Professional Documents

Culture Documents

Phe M3

Uploaded by

Vishnu Vardhan . COriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phe M3

Uploaded by

Vishnu Vardhan . CCopyright:

Available Formats

ï Go to secondary index

Plate Heat Exchanger

M3

Standard design

The plate heat exchanger consists of a pack of corrugated

metal plates with portholes for the passage of the two fluids

between which heat transfer will take place.

The plate pack is assembled between a frame plate and a

pressure plate and compressed by tightening bolts. The plates

are fitted with a gasket which seals the channel and directs the

fluids into alternate channels. The number of the plates are

determined by the flow rate, physical properties of the fluids,

pressure drop and temperature program. The plate corrugations

promote fluid turbulence and support the plates against differen-

tial pressure.

The plates and the pressure plate are suspended from an upper

carrying bar and located by a lower guiding bar both of which

are fixed to the support columns.

Connections are located in the frame cover, or if either or both

fluids make more than a single pass within the unit, in the frame

and pressure plates.

M3-FM

Plates can be obtained in all pressable materials. Gaskets are

available in a wide range of elastomers.

Flow rate

(Depends on media, permitted pressure drop and temperature

program).

Flow principle of an M3

Up to 14 m3/h (3100 igph). plate heat exchanger

Plate types

M3 and M3-X, where M3 provides parallel and M3-X diagonal

flow (see figures).

Frame types

FM, FGL and FG.

Working principle Flow principle of an M3-X

plate heat exchanger

Channels are formed between the plates and corner ports are

arranged so that the two media flow through alternate channels.

The heat is transferred through the thin plate between the

channels, and complete counter current flow is created for

highest possible efficiency. No intermixing of the media or

leakage to the surroundings will take place as gaskets around

the edges of the plates seal the unit. The corrugation of the

plates provides a suitable passage between the plates, support

of each plate against the adjacent one and a strong turbulence

resulting in maximum heat transfer efficiency.

Plate Heat Exchanger

M3

Standard Materials Dimensions (measurement in mm)

Frame

Mild steel, epoxy resin painted

M3-FGL

180 C

Nozzles 60 15 A 15

Stainless steel AISI 316, Titanium

Plates 20

20

Stainless steel AISI 316, Titanium

480

357

Gaskets 105

M3: NBR (clip-on), EPDM (clip-on).

R 1 1/4"

55

M3-X: NBR and EPDM, Clip-on and glued, Viton glued

62

Connections

Straight pipe thread ISO-R 1 1/4 " B

Straight pipe thread ISO-G 1/4 " M3-FM, M3-XFM

180 C

60 20 A 20

35

Technical Data

Max. working temperature

ø18

480

357

145

Rubber gaskets, temperature up to 140° C (284° F)

R 1 1/4"

148

Max. working pressure

167.5

59

FM - 1.0 Mba (144 psig)

62

FG, FGL - 1.6 Mba (230 psig)

B

Heat transfer coefficient M3-FG, M3-XFG

3500 - 5500 W/m2 °C (600-1,000 BTU/ft2h° F) 180 C

60 20 A 20

Max. heat exchanger surface

FM, FG : 3,9 m2 (41.8 sq ft)

FGL : 2.7 m2 (28.9 sq ft) 35

Heating surface per plate

480

357

0.032 m2 (0.34 sq ft) 148

ø18

R 1 1/4"

240

59

62

Particulars required for quotation B

– Flow rates or heat load

A= (2.4 + 0.6 Titanium) x n mm. (n = Number of plates)

– Temperature program (2.4 + 0.5 AISI 316) x n mm. (n = Number of plates)

FM, FG B= 175 mm C= 240 mm (Max. 49 Plates)

– Physical properties of liquids in question (if not water) 350 mm 300 mm (Max. 63 Plates)

– Desired working pressure 550 mm 500 mm (Max. 95 Plates)

FGL B = 250 mm C= 300 mm (Max. 63 Plates)

– Maximum permitted pressure drop 500 mm 500 mm (Max. 95 Plates)

PD 68072 E2 / 9910

You might also like

- Metric Measurement and Volume Displacement Lab ActivityDocument10 pagesMetric Measurement and Volume Displacement Lab ActivityHaris Khan100% (1)

