 100 = 14%

Sales turn over 26,10,000

5. Rate of return on Investment :

___ Profit x 100_____ = 3,67,400 x 100 = 37%

Total Cap. Investment 9,83,000

6. Break Even Point (% of total prod. Envisaged)

i) Fixed Cost

a) Total depreciation 59,500.00

b) Insurance 6,000.00

c) Int. on investment 1,67,100.00

d) 40% of salary and wages 1,83,400.00

e) 40% of other cont. expenses excluding insurance 31,200.00

4,47,200.00

ii) Net profit per year : Rs.3,67,400/-

B.E.P. = FC x 100 = 447200 x 100

FC +Profit 447200 + 367400

= 44720000 = 447200 = 54.9%

814600 8146

ADDITIONAL INFORMATION :

To ensure better economy in the process of manufacture of FAL-G bricks the

following factors are to be considered .

i) The unit has to be set up within a radius of 150 km approx. from

the source of fly ash.

ii) To economize the cost of lime a small country lime kiln can be

very well constructed within the units premises. As the same time

as an alternative measure low cost and high quality lime can be

made available from oxygen, acetylene and paper manufacturing

plants.

iii) Locally available gypsum can be calcined at the factory site to get

calcined gypsum at a cheaper rate. However, phosphor gypsum the

by product of Paradeep Phosphates Ltd. can be used as an

alternative to calcined gypsum but the same has to be made acid

free.

iv) For more details on FAL-G bricks the entrepreneur may contact

Institute of Solid Waste research and Ecological Balance.

35m Sri Venkateswara Colony, Sheilanagar, Visakhapatnam-

530012.

v) Though the selling price is little higher in comparison to red

clay burnt bricks but the consumption of cement will be low.

J . ADDRESSES OF MACHINERY AND EQUIPMENT

SUPPLIERS :

1. M/s. Dash Engineering Works, Gandarpur, Cuttack-753003.

2. M/s. Engineers Enterprises, 189 Bharathiyar Road, Ganapathy,

Coimbatore-641006.

3. M/s. Constro Enterprises, 10/2, Athipalayam Road, Ganapathy,

Coimbatore-641006.

4. M/s. Conmach Manufacturers Eastern Pvt. Ltd., 86 D, Dr. Suresh

Sarkar Road, Kolkata- 700014.

5. M/s. Neervan Engg. Co., 42/8, Kashinath Dutta Road, Kol.-700014.

K. ADDRESSES OF RAW MATERIALS SUPPLIERS :

1. SOURCE OF FLY ASH :

a) NTPC, Farakka,

b) DSP, Durgapur .

c) Kolaghat Thermal Power Station.

d) NALCO, Orissa.

e) RSP, Rourkela etc.

2. SOURCE OF LIME :

a) M/s. J ai Bajrang Limes, Rajgangpur .

b) M/s. Gadodia Chemicals, Rajgangpur.

c) M/s. Rourkela Limes, Power House Road, Rourkela.

d) M/s. stone & Stone Co., Garh Khunda, Khurda.

e) Local traders , Kolkata.

3. SOURCE OF CALCINED GYPSUM

a) M/s. Saravana Fertilizers and Chemicals, 27, Dharmalingapuram ,

Cuddalore-607005, T.N.

b) M/s. Mahavir Minerals Pvt. Ltd., Ratankunj, New Bank Colony,

Ajmer Road, Beawar-305901, Rajasthan.

L. List of units set up by using this Project Profile : Not available

******

You might also like

- Project Report of Fly Ash Bricks by Karmyog Ind.Document11 pagesProject Report of Fly Ash Bricks by Karmyog Ind.Vineet Singhal80% (5)

- The Fly Ash Brick Production TechnologyDocument18 pagesThe Fly Ash Brick Production TechnologyVishal KedarNo ratings yet

- Fly Ash BricksDocument12 pagesFly Ash BrickssivajibuddyNo ratings yet

- PROF. NO.23 Project Profile On Fly Ash Bricks Manufacturing UnitDocument8 pagesPROF. NO.23 Project Profile On Fly Ash Bricks Manufacturing UnitKroya HunNo ratings yet

