Professional Documents

Culture Documents

Composite Slab

Uploaded by

kosithuag50%(2)50% found this document useful (2 votes)

395 views13 pagesCOMPOSITE SLAB DESIGN (STEEL DECK) LONGROVE and ASSOCIATES Civil and Structural Consulting Engineers Project 'j a.tA.I-o Ce. ::bFo ".' Designed by Sheet No. Date Job No.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCOMPOSITE SLAB DESIGN (STEEL DECK) LONGROVE and ASSOCIATES Civil and Structural Consulting Engineers Project 'j a.tA.I-o Ce. ::bFo ".' Designed by Sheet No. Date Job No.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

395 views13 pagesComposite Slab

Uploaded by

kosithuagCOMPOSITE SLAB DESIGN (STEEL DECK) LONGROVE and ASSOCIATES Civil and Structural Consulting Engineers Project 'j a.tA.I-o Ce. ::bFo ".' Designed by Sheet No. Date Job No.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

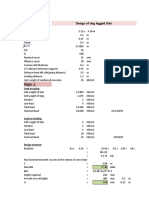

COMPOSITE SLAB DESIGN (STEEL DECK)

LONGROVE & ASSOCIATES

Civil & Structural Consulting Engineers

Date

Job No.

Designed by

Sheet No.

Project

S pe-..... I L -= '2- T '3 0 ....,"-

Co':' c ~. ~.J.-re,.,~h, ."fu ~ 20 ,t-y~_ "'-

DL..

(Lc; ~ 10-'1:> =i » .,.

~~ ~~5e-~T~ ... ~~·\.es

p c-: r- t ~ t-I """"'

-~~~el decl

::. OdS

=' O. '5.

~ 1 o

- ,f... 0 .; k,..> I ..... ~ . E" ~ -:2 J 10 S N /.-..._ .... ,

K.;"; _"l.

Ki>-J/":" -i ~r-1/.J"_

1.<..3'0-.. '>< c; ·%l /I~<JO:;O O~r:l. t<.~/.._ ~,

A ,IT- '.k..., I '"" ~ ,

L.'-- ,?",s. k N I~ '"7'"

To-le-I L~c..-.cl i", '(J. (0":1--,1<- 0..):1 ~ --" , .,

't¢~\F~c!-.,l'"(d foe-.,f"'" (il,4 )L "\.,~)~ C,,(p ,.~.,?)_:<:" I;i.~~ k..,j/_'L

tf" l~_::) L 0 ,_.' - "It...;- c.~' c;.4e.e- ( d eo kQ_ 1 Co ..... ...;.... .f L-k. q.,_ 6

~ 1 t"OV o~f-~r<;..

0.1,,5. . C~,it~Y-; ?~;~-~ -fL~~~i""~'-:' "=,----

__ , .. I.:g-c __

- - -- ... _,:---~. -

.To-fco-t T~~<;.;l<-

'E' _,<r, +- F:

.... >r -, - -=>\." .... '>'1,...

Designed by

Sheet No.

Date

Job No.

LONGROVE & ASSOCIATES

Civil & Structural Consulting Engineers

Project

..

'~j~ a.tA..I-~o

0, '"'2-S w,t.,."L ,~ec:..'

Ce. ::b- Fo<.>~".'

. I~ 101 eS(Ia)

-_

2--5-

13:, S

~ D. ,?~CCf,~ a) ('l-~~J~ C 10.""),. ') (leer. Ceo ",,'0 ">

'i..... z_''''

. ..., ~ .10, .....

1,0

~ 'e, s· W (.:.t ..., :til ~ l=.

!> )<- (p, (p-? "z:=r"30't -;~~4_~ ,ft-'" ,<>~.} ",{c,_,s,_,,',o'-)'

.~#t-t'--

_f,..) ~i"'-'D tc_.' ... d-~~.~

, Cc,Jr"f ebred )

I'

-:--

4~

. ~-..- 0, s: we-

- _.-'-....,...- _"_ - - .... '_ - _._--- .