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- 03 Ball Mill EDMDocument47 pages03 Ball Mill EDMVishnu Vardhan . C92% (13)

- Strength of Materials - Task 1. Chapter 1.Document3 pagesStrength of Materials - Task 1. Chapter 1.Eduard Avila Meriño100% (1)

- Dr. Fixit Prebond: Hdpe Pre Applied Fully Bonded MembraneDocument3 pagesDr. Fixit Prebond: Hdpe Pre Applied Fully Bonded Membranevelmurug_balaNo ratings yet

- Datasheet TS6Document9 pagesDatasheet TS6HUMBERTO OLIVEIRANo ratings yet

- Irjet V4i1053 PDFDocument6 pagesIrjet V4i1053 PDFdynamo ShaikhNo ratings yet

- Válvula Esfera SBVF360 - DatasheetDocument4 pagesVálvula Esfera SBVF360 - DatasheetFabio GiehlNo ratings yet

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- 87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Document1 page87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Hung NguyenNo ratings yet

- Valves BrochureDocument16 pagesValves BrochurePeradNo ratings yet

- Bite Type Tube Fittings (DIN 2353) : The Best Partner For Value Creation We Support The Innovations of CustomersDocument54 pagesBite Type Tube Fittings (DIN 2353) : The Best Partner For Value Creation We Support The Innovations of CustomersNIKESHNo ratings yet

- A Belgas Catalog 2018Document307 pagesA Belgas Catalog 2018TitexPlusNo ratings yet

- 5/3 Internal Pilot Operated, Center Off Poppet Solenoid ValveDocument2 pages5/3 Internal Pilot Operated, Center Off Poppet Solenoid ValveGaurav TripathiNo ratings yet

- Fig - 3616 TI P160 04 ENDocument4 pagesFig - 3616 TI P160 04 ENAditomo PutrantoNo ratings yet

- Hoja de Datos Bomba RotanDocument15 pagesHoja de Datos Bomba RotanAngel Orlando Bravo LeonNo ratings yet

- Toyo Stainless Steel Valves PDFDocument16 pagesToyo Stainless Steel Valves PDFvirgilius lopezNo ratings yet

- Fig Fm463 Fm466 Fa463 Check Cranefs Ds 1702 p95Document1 pageFig Fm463 Fm466 Fa463 Check Cranefs Ds 1702 p95Daniel FloresNo ratings yet

- SERIES 5000 - 6000: 3 Piece Full Port Ball ValvesDocument2 pagesSERIES 5000 - 6000: 3 Piece Full Port Ball Valvesko2aahsNo ratings yet

- FINAL BOQ-Civil-07052020Document1 pageFINAL BOQ-Civil-07052020vinoj chandranNo ratings yet

- 88A-200 SERIES: Standard Material List Variations AvailableDocument8 pages88A-200 SERIES: Standard Material List Variations AvailableBalotileNo ratings yet

- 1 1 1 Az GB Iso Standard f2Document6 pages1 1 1 Az GB Iso Standard f2Thássio MartinsNo ratings yet

- P627 High Flow Gas Regulator: ApplicationsDocument17 pagesP627 High Flow Gas Regulator: ApplicationsWilmar salgado cañateNo ratings yet

- Inverted Bucket Idh Lf2Document2 pagesInverted Bucket Idh Lf2Roo FaNo ratings yet

- Carbon Steel Ball Valve: Design FeaturesDocument1 pageCarbon Steel Ball Valve: Design FeaturesChanchal K SankaranNo ratings yet

- Widegap 350Document2 pagesWidegap 350Nguyễn HưngNo ratings yet

- Technical Specifications: PlateDocument2 pagesTechnical Specifications: PlateIgnacio LopezNo ratings yet

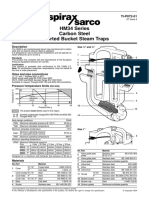

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

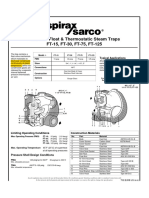

- STEAM CONTROL - TRAMPA FLOTADORA SPIRAX SARCO FT-125 DE 0.75 A 2 INDocument2 pagesSTEAM CONTROL - TRAMPA FLOTADORA SPIRAX SARCO FT-125 DE 0.75 A 2 INjefe.mantenimientoNo ratings yet

