Professional Documents

Culture Documents

Calcul Planseu Compus

Uploaded by

danibl30Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calcul Planseu Compus

Uploaded by

danibl30Copyright:

Available Formats

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

Example: Composite floor slab

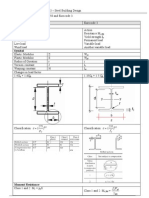

This example shows the design of a composite floor slab for both construction stage and composite stage. The composite slab is checked at both ultimate limit state and serviceability limit state. In many markets there are benefits in avoiding propped construction but in this example props are used for pedagogical reasons. The slab considered is propped, as shown below

[mm]

P

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

P 1800 1800 1800 1800

P 1800

1800

P are temporary props during casting of the concrete Sheeting data: The characteristic values for the chosen sheeting are as follows: Yield strength Thickness Effective steel area Second moment of area of steel core Plastic bending resistance Sagging bending resistance Hogging bending resistance Resistance to support reaction Resistance to horizontal shear fyp,k = 320 N/mm ts = 0,778 mm Ap = 955 mm2/m Ip = 33,0 104 mm4/m Mpa,Rk = 5,29 kNm/m

+ M a,Rk = 3,41 kNm/m M a,Rk = 2,86 kNm/m

2

From trade literature

Rw,k = 34,0 kN/m

u,Rk = 0,306 N/mm2

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

Slab data: Slab depth Slab mean depth Slab depth above sheeting Effective depth Concrete C25/30 ht = 120 mm hred = 103,5 mm hc = 75 mm dp = 101 mm fck = 25 N/mm2 Ecm = 31000 N/mm2 Sheeting geometry and slab:

[mm]

dp

ht

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

19

10 45

30 50o 60 150 900

27

Partial safety factors: Loads: The slab is designed for both the construction stage and the composite stage. In the construction stage, the steel sheeting acts as shuttering and has to carry its own weight, the wet concrete and the construction loads. In the composite stage the slab has to carry its own weight, floor finishes and the live load. The following loads are considered in this example: G = 1,35 Q = 1,5 M0 = 1,0 M1 = 1,0 C = 1,5 VS = 1,25 (permanent loads) (variable loads) EN 1993-1-1 EN 1993-1-1 EN 1992-1-1 EN 1994-1-1 EN 1990

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

Construction stage: Self weight of the sheeting Self weight of the wet concrete Distributed construction load Concentrated construction load Composite stage: Self weight of the slab Floor finishes Live load (hotel) g1 = 2,5 + 0,09 = 2,6 kN/m2 g2 = 1,2 kN/m2 q = 5,0 kN/m2 gp = 0,09 kN/m2 gc = 2,6 kN/m2 q1 = 0,75 kN/m2 q2 = 1,5 kN/m2

Verification of the sheeting as shuttering

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

The sheeting resistance needs to be verified in the construction stage in both ultimate and serviceability limit state according to EN 1993-1-3. Ultimate limit state: Maximum sagging bending moment:

+ + + M Ed = G M g + Q M q

+ + + M g = M gp + M gc = 0, 078 0, 09 1, 82 + 0, 094 2, 6 1, 82 = 0,81 kNm/m

+ M q = 0, 094 1, 5 1, 82 = 0,46 kNm/m

+ M Ed = 1, 35 0, 81 + 1, 5 0, 46 = 1,78 kNm/m

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

Maximum hogging bending moment:

q2 q1 gc gp

3000

M Ed = G M g + Q M q = 1, 35 1, 01 + 1, 5 0, 55 = 2,18 kNm/m

FEd = G FG + Q Fq = 1,35 5,75 + 1,5 3,15 = 12,5 kN/m

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

M g , M q , Fg and Fq are calculated by computer.

Design check: Positive bending

+ M Rd = + M Rk

M0

3,41 + = 3,41 kNm/m > M Ed =1,78 kNm/m OK 1,0

Negative bending M

Rd

M Rk

M0

2,86 = 2,86 kNm/m > M Ed = 2,18 kNm/m OK 1,0

Support reaction

RRd =

M1

RRk

34,0 = 34,0 kN/m > FEd= 12,5 kN/m 1,0

OK

Interaction, moment and support reaction

M Ed F + Ed 1,25 M Rd Rw,Rd

EN 1993-1-3 6.1.11 (6.28) OK

2,18 12, 5 + = 1,13 < 1, 25 2, 86 34, 0 All design checks are OK at the ultimate limit state.