£_ot!. _ T~61.e ~(b

'-z+' o.,.~~L0_._~I!) C:z._!t"!)(}) - (!~~,~) C 0;.7 •. ~)

-,.0 ,j,,\ ":fN/"- ........ _"':. .c::__

.. --

('3 '>: C~c.-k:. ~e.''''~orc e--c.- ..... 4

As, -=- 0, dc> is J_ i:>

1.-'4--r-<.- 4 e- (!.ffe.-Jive-- de-pJ-l. '. b_~ '0c?9."":~

.. J __ , _:_____ _, _ .. 1-_ ..

= 0, 00:1 t;.G~:'J:.,?>)(bOO) 130.. '1'" i-, ~ 'l-- 1_

---~ ,._,_ ~--~

- . --, - ~ ---

-- .. !

Designed by

Sheet No.

Date

Job No.

LONGROVE & ASSOCIATES

Civil & Structural Consulting Engineers

PrOject

A

'H.tio.'I" 'or) Su(*-H-f:J<g~cf lo-d h eo.,"'~ D,.;e I ~- E!c ~T ere»

"2. SOlS

.......... )

"",<..)~r

~+ -I~~-; ~ 9~~ ll~-,:.._~ FfrVf':>

.cc> ~s*r-vt!-+[O~ .... F ~~ ~L .

-rf..e(""C.h,~-, &. Spv.- .... :"2-"7~() .......... ",",v":>t-J...."",'"e

.' +ll ... $.uff'o.-t- . s+~e(.51 eck_clr.; ~,l~

CONDECK DESIGN PRINCIPLES

FLOOR DESIGN LOADINGS

TABLE 1 FLOOR LIVE LOADS

The Condeck composite slab is designed to withstand total loadings made up of the following load types:

(i) Dead Load - the weight of the slab i.e.

Condeck, concrete and reinforcing mesh.

(ii) Superimposed live Load - these load intensities for various building occupancies are as per CP 3, Part 1 Dead and Live Loads (see Table 1).

(iii) Superimposed Dead Load - allowances for partitions, floor finishes and suspended ceilings, etc.

Min. Floor

Classification Live Loads

kN/m2

Domestic Buildings - 1 & 2 Storey 1.5

Over 2 Storey 2.0

Hotel bedrooms, hospital wards,

restaurants, toilets 2.0

Carports, churches, classrooms,

corridors, offices, passageways 3.0

Balconies, dance floors, school

assembly rooms, stairways, theatres 4.0

Drill halls, grandstands, gymnasiums,

non-domestic kitchens 5.0

Factories, filing rooms, motor

rooms, shops. strong rooms ,5.0

Boiler rooms. stages 7.5 COMPOSITE SLAB

Condeck Composite Slabs have been designed in accordance with CP 114 structural use of reinforced concrete in building, BS 449 Steel Structures Code and CP 117, Part 1 Composite Construction Code.

1. The slabs are designed as one way concrete slabs in which the whole area of the Condeck section is considered to act as positive tensile reinforcement.

2. The slab properties (Tables 5 & 6) are based on:

(i) Ultimate Concrete compressive stress Pc = 25 N/mm2 and 30 N/mm2 (iij Permissible stress = 11.0 and 13.5 N/mm2

(iii) Modular ratio n = 8.5 and 7.5

Note: Tables for F'c values of 20 N/mm2 are available on request.

3. Maximum span to depth ratios for composite slabs have been taken as: (i) Simple span ..b. = 33

d

(iij Double span.]; = 35 d

(iii) Continuous span ..b. = 39 (greater than 2 spans) d

4. Bond between the Con deck and the concrete is assumed to exist only along the periphery of the ribs and is calculated as 0.50 N/mm2.

5. Deflection limitation under superimposed load is SPAN

480

SIMPLE DESIGN - SIMPLY SUPPORTED SPANS (No Negative Reinforcement) The composite Condeck and concrete slab is assumed to be a series of single span one way slabs. This is simple to design and requires only secondary reinforcement (Table 2) or distribution mesh in the top of the slab to reduce surface cracking due to shrinkage.