- Technical Sheet BTM7Document6 pagesTechnical Sheet BTM7Malik DaniyalNo ratings yet

- 317 Cast Iron PR 3asDocument1 page317 Cast Iron PR 3asAgung YudistiraNo ratings yet

- Spirax Sarco (TI) - Valvula Cheque DCV4 (TI-P134-04-EN)Document4 pagesSpirax Sarco (TI) - Valvula Cheque DCV4 (TI-P134-04-EN)Nestor LozanoNo ratings yet

- P119 Control Valve: ApplicationsDocument3 pagesP119 Control Valve: Applicationsyahir_aguilera14No ratings yet

- Two Orifice Float Trap: DescriptionDocument4 pagesTwo Orifice Float Trap: DescriptionHiranthaNo ratings yet

- Cpe Crane Fkx9000asme TD Es A4 2018-03-01 WebDocument2 pagesCpe Crane Fkx9000asme TD Es A4 2018-03-01 WebJhorman RamosNo ratings yet

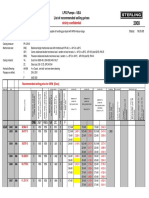

- Sterling Fluid Systems: LPG Pumps - UEA List of Recommended Selling PricesDocument3 pagesSterling Fluid Systems: LPG Pumps - UEA List of Recommended Selling Pricesrebelde1986No ratings yet

- Keystone K-Lok 360-370 Data SheetDocument12 pagesKeystone K-Lok 360-370 Data SheetMnttoMecNo ratings yet

- 82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsDocument1 page82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsAniket AngreNo ratings yet

- S80 - Sales Borchure EnglishDocument2 pagesS80 - Sales Borchure Englishevilnemesis133No ratings yet

- Alfa Laval Gunclean Toftejorg I40 D: Dual-Nozzle Tank Cleaning MachineDocument4 pagesAlfa Laval Gunclean Toftejorg I40 D: Dual-Nozzle Tank Cleaning MachineSamo SpontanostNo ratings yet

- E gp10f HPDocument4 pagesE gp10f HPabarry_personalNo ratings yet

- Plug Valves PLV Series Rev 00Document6 pagesPlug Valves PLV Series Rev 00lis sugiantoroNo ratings yet

- BelGAS P627 R627 F627Document24 pagesBelGAS P627 R627 F627Prihartono Danan WingusNo ratings yet

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarNo ratings yet

- Magflo Mag 1100Document84 pagesMagflo Mag 1100Mario RibeiroNo ratings yet

- P PT Industrial Stainless Steel Filter HousingsDocument4 pagesP PT Industrial Stainless Steel Filter Housingsliceth.emilio30mpNo ratings yet

- Series HPRV Product LiteratureDocument2 pagesSeries HPRV Product Literatureenghassanain6486No ratings yet

- V81 (March 2015) PDFDocument2 pagesV81 (March 2015) PDFTran Duc DungNo ratings yet

- PG 36Document1 pagePG 36anon-71881No ratings yet

- Valv Mariposa A536 Epdm REXDocument1 pageValv Mariposa A536 Epdm REXprosteelperusacNo ratings yet

- Mooney 2 LP FLowgrid Shutoff ValveDocument2 pagesMooney 2 LP FLowgrid Shutoff ValveLuis mario Castillo olveraNo ratings yet

- Wilo 497649Document24 pagesWilo 497649Gustavo AmezquitaNo ratings yet

- DoubleDoor 300WT-SeriesDocument3 pagesDoubleDoor 300WT-SeriesDaniel FigueroaNo ratings yet

- Series 450 - JOUCOMATIC Tie Rod Cylinders Type PESDocument2 pagesSeries 450 - JOUCOMATIC Tie Rod Cylinders Type PESIrham Lazuardi100% (1)

