Professional Documents

Culture Documents

Service Rig Walk Around

Uploaded by

Mannit ButtarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Rig Walk Around

Uploaded by

Mannit ButtarCopyright:

Available Formats

Don't be Lazy

Do the Walk

P bar Y Safety Consultants Alberta Canada

Workover Checklist

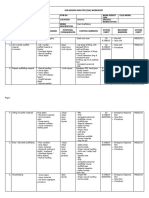

Checklist Sections:

General Safety

Guying & Foundation

Derrick & Carrier

Drawworks & Rig Floor

Tools & Equipment

Well Control Equipment

Safety Equipment & Practices

Dog house and Crew Truck

P bar Y Safety Consultants Alberta Canada

Rig Checklist General Safety

ENTRANCE TO LOCATION

SIGNS PRESENT TO

ADVISE VISITORS AND

CONTRACTOR

EMPLOYEES OF

REPORTING

PROCEDURES, 'NO

SMOKING', AND

PERSONAL PROTECTIVE

EQUIPMENT

REQUIREMENTS

Road Safety is Everyone's Business!

P bar Y Safety Consultants Alberta Canada

The Oil Patch Is A Dangerous Place

P bar Y Safety Consultants Alberta Canada

WHY BE CONCERNED WITH EMPLOYEE

SAFETY?

Safety is good business

Right thing to do

Improves employee morale/protects your most valuable

resource

Controls costs (direct and indirect)

Safety and health excellence correlates with business

excellence (quality, efficiency, profitability)

Protects the reputation of the company (Good will from the

community could mean fewer confrontations and delays)

P bar Y Safety Consultants Alberta Canada

Hazards In The Oil Field

P bar Y Safety Consultants Alberta Canada

Production Rigs / Workover Rigs

Production Rigs / Workover Rigs - involving

rotary, pump, pits, and auxiliaries to permit

handling and working a drill string. Examples

of maintenance activities associated with the

well when using these devices include:

Removing the horse head (pumping unit only)

Removing the wellhead

Pulling and running rod

Pulling and running tubing

P bar Y Safety Consultants Alberta Canada

Well Services

Special services operation activities include:

Wireline operations

Well logging

Perforating

Cementing

Stimulation

Swabbing

Hot Oiling

Snubbing

Coil Tubing

P bar Y Safety Consultants Alberta Canada

Some Potential Hazards and Their

Sources

Hazard

Source

Struck by

Falling/moving pipe; tongs and/or spinning chain, kelly, rotary table, etc.;

high pressure hose connection failure causing employees to be struck

by whipping hose; tools/debris dropped from elevated location in rig;

vehicles

Caught

in/Between

Collars and tongs, spinning chain, and pipe; clothing gets caught in rotary

table/drill string

Fire/Explosion/

High Pressure

Release

Well blowout, drilling/tripping out/swabbing etc. results in release of gas

which might be ignited if not controlled at the surface; welding/cutting

near combustible materials, uncontrolled ignition sources near the well

head, e.g., heater in the doghouse, unapproved or poorly maintained

electrical equipment; aboveground detonation of perforating gun

Rig Collapse

Overloading beyond the rated capacity of the rig; improper

anchoring/guying; improper raising and lowering the rig; existing

maintenance issues with the rig structure which impacts the integrity

Falls

Fall from elevated areas of the rig, i.e., stabbing boar, monkey board,

ladder, etc.; fall from rig floor to grade

Hydrogen

Sulfide (H

2

S)

Exposure

H2S release during drilling, swabbing, perforating operations, etc. resulting

in employee exposures; production tank gauging operations, gaugers

sometimes exposed to H2S

P bar Y Safety Consultants Alberta Canada

COMPLIANCE vs. PERFORMANCE

Compliance is reactive rather than proactive

and can only address problems after they

happen.

Performance sets goals and uses past

performance to look forward.