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

Serviceability limit state: The deflection, s, due to the wet concrete and the self weight of the sheeting should not, unless otherwise noted in the National Annex, exceed s,max = L/180. EN 1994-1-1 9.6 (2)

s =

( 2, 65 g p + 3, 4 g c ) L4 384 EI p

Check if the sheeting is fully effective, i.e. does Ip need to be recalculated due to local buckling? Maximum positive moment in serviceability limit state:

M sls = 0, 078 0, 09 1, 82 + 0, 094 2, 6 1,82 = 0,81 kNm/m

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Maximum compression stress in top flange:

com =

p = =

M sls 0, 81 106 z = ( 45 19) = 63,8 N/mm2 4 Ip 33, 0 10

fy

cr

235

b/t 28, 4 k 235 = 1,9 63, 8

EN 1993-1-5 4.4

com

with = 1, Table 4.1 gives k = 4

p =

30 / 0, 778 28, 4 1, 9 4, 0

EN 1993-1-5 Table 4.1

= 0,36

= 1, 0

Since the reduction factor, = 1, 0 , no reduction of the top flange is necessary, i.e. Ip is fully effective.

s =

( 2, 65 0, 09 + 3, 4 2, 6) 18004 = 3,6 mm 384 210000 33, 0 104

L 1800 =10 mm > 3,6 mm = s = 180 180

s,max =

OK EN 1994-1-1 9.3.2 (2)

The deflection, s, is less than 1/10 of the slab depth, therefore no ponding effects need to be taken into account. Hence, the serviceability limit state is also OK. The sheeting can work as shuttering in the construction stage.

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

Verification of the composite slab:

Ultimate limit state: The continuous slab will be designed as a series of simply supported spans. EN 1994-1-1 9.4.2 (5)

q g1+g2

M Ed =

M Ed

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

[ G ( g1 + g 2 ) + Q q] L2 8

[1, 35 ( 2, 6 + 1, 2) + 1, 5 5, 0] 3, 62 = 20,5 kNm/m = 8

Design bending resistance: The sagging bending moment resistance should be calculated from the stress distribution in the figure below, if the neutral axis is above the sheeting.

0,85 fcd xpl dp + fyp,d

centroidal axis of the profiled steel sheeting

Nc,f z Np Mpl,Rd

EN 1994-1-1 Figure 9.5

xpl =

Ap f yp,d 0, 85 b f cd f yp,k

f yp,d =

M0

f ck

320 = 320 N/mm2 1, 0

f cd =

25 = 16,7 N/mm2 1, 5

pl =

955 320 = 21,6 mm 0,85 1000 16,7

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

For full shear connection:

M pl,Rd = Ap f yd d p xpl / 2

M pl,Rd = 955 320 (101 21, 6 / 2 ) 103 = 27,5 kNm/m > 20,5 = MEd Longitudinal shear by partial connection method: Shear span required for full shear connection

N c = u,Rd b Lx N cf

EN 1994-1-1 9.7.3 (8)

The distance to the nearest support, Lx, required for full shear connection can be determined by

Lx =

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Ap f yd N cf = b u,Rd b u,Rd

u,Rd =

Lx =

u,Rk 0, 306 = = 0,245 N/mm2 Vs 1, 25

955 320 = 1247 mm 1000 0,245

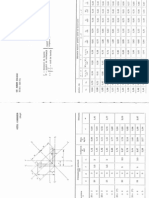

Hence, at a distance of 1247 mm from the support a full shear connection is fulfilled. Design check using the simplified partial interaction diagram: For any cross section along the span it has to be shown that the corresponding design bending moment, MEd, does not exceed the design bending resistance, MRd. In the figure x is the distance from the support.