- 05 Jan 2015guidelines For Manufacturing Quality Fly Ash BricksDocument11 pages05 Jan 2015guidelines For Manufacturing Quality Fly Ash BricksJoy Prokash RoyNo ratings yet

- Fly Ash BricksDocument13 pagesFly Ash BricksPrabhat RaiNo ratings yet

- Fly Ash BrickDocument8 pagesFly Ash BrickYashraj PatidarNo ratings yet

- Fly AshDocument16 pagesFly AshSavita Sehrawat0% (1)

- Final Project ReportDocument15 pagesFinal Project ReportRishi Mehta100% (1)

- Fly Ash Bricks Vs Clay BricksDocument4 pagesFly Ash Bricks Vs Clay Brickskishor150688No ratings yet

- Fly Ash Bricks Mixing Proportion - 3 Important Formulas PDFDocument2 pagesFly Ash Bricks Mixing Proportion - 3 Important Formulas PDFsonianchal233No ratings yet

- Volumetric Concrete Mixer Proposal For Ready Mix CompaniesDocument6 pagesVolumetric Concrete Mixer Proposal For Ready Mix CompaniesHabtamu Sedie0% (1)

- SRD Project Doc FinalDocument65 pagesSRD Project Doc FinalRavi JoshiNo ratings yet

- Cement PPT ArunDocument10 pagesCement PPT ArunAbhishek SharmaNo ratings yet

- Jkcement Summer Training Report by SunilDocument50 pagesJkcement Summer Training Report by Sunilanirudh singh solankiNo ratings yet

- Beumer Central Chain Bucket ElevatorDocument8 pagesBeumer Central Chain Bucket ElevatorIrshad HussainNo ratings yet

- Fly Ash Brick PDFDocument8 pagesFly Ash Brick PDFmalaya tripathyNo ratings yet

- QT8 FlyAsh Bricks Project Report May-2014 PDFDocument15 pagesQT8 FlyAsh Bricks Project Report May-2014 PDFesha108No ratings yet

- Fly Ash Bricks Rajesh FINALDocument43 pagesFly Ash Bricks Rajesh FINALHemeswarareddy KarimireddyNo ratings yet

- Power Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsDocument9 pagesPower Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsRajeshNo ratings yet

- Analysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshDocument6 pagesAnalysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshEditor IJTSRDNo ratings yet

- 4.IS 10262 2019 New Mix DesignDocument90 pages4.IS 10262 2019 New Mix DesignAli_nauman429458No ratings yet

- Cement Fineness Test: (By Dry Sieving) (As Per IS: 4031 - 1968)Document29 pagesCement Fineness Test: (By Dry Sieving) (As Per IS: 4031 - 1968)tejakandulaNo ratings yet

- A Look Into The Indian Cement Industry PresentationDocument27 pagesA Look Into The Indian Cement Industry PresentationsumitkumareceNo ratings yet

- Dramix Industrial Floors - BrochureDocument12 pagesDramix Industrial Floors - Brochurehareesh13hNo ratings yet

- Concrete Mix Plant Bis 4925.2004Document14 pagesConcrete Mix Plant Bis 4925.2004DilipKumarDaddalaNo ratings yet

- Is-3952 - (1988) - Burnt Clay Hollow Bricks For WallsDocument10 pagesIs-3952 - (1988) - Burnt Clay Hollow Bricks For WallsStacy WilsonNo ratings yet

- Project PPT Moin 12Document20 pagesProject PPT Moin 12Maharshi SalviNo ratings yet

- Rice Hull Ash CementsDocument100 pagesRice Hull Ash CementsArn CruzNo ratings yet

- Mix Design CalculationDocument8 pagesMix Design CalculationEr Digvijay SinghNo ratings yet

- Setting Up A Ready-Mix Concrete Manufacturing Plant-875187 PDFDocument73 pagesSetting Up A Ready-Mix Concrete Manufacturing Plant-875187 PDFGaneshNo ratings yet