P bar Y Safety Consultants Alberta Canada

Fatalities

Lost Time

Unsafe Acts / Conditions

At Risk Behaviors

Near Miss

First Aid

Recordable Injury/Illness

P bar Y Safety Consultants Alberta Canada

Performance Metrics

Attitudes

(set up conditions,

behavior)

Program

Elements

Physical

conditions

Behavior

(action)

- Perception

surveys

- Training

- Accountability

- Communications

- Planning &

Evaluation

- Roles &

Procedures

- Incident

Investigations

-Inspections

-Audits

-Risk

assessments

-Prevention &

control

-Observations

-Feedback

loops

Incident

or Near

Miss

- OSHA

Recordables

- Lost

Workdays

- Restricted

Workdays

Leading

metrics

Trailing

metrics

P bar Y Safety Consultants Alberta Canada

WAYS TO INVOLVE EMPLOYEES

Regular communication with employees on the

subject of safety, risk, and hazards

Provide access to information

Provide ways to participate in the program

e.g., worksite self inspections, safety and health annual

evaluation process, incident investigation

Provide ways to report hazards, injuries, and make

recommendations to control hazards

P bar Y Safety Consultants Alberta Canada

Performance Architecture

Behavior

Systems

Culture

Safety is a Value in the Organization

And is Integrated into the Fabric of the Management Process

Building Blocks for a Performance Focus

The organization has

management systems that

ensure that objectives,

processes and resources are

adequate and effective and

continuously improving

Staff at all levels

has the knowledge and

is empowered to

intervene to support

safe work. Safety is

everybodys job

Management constantly

and consistently sends

the message that the

organization is fully

committed to safe work

and that accidents are

preventable and

unacceptable

P bar Y Safety Consultants Alberta Canada

Hard Hat

Safety

P bar Y Safety Consultants Alberta Canada

Rig Checklist General Safety

PUMPS, TANKS, AND OTHER AUXILIARY EQUIPMENT EXHAUSTS

POSITIONED MINIMUM OF 50 FEET AWAY AND CROSSWIND OR UPWIND

FROM THE WELL HEAD. SPARK ARRESTORS ARE REQUIRED ON ALL

EXHAUSTS WITHIN 100 FEET OF THE WELLHEAD.

50 Foot Min.

P bar Y Safety Consultants Alberta Canada

In Alberta Part 37 Oil and Gas Wells

Application

750 This Part applies to activities and auxiliary processes associated with

exploring for and drilling, operating or servicing wells for gas, crude oil or

geothermal energy.

Competent supervisor

751(1) An employer must appoint a supervisor to supervise an exploration,

drilling, servicing, snubbing, testing or production operation.

(2) An employer must ensure the supervisor is competent in each of the

following that is within the supervisors area of responsibility:

(a) safe work practices, including the safe operation of a plant at the work

site;

(b) the safe handling, use and storage of hazardous substances;

(c) well control and blow out prevention;

(d) detecting and controlling worker exposure to hydrogen sulphide;

(e) handling, using, maintaining and storing personal protective

equipment;

(f) appropriate responses to emergencies at the work site;

(g) the duties and responsibilities of all workers supervised by the

supervisor;

(h) training workers supervised by the supervisor in safe work practices

and procedures;

(i) health and safety programs.

P bar Y Safety Consultants Alberta Canada

Operating load of derrick or mast

753(1) An employer must ensure that the maximum safe operating

load of a

derrick or mast

(a) is specified in the manufacturers specifications or specifications

certified by a professional engineer,

(b) is prominently displayed on the derrick or mast, and

(c) is not exceeded.

(2) If a structural modification or repair is made to a derrick or

mast, an

employer must ensure that

(a) the structural modification or repair is certified by a professional

engineer,

(b) the maximum safe operating load of the derrick or mast is

determined

and certified by a professional engineer, and

(c) the load marking on the derrick or mast is replaced if the maximum

safe operating load is changed.

P bar Y Safety Consultants Alberta Canada

Personal Protection

Hard hats protect

against against

impacts from falling

objects or debris,

electrical shocks and

burns, penetration

and flammability.

P bar Y Safety Consultants Alberta Canada

Safety is no accident!

When hard hats are required

employees should know:

Proper hard hat use (how to put on, wear, adjust,

remove)

When it is necessary to use a hard hat

What kind of hard hats are necessary

The limitations of hard hats in injury protection

How to properly clean and maintain hard hat

P bar Y Safety Consultants Alberta Canada

Rig Checklist Guying

Section A

Power lines

Rig driver Permits

& insurance

Fall lane of derrick is

clear -

50 foot spacing on

exhaust

Spark arrestors

Key Energy Services

Rig Fall Line For

96 ft. Derrick

100 ft 100 ft

100 ft

P bar Y Safety Consultants Alberta Canada

Rig Checklist Guying

MINIMUM OF 10' CLEARANCE

FROM GUY LINES AND OTHER

EQUIPMENT TO OVERHEAD

POWER LINES When checking

fall lane include the length of

the derrick plus any

attachments to the ground and

add 10. For example if the

derrick is 92 and the carrier is

5 and there is a light attached

to the top of the derrick and it

sticks up 5 then you have a

total of 102 of derrick plus 10

clearance for a total fall lane of

112. The power lines must be

112 from the well.

