Professional Documents

Culture Documents

SERIES 5000 - 6000: 3 Piece Full Port Ball Valves

Uploaded by

ko2aahsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SERIES 5000 - 6000: 3 Piece Full Port Ball Valves

Uploaded by

ko2aahsCopyright:

Available Formats

FLOW-TEK

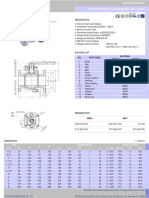

SERIES 5000 | 6000

3 Piece Full Port Ball Valves

Flow-Tek’s Series 5000/6000 ball These valves offer quarter turn Each Series 5000/6000 valve features

valves offer the convenience of operation and low operating torque. an integrally cast mounting pad

a three piece body design at an Series 5000/ 6000 valves feature complying with ISO 5211 that provides

economical price. The 3 Piece design adjustable stem packing, stainless positive alignment when mounting

with a swing out center section allows steel safety trigger locking handles actuators, gear operators or control

for ease of in-line and out-of-line and travel stops which limit handle accessories.

maintenance. Standard valve bodies movement to set 90° intervals. Flow-

are investment cast CF8M Stainless Tek‘s heavy duty, high quality stems

Steel or WCB Carbon Steel. All body are internal entry and blowout proof

castings are marked with a foundry for maximum safety.

heat number for full traceability.

Size Pressure Rating Temp. Range End Connections Body Material

1/4" to 2" 1000 psi WOG -50°F to +450°F Threaded (NPT): 5000:

8mm to 50mm 69 bar -46°C to +232°C SS CF8M or CS WCB Stainless Steel CF8M

2-1/2" to 4" 800 psig WOG Socket Weld: 6000:

65mm to 100mm 55 bar SS CF3M or CS WCB Carbon Steel WCB

WWW.BRAY.COM THE HIGH PERFORMANCE COMPANY

COMPONENTS AND MATERIALS SPECIFICATIONS

> All Series 5000/6000 valves

Item Name Material Qty.

comply with, and are tested in

1 Body ∆ ASTM A351 Gr CF8M 1 accordance with, MSS-SP 72. 26

28

2 End Cap ∆ ASTM A351 Gr CF8M 2 > Vacuum Service to 29 inches 19

Hg. gauge. 25

3 Ball ASTM A479 Type 316 1 29

> Threaded End Connections meet

4 Seat •• RPTFE 2 ASME B1.20.1 NPT.

5 Stem ASTM A479 Type 316 1 > Socket Weld End Connections

15 24

6 Body Seal•• PTFE 2 meet ASME B16.11.

23

7 Washer SS304 * 12 14

8 Body Nut SS304 * 8

7

5

9 Body Bolt / Stud SS304 ** 2

12 Thrust Washer •• PTFE 1 6

4

14 Stem Packing•• PTFE 1

15 Gland Nut SS304 1

19 Handle Washer SS304 1 1 1/4" – 2" Valve

23 Stop Set Sleeve SS304 1 Style Shown

3

24 Stop Bolt SS304 1

4

25 Handle SS304*** 1

26 Handle Nut SS304 2 6

28 Handle Sleeve Vinyl 1

29 Locking Device SS304 1 2

9 PRESSURE/TEMPERATURE - RPTFE Seat Material

* Number of Nuts & Lock Washers Body and End Cap Materials

1/4"– 2" Valves 4 Body CF8M

Pressure (psi)

2-1/2"– 3" Valves 8 5000∆ Threaded End CF8M

4" Valves 12 Weld End CF3M

** Number of Body Bolts or Studs 6000∆ Body & Ends A216-WCB

1/4"– 2" 4 (Bolts)

2-1/2"– 3" 4 (Studs)

4" Valves 6 (Studs)

*** Handles on 3" - 4" are Carbon Steel

•• Parts included in the repair kits Temperature (°F)

Note: Carbon Steel valves limited to -20°F.