For Condeck slabs the minimum secondary reinforcement is based on the concrete area above the Condeck ribs.

TABLE 2 SECONDARY REINFORCEMENT Area of reinforcement as per CP 114

Slab Depth 90 100 110 120 130 140 150 160 170 180 190 200

Mesh Size A7/B5 A7/B5 AB/B6 AB/BS AB/BS AB/B6 AB/BS

(mm'/m) A5 A5 A5 A7 A7

(98) (98) (98) (193) (193) (193/196) (193/196) (252/283) (2521283) (252/283) (252/283) (252/283) NOTE: Negative Reinforcement can be used to obtain continuous one way slabs (See Fig. 2) by being designed and placed over internal supports in accordance with conventional concrete deSign principles.

For further information and slab selection, see Tables 6 (b) and 7 (b).

CONDECK PROPPING

During concrete placement, the Condeck has to withstand the weight of the wet concrete plus temporary construction loads. The allowance for construction loads is 1.5 kN/m2. Temporary propping to Condeck (Table 3) is required for any of the following:

It 1. Under the weight of the wet concrete, the deflection of the Condeck exceeds Span/240.

2. For 2 or more temporary props the deflection between props exceeds 3mm.

3. Under the weight of the wet concrete plus the constructional load allowance, the allowable section moment capacities are exceeded. (See Table 4)

TABLE 3 PROPPING TABLE

SINGLE SPAN DOUBLE SPAN CONTINUOUS SPAN

Slab CON DECK CONDECK CONDECK

Thickness Max Span Max Span Max Span Max Span Max Span Max Span

Without With Without With Without With

Prop 1 Prop Prop 1 Prop Prop 1 Prop

0.75 1.00 0.75 1.00 0.75 1.00 0.75 1.00 0.75 1.00 0.75 1.00

90 2340 2550' 2550' 2550· 2430 2960 3020' 3020' 2640 3020· 3020· 3020·

100 2260 2480 2880· 2880' 2360 2870 3410' 3410' 2570 2950 3410· 3410·

110 2190 2400 3210· 3210' 2290 2790 3800· 3800· 2500 2870 3BOO' 3800'

120 2120 2330 3540· 3540' 2230 2710 4190· 4190· 2420 2800 4190' 4190'

125 2100 2300 3700' 3700· 2190 2680 4380' 4380· 2390 2760 4380· 4330'

130 2070 2270 3870' 3870· 2170 2650 4580· 4580' 2370 2730 . 4580' 4580'

140 2020 2220 4200· 4200· 2120 2570 4500 4960· 2310 2650 4530 4970'

150 1970 2170 4140 4540' 2070 2520 4400 5210 2250 2600 4430 5230

160 1930 2120 4040 4860· 2020 2460 4300 5100 2200 2530 4330 5130

170 1890 2080 3960 4800 1980 2400 4210 4990 2160 2480 4250 5020

180 1860 2040 3880 4700 1940 2350 4120 4890 2100 2430 4150 4940

190 1830 2000 3800 4600 1900 2300 4040 4810 2070 2380 4070 4850

200 1790 1970 3720 4520 1860 2260 3960 4720 2020 2350 3980 4760 NOTE:

1. An allowance should be made for the extra mass of concrete due to Condeck panel deflection, for long unpropped spans.

2. The deflection limitation of SPAN/240 can be relaxed to the greater of the abovementioned criteria in particular cases, but the final decision is left to the discretion of the Structural Engineer.

3. When using temporary props, especially if the Con deck soffit is to be left exposed as a ceiling feature, it is recommended that a piece of caneite or similar material be placed between the prop timber bearer and the

Con deck panel to reduce the effect of unsightly "propping lines".

4. * ~ ratio governs.

5. Concrete density assumed as follows: 25 Grade = 2400 kg/rn3

30 Grade = 2400 kg/m3

6. The temporary props must be' left in place until the concrete has reached at least 70% of its design strength. The full design load Should not be applied until the design strength is attained.

Temporary props and bearers in position ready to support the Condeck panels and wet concrete load.