NO VEHICLES OR EQUIPMENT

ARE PARKED WITHIN THE

FALL LANE OF THE DERRICK

P bar Y Safety Consultants Alberta Canada

Rig Checklist Guying

FOUR GROUND TO CROWN GUY

WIRES AND TWO TUBING

BOARD GUY WIRES Check for

condition of anchors and if they

have pull test tags on anchors. If

not then check to see if

production office has

documentation the anchors have

been pull tested within the last

two years. Have well operator fix

whatever issues are found on the

anchor system.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Guying

Guying

Position, tension and

condition

Flagging

Anchor testing

Tubing board guy lines

crossed

Internal load guys

Outriggers

P bar Y Safety Consultants Alberta Canada

Rig Checklist Foundation

RIG FOUNDATION IS ADEQUATE FOR SOIL

CONDITIONS, SPOTTING, AND GUYED TO

MANUFACTURER'S SPECIFICATIONS OR

ENGINEERED ALTERNATIVE SUCH AS A BASE BEAM

P bar Y Safety Consultants Alberta Canada

Rig Checklist Mast/Derrick

MAST SPECIFICATION PLATE PRESENT AND LEGIBLE This is usually on the

derrick leg or somewhere in the vicinity of where the operator is. It will show

the derrick serial number and what the lifting loads would be with different

strung lines. This could be 4, 6, 8 etc. lines strung.

MAST

SPECIFICATION

PLATE

P bar Y Safety Consultants Alberta Canada

Rig Checklist Mast/Derrick

General Condition

Derrick ladder straight and

secure -rungs begin within 18

inches of the ground or deck

Derrick fall protection in

place that provides 100% fall

protection

Tubing board and rod basket

in good condition

Y-base locking pins/bolts are

in place with safety pins or

nuts tight Pivot pins

trapped

P bar Y Safety Consultants Alberta Canada

Acceleration due to Gravity

Special case of Uniform Acceleration

Constant force acting on an object

imparts uniform acceleration

Gravity is a constant force

Any dropped object accelerates uniformly

Measuring the Acceleration due to

Gravity

Falling Objects

P bar Y Safety Consultants Alberta Canada

Bottom Line You Build Speed and Weight as you Fall

P bar Y Safety Consultants Alberta Canada

Rig Checklist Mast/Derrick

Derrick Components

Latch dogs must be verified by derrickman and

flagged before pulling on anything with blocks.

Scoping ram stabilizers functional and in a

horizontal position.

Crown sheave guards in place.

Rod and tubing fingers secured.

Circulating hose, standpipe and light secured.

Crown a contrasting color.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Mast/Derrick

SAFETY CHAINS/LINES ON ALL TUBING BOARD FINGERS

See Any Chains

Monkey Board Fingers

3 Clips and Thimble in Cable Eye-GOOD

No Safety Chains on Tubing Fingers-BAD

P bar Y Safety Consultants Alberta Canada

Rig Checklist Rig Carrier

RIG SHIFTED FROM ROAD TO WINCH POSITION This

is a shift lever either by the engine or somewhere close

to the middle of the rig carrier. See that it is locked into

position and pinned.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Drawworks/

Winch

Tubing and winch lines inspected daily, weekly and monthly.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Drawworks &

Winch

Check that Sand Line and Cable

P bar Y Safety Consultants Alberta Canada

Rig Checklist Drawworks &

Winch

Inspect and Re-inspect

P bar Y Safety Consultants Alberta Canada

Rig Checklist Tools and

Equipment

DOCUMENTATION OF API

INSPECTION (AS PER API RP 8B,

CATEGORY III) FOR ALL

ELEVATORS, BAILS, AND OTHER

HOISTING EQUIPMENT BY A

COMPETENT PERSON WITHIN

THE LAST YEAR AVAILABLE

P bar Y Safety Consultants Alberta Canada

Rig Checklist Tools &

Equipment

ELEVATORS SIZED AND MANTAINED FOR TUBING IN USE

LATCHES MUST OPERATE FREELY AND LATCH SECURELY, NO EXCESSIVE

SLACK IN HINGE POINTS

P bar Y Safety Consultants Alberta Canada

Rig Checklist Tools &

Equipment

ROD TRANSFERS MUST BE EQUIPPED WITH A SAFETY RING OR LATCH AND

ATTACHED TO ROD TRANSFER CABLE WITH A CLEVIS.