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

MRd, MEd [kNm/m]

30

Mpl,Rd MRd

20

10

M Ed =

[ G ( g1 + g 2 ) + Q q ] x 2

( L x)

Mpa

0

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

x [m]

0 0.4 0.8 1.2

Lx

1.6

M Ed M Rd for all cross sections Vertical shear: VEd =

VEd =

[ G ( g1 + g 2 ) + Q q ] L 2

[1, 35 ( 2, 6 + 1, 2) + 1, 5 5, 0] 3, 6 = 22,7 kN/m 2

Design vertical shear resistance: Vv,Rd = CRd,c k (100 I f ck )1 / 3 + k1 cp bw d p with a minimum of

Vv,Rd,min = ( vmin + k1 cp ) bw d p

EN 1992-1-1 6.2.2

CRd,c = k = 1+

0,18

0,18 = 0,12 1, 5

See Note in EN 1992-1-1 6.2.2

200 200 = 1+ = 2, 4 dp 101

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

l =

Asl 0,02 bw d p

Asl is the area of the tension reinforcement in [mm], i.e Asl = Ap bw = 400 mm/m, i.e. the smallest width in [mm] of the section in the tension area.

l =

955 = 0,024 > 0,02 400 101

l = 0,02

cp =

N Ed = 0 , since NEd = 0, i.e. no axial forces or prestress. Ac

k1 = 0,15 Vv,Rd = 0,12 2, 4 (100 0, 02 25)1 / 3 + 0,15 0 400 101

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

See Note in EN 1992-1-1 6.2.2

Vv,Rd = 42,8 kN/m Minimum value

1/2 vmin = 0, 035 k 3 / 2 f ck = 0, 035 2, 43 / 2 251 / 2 = 0,65

Vv,Rd,min = ( 0, 65 + 0,15 0) 400 101 = 26,3 kN/m

Vv,Rd = 42,8 kN/m > 22,7 kNm/m = VEd

OK

All design checks of the composite slab in the ultimate limit state are OK. Serviceability limit state: Cracking of concrete: As the slab is designed as simply supported, only anti-crack reinforcement is EN 1994-1-1 needed. The cross-sectional area of the reinforcement above the ribs should be 9.8.1 (2) not less than 0,4% of the cross-sectional area of the concrete above the ribs. min As = 0, 004 b hc = 0, 004 1000 75 = 300 mm2/m 8 s160 mm will be enough for this purpose.

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

10

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

Deflection: For the calculations of the deflections of the slab, the slab is considered to be continuous. The following approximations apply: the second moment of area may be taken as the average of the values for the cracked and un-cracked section; for concrete, an average value of the modular ratio, n, for both longand short-term effects may be used.

n= Ep E

' cm

EN1994-1-1 9.8.2 (5)

Ep E 1 Ecm + cm 2 3

210000 10 2 31000 3

Second moment of area for the cracked section

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

I bc =

3 b xc + Ap ( d p xc )2 + I p 3 n

xc =

Ai zi Ai

n Ap 2 b dp 1+ 1 b n Ap

xc =

10 955 2 1000 101 1+ 1 = 35,4 mm 1000 10 955

I bc =

1000 35, 43 + 955 (101 35, 4)2 + 33, 0 104 = 5, 92 106 mm4/m 3 10

Second moment of area for the un-cracked section

I bu b hc3 b hc = + 12 n n

2 3 hp hc b0 hp b0 hp xu + + ht xu + 2 12 n n 2 2

Ap ( d p xu )2 + I p

b xu =

h hc2 + b0 hp ht p + n Ap d p 2 2 b hc + b0 hp + n Ap

Example: Composite floor slab

CALCULATION SHEET

Document Ref: Title

SX009a-EN-EU

Sheet

11

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by Checked by

March 2005 April 2005

1000 xu =

752 45 + 650 45 120 + 10 955 101 2 2 = 58,3 mm 1000 75 + 650 45 + 10 955

2

I bu

1000 753 1000 75 75 610 453 + = + 58, 3 + 12 10 10 2 12 10 610 45 45 120 58, 3 + 955 (101 58, 3)2 + 10 2 33, 0 104 = 13, 5 106 mm 4 /m