- JSW GGBS by Shailesh GosaviDocument54 pagesJSW GGBS by Shailesh GosaviRohan Bagadiya100% (1)

- Air Entraining CementDocument14 pagesAir Entraining CementBashairu WaseemNo ratings yet

- Project Profile On Fly Ash BricksDocument15 pagesProject Profile On Fly Ash BricksHarshit JajuNo ratings yet

- Test Report 10034-1 Raw Material Grasim Rawan IndiaDocument6 pagesTest Report 10034-1 Raw Material Grasim Rawan IndiaKenny RuizNo ratings yet

- Block Egg LayingDocument17 pagesBlock Egg LayingDebasishSwainNo ratings yet

- Nanotechnology in The Cement Industry - A Patent AnalysisDocument9 pagesNanotechnology in The Cement Industry - A Patent AnalysisOscar Santos EstofaneroNo ratings yet

- Is 1443 1972 PDFDocument17 pagesIs 1443 1972 PDFRiteshRajputNo ratings yet

- CementDocument11 pagesCementAbubakar Musa100% (1)

- Lubricants For - Cement & MiningDocument2 pagesLubricants For - Cement & Miningarslan0989No ratings yet

- On Modified BitumenDocument19 pagesOn Modified BitumenTejeshwini SNo ratings yet

- ACC CementDocument49 pagesACC CementArpitJainNo ratings yet

- Project Report On Ductile PipeDocument8 pagesProject Report On Ductile PipeEIRI Board of Consultants and PublishersNo ratings yet

- Fly Ash ClasificationDocument15 pagesFly Ash ClasificationprabhuwbNo ratings yet

- Chemistry Investigatory Project: Setting of CementDocument17 pagesChemistry Investigatory Project: Setting of CementAnonymous s8OrImv8No ratings yet

- AAC Sample Project Profile Universal-Ver-2Document7 pagesAAC Sample Project Profile Universal-Ver-2N Gangadhar Reddy100% (1)

- Cold Mix Technology CRRI PDFDocument76 pagesCold Mix Technology CRRI PDFvvt102No ratings yet

- Micro Silica ConcreteDocument50 pagesMicro Silica ConcreteShibinMohammedIqbalNo ratings yet

- Cement and Its QualityDocument3 pagesCement and Its QualityTuhin TahmidNo ratings yet

- Is 16720 Product Manual Fuel AshDocument7 pagesIs 16720 Product Manual Fuel AshKolkata PIUNo ratings yet

- Presentation of Calcium AluminateDocument18 pagesPresentation of Calcium AluminateASHRAFUL KABIRNo ratings yet

- Quotation For Fly Ash Brick MachinesDocument9 pagesQuotation For Fly Ash Brick MachinesVetri Odayakulam100% (1)

- Cement PresentationDocument33 pagesCement PresentationAnamika PoudyalNo ratings yet

- Wagon Loader SystemDocument12 pagesWagon Loader Systemayaskant751001100% (1)

- 9 JK Cement5Document99 pages9 JK Cement5rahulsogani123No ratings yet

- ABOUT CEMENT & ITS USE - What Is Cement?Document5 pagesABOUT CEMENT & ITS USE - What Is Cement?Prasanjeet DebNo ratings yet

- Internship Report VedantDocument59 pagesInternship Report Vedantvgsuryawanshib20No ratings yet

- IS-8042-Product-Manual-WHITE CEMENTDocument14 pagesIS-8042-Product-Manual-WHITE CEMENTSauravTekriwalNo ratings yet

- Fly Ash Building BricksDocument12 pagesFly Ash Building BricksAnonymous g1LSaA100% (1)

- Fly Ash BrickDocument5 pagesFly Ash BricksansiNo ratings yet

- NDT For RenewablesDocument17 pagesNDT For RenewablesAvijit MondalNo ratings yet

- AC10P Catalog 5.41Document16 pagesAC10P Catalog 5.41cocacolapepsiNo ratings yet

- Foundations B ReadersDocument34 pagesFoundations B ReadersMaribel SalasNo ratings yet