ROD TRANSFERS SHOULD BE REMOVED FROM THE DERRICK WHEN THEY

ARE NOT IN USE

P bar Y Safety Consultants Alberta Canada

Rig Checklist Tools &

Equipment

BACK UP CABLE (SNUB LINE) INSTALLED TO

SEPARATE ANCHOR POINT FROM STIFF ARM ON

TONGS.

DOOR GUARD USED AND SPRING KEEPS GUARD

CLOSED.

STIFF-ARM INSTALLED WITH BOLT, NUT, AND

RETAINER CLIP. Use a 5/8 grade 8 bolt or greater for

the stiff arm and snub line pin.

P bar Y Safety Consultants Alberta Canada

Rig Checklist BOP Equipment

SIGN OR OTHER DEVICE USED

WHEN BOP'S ARE CLOSED This

should be a sign or device attached to

the brake control and easily

recognized by the operator of the rig

when the BOP equipment is closed.

Manual closing wheels are to be

securely attached to the ram shafts.

Accumulator controls are to be in the

open or closed position not

neutral.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Circulating

Equipment

ALL PUMP LINES, NIPPLES, AND CIRCULATING HOSES

RATED AT OR ABOVE THE RATED WORKING PRESSURE

OF THE PUMP.

Safety devices are in place if pressure is exceeded such

as pop-off relief valves with manufacturer approved

shear pins. Relief lines are tied back into the return tank

and the line is secured to the tank.

Pump fan, alternator, lubricating pump belt and swabs are

properly guarded to prevent contact.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Circulating

Equipment

SAFETY CLAMPS/CHAINS ON CIRCULATING

HOSE/KELLY HOSE

Safety Clamp

F

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

GERONIMO UNIT INSTALLED

[Proper angle of line which should be 2 times height i.e. 60 height = 120 run | If flagged

used proper materials (no rags, ropes) use vinyl or plastic tape only | Handle on the right

side of line and attached properly to derrick]

INSTALLATION

RIGHT

WRONG

WRONG

WRONG

USE

1. To Go Move handle in direction A

A

B

2. To Stop or Slow Move handle in

direction B

1. Cable length should be twice the Height (Length + 2 x Height)

2. Cable size-7/16 or 1/2 plow steel standard six strand

3. Slack-6 feet of sag

4. Dead man must be able to support a

cable pull of 3000 lbs.

CAUTION

Do not attempt to field repair

when worn or damaged.

Dispose of and replace

Dead Man

App. 5

H

E

I

G

H

T

Standing Kink in Geronimo Line

Attachment of Geronimo

Line to Permanent Anchor

1 Clip

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

GERONIMO UNIT INSTALLED

Proper angle of line which should be 2 times height

i.e. 60 height = 120 run.

If flagged used proper materials (no rags, ropes)

use vinyl or plastic tape only.

Handle on the right side of line and attached

properly to derrick or tubing board escape gate.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

SUFFICIENT FIRE

EXTINGUISHERS PRESENT

AND INSPECTED

[Minimum 20 lb. BC or ABC

type within 50 feet of any

potential flammable

hazards (electrical or

hydrocarbon | properly

inspected and tagged] with

a minimum of 60# of

extinguisher capacity for

rig locations.

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

HAZARD COMMUNICATION PROGRAM, SPILL

CONTROL PLAN, AND EAP IN PLACE AND TRAINED

MSDS SHEETS UPDATED & IN PLACE FOR PRODUCTS

ON LOCATION

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

EACH CREW HAS AT LEAST

ONE TRAINED PERSON(S)

IN CPR/1ST AID

FIRST AID SUPPLIES ARE

READILY AVAILABLE

EYE-WASH AND BODY

FLUSH ARE AVAIALABLE

WHEN CAUSTICS OR

CORROSIVES ARE

PRESENT

EMERGENCY PHONE

NUMBERS ARE ACCURATE

AND AVAILABLE

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

ALL PERSONAL PROTECTIVE EQUIPMENT NEEDED FOR JOB AVAILABLE

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

CONFINED SPACE

PROGRAM IN PLACE,

TRAINED AND DISCUSSED

LOCKOUT / TAGOUT

PROGRAM IN PLACE ,

TRAINED AND DISCUSSED

Confined Space Program

Lockout/Tagout Program

P bar Y Safety Consultants Alberta Canada

Rig Checklist Safety

Equipment &

Practices

HOT WORK PERMITTING

PROGRAM IN PLACE ,

TRAINED AND DISCUSSED

H2S CONTINGENCY PLAN

IN PLACE , TRAINED,

DISCUSSED & EQUIPMENT

AVAILABLE (IN AREAS

WHERE H2S IS PRESENT)

Hot Work Permits

H2S Plan

P bar Y Safety Consultants Alberta Canada

P bar Y Safety Consultants Alberta Canada

Listed below are a few of the standard systems and equipment now on many of the service and

drilling rigs around the world for fall protection while at height:

Sealed self retracting lifelines installed at the crown and/or LADSAF ladder safety systems installed

for protection while climbing the derrick ladder.