2

Average Ib of the cracked and un-cracked section

Ib =

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

I bc + I bu 5, 92 + 13, 5 = 106 = 9, 7 106 mm 4 /m 2 2

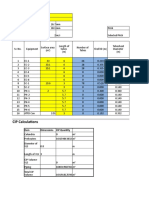

Deflections The total deflection under the worst load case should not exceed L/250. Weight of floor finishes: 0, 0068 g 2 L4 0, 0068 1, 2 36004 = = = 0,67 mm E Ib 210000 9, 7 106 EN1992-1-1 7.4.1(4)

c,g

Live load, worst case:

c,q =

0, 0099 1 q L4 0, 0099 0, 7 5, 0 36004 = = 2,86 mm E Ib 210000 9, 7 106

Removal of the props:

G 1' G 1' G 1'

G1 = g1

L 3, 6 = 4,68 kN/m = 2, 6 2 2

c,G =

1

0, 01146 G1 L3 0, 01146 4680 36003 = = 1,23 mm E Ib 210000 9, 7 106

x g

CALCULATION SHEET

i

Document Ref: Title

SX009a-EN-EU

Sheet

12

of

12

Example: Composite floor slab EN 1994-1-1, EN 1993-1-3, EN 1992-1-1 & EN 1993-1-1 Jonas Gozzi Bernt Johansson

Date Date

Eurocode Ref Made by

March 2005 April 2005

Checked by

Total deflection:

p

c = c,G + c,g + c,q = 1, 23 + 0, 67 + 2, 86 = 4,76 mm

1 2

y o

c = 4,76 mm <

L 3600 = = 14,4 mm 250 250

OK

s r h C T r h e i a s t e m d a t o e n r i T a l u i s

Example: Composite floor slab

Example: Composite floor slab SX009a-EN-EU

Quality Record

RESOURCE TITLE Reference(s) ORIGINAL DOCUMENT Name Created by Technical content checked by Editorial content checked by Technical content endorsed by the following STEEL Partners: 1. UK 2. France 3. Sweden

Created on Thursday, June 16, 2011 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Access Steel Licence Agreement

Example: Composite floor slab

Company SBI SBI

Date 10/03/2005 08/04/2005

Jonas Gozzi Bernt Johansson

G W Owens A Bureau A Olsson C Muller J Chica G W Owens

SCI CTICM SBI RWTH Labein SCI

7/7/05 17/8/05 8/8/05 10/8/05 12/8/05 06/7/06

4. Germany 5. Spain Resource approved by Technical Coordinator TRANSLATED DOCUMENT This Translation made and checked by: Translated resource approved by:

You might also like

- Composite SlabDocument13 pagesComposite Slabkosithuag50% (2)

- Minimum Edge Distances As Identified in BS 5950Document1 pageMinimum Edge Distances As Identified in BS 5950Jagdish DhanuskarNo ratings yet

- Composite Beam IDocument30 pagesComposite Beam IWr Ar100% (1)

- Eurocode 4 Seminar Composite Structures Composite Slabs With Profiled Steel SheetingDocument23 pagesEurocode 4 Seminar Composite Structures Composite Slabs With Profiled Steel Sheetingjplezp100% (1)

- Design of Steel-Concrete Composite Structures Using High-Strength MaterialsFrom EverandDesign of Steel-Concrete Composite Structures Using High-Strength MaterialsNo ratings yet

- Access Steel - SX023a - Effective Section Properties of Steel Lipped Channel in CompressionDocument10 pagesAccess Steel - SX023a - Effective Section Properties of Steel Lipped Channel in Compressiongianniorlati1972No ratings yet

- Example of Structural CalculationDocument18 pagesExample of Structural Calculationdeua2004No ratings yet

- Composite Beam Design ExampleDocument7 pagesComposite Beam Design Exampledgreally1gmailcom100% (1)

- Example Calculation of Alpha-Cr PDFDocument9 pagesExample Calculation of Alpha-Cr PDFHerdean RemusNo ratings yet

- Composite Slab ReportDocument10 pagesComposite Slab ReportAhmed Moustafa AboelelaNo ratings yet