5

SECTION PROPERTIES

Con deck Section Properties and Composite Slab properties have been computed in accordance with BS 2994 Cold Formed Steel Structures and conventional reinforced concrete design principles respectively. The allowable Design Stress is 330 N/mm2.

,

21

_,23r-la 1 H---f

k 300

<

0-

o

H~

~ Composite Slab

Conoeck Panels

TABLE 4 CONDECK PANEL PROPERTIES PER METRE WIDTH

Thick· Mass Cross Yl:1I PositiVI Bending Moment Negative Bending Moment Sale End Rlaclfon Sale Intem~1 Rncll~n

"'" Sedlunal Allowable

(Ball Ana Shul 20mm 50mm 20mm 50mm

mltal) I, Zpt ZIK Mp In Ziti ZIR Mil Ftn:1 Blaring Bearing Bearing Bearing

mm kg/mt mmt mm 1GIXF1t1t14 l03x!M13 103xmm3 kN.m lOfXmm4 1D3xmm3 1Il3Xmm3 kN.m kN kN kN kN kN

0.75 9.47 1150 12.70 0.445 35.07 10.53 3.47 0.201 B.08 B.72 2.21 26.67 18.64 22.91 1B.26 23.88

1.00 12.04 1533 12.70 0.582 45.93 13.75 4.53 0.289 10.93 10.10 3.33 55.43 30.69 37.12 30.68 39.47 Ip - second moment of area for positive moment regions (strength). In = second moment of area for negative moment regions (strength).

Zpt ~ Elastic modulus for positive moment zone-tension flange.

Znt - Elastic modulus for negative moment zone-tension flange.

Zpc = Elastic modulus for positive moment zone-compression flange. Znc = Elastic modulus for negative moment zone-compression flange.

Mp = Governing moment capacity of section In the positive zone. Mn = Governing moment capacity of section in the negative zone.

Condeck formers placed in position ready to act as permanent foimwork for the wet concrete and construction load.

For this particular application, temporary propping is not required.

TABLE 5 la, - COMPOSITE SLAB PROPERTIES PER METRE WIDTH OFSLAB(F'c-25 N/mm2)

THICK· SLAB SLAB SLAS EFFECTIVE STEEL BASED SOND DATA (U = 0.5 N/mm2)

NESS DEPTH MASS WEIGHT DEPTH FLEXURAL PROPERTIES

"IY' DENSE

WGT d kd ys m ld I Ze Zt X ib Io Ibl:oU

CONCR

mm mm kglm2 kNlm2 mm mm mm mm mm 106 X mm4 103 X mm3 lol X mm3 mm mm .mm kN

90 216 2.12 77.3 29.7 60.3 47.6 67.4 3.9 132.0 65.0 43.90 12.00

100 240 2.35 87.3 32.0 68.0 55.3 76.6 5.0 157.5 74.1 53.13 14.52

110 264 2.59 97.3 34.2 75.8 63.1 85.9 6.3 185.1 83.5 62.40 17.05

120 288 2.83 107.3 36.3 83.7 71.0 95.2 7.8 214.8 93.0 71.70 19.59

125 300 2.94 112.3 37.3 87.7 75.0 99.9 8.6 230.3 97.8 76.37 20.87

130 312 3.06 117.3 38.3 91.7 79.0 104.5 9.4 246.3 102.7 81.03 22.14

0.75 140 336 3.30 127.3 40.2 99.8 87.1 113.9 11.2 279.7 112.5 36.2 90.40 546.5 24.70