A sloped line cable or boom arm installed over the monkey board to provide an anchor for a

smaller self retracting lifeline used for secondary protection to the primary positioning lanyard by the

derrick-hand while tripping.

New harness designs specific for use by rig workers for added comfort and safety are now standard.

Horizontal lifelines installed for use by workers when rigs are laid over and in other areas such as

above the BOPs and stabbing board.

Fall protection equipment lockers including anchoring products, double legged lanyards and extra

self retracting lifelines

P bar Y Safety Consultants Alberta Canada

With the changes that we have seen in fall protection and rescue in this industry there are

still many other systems and equipment that could be implemented for added safety. Some

include:

New sloped line escape systems to replace the aging and often unsafe Geronimo escape

system.

Man rated tuggers (winch lines) and/or new load limiters that can be used to safely raise

workers to difficult to access areas up the derrick.

Rig Floor/Deck Horizontal Lifeline Systems are now starting to become required and

installed during rig up and

down while guardrails are removed.

Trauma suspension systems and high angle rescue products for use post fall arrest.

. The next hurdle to now overcome includes the challenge of providing comprehensive

training for workers using the equipment; a10 minute doghouse talk just doesnt cut it...

Stop Work process

If an individual will not

respond to questioning,

you may need to stop

the work and call for

their immediate

supervisor.

Do not allow anyone to

continue to work in an

at-risk situation.

Scan the work site

for safe or at risk

behaviors

STOP ALL WORK

Control the hazards

then assemble in a

safe area

Tell me what you

are doing and why

you do it this way..

Thats great! Thank

you for doing this job

safely!

How could you be

injured?

How could you do

this more safely?

Will you do it that

way in the future?

No one is in

immediate danger

Could you stop for a

moment and talk with

me?

Someone is in

immediate danger

Do you need anything

to help you work

safely?

Thank you for caring

about yourself and

everyone else!

P bar Y Safety Consultants Alberta Canada

Stop Work Authority

Who is

responsible for

correcting unsafe

behaviors and

conditions?

YOU

have the right

and obligation

to stop unsafe

operations!

P bar Y Safety Consultants Alberta Canada

Rig Checklist Closing

Performing a full inspection of any worksite requires a

variety of skills and knowledge;

Knowledge of the work being performed keep

yourself out of danger.

Knowledge of the equipment and the standards that

relate to it.

The ability to recognized actions or situations that

place people at risk.

The skill and the will to intercede set and maintain

high standards to prevent incidents.

P bar Y Safety Consultants Alberta Canada

SAFETY EXCELLENCE MODEL

Management

Commitment

Systems

Safety and Health

Site Leadership

Employee

Involvement

P bar Y Safety Consultants Alberta Canada

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Surface BOP Closing Systems & EquipmentDocument64 pagesSurface BOP Closing Systems & EquipmentRoby RidoNo ratings yet

- Idc 37 Rig Move PlanDocument15 pagesIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Common Well Control Hazards: Identification and CountermeasuresFrom EverandCommon Well Control Hazards: Identification and CountermeasuresRating: 4.5 out of 5 stars4.5/5 (4)

- RP 1.0a Edition 5 - 2019 - FinalDocument22 pagesRP 1.0a Edition 5 - 2019 - FinalKevin BryarNo ratings yet

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- CHAPTER ONE Structural GeologyDocument46 pagesCHAPTER ONE Structural GeologyAfolabi Eniola AbiolaNo ratings yet

- HPHBT 2004 Land-Rig Drilling ManualDocument122 pagesHPHBT 2004 Land-Rig Drilling ManualWaleed Barakat Maria100% (2)

- Drill Pipe ChartsDocument12 pagesDrill Pipe ChartsDileep Kumar PmNo ratings yet

- HIRADC Assessment-INSTALLATION OF CABLING WORKDocument6 pagesHIRADC Assessment-INSTALLATION OF CABLING WORKTengkudin LatifNo ratings yet

