Professional Documents

Culture Documents

Volumetric Concrete Mixer Proposal For Ready Mix Companies

Uploaded by

Habtamu SedieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Volumetric Concrete Mixer Proposal For Ready Mix Companies

Uploaded by

Habtamu SedieCopyright:

Available Formats

Expanding Your Business by Adding

Volumetric Concrete Mixer to Your

Concrete Delivery System

Prepared by Eng. Habtamu Sedie

Introduction

Nearly every facet of the construction industry uses concrete, from

building major highways to decorative landscaping. No matter how

small or large the job, the traditional method of concrete delivery has

remained the same—drum mixers bring in a load from the batch

plant. Sometimes, they arrive late. Sometimes, they bring too much or

too little. Other times, the quality varies from batch to batch.

The truck-based volumetric mixer has solved these and many other

problems. It is essentially a batch plant on wheels that produces a

high-quality, custom-made mix at the jobsite. This type of mixing

involves two basic principles:

Having all the materials needed to provide a customized mix at

the pour site

Using advanced technology to ensure a precise mix and exact

quantity with every pour

The volumetric mixer provides a fresh pour every time, eliminating

time spent waiting for the drum mixer and worrying about hot loads

or overages. On-demand volumetric mixing is less costly, more time

efficient, more versatile and offers a better return on investment.

1. Reasons To Add Volumetric Mixers To Your Concrete

Delivery Business

Adding volumetric mixers, also referred to as mobile mixers, to your

concrete delivery business delivers several benefits to your operations.

You’ll see these benefits by adding volumetric mixers to your fleet:

Say goodbye to hot loads. If the finishing crew hasn’t arrived, or

more forming needs to be done, don’t panic. Mobile mixers produce

fresh concrete on site when you need it, so you never waste a batch.

Deliver the exact amount. With mobile mixers, customers receive

exactly what they ordered.

Eliminate short-load fees. Because mobile mixers are versatile, they

can be used for a variety ofapplications: set up a mobile batch plant

for large jobs, pour a quarter yard for a fence post at one job, and then

travel to another job to pour three yards for a sidewalk repair.

Stop waiting on drum trucks. When workers consistently have to

wait around for ready mix trucks to arrive, lost profits quickly add up.

Easily change mix designs. Mobile mixers are more versatile than

ever. They can mix and pour one batch of concrete and easily switch

mix designs to support any client need. They also offer many admix

systems, fiber and color choices, and multiple speed cement options.

Clean up is easy. Have you heard of someone chipping out cured

concrete in a barrel truck? Add a mobile mixer to your fleet to avoid

that nightmare with quick clean up.

Weekend deliveries. Using drum trucks ties you to the plant’s

schedule. But owning a mobile mixer lets you create your own

schedule, with no batch plant operator needed, allowing you to

schedule weekend deliveries without hassle.

Deliver concrete to rural and remote areas. Once water hits the

powder, a chemical reaction starts and the small window in which the

concrete can be used. This causes limitations if drum trucks need to

travel long distances to job sites. Mobile mixers allow you to provide

quality concrete to clients in rural and remote areas.

Go green. Barrel trucks must constantly run to keep the drum

running and the concrete moving. With mobile mixers, you simply

shut off the truck until concrete is needed. They also require less

water during cleanup, as you only wash out the mixing auger

assembly rather than the whole barrel of a drum truck.

Mix specialty concrete. Specialty concrete and technologies such as

latex-modified concrete and fast-setting cements and polyester

concrete demand mobile mixers for best placement and quality.

2. Owner Your Schedule

Because construction schedules can vary so much, customers like the

ability to have all the concrete they need on-site when they’re ready to

use it, rather than waiting for the ready-mix truck. With volumetric

mixers, contractors can perform flat work and move to several

locations in a day without worrying about aging or wasted materials.

This flexibility is the primary differentiator between ready-mix and

volumetric trucks. A cusromer may pour a sidewalk that needs fiber,

or they may need flowable fill or lean concrete for utility work. A

backyard patio may need color tint. Chances are, this won’t all be

done at one time, but it can be done at different sites on the same day

with a volumetric truck.

2.1 Benefits For Your Business

➢Increase profits by paying less for concrete, have better control over

your schedule and employee time.

➢Expand the type of concrete applications you can offer as part of

your business with one mixer unit or do multiple jobs without

having to come back to the plant between jobs.

2.2 Benefits For Your Customers

➢Eliminate complaints about shortages and overages by mixing fresh

on-site in the amount required.