Dimensions (inch)

Size ØB Torque* Weight D

A C C1 D ØE F M ØP U Cv Ød

in Port lbs-in lb

1/4 2.4 0.46 2.6 1.5 4.7 0.57 0.5 0.20 0.31 M5 8 FO3 - 1.42 60 1.0

3/8 2.4 0.49 2.6 1.5 4.7 0.70 0.5 0.20 0.31 M5 8 FO3 - 1.42 60 1.0

1/2 3.0 0.59 2.9 1.8 4.7 0.87 0.5 0.20 0.37 M5 32 FO3 - 1.42 70 1.4

3/4 3.0 0.79 3.0 1.9 5.7 1.10 0.6 0.26 0.37 M5 54 FO3 - 1.42 95 1.75 C

1 3.4 0.98 3.3 2.3 6.1 1.34 0.6 0.31 0.45 M5 105 FO4 - 1.65 140 2.45 C1

1-1/4 4.1 1.26 3.5 2.5 6.1 1.69 0.7 0.31 0.45 M5 200 FO4 - 1.65 195 4.0

1-1/2 4.7 1.50 4.1 3.0 6.7 1.93 0.7 0.33 0.63 M6 275 FO5 - 1.97 315 5.6

2 5.1 1.97 4.3 3.3 6.7 2.42 0.8 0.33 0.63 M6 500 FO5 - 1.97 510 8.7

2-1/2 6.5 2.56 5.2 4.5 9.1 3.03 0.9 0.47 0.79 M8 780 FO7 - 2.76 730 17.7

øB

3 7.2 2.99 5.5 4.8 9.1 3.54 1.0 0.47 0.79 M8 1150 FO7 - 2.76 990 25.0

4 9.1 3.82 6.9 6.5 10.8 4.54 1.2 0.63 0.98 M10 1700 F10 - 4.02 3100 52.0 A

Socket

Dimensions (mm)

Weld End Ux4

Size ØB Torque* Weight

A C C1 D ØE F M ØP U Cv Ød

mm Port Nm Kg

8 60 11.6 67 37.7 120 14.4 12 5 7.9 M5 8 36 7 0.45

10 60 12.5 67 37.7 120 17.8 12 5 7.9 M5 8 36 7 0.43 øE øP M

15 75 15 73 44.7 120 22 12 5 9.4 M5 32 36 8 0.6

20 77 20 76 48 145 27.4 14 6.5 9.4 M5 54 36 11 0.74

ød

25 85 25 84 58.5 155 34.1 15 8 11.4 M5 105 42 16 1.04 F

32 104 32 89 63.1 155 42.9 17 8 11.4 M5 200 42 22 1.72

40 120 38 103 76.6 170 49 17 8.5 16 M6 275 50 36 2.46 Verify mounting dimensions before

50 130 50 109 83.5 170 61.5 20 8.5 16 M6 500 50 58 3.8 manufacturing mounting hardware.

65 165 65 132 114.2 230 77 23.8 12 20 M8 780 70 82 8.2

80 182 76 140 122 230 90 25 12 20 M8 1150 70 112 11

Automated valves may require

100 230 97 176 164.3 275 115.4 30 16 25 M10 1700 102 350 23.5

periodic gland nut adjustments.

*Torque based on RPTFE seats in clean water at full rated pressure.

HEADQUARTERS All statements, technical information, and recommendations in this bulletin are for general

use only. Consult Flow‑Tek representatives or factory for the specific requirements and

BRAY INTERNATIONAL, INC. material selection for your intended application. The right to change or modify product

design or product without prior notice is reserved.

13333 Westland East Blvd.

Flow-Tek® is a registered trademark of Bray International, Inc.

Houston, Texas 77041

© 2022 Bray International, Inc All rights reserved.

Tel: 281.894.5454 EN_F-2302_S5000-6000_20220808

You might also like

- Cpe Crane Fkx9000asme TD Es A4 2018-03-01 WebDocument2 pagesCpe Crane Fkx9000asme TD Es A4 2018-03-01 WebJhorman RamosNo ratings yet

- S5000 S6000 Ficha TecnicaDocument2 pagesS5000 S6000 Ficha TecnicaJackNo ratings yet

- 5592F - Válvula de Bola (Roscada)Document1 page5592F - Válvula de Bola (Roscada)Rafael SalazarNo ratings yet

- TBV Series 21 80 Cryogenic Large Bore Split Body Ball ValveDocument2 pagesTBV Series 21 80 Cryogenic Large Bore Split Body Ball ValveRizal NasutionNo ratings yet

- Forged High Pressure Ball Valves: SBVF360 SeriesDocument4 pagesForged High Pressure Ball Valves: SBVF360 SeriesToty DzNo ratings yet

- Wheatley Series 822 Check Valves FlyerDocument2 pagesWheatley Series 822 Check Valves FlyerLorena DávilaNo ratings yet