- Drilling Practice Bridge PlugsDocument1 pageDrilling Practice Bridge PlugsJevi SeptiawanNo ratings yet

- SPE Rig SelectionDocument8 pagesSPE Rig SelectionEyoma EtimNo ratings yet

- Well Testing EquipmentDocument26 pagesWell Testing Equipmentlaribi mohammedNo ratings yet

- Acceptance Check ListDocument2 pagesAcceptance Check ListMohamed HamdyNo ratings yet

- 13 3-8" Cementing Program ChecklistDocument2 pages13 3-8" Cementing Program ChecklistYougchu LuanNo ratings yet

- Drilling Levels 3 and 4 Syllabus PDFDocument35 pagesDrilling Levels 3 and 4 Syllabus PDFGOKUL PRASADNo ratings yet

- DOP 206 - Rev 4Document12 pagesDOP 206 - Rev 4Fernando AybarNo ratings yet

- Risk Assessment and Business Impact AnalysisDocument11 pagesRisk Assessment and Business Impact AnalysisNoor Muddassir Khan100% (2)

- Whipstock Milling Operation - Best PracticesDocument1 pageWhipstock Milling Operation - Best PracticesYougchu LuanNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- 4 Workover and Potential HazardsDocument24 pages4 Workover and Potential HazardsaliNo ratings yet

- 15 Fishing Tools PDFDocument15 pages15 Fishing Tools PDFjoo123456789No ratings yet

- Pick Up Drill PipeDocument5 pagesPick Up Drill PipeinfonexusNo ratings yet

- Basic Services and Facilities Matrix - Local Gov''tDocument2 pagesBasic Services and Facilities Matrix - Local Gov''tMishi Liao100% (2)

- #101 - Oilfield HSE Inspection HandbookDocument30 pages#101 - Oilfield HSE Inspection HandbookEagle EyeNo ratings yet

- Drilling and Well ConstructionDocument36 pagesDrilling and Well ConstructionMarcio Nascimento BezerraNo ratings yet

- Snubbing Unit PresentationDocument7 pagesSnubbing Unit PresentationDimitri Elitist BlessNo ratings yet

- 1 - Construction SafetyDocument43 pages1 - Construction SafetyHawaiiChongNo ratings yet

- Drilling Rig Components Illustration - Komponen Utama PemboranDocument86 pagesDrilling Rig Components Illustration - Komponen Utama PemboranPuji LestariNo ratings yet

- BP TEXAS Accident REPORT PDFDocument26 pagesBP TEXAS Accident REPORT PDFDelfi Karmila Thessa100% (4)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Service Tools RBPDocument26 pagesService Tools RBPTeguh Akbar HarahapNo ratings yet

- Operations Auditing: - o o - o - o oDocument9 pagesOperations Auditing: - o o - o - o oLORI-LYN GUICONo ratings yet

- 39 Packer Comparison ChartDocument1 page39 Packer Comparison ChartGhinet Teodor-ioan100% (2)

- Land RigDocument2 pagesLand RigRoger AddyNo ratings yet

- Tie Back Seal Nipple ProcedureDocument2 pagesTie Back Seal Nipple ProceduredevillipsNo ratings yet

- Color Management Handbook Vol2Document28 pagesColor Management Handbook Vol2ianjpr100% (2)

- TOS Slickline SOP V1.0Document16 pagesTOS Slickline SOP V1.0Donald TchiroueNo ratings yet

- Standard Format Equipment List Land Drilling Units (Land Rigs)Document51 pagesStandard Format Equipment List Land Drilling Units (Land Rigs)Shofwan Hilal100% (1)

- Best Practices Drilling 26 inDocument6 pagesBest Practices Drilling 26 inmanuelperdomotNo ratings yet

- Why CPVC Pipes FailDocument12 pagesWhy CPVC Pipes FailNikita Kadam100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Onshore Oil & Gas Rig Move Logistics MTLNextGen SoftwareDocument13 pagesOnshore Oil & Gas Rig Move Logistics MTLNextGen SoftwareSanjeev MadaviNo ratings yet

- Back OffDocument3 pagesBack OffSasan AbbasiNo ratings yet

- Fish Tools ExternalDocument50 pagesFish Tools ExternalShaikh Sabir HussainNo ratings yet

- Drilling TerminologyDocument75 pagesDrilling TerminologyAshish Kumar JhaNo ratings yet

- Handling Tools PDFDocument26 pagesHandling Tools PDFHaridevNo ratings yet

- Guidance Checklist WebDocument5 pagesGuidance Checklist WebmeidiansyahNo ratings yet