➢Handle short loads, emergencies or weekend jobs with a mixer that

is flexible and can be used for any size job on shot notice

3. Build the Bottom Line

Sand, stone, cement and water are all in separate compartments of

the volumetric mixing truck, so the mix is always fresh. Some mixers

offer the ability to make up to five types of concrete in one truck—

standard, fiber reinforced, lean or self-consolidating concrete (SCC),

gunite and color mixes. This replaces the need to have separate ready-

mix deliveries and trips back to the batch plant, as well as

customization at one or multiple jobsites. The volumetric mixer can

also dispense flowable fill materials in addition to standard concrete

mixes.

4. Explore Other Benefits

Further time flexibility—You can set up at the site and start

pouring within minutes, as concrete can be mixed in off-hours.

High-speed mixing with an auger solution means faster clean out

as well.

Quality—Volumetric mixers allow production of a fresh mix one

pour at a time. Current technologies allow all the variables to be

programmed ahead of the pour so that there is no operator error.

The water to cement ratio is always correct, so no water has to be

added to the solution. A number of third-party tests have proven

that the strength of concrete from volumetric mixers matches or

exceeds concrete from drum trucks.

Less waste—A drum truck has 60 to 90 minutes before it has to

dump the load. After that, it can be turned away from a jobsite,

and concrete is wasted, as is the fuel and labor used to transport

it. Volumetric mixers not only reduce wasted materials, such as

sand, rock and cement powder; they also reduce the amount of

water needed for mixing and washing down, and having fewer

batch plants and drum trucks on the road reduces emissions.

5. Plan for the Future

Concrete will always be in demand. Investing in labor and time-

saving technology like volumetric mixers can be a good

diversification strategy if you’re looking for more profit down the

road.

You might also like

- RMC Civil EngineeringDocument27 pagesRMC Civil EngineeringPavan Kumar100% (1)

- 3.concrete - ProductionDocument24 pages3.concrete - ProductionSUMANT KUMARNo ratings yet

- KCET BrochureDocument43 pagesKCET BrochureAlan GirishNo ratings yet

- Solid Block Manufacturing ProcessDocument4 pagesSolid Block Manufacturing Processa paul jayakumarNo ratings yet

- Concrete Mix Plant Bis 4925.2004Document14 pagesConcrete Mix Plant Bis 4925.2004DilipKumarDaddalaNo ratings yet

- Chapter 1Document56 pagesChapter 1Surbhi JainNo ratings yet

- Membrane Cell TechnologyDocument13 pagesMembrane Cell Technologyup4allNo ratings yet

- Concrete Making MaterialsDocument8 pagesConcrete Making MaterialsEng Aidaruos Abdi MatanNo ratings yet

- Ladrillos ManualDocument27 pagesLadrillos ManuallafecapoNo ratings yet

- Nanotechnology in The Cement Industry - A Patent AnalysisDocument9 pagesNanotechnology in The Cement Industry - A Patent AnalysisOscar Santos EstofaneroNo ratings yet

- Concrete Pumps and Mixers For Ready Made ConcreteDocument15 pagesConcrete Pumps and Mixers For Ready Made ConcreteRhythm SatyaNo ratings yet

- Block Egg LayingDocument17 pagesBlock Egg LayingDebasishSwainNo ratings yet

- ABOUT CEMENT & ITS USE - What Is Cement?Document5 pagesABOUT CEMENT & ITS USE - What Is Cement?Prasanjeet DebNo ratings yet

- Importance of Dedusting Pipe LayoutDocument4 pagesImportance of Dedusting Pipe LayoutManoj ThakurNo ratings yet

- Beumer Central Chain Bucket ElevatorDocument8 pagesBeumer Central Chain Bucket ElevatorIrshad HussainNo ratings yet

- Slump LossDocument4 pagesSlump LossAman SahadeoNo ratings yet

- Modeling The Prediction of Compressive Strength For Cement andDocument12 pagesModeling The Prediction of Compressive Strength For Cement andAnil Kumar Sharma100% (1)

- Presentation of Calcium AluminateDocument18 pagesPresentation of Calcium AluminateASHRAFUL KABIRNo ratings yet

- Fly Ash Building BricksDocument12 pagesFly Ash Building BricksBabor HossainNo ratings yet

- Special ConcreteDocument20 pagesSpecial ConcreteAshok Kumar RajanavarNo ratings yet

- Bal Gangadhar Tilak BiographyDocument2 pagesBal Gangadhar Tilak Biographydipendra2004100% (1)

- 4.IS 10262 2019 New Mix DesignDocument90 pages4.IS 10262 2019 New Mix DesignAli_nauman429458No ratings yet

- 003 Bt3-Manufacturing of Concrete by ArtDocument58 pages003 Bt3-Manufacturing of Concrete by ArtItzuki FujiwaraNo ratings yet