- Carbon Steel Ball Valve: Design FeaturesDocument1 pageCarbon Steel Ball Valve: Design FeaturesChanchal K SankaranNo ratings yet

- F1511 Data SheetDocument2 pagesF1511 Data SheetJV Balisi100% (1)

- Forged High Pressure Ball Valves GuideDocument4 pagesForged High Pressure Ball Valves GuideFabio GiehlNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- 280B Válvulas RWVDocument1 page280B Válvulas RWVПабло Рамирес РамиресNo ratings yet

- Mud ValvesDocument4 pagesMud ValvesFabio Peres de LimaNo ratings yet

- Optional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Document2 pagesOptional Fire Safe, API 607 4th Edition Certified: 1 Piece Reduced Port Ball Valves: / "-2"Oscar Horta PolaniaNo ratings yet

- DelVal Series 64 3-PC Industrial Ball ValvesDocument2 pagesDelVal Series 64 3-PC Industrial Ball ValvesProcess Controls & ServicesNo ratings yet

- Flanged Ball ValveDocument20 pagesFlanged Ball ValveToty DzNo ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- High Pressure Bar Stock Needle Valves: SHBNV SeriesDocument2 pagesHigh Pressure Bar Stock Needle Valves: SHBNV SeriesToty DzNo ratings yet

- 208B Válvulas RWVDocument1 page208B Válvulas RWVПабло Рамирес РамиресNo ratings yet

- Pneumatic Stainless Steel Flange Ball Valve SpecsDocument1 pagePneumatic Stainless Steel Flange Ball Valve SpecsAutoma Viet NamNo ratings yet

- Grooved Resilient OS&Y Gate Valve (XZ81X), UL/FM Approved Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM ApprovedDocument1 pageGrooved Resilient OS&Y Gate Valve (XZ81X), UL/FM Approved Flanged Resilient OS&Y Gate Valve (XZ41X), UL/FM Approvedtaaj77No ratings yet

- Catalog 79027ENG HOKE 7C Series Valve English 101414Document12 pagesCatalog 79027ENG HOKE 7C Series Valve English 101414kaniappan sakthivelNo ratings yet

- 5" Storz Connectionfor Pumper: Page 62 of 148Document5 pages5" Storz Connectionfor Pumper: Page 62 of 148AmirNo ratings yet

- REL OSY 399F - FM UL OS&Y Multi LingualDocument2 pagesREL OSY 399F - FM UL OS&Y Multi LingualAhmed Salah Abd EL-WahedNo ratings yet

- V81 SERIES BALL VALVE SPECSDocument2 pagesV81 SERIES BALL VALVE SPECSTran Duc DungNo ratings yet

- Safety and Relief ProductsDocument4 pagesSafety and Relief ProductsSamuel OlmosNo ratings yet

- Data Sheets Series 155 FloatingDocument4 pagesData Sheets Series 155 Floatingbayarjargal SuwdusNo ratings yet

- PASCAL Check Valves CatalogueDocument19 pagesPASCAL Check Valves Cataloguecrys100% (1)

- S80 - Sales Borchure EnglishDocument2 pagesS80 - Sales Borchure Englishevilnemesis133No ratings yet

- Relief ValveDocument2 pagesRelief ValveRobertoNo ratings yet

- 2 Piece Threaded Standard Port Ball Valves: / "-3": Series S70 & Series S90Document2 pages2 Piece Threaded Standard Port Ball Valves: / "-3": Series S70 & Series S90andres12636No ratings yet

- Wafer Butterfly Valve With Tamper Switch (Xd371X), Ul/Fm/Vds Approved Lugged Wafer Butterfly Valve With Tamper Switch (Xd371Xl), Ul/Fm/Vds ApprovedDocument1 pageWafer Butterfly Valve With Tamper Switch (Xd371X), Ul/Fm/Vds Approved Lugged Wafer Butterfly Valve With Tamper Switch (Xd371Xl), Ul/Fm/Vds Approvedtaaj77No ratings yet

- 5 Catalogue Winway DBB Valve-MinDocument19 pages5 Catalogue Winway DBB Valve-MinAsyadullah Al-FatihNo ratings yet

- V3-GAN-A125 Gate Valve SpecificationDocument1 pageV3-GAN-A125 Gate Valve SpecificationArthur DeiparineNo ratings yet