- Design of composite slabDocument7 pagesDesign of composite slabjonathanbido100% (4)

- Readme v4B PDFDocument4 pagesReadme v4B PDFlucianduNo ratings yet

- Wind Loads UK Portal Frame WEDocument31 pagesWind Loads UK Portal Frame WEmandregomes100% (1)

- Steel-Concrete Composite Slab Design Using ExcelDocument9 pagesSteel-Concrete Composite Slab Design Using ExcelTasnuva NazmulNo ratings yet

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Document14 pagesSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNo ratings yet

- Design Data for Composite Steel-Concrete BeamsDocument33 pagesDesign Data for Composite Steel-Concrete BeamsManikanta Sharma100% (1)

- Plastic Design Portal Frame To Ec3Document53 pagesPlastic Design Portal Frame To Ec3Max Yap100% (1)

- Portal Frame Stablity CheckDocument2 pagesPortal Frame Stablity CheckAlma M. LaraNo ratings yet

- Composite Beams and Slabs1Document9 pagesComposite Beams and Slabs1rameshbabu_1979100% (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Manual For The Design of Reinforced Concrete Building Structure To BS 8110Document89 pagesManual For The Design of Reinforced Concrete Building Structure To BS 8110Issa AzeerNo ratings yet

- Retaining Wall Counterfort PDFDocument48 pagesRetaining Wall Counterfort PDFSilver Olguín CamachoNo ratings yet

- Elastic Analysis of A Single Bay Portal FrameDocument31 pagesElastic Analysis of A Single Bay Portal Framelanmark100% (1)

- Evo Design - Structural Design: Calculation SheetDocument7 pagesEvo Design - Structural Design: Calculation SheetAnand.5No ratings yet

- Cold-formed Tubular Members and Connections: Structural Behaviour and DesignFrom EverandCold-formed Tubular Members and Connections: Structural Behaviour and DesignRating: 5 out of 5 stars5/5 (2)

- Axially Loaded Columns - Base Plate DesignDocument2 pagesAxially Loaded Columns - Base Plate DesignaomareltayebNo ratings yet

- Access Steel Data Sheets BindedDocument154 pagesAccess Steel Data Sheets BindedblueswanNo ratings yet

- Standard Lighting Column FoundationsDocument2 pagesStandard Lighting Column FoundationsEm MarNo ratings yet

- Proracun - Example Cold Formed SteelDocument10 pagesProracun - Example Cold Formed SteelpedjaNo ratings yet

- Conc. Folded SlabDocument17 pagesConc. Folded SlabBenedict CharlesNo ratings yet

- Composite Column DesignDocument3 pagesComposite Column DesignEngDbt50% (2)

- Aluminium DesignDocument9 pagesAluminium Designikanyu79No ratings yet

- BS and ECDocument9 pagesBS and ECNGUYENNo ratings yet

- Beam-Column Connection To BS5950Document6 pagesBeam-Column Connection To BS5950Mitra RampersadNo ratings yet

- B17 RC Detailing To EC2Document69 pagesB17 RC Detailing To EC2Mahmoud Moustafa Elnegihi100% (1)

- Sepakat Setia Perunding SDN BHD: Design Information DimensionsDocument30 pagesSepakat Setia Perunding SDN BHD: Design Information Dimensionsعصام السامرائيNo ratings yet

- Composite Steel DesignDocument33 pagesComposite Steel DesignscegtsNo ratings yet

- Column Design EC2Document41 pagesColumn Design EC2Azrai AzizNo ratings yet

- Design of Timber Roof Truss To British Code - Solved Example - StructvilleDocument9 pagesDesign of Timber Roof Truss To British Code - Solved Example - StructvilleDeRudy100% (3)

- Design Procedure For Steel Frame Structures According To Bs 5950Document46 pagesDesign Procedure For Steel Frame Structures According To Bs 5950Ali Gaffar100% (2)

- Worked Example 1 - Composite Beam - Normal DesignDocument26 pagesWorked Example 1 - Composite Beam - Normal DesignTudor Tudor100% (1)