- Subcontractor Safety (EDocFind - Com)Document41 pagesSubcontractor Safety (EDocFind - Com)Satya NaiduNo ratings yet

- Process Safety ManagementDocument26 pagesProcess Safety Managementhse.farhiNo ratings yet

- Asia Pacific Weekly Incident Summary 08-Jul-2014 (Indonesia)Document15 pagesAsia Pacific Weekly Incident Summary 08-Jul-2014 (Indonesia)Anonymous cKdbnUHNo ratings yet

- Workshop K - RinggerDocument59 pagesWorkshop K - RinggerHumberto AnguloNo ratings yet

- HIRADC Assessment-INSTALLATION OF BUSDUCTDocument6 pagesHIRADC Assessment-INSTALLATION OF BUSDUCTTengkudin LatifNo ratings yet

- Permit To Work (PTW) AwarenessDocument13 pagesPermit To Work (PTW) AwarenessNur FaizahNo ratings yet

- Petra Jsa Scaffolding 2022Document2 pagesPetra Jsa Scaffolding 2022Che Wan ErliyasNo ratings yet

- MSH TB AssessingRiskTaskDocument19 pagesMSH TB AssessingRiskTasksaravanan1107No ratings yet

- Risk-Based AuditingDocument16 pagesRisk-Based AuditingMohammed JabbarNo ratings yet

- Your Company Safety ProgramDocument24 pagesYour Company Safety ProgramTerry PenneyNo ratings yet

- Whmis Yes Another ReminderDocument26 pagesWhmis Yes Another ReminderTerry PenneyNo ratings yet

- You Know Welding Cutting Safety EtcDocument136 pagesYou Know Welding Cutting Safety EtcTerry PenneyNo ratings yet

- Y14 Lowboy 2Document15 pagesY14 Lowboy 2Terry PenneyNo ratings yet

- Winter in AlbertaDocument19 pagesWinter in AlbertaTerry PenneyNo ratings yet

- What Are Your Hazards and How Are YouDocument41 pagesWhat Are Your Hazards and How Are YouTerry PenneyNo ratings yet

- In Cid en TS: Is The Problem A Little Up HillDocument35 pagesIn Cid en TS: Is The Problem A Little Up HillTerry PenneyNo ratings yet

- Worker OrientationDocument31 pagesWorker OrientationTerry PenneyNo ratings yet

- Slips Trips Falls and We Mean No STFsDocument15 pagesSlips Trips Falls and We Mean No STFsTerry PenneyNo ratings yet

- SWA 11-11-08 EngDocument1 pageSWA 11-11-08 EngTerry PenneyNo ratings yet

- Un-Health Work Only If You Let It!: You Hold The Keys To Safety Just Pick Them Up and Apply Your KnowledgeDocument61 pagesUn-Health Work Only If You Let It!: You Hold The Keys To Safety Just Pick Them Up and Apply Your KnowledgeTerry PenneyNo ratings yet

- What A Little Less Sizzle at WorkDocument28 pagesWhat A Little Less Sizzle at WorkTerry PenneyNo ratings yet

- Slip and Trips in The WorksitesDocument33 pagesSlip and Trips in The WorksitesTerry PenneyNo ratings yet

- Slip Trip Fall One PageDocument1 pageSlip Trip Fall One PageTerry PenneyNo ratings yet

- Shamrock Ground DisturbanceDocument85 pagesShamrock Ground DisturbanceTerry PenneyNo ratings yet

- Scaffolds What Goes Up Will Come Down IfDocument15 pagesScaffolds What Goes Up Will Come Down IfTerry PenneyNo ratings yet

- Shamrock Valley Ent LTD OrientationDocument101 pagesShamrock Valley Ent LTD OrientationTerry PenneyNo ratings yet

- Skilled Worker Module 6Document40 pagesSkilled Worker Module 6Terry PenneyNo ratings yet

- Silica: The Partials That Bind and Harm UsDocument20 pagesSilica: The Partials That Bind and Harm UsTerry PenneyNo ratings yet

- Shamrock Valley Dangerous Goods Training 2009Document143 pagesShamrock Valley Dangerous Goods Training 2009Terry PenneyNo ratings yet

- Safety Matrix of Your ProgramDocument31 pagesSafety Matrix of Your ProgramTerry PenneyNo ratings yet

- Scaffolding: Your Key To Stability: Presented By: Georgia Tech Occupational Safety and Health ProgramDocument33 pagesScaffolding: Your Key To Stability: Presented By: Georgia Tech Occupational Safety and Health ProgramTerry PenneyNo ratings yet