- 603 Swing Check Valve Class 600Document1 page603 Swing Check Valve Class 600Cricri CriNo ratings yet

- TFP1546 03 2021Document16 pagesTFP1546 03 2021MaintenanceNo ratings yet

- InsulatedUnionMeterDocument1 pageInsulatedUnionMetervidaltigres88No ratings yet

- Bellows Sealed DN20Document3 pagesBellows Sealed DN20Turbo Snail RNo ratings yet

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarNo ratings yet

- Valvula Compuerta OS&Y Poste Indicador Class150Document16 pagesValvula Compuerta OS&Y Poste Indicador Class150Roobens SC LaraNo ratings yet

- Catalogue Triple Offset Butterfly Valve 1Document1 pageCatalogue Triple Offset Butterfly Valve 1Sandy ZhangNo ratings yet

- Hidrante Humedo Fivalco FV-WBH-2H1PDocument1 pageHidrante Humedo Fivalco FV-WBH-2H1PCesar RomeroNo ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- S23-Ss-Ygg-L-015 Flo TiteDocument2 pagesS23-Ss-Ygg-L-015 Flo TiteMichNo ratings yet

- Válvulas de Alívio NaucoDocument12 pagesVálvulas de Alívio NaucoBruno CoutoNo ratings yet

- Van bi inox tay gạt lắp bichDocument1 pageVan bi inox tay gạt lắp bichAutoma Viet NamNo ratings yet

- K-020 Kinetic For SewageDocument2 pagesK-020 Kinetic For SewageironeousNo ratings yet

- FICHA TECNICA 366 VALVULA DE SEGURIDAD - RemovedDocument3 pagesFICHA TECNICA 366 VALVULA DE SEGURIDAD - RemovedEdgar Manuel Morales MitmaNo ratings yet

- Argus FK 76M Ball Valve Material ListDocument2 pagesArgus FK 76M Ball Valve Material ListFelipe Gamboa Gálvez100% (1)

- Kamvalok Dry Disconnect Couplings Installation Instructions EnglishDocument10 pagesKamvalok Dry Disconnect Couplings Installation Instructions EnglishAyman64No ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- Pig Valve: Meridian Double Block and BleedDocument8 pagesPig Valve: Meridian Double Block and BleedCesar GouroNo ratings yet

- Steam & Condensate Manifold: M4/SM/CMDocument2 pagesSteam & Condensate Manifold: M4/SM/CMBillal Al-ankarNo ratings yet

- Plug Valves PLV Series Rev 00Document6 pagesPlug Valves PLV Series Rev 00lis sugiantoroNo ratings yet

- NRS Flanged Ends 3288 300 FLFDocument1 pageNRS Flanged Ends 3288 300 FLFgoviaNo ratings yet

- Pipeline Repair Project FEED 2Document18 pagesPipeline Repair Project FEED 2Nurcahyo Djati W100% (4)

- technical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_bspDocument5 pagestechnical_datasheet_forged_carbon_steel_a105n_gate_valve_trim8_class800_bspBenny 37No ratings yet

- R 2361 6Document2 pagesR 2361 6Angelo100% (1)

- Kunkle Relief ValveDocument4 pagesKunkle Relief ValveJonathanHarker DPZNo ratings yet

- Flow Meter FciDocument1 pageFlow Meter Fciko2aahsNo ratings yet

- Alpha-I Data Sheet: 0.50 0.50 40 0.84 0.109 - NoneDocument1 pageAlpha-I Data Sheet: 0.50 0.50 40 0.84 0.109 - Noneko2aahsNo ratings yet

- FCI - ST80-SeriesDocument12 pagesFCI - ST80-Seriesabdulkidwai2009No ratings yet

- Apco Cdd-9000T Double Door Check Valve: BulletinDocument9 pagesApco Cdd-9000T Double Door Check Valve: Bulletinko2aahsNo ratings yet

- ABB Flowmeter Selection for Air FlowDocument4 pagesABB Flowmeter Selection for Air Flowko2aahsNo ratings yet

- 1490 5 Digit 1/8 DIN Panel IndicatorDocument3 pages1490 5 Digit 1/8 DIN Panel Indicatorko2aahsNo ratings yet

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinNo ratings yet

- Slqs Journal Slqs Journal Slqs JournalDocument7 pagesSlqs Journal Slqs Journal Slqs Journalfhsn84No ratings yet