- Prokon - Base Plate Design To EurocodeDocument7 pagesProkon - Base Plate Design To EurocodeArnold TunduliNo ratings yet

- CP 114 - Concrete CoverDocument2 pagesCP 114 - Concrete CoverJibeesh CMNo ratings yet

- Composite Beam ExampleDocument4 pagesComposite Beam Examplexxazninvasionxx2697100% (1)

- Composite Beams & Columns To Eurocode 4Document155 pagesComposite Beams & Columns To Eurocode 4dfdfdfasd324sad100% (2)

- Osb PDFDocument25 pagesOsb PDFAndres Byke SepulvedaNo ratings yet

- Flow Chart: Floor Slab DesignDocument8 pagesFlow Chart: Floor Slab Designtecon ploiestiNo ratings yet

- Low pitch roof truss designDocument24 pagesLow pitch roof truss designWilliam CaballeroNo ratings yet

- Types and Costs of Materials in The Civil Engineering IndustryDocument10 pagesTypes and Costs of Materials in The Civil Engineering IndustryKarl Andre CabañeroNo ratings yet

- Steelin Light Gauged Steel Building Quotation For Foreign BidDocument4 pagesSteelin Light Gauged Steel Building Quotation For Foreign BidmoaazNo ratings yet

- PPROJ-1354 CIVIL TRMT-22 REV-0 MAB ResponseDocument1 pagePPROJ-1354 CIVIL TRMT-22 REV-0 MAB ResponseMOHAMEDNo ratings yet

- 4 Panel Layout: Intel Products VietnamDocument1 page4 Panel Layout: Intel Products VietnamDuy BuiNo ratings yet

- Transit Center - Structural Design Calculations1Document26 pagesTransit Center - Structural Design Calculations1yan naingNo ratings yet

- Precast Concrete Sheet Pile DesignDocument4 pagesPrecast Concrete Sheet Pile DesignNaresh GajNo ratings yet

- Steel Truss Design Eurocode PDFDocument24 pagesSteel Truss Design Eurocode PDFCarlos Eduardo RodriguezNo ratings yet

- Assignment 2Document10 pagesAssignment 2Karl Andre CabañeroNo ratings yet

- Series Series: General Purpose Enclosures General Purpose EnclosuresDocument11 pagesSeries Series: General Purpose Enclosures General Purpose Enclosureseser kiyanNo ratings yet

- Pavement Design IntroductionDocument62 pagesPavement Design IntroductionblastmcNo ratings yet

- RV WU1348 Eldoret Mtungi Road - DesignDocument6 pagesRV WU1348 Eldoret Mtungi Road - DesignIKO NETWORKNo ratings yet

- Fire Resistance Ratings - ANSI/UL 263: Design No. U309Document4 pagesFire Resistance Ratings - ANSI/UL 263: Design No. U309DavidNo ratings yet

- Pereti Exteriori - Solutii - Varianta ScurtaDocument180 pagesPereti Exteriori - Solutii - Varianta ScurtaZamfira OctavianNo ratings yet

- Dubina EccsDocument43 pagesDubina EccsZamfira OctavianNo ratings yet

- Earthquake Resistant Steel StructuresDocument128 pagesEarthquake Resistant Steel StructuresQamar Uz Zaman100% (1)

- Systemline Guide 2Document56 pagesSystemline Guide 2Zamfira OctavianNo ratings yet

- Caracteristici Geometrice Profile LaminateDocument7 pagesCaracteristici Geometrice Profile LaminateMoca AlexNo ratings yet

- Systemline Guide 3Document62 pagesSystemline Guide 3Zamfira OctavianNo ratings yet

- Systemline Guide 1Document48 pagesSystemline Guide 1Zamfira OctavianNo ratings yet

- DwaDocument1 pageDwaZamfira OctavianNo ratings yet

- Office BuildingDocument10 pagesOffice BuildingZamfira Octavian100% (1)

- Sustainable DesignDocument61 pagesSustainable DesignZamfira OctavianNo ratings yet

- Advances in Drilling: Drill Bit InnovationsDocument96 pagesAdvances in Drilling: Drill Bit InnovationsshaonaaNo ratings yet