- JK Lakshmi Cement LTD: 10 National Award For Excellence in Energy Management-2009Document25 pagesJK Lakshmi Cement LTD: 10 National Award For Excellence in Energy Management-2009albeta01No ratings yet

- Concrete Plant: Atlasindustries - inDocument15 pagesConcrete Plant: Atlasindustries - innew2trackNo ratings yet

- Paper Darab Cement Kiln SealDocument11 pagesPaper Darab Cement Kiln Sealomid1302No ratings yet

- Costs of EqpmentsDocument7 pagesCosts of EqpmentsNishithNo ratings yet

- Competence in CementDocument24 pagesCompetence in CementJackson VuNo ratings yet

- Beumer Bulk MaterialDocument20 pagesBeumer Bulk MaterialMahmoud NaelNo ratings yet

- Cement PPT ArunDocument10 pagesCement PPT ArunAbhishek SharmaNo ratings yet

- Cement Plant Simulation and Dynamic Data PDFDocument8 pagesCement Plant Simulation and Dynamic Data PDFUsman HamidNo ratings yet

- Chemistry Investigatory Project: Setting of CementDocument17 pagesChemistry Investigatory Project: Setting of CementAnonymous s8OrImv8No ratings yet

- 1 BravermanDocument105 pages1 Bravermanridho ma'rufNo ratings yet

- 1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineDocument1 page1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineYeimsNo ratings yet

- VRM Daily Stoppage DetailsDocument7 pagesVRM Daily Stoppage DetailsValipireddy NagarjunNo ratings yet

- 2018 Fillers in Cementitious Materials - Experience, Recent Advances and Future PotentialDocument14 pages2018 Fillers in Cementitious Materials - Experience, Recent Advances and Future PotentialTiago BragaNo ratings yet

- Coal Shearer (Underground Mining Machine)Document16 pagesCoal Shearer (Underground Mining Machine)Donald Berbatov SilitongaNo ratings yet

- Dramix Industrial Floors - BrochureDocument12 pagesDramix Industrial Floors - Brochurehareesh13hNo ratings yet

- Jaw Crushers and Disk Mills: FritschDocument20 pagesJaw Crushers and Disk Mills: FritschAnil Kumar KnNo ratings yet

- Analysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshDocument6 pagesAnalysis of The Characteristic Behaviour of Concrete With Rice Husk Ash and Sugarcane Bagasse AshEditor IJTSRDNo ratings yet

- The Disadvantages of Fly AshDocument8 pagesThe Disadvantages of Fly AshShariar Masud TowhidNo ratings yet

- C917 PDFDocument9 pagesC917 PDFDIAZCORDOBANo ratings yet

- Application of Geopolymer Concrete AppliDocument5 pagesApplication of Geopolymer Concrete AppliTrúc LyNo ratings yet

- CB Continental CatalogueDocument69 pagesCB Continental CatalogueAina LikuntatiNo ratings yet

- KCET - 2023 Infomration Bulletin NewDocument55 pagesKCET - 2023 Infomration Bulletin NewWalker GamingNo ratings yet

- Manual RF Baghouse CollectorDocument24 pagesManual RF Baghouse Collectorheroj83100% (1)

- Crushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDocument24 pagesCrushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDanny Joaquin Flores CruzNo ratings yet

- Pan ConveyorsDocument24 pagesPan ConveyorswereerNo ratings yet

- Introduction of Cement: When Was Cement Begin?Document11 pagesIntroduction of Cement: When Was Cement Begin?مايف سعدونNo ratings yet

- Nelson Machinery Int'l Equipment Highlights 2019-04Document64 pagesNelson Machinery Int'l Equipment Highlights 2019-04Andy GNo ratings yet

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFDocument9 pagesFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresNo ratings yet

- Options For The Future of CementDocument11 pagesOptions For The Future of CementDIAZCORDOBANo ratings yet

- Cement: CIEN 30023 S.Y. 2ND SEM 2020-2021Document32 pagesCement: CIEN 30023 S.Y. 2ND SEM 2020-2021Mhervin BisisNo ratings yet

- BV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Document20 pagesBV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Kenny RuizNo ratings yet

- Is 9295 - 2002 - Steel Tubes For Idlers For Belt ConveyorsDocument14 pagesIs 9295 - 2002 - Steel Tubes For Idlers For Belt ConveyorsavijayakumarsamyNo ratings yet

- Building MaterialsDocument15 pagesBuilding MaterialsPriyanka BasuNo ratings yet

- Characterization of Silica Fume and Its Effects On Concrete PropertiesDocument49 pagesCharacterization of Silica Fume and Its Effects On Concrete PropertiessultanNo ratings yet