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- RF1000-R2, AISI316, FRAME AISI304 Main DWG, Rf1000: General Tolerances Scale ProductDocument1 pageRF1000-R2, AISI316, FRAME AISI304 Main DWG, Rf1000: General Tolerances Scale ProducthazemNo ratings yet

- "S" Type Stainless Steel Pitot Tubes: Large, Open Tip Design Resists Fouling Optional Permanent Mount ModelsDocument1 page"S" Type Stainless Steel Pitot Tubes: Large, Open Tip Design Resists Fouling Optional Permanent Mount ModelsAJITHNo ratings yet

- Pressure Reducing Valve - Thread EndDocument1 pagePressure Reducing Valve - Thread EndMohamed RaafatNo ratings yet

- Bellows Sealed Matering Valves BM Series (Ms-01-23) R3Document4 pagesBellows Sealed Matering Valves BM Series (Ms-01-23) R3herysyam1980No ratings yet

- Technical Sheet DT300FDocument2 pagesTechnical Sheet DT300FMalik DaniyalNo ratings yet

- M10S Ball Valve DN " To DN2 ": DescriptionDocument7 pagesM10S Ball Valve DN " To DN2 ": DescriptionAlfredo Oro vidalNo ratings yet

- FT 20 Ball Float Steam TrapDocument2 pagesFT 20 Ball Float Steam Trapravindrasuryavanshi6No ratings yet

- S5000 S6000 Ficha TecnicaDocument2 pagesS5000 S6000 Ficha TecnicaJackNo ratings yet

- Water PumpsDocument3 pagesWater PumpsDubaiHMARNo ratings yet

- Central or Girth Gear Drive For Ball Mills - 1Document26 pagesCentral or Girth Gear Drive For Ball Mills - 1Vishnu Vardhan . C100% (3)

- Plate Heat Exchanger: ApplicationsDocument2 pagesPlate Heat Exchanger: ApplicationsVishnu Vardhan . CNo ratings yet

- The Hound of Baskervilles by Sir Arthur Conan DoyleDocument223 pagesThe Hound of Baskervilles by Sir Arthur Conan DoyleCristinaNo ratings yet

- AllignmentDocument2 pagesAllignmentVishnu Vardhan . CNo ratings yet

- Honeywell On SystemDocument2 pagesHoneywell On SystemVishnu Vardhan . CNo ratings yet

- 07 VRM PregrinderDocument22 pages07 VRM PregrinderVishnu Vardhan . C100% (9)

- WIS5 Imperfections 2006 PDFDocument81 pagesWIS5 Imperfections 2006 PDFWatcharapong Puangthaisong100% (1)

- HVAC & Refrigeration SystemDocument22 pagesHVAC & Refrigeration SystemSivakumar NadarajaNo ratings yet

- Grinding Course: Ball Charge Design MethodsDocument12 pagesGrinding Course: Ball Charge Design MethodsVishnu Vardhan . C100% (12)

- Kiln Drive Application Considerations Ias ArticleDocument17 pagesKiln Drive Application Considerations Ias Articleschumi917No ratings yet

- Impact CrusherDocument3 pagesImpact CrusherVishnu Vardhan . C100% (1)

- Grinding With Ball Mill Systems: SeparatingDocument64 pagesGrinding With Ball Mill Systems: SeparatingVishnu Vardhan . C100% (3)

- Mill Ventilation: Grinding With Ball Mill SystemsDocument20 pagesMill Ventilation: Grinding With Ball Mill SystemsVishnu Vardhan . C100% (2)

- 04 Vertical Roller MillsDocument12 pages04 Vertical Roller MillsVishnu Vardhan . C100% (4)

- KilnDocument26 pagesKilnVishnu Vardhan . C100% (4)

- ESP OperationDocument22 pagesESP OperationVishnu Vardhan . C100% (1)

- Basic WeldingDocument40 pagesBasic WeldingVishnu Vardhan . C100% (8)

- Compressed Air System Design ManualDocument26 pagesCompressed Air System Design ManualBadrul HishamNo ratings yet

- Engineers Level Calibration InstructionsDocument1 pageEngineers Level Calibration InstructionsCarlos TarquinoNo ratings yet