150 360 3.53 137.3 42.0 108.0 95.3 123.3 13.2 314.7 122.4 99.80 27.27

160 384 3.77 147.3 43.8 116.2 103.5 132.7 15.4 351.4 132.4 109.20 29.84

170 408 4.00 157.3 45.5 124.5 111.8 142.1 17.7 389.7 142.4 118.63 32.42

180 432 4.24 167.3 47.2 132.8 120.1 151.6 20.3 429.5 152.5 128.07 35.00

190 456 4.47 177.3 48.8 141.2 128.5 161.0 23.0 470.7 162.6 137.53 37.58

200 480 4.71 187.3 50.4 149.6 136.9 170.5 25.9 513.4 172.8 147.00 40.17

90 216 2.12 77.3 33.2 56.8 44.1 66.2 4.9 146.3 85.6 42.83 11.63

100 240 2.35 87.3 35.9 64.1 51.4 75.3 6.3 174.6 97.7 51.93 14.11

110 264 2.59 97.3 38.4 71.6 58.9 84.5 7.9 205.4 110.2 61.10 16:60

120 288 2.83 107.3 40.8 79.2 66.5 93.7 9.7 238.6 122.9 70.30 19.10

125 300 2.94 112.3 42.0 83.0 70.3 98.3 10.7 256.0 129.3 74.90 20.35

130 312 3.06 117.3 43.1 86.9 74.2 102.9 11.8 273.9 135.8 79.53 21.60

1.00 140 336 3.30 127.3 45.3 94.7 82.0 112.2 14.1 311.4 148.9 36.1 88.80 543.3 24.12

150 360 3.53 137.3 47.4 102.6 89.9 121.5 16.6 350.7 162.2 98.10 26.65

160 384 3.77 147.3 49.5 110.5 97.8 130.8 19.4 392.0 175.5 107.40 29.18

170 408 4.00 157.3 51.5 118.5 105.8 140.1 22.4 435.1 188.9 116.73 31.71

180 432 4.24 167.3 53.4 126.6 113.9 149.5 25.6 480.0 202.4 126.10 34.26

190 456 4.47 177.3 55.3 134.7 122.0 158.9 29.1 526.6 216.0 135.47 86.80

200 480 4.71 187.3 57.1 142.9 130.2 168.3 32.8 574.9 229.6 144.87 39.35 e TABLE 5 (b) - COMPOSITE SLAB PROPERTIES PERMETREWIOTHOFSLAB(F'c=30N/mm2)

THICK· SLAB SLAB SLAB EFFECTIVE STEEL BASED BOND DATA (U = 0.5 N/mm2)

NESS DEPTH MASS WEIGHT DEPTH FLEXURAL PROPERTIES

"D" DENSE

WGT d kd ys m jd I Ze Zt X Ib 1:0 IbroU

CONCR

mm mm kglm2 kNlm2 mm mm mm mm mm 106 X mm4 103 X mm3 11)3 x mm3 mm mm mm kN

90 216 2.12 77.3 28.3 61.7 49.0 67.9 4.0 143.0 65.6 44.37 12.12

100 240 2.35 87.3 30.5 69.5 56.8 77.1 5.2 170.6 74.7 53.63 14.65

110 264 2.59 97.3 32.5 77.5 64.8 86.5 6.5 200.5 84.2 62.97 17.21

120 288 2.63 107.3 34.5 65.5 72.8 95.8 8.0 232.5 93.8 72.30 19.76

125 300 2.94 112.3 35.4 89.6 76.9 100.5 8.8 249.3 98.6 77.00 21.04

130 312 3.06 117.3 36.4 93.6 60.9 105.2 9.7 266.6 103.5 81.67 22.32

0.75 140 336 3.29 127.3 36.2 101.8 89.1 114.6 11.5 302.6 113.4 36.2 91.07 546.5 24.86