- Is-3952 - (1988) - Burnt Clay Hollow Bricks For WallsDocument10 pagesIs-3952 - (1988) - Burnt Clay Hollow Bricks For WallsStacy WilsonNo ratings yet

- Premix Concrete Supplier - Company ProfileDocument7 pagesPremix Concrete Supplier - Company ProfileSolomon BalemeziNo ratings yet

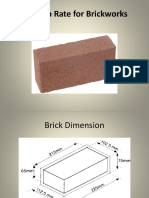

- Built Up Rate For BrickworksDocument20 pagesBuilt Up Rate For BrickworksfarhanimNo ratings yet

- Santillan LBYME3A Activity 3Document13 pagesSantillan LBYME3A Activity 3Nygel Gian SantillanNo ratings yet

- Pmu RabDocument2 pagesPmu RabchandraNo ratings yet

- E2k File For EtabsDocument17 pagesE2k File For EtabsRiyaz SiddiqueNo ratings yet

- Ready Mix Concrete PPT 01Document28 pagesReady Mix Concrete PPT 01Pavan Kumar88% (16)

- Estimate of Materials: 1. FootingsDocument24 pagesEstimate of Materials: 1. FootingskennysawegNo ratings yet

- Fibermesh Sikafiber Guide and ChartDocument6 pagesFibermesh Sikafiber Guide and ChartajatNo ratings yet

- Bill of Quantity TryDocument14 pagesBill of Quantity TryMuhammad Zulhusni Che RazaliNo ratings yet

- ConcreteDocument11 pagesConcretesiddhi gangwalNo ratings yet

- Work Instruction of Workability Test of Concrete (Slump)Document1 pageWork Instruction of Workability Test of Concrete (Slump)Biplab dattaNo ratings yet

- Beban Imbang 25-26 PDFDocument32 pagesBeban Imbang 25-26 PDFreno harahabNo ratings yet

- Admixtur PDFDocument19 pagesAdmixtur PDFÖmer ErcanNo ratings yet

- Examples Design Reinforced Concrete Buildings Bs8110 PDFDocument2 pagesExamples Design Reinforced Concrete Buildings Bs8110 PDFDanielle59% (17)

- Rate AnalysisDocument19 pagesRate AnalysisNikhil63% (8)

- Trial Mix Designs 05.12.2021Document4 pagesTrial Mix Designs 05.12.2021Rafael ObusanNo ratings yet

- Certif CATE NO LD/CT/20165215: ResultsDocument12 pagesCertif CATE NO LD/CT/20165215: ResultsKasun HewagamaNo ratings yet

- One Way SlabDocument4 pagesOne Way SlabFarly VergelNo ratings yet

- Aci 211.1-91Document18 pagesAci 211.1-91farhadam0% (4)

- ITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1Document10 pagesITP For Injection Work of Basement Walls: King Abdullah Financial District (KAFD) Cluster J1amirskbkbkNo ratings yet

- 1C-6 (400x400) - COLUMNDocument1 page1C-6 (400x400) - COLUMNJaycee Bareng PagadorNo ratings yet

- Brickwall Estimating With Calculation and For ReferrenceDocument6 pagesBrickwall Estimating With Calculation and For Referrencesubin nguNo ratings yet

- Strengthening of RC Beams by Wrapping FRP On Steel Bars - IJERTDocument16 pagesStrengthening of RC Beams by Wrapping FRP On Steel Bars - IJERTThilan SenarathneNo ratings yet

- Astm C 478Document10 pagesAstm C 478Diego SanchezNo ratings yet

- Status of TestDocument271 pagesStatus of TestMichael LabayoNo ratings yet

- Txdot Producer List For Admixtures For ConcreteDocument18 pagesTxdot Producer List For Admixtures For ConcretefiercecatNo ratings yet

- Concrete Mix Design Calculation For M20Document25 pagesConcrete Mix Design Calculation For M20Kosygin Leishangthem100% (2)

- Utilization of Spent Bleaching Earth Waste On Clay Stabilization Using Clean Set CementDocument7 pagesUtilization of Spent Bleaching Earth Waste On Clay Stabilization Using Clean Set CementAji Prasetyo NotonegoroNo ratings yet

- Weekly Report - No#6.... (Sample)Document10 pagesWeekly Report - No#6.... (Sample)Hesham HassanNo ratings yet

- Panel-Pagar Concrete-Fence-Brosur-1 PreconDocument3 pagesPanel-Pagar Concrete-Fence-Brosur-1 PreconTeknik produksi wikonNo ratings yet

- Construction SchedulingDocument3 pagesConstruction SchedulingJoshua CastilloNo ratings yet