- SHORT REPORT - 606 - Liner DisplacementDocument26 pagesSHORT REPORT - 606 - Liner DisplacementwongpeisenNo ratings yet

- In Process Quality Control Tests (IPQC) For Solid Dosage FromDocument28 pagesIn Process Quality Control Tests (IPQC) For Solid Dosage FromSagar kishor savale75% (8)

- Computational Fluid Dynamics Analysis of Greenhouse Solar DryerDocument19 pagesComputational Fluid Dynamics Analysis of Greenhouse Solar DryerPurusothamanManiNo ratings yet

- Science 10 q4 Week 1Document11 pagesScience 10 q4 Week 1Jacqueline FabiaNo ratings yet

- Phy Worksheet IG 3 Phase 1Document6 pagesPhy Worksheet IG 3 Phase 1Umair RazaNo ratings yet

- UNIT IV NMR Mass - WatermarkDocument23 pagesUNIT IV NMR Mass - WatermarkvickyNo ratings yet

- Edited and Compiled By: Haramaya University College of Natural and Computational Sciences Department of ChemistryDocument158 pagesEdited and Compiled By: Haramaya University College of Natural and Computational Sciences Department of Chemistrygetaneh achenifNo ratings yet

- Catálogo Dexco 2020Document108 pagesCatálogo Dexco 2020Adalberto Santana JuniorNo ratings yet

- Iacs W-22 2004Document15 pagesIacs W-22 2004Guilherme de BarrosNo ratings yet

- Steps To Improve Roads On Black Cotton SoilsDocument9 pagesSteps To Improve Roads On Black Cotton SoilsAmrutha SivaramanNo ratings yet

- 16kw ManualDocument48 pages16kw ManualJamesBrionesNo ratings yet

- Ray Optics DPPDocument38 pagesRay Optics DPParpitarathore024No ratings yet

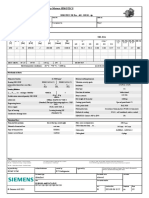

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4PDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4Pnadia perezNo ratings yet

- Lesson 8 Shear or Diagonal Tension in RC BeamsDocument8 pagesLesson 8 Shear or Diagonal Tension in RC BeamsJoshua John JulioNo ratings yet

- Dye Laser: Navigation SearchDocument6 pagesDye Laser: Navigation SearchselvakanmaniNo ratings yet

- SD-NOC-EC-602 Pre-Commissioning ExecutionDocument156 pagesSD-NOC-EC-602 Pre-Commissioning ExecutionBadri AbdullahNo ratings yet

- NEW Atlanta Permaline 2019Document2 pagesNEW Atlanta Permaline 2019gregNo ratings yet

- Engeneering Notebook 2019-20Document39 pagesEngeneering Notebook 2019-20api-478966175No ratings yet

- Adsorption Dryer HRS: Technical DataDocument3 pagesAdsorption Dryer HRS: Technical DataReza JabbarzadehNo ratings yet

- Math 2021 Past PaperDocument27 pagesMath 2021 Past PaperayaanrayhaanNo ratings yet

- Uk-Lr10 4 PDFDocument2 pagesUk-Lr10 4 PDFViệt Dương ĐứcNo ratings yet

- Hy-Gain 414 Big Gun 2Document11 pagesHy-Gain 414 Big Gun 2Robert GettyNo ratings yet

- Midterm and HomeworksDocument10 pagesMidterm and HomeworksSeila MolinaNo ratings yet

- CU-2022 B.sc. (Honours) Mathematics Semester-1 Paper-CC-1 QPDocument4 pagesCU-2022 B.sc. (Honours) Mathematics Semester-1 Paper-CC-1 QPMy MathNo ratings yet

- Nameof Work:-Design of Circular Water Tank: Narok ETPDocument27 pagesNameof Work:-Design of Circular Water Tank: Narok ETPAbhay Thakur100% (1)

- PV Sol-Main-11014092 (En) Hi PDFDocument56 pagesPV Sol-Main-11014092 (En) Hi PDFŁukasz Misak100% (1)

- Night Vision Technology1Document20 pagesNight Vision Technology1Srinivas RaoNo ratings yet