- Sand 2009 1947 P Non-Electrical Workers Basic Electrical SafetyDocument44 pagesSand 2009 1947 P Non-Electrical Workers Basic Electrical SafetySharat MallikNo ratings yet

- Safety Is A Dish Served WarmDocument47 pagesSafety Is A Dish Served WarmTerry PenneyNo ratings yet

- Safety Framing: What Surrounds Your ProgramDocument24 pagesSafety Framing: What Surrounds Your ProgramTerry PenneyNo ratings yet

- Safety Meeting 06-01-2010Document1 pageSafety Meeting 06-01-2010Terry PenneyNo ratings yet

- Safety Incentive Presentation 032808Document6 pagesSafety Incentive Presentation 032808Terry PenneyNo ratings yet

- Safety Is A Dish Served WarmDocument47 pagesSafety Is A Dish Served WarmTerry PenneyNo ratings yet

- Safety For Supervisors inDocument76 pagesSafety For Supervisors inTerry PenneyNo ratings yet

- Repository Your Right To Breath at WorkDocument58 pagesRepository Your Right To Breath at WorkTerry PenneyNo ratings yet

- Law EssayDocument7 pagesLaw EssayNahula AliNo ratings yet

- Islm ModelDocument7 pagesIslm ModelPrastuti SachanNo ratings yet

- GM1. Intro To FunctionsDocument5 pagesGM1. Intro To FunctionsGabriel Benedict DacanayNo ratings yet

- Gcm02-Mt-Ing4 New1 PDFDocument57 pagesGcm02-Mt-Ing4 New1 PDFabdel jabbar67% (3)

- Arbitrage Calculator 3Document4 pagesArbitrage Calculator 3Eduardo MontanhaNo ratings yet

- 2 - Water Requirements of CropsDocument43 pages2 - Water Requirements of CropsHussein Alkafaji100% (4)

- Psar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0Document183 pagesPsar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0PhatNo ratings yet

- Linux Memory ExplainedDocument60 pagesLinux Memory ExplainedRaphael AraujoNo ratings yet

- Talent Neuron NewsletterDocument2 pagesTalent Neuron NewsletterTalent NeuronNo ratings yet

- Presentation 2Document32 pagesPresentation 2Jackie LeeNo ratings yet

- Design Calculation of Braking System (Landcruiser) : AbstractDocument4 pagesDesign Calculation of Braking System (Landcruiser) : AbstractDr. Aung Ko LattNo ratings yet

- OIG ReportDocument43 pagesOIG ReportRohan M100% (1)

- Account Statement From 27 Dec 2017 To 27 Jun 2018Document4 pagesAccount Statement From 27 Dec 2017 To 27 Jun 2018mrcopy xeroxNo ratings yet

- Course Outline of Lecturer Economics For Service Commissions TestDocument5 pagesCourse Outline of Lecturer Economics For Service Commissions TestSheraz Ali KhanNo ratings yet

- 164 Dashboard Annotated Ver 2a W-InsertDocument1 page164 Dashboard Annotated Ver 2a W-Insertoleg164No ratings yet

- PR Status ReportDocument28 pagesPR Status ReportMascheny ZaNo ratings yet

- Sop ECUDocument5 pagesSop ECUSumaira CheemaNo ratings yet

- Amendment Notes For June 2021Document32 pagesAmendment Notes For June 2021arohi gupta0% (2)

- Sample Resume FinalDocument2 pagesSample Resume FinalSyed Asad HussainNo ratings yet

- Azhar Marketing Final PPRDocument9 pagesAzhar Marketing Final PPRafnain rafiNo ratings yet

- Degree 21-22 INTERNSHIPDocument4 pagesDegree 21-22 INTERNSHIPkoushik royalNo ratings yet

- IT 118 - SIA - Module 1Document9 pagesIT 118 - SIA - Module 1Kim Zyrene DominoNo ratings yet

- Taguig City University: College of Information and Communication TechnologyDocument9 pagesTaguig City University: College of Information and Communication TechnologyRay SenpaiNo ratings yet

- Google Translate - Google SearchDocument1 pageGoogle Translate - Google SearchNicole Alex Bustamante CamposNo ratings yet

- Web Development Company in BhubaneswarDocument4 pagesWeb Development Company in BhubaneswarsatyajitNo ratings yet

- PROPOSALDocument4 pagesPROPOSALsacheendra singhNo ratings yet