- Chapter 1 Introduction.Document38 pagesChapter 1 Introduction.yaqoobNo ratings yet

- Daftar Ebook Manajemen KonstruksiDocument3 pagesDaftar Ebook Manajemen KonstruksiMohamad Zaenudin Zanno AkilNo ratings yet

- Volvo EC330Cl Excavator SpecsDocument12 pagesVolvo EC330Cl Excavator Specswalk111No ratings yet

- Volume and Temperature Correctors Operating InstructionsDocument49 pagesVolume and Temperature Correctors Operating InstructionsArsalan KhanNo ratings yet

- PC500LC 8RDocument20 pagesPC500LC 8RSabahNo ratings yet

- FX 140Document136 pagesFX 140tystar_21100% (1)

- TASKalfa 1800 2200 DP 480 DU 480 PF 480 SM UKDocument442 pagesTASKalfa 1800 2200 DP 480 DU 480 PF 480 SM UKJoshua WilsonNo ratings yet

- BIM 3D To 7D Implementation - Hani Elsafadi - Pulse - LinkedInDocument4 pagesBIM 3D To 7D Implementation - Hani Elsafadi - Pulse - LinkedInNurul Nabila SahriNo ratings yet

- Toe-S606-12 1h 15Document140 pagesToe-S606-12 1h 15mssurajNo ratings yet

- Mformat Arch PDFDocument11 pagesMformat Arch PDFMary Grace ManiponNo ratings yet

- Xa-Uir 22052 A109s Cumplimiento Ad's Motores Jun-01-2010Document1 pageXa-Uir 22052 A109s Cumplimiento Ad's Motores Jun-01-2010Carlo VillegasNo ratings yet

- Shop Manual Komatsu WA250-1lcDocument648 pagesShop Manual Komatsu WA250-1lcElmer Lagua Malpaso100% (7)

- Kings smp5Document2 pagesKings smp5api-456426550No ratings yet

- DeaeratorDocument4 pagesDeaeratorAnonymous NFoZJKYNo ratings yet

- Agepan EducationDocument100 pagesAgepan EducationsswinforNo ratings yet

- Uplift in FootingDocument7 pagesUplift in Footingjavier861No ratings yet

- (Rock Crusher) : Machine Design 2Document64 pages(Rock Crusher) : Machine Design 2almira genabeNo ratings yet

- Pushover Analysis ExplainedDocument62 pagesPushover Analysis ExplainedRakesh7770100% (2)

- Aircraft Performance I PDFDocument18 pagesAircraft Performance I PDFJJNo ratings yet

- Calculating Overall Equipment EffectivenessDocument2 pagesCalculating Overall Equipment Effectivenessbhavesh_balasNo ratings yet

- OTC 5886 Field Experience and Design Evolution of The Diverless Lay-Away Flowline Subsea TreeDocument6 pagesOTC 5886 Field Experience and Design Evolution of The Diverless Lay-Away Flowline Subsea TreeKevin GarciaNo ratings yet

- Ee3002 IntroDocument17 pagesEe3002 IntroAnonymous JnvCyu85No ratings yet

- Foundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Document1 pageFoundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Godino ChristianNo ratings yet

- VW Golf 3 Power Steering Gear ZFDocument9 pagesVW Golf 3 Power Steering Gear ZFNPNo ratings yet

- Overhead FPIDocument2 pagesOverhead FPIbibhas_samantaNo ratings yet

- Caterpillar 914GDocument28 pagesCaterpillar 914GForomaquinas100% (3)

- Minimum Heights and Size Standards For Rooms Ensures That There Is Good VentilationDocument4 pagesMinimum Heights and Size Standards For Rooms Ensures That There Is Good VentilationJaved ZakhilNo ratings yet

- Mig Mag Spare Parts List 2 0 v1 PDFDocument176 pagesMig Mag Spare Parts List 2 0 v1 PDFZoran TrajkovicNo ratings yet

- Calculations For Heat Exchanger, CIP & ATFD (Master Copy)Document21 pagesCalculations For Heat Exchanger, CIP & ATFD (Master Copy)saurabhzalte100% (1)