- Glass Fiber-Reinforced Polymer Composite - A Review - OriginalDocument20 pagesGlass Fiber-Reinforced Polymer Composite - A Review - OriginalAvinash Singh100% (1)

- Beam To Column Connection1Document5 pagesBeam To Column Connection1Sudhakar Krishnamurthy50% (2)

- Soak-Away Pit DesignDocument1 pageSoak-Away Pit DesignAbdul Hayyi bin AwangNo ratings yet

- ASCE7 & API Load Combinations PDFDocument2 pagesASCE7 & API Load Combinations PDFTharach JanesuapasaereeNo ratings yet

- Prabodh Dahal, PH.DDocument6 pagesPrabodh Dahal, PH.DNischal KafleNo ratings yet

- Peek Compression MoldingDocument3 pagesPeek Compression MoldingSh.nasirpurNo ratings yet

- Construction Method of Steel BridgeDocument95 pagesConstruction Method of Steel BridgeAce Joker100% (2)

- ACO Aeropur Plus 3 - 100Document8 pagesACO Aeropur Plus 3 - 100duga11No ratings yet

- 2006 Investigation of Pipe Installation Using HDD 214Document8 pages2006 Investigation of Pipe Installation Using HDD 214samer ayashNo ratings yet

- Non-Segregated Phase Bus Duct - TranspositionDocument1 pageNon-Segregated Phase Bus Duct - TranspositionRuben GutierrezNo ratings yet

- EXHAUST System - LEBW4970-06 PDFDocument42 pagesEXHAUST System - LEBW4970-06 PDFdimaomarNo ratings yet

- Tremie Concrete Mixes and Placement TechniquesDocument8 pagesTremie Concrete Mixes and Placement TechniquesYash SharmaNo ratings yet

- Porous Asphalt Pavements PDFDocument52 pagesPorous Asphalt Pavements PDFjegancivil75% (4)

- Qutb Minar of IndiaDocument28 pagesQutb Minar of IndiaNivedhithaVenkatakrishnanNo ratings yet

- Composite Steel and Concrete Structural Systems For Seismic Engineering and Axial LoadingDocument21 pagesComposite Steel and Concrete Structural Systems For Seismic Engineering and Axial Loadingpooria_j92No ratings yet

- 497TC TBL315VDocument48 pages497TC TBL315VKamaldeep SinghNo ratings yet

- Book Reviews From TensiNewsDocument26 pagesBook Reviews From TensiNewsm,narNo ratings yet

- Bosch Spark Plug & IgnitionDocument15 pagesBosch Spark Plug & IgnitioncarlosNo ratings yet

- Mechanical Testing of Composites and Their - CompressDocument73 pagesMechanical Testing of Composites and Their - Compressajay pandeyNo ratings yet

- Estimation and Costing MCQ PDF (Erexams - Com)Document21 pagesEstimation and Costing MCQ PDF (Erexams - Com)krishna chaithanyaNo ratings yet

- Rigid Pavement Design: 29.1.1 Modulus of Sub-Grade ReactionDocument9 pagesRigid Pavement Design: 29.1.1 Modulus of Sub-Grade Reactionnageshkumarcs100% (1)

- Handbook For CLT Buildings en PDFDocument178 pagesHandbook For CLT Buildings en PDFTanase MariusNo ratings yet

- CHYHBH-AV32 - 4PEN471761-1C - 2019 - 09 - Installer Reference Guide - EnglishDocument108 pagesCHYHBH-AV32 - 4PEN471761-1C - 2019 - 09 - Installer Reference Guide - EnglishChris BrauchliNo ratings yet

- tm3 34x46 PDFDocument268 pagestm3 34x46 PDFford62bNo ratings yet

- Allen, D.E. - Building Vibrations From Human ActivitiesDocument12 pagesAllen, D.E. - Building Vibrations From Human ActivitiesHugo VerissimoNo ratings yet

- Bit Mesra Architecture SyllabusDocument101 pagesBit Mesra Architecture SyllabusSrishti ShamelNo ratings yet

- Gyplyner Encase Oct 2022Document15 pagesGyplyner Encase Oct 2022Olivia SaferNo ratings yet

- Completion Des4Document30 pagesCompletion Des4Ian GamitNo ratings yet

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Climate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysFrom EverandClimate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)