- Part Winding Motor PDFDocument4 pagesPart Winding Motor PDFBj Valdez100% (2)

- Making Light Weight Refractory Ceramic From Perlite and ClayDocument5 pagesMaking Light Weight Refractory Ceramic From Perlite and Claychrysto_gypsyNo ratings yet

- Sensair Manual 1.0 en PDFDocument104 pagesSensair Manual 1.0 en PDFPaul KinsellaNo ratings yet

- 管線腐蝕案例Document12 pages管線腐蝕案例Tzu Huan PengNo ratings yet

- Electronic Controlled Fuel SystemDocument34 pagesElectronic Controlled Fuel SystemMohamed ZakiNo ratings yet

- Azipod Co Brochure - 2010Document4 pagesAzipod Co Brochure - 2010Aaron MalekNo ratings yet

- Las Week 3 Smaw Grade 9Document12 pagesLas Week 3 Smaw Grade 9Hebe KamaNo ratings yet

- Study On Reactive DyesDocument14 pagesStudy On Reactive DyesTahmidRahmanNo ratings yet

- Wall Panel SystemsDocument19 pagesWall Panel SystemsLaura Sacdalan94% (17)

- Ingersoll Rand System Automation Operator's Manual X8I: More Than Air. AnswersDocument502 pagesIngersoll Rand System Automation Operator's Manual X8I: More Than Air. AnswersIbnboubakr MohamedNo ratings yet

- Physical Science Reviewer FinalsDocument8 pagesPhysical Science Reviewer FinalsKathNo ratings yet

- Searchable Text2Document547 pagesSearchable Text2ChrisNo ratings yet

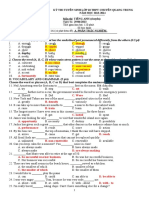

- I. Phonetics (1 PT) 1. Choose A Word (A, B, C, D) That Has The Underlined Part Pronounced Differently From The Others. (0.5 PT)Document6 pagesI. Phonetics (1 PT) 1. Choose A Word (A, B, C, D) That Has The Underlined Part Pronounced Differently From The Others. (0.5 PT)Hồng Anh ĐỗNo ratings yet

- Manual Phe THTDocument48 pagesManual Phe THTWahyu Alghifari PuspitoNo ratings yet

- Power Hump Project DetailsDocument67 pagesPower Hump Project DetailsSantosh Kumar Alpete33% (3)

- Enhanced 1Document8 pagesEnhanced 1Lakshman JangamNo ratings yet

- GEH-6789-EX2100e Excitation Control Diagnostic Alarms For Thyristor Systems Troubleshooting GuideDocument188 pagesGEH-6789-EX2100e Excitation Control Diagnostic Alarms For Thyristor Systems Troubleshooting GuideLê Trung Dũng100% (1)

- Microwave Communication Basics Ebook CO-109477-EN PDFDocument156 pagesMicrowave Communication Basics Ebook CO-109477-EN PDFIdir BenferhatNo ratings yet

- Metering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1Document198 pagesMetering Pumps Components Metering Systems ProMinent Product Catalogue 2016 Volume 1kambiadoNo ratings yet

- Nozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSDocument5 pagesNozzles and Spare Parts For: Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPS Unit Injectors UIS/UPSAnonymous AF2Rv0Kaxc100% (1)

- Gizmo Energy ConversionsDocument6 pagesGizmo Energy ConversionsDerick GeorgesNo ratings yet

- ICAM Sub StationDocument66 pagesICAM Sub StationAslam NayyerNo ratings yet

- Hatapla WinchDocument32 pagesHatapla WinchRaffaele Piccirillo100% (1)

- The Case For Methanol As A Green H2 CarrierDocument2 pagesThe Case For Methanol As A Green H2 Carrierdavid limNo ratings yet

- Chapter 1 Mathematical Modelling by Differential Equations: Du DXDocument7 pagesChapter 1 Mathematical Modelling by Differential Equations: Du DXKan SamuelNo ratings yet

- Method of Statement For Micropile 01Document7 pagesMethod of Statement For Micropile 01NedyHortetlNo ratings yet