150 360 3.53 137.3 39.9 110.1 97.4 124.0 13.6 340.4 123.3 100.50 27.46

160 384 3.77 147.3 41.6 118.4 105.7 133.4 15.8 379.9 133.3 109.93 30.04

170 408 4.00 157.3 43.2 126.8 114.1 142.9 18.2 421.1 143.4 119.40 32.63

180 432 4.24 167.3 44.7 135.3 122.6 152.4 20.8 464.0 153.5 128.90 35.22

190 456 4.47 177.3 46.3 143.7 131.0 161.9 23.5 508.4 163.7 138.37 37.81

200 480 4.71 187.3 47.7 152.3 139.6 171.4 26.5 554.4 173.8 147.90 40.41

90 216 2.12 77.3 31.7 58.3 45.6 66.7 5.0 158.8 86.4 43.33 11.77

100 240 2.35 87.3 34.2 65.8 53.1 75.9 6.5 189.6 98.7 52.50 14.26

110 264 2.59 97.3 36.6 73.4 60.7 85.1 8.2 223.0 111.2 61.70 16.76

120 288 2.83 107.3 36.9 81.1 68.4 94.3 10.1 258.9 124.0 70.93 19.27

125 300 2.94 112.3 40.0 85.0 72.3 99.0 11.1 277.7 130.5 75.57 20.53

130 312 3.06 117.3 41.0 89.0 76.3 103.6 12.2 297.1 137.1 80.23 21.79

1.00 140 336 3.29 127.3 43.1 96.9 84.2 112.9 14.6 337.6 150.2 36.1 89.53 543.3 24.32

150 360 3.53 137.3 45.1 104.9 92.2 122.3 17.2 380.2 163.5 98.87 26.86

160 384 3.77 147.3 47.0 113.0 100.3 131.6 20.0 424.7 176.9 108.23 29.40

170 408 4.00 157.3 48.9 121.1 108.4 141.0 23.1 471.3 190.4 117.60 31.95

180 432 4.24 167.3 50.7 129.3 116.6 150.4 26.4 519.7 204.0 127.00 34.50

190 456 4.47 177.3 52.5 137.5 124.8 159.8 29.9 569.9 217.6 136.40 37.05

200 480 4.71 187.3 54.2 145.8 133.1 169.2 33.7 621.9 231.3 145.83 39.61 I slab - t (kd)3 + Asm2 + I Steel Section - Based on converting concrete area into equivalent steel area where n = 8.5 and 7.5 for Grade 25 and 30 concrete respectively.

7

CONDECK COMPOSITE

ALLOWABLE GRADE 25 CONCRETE

TABLE 6 (a' SINGLE SPAN SLABS (SLABS WITHOUT NEGATIVE REINFORCING)

Ei---=~+----~

E~~+-----~~

U)~~~~~~...... t----=-:'=----+--~---+~~+-"'-'---'---"'--" c)~~~~~~~+---~~~

~~~,_---+--~r---+----+~==

o

LU~~~--~r---~---4----~--~---

Clr-~~--~r---~--~----~-----+----~~~ Z~~4----+----+---~----~--~---+----~~

()1~~+-~4---~---+--~----~--+---4----F~~

o

~~---+----~----~--~----~-----+----~---+----+----+~~

Ef--=~l-----E ~~-----J'l=o.:L. ot----=-~-+----t---~~~1----+----~==~

'_~~4----+----+---~~~

~~~'_---+--~~--+---~---4~~

O~~'_---+ __ ~r- __ +- __ -+ __ _' _

W

Cl~~~--~r---4---~-~--~---t-----~~~

Z~~1----+----+---~--~r---~---+----r---()~~+---~--~----+----+--~----~---+----+~~

O~~'_---+ ~ __ 4- __ -+ __ ~ +- __ ~ __ ~ ~~

-

No propping

Three lines of props

_ One line of props

_ Two lines of props

I> ,..... ., Arbitrary Deflection Limits (See Note 5)

NOTES TO TABLES 6 (a) and 6 (bl

1. Propping recommendations in Tables 6 (a) and 6 (b) are as per Table 3 for single span and continuous span Condeck respectively.

2. No adjustment to the allowable superimposed load is required if "propping" or "non-propping" is undertaken in accordance with Tables 6 (a) and 6 (b).

However should a designer adopt a temporary prop for a span that Tables 6 (a) and 6 (b) indicates requires no such extra support, then the allowable superimposed load as indicated in Tables 6 (a) and 6 (b) has to be reduced by the slab's self weight.

8

SLAB CAPACITI ES

SUPERIMPOSED LOAD lkN/m2) (F'c = 25 N/mm2)

TABLE 8 lb) CONTINUOUS SLABS (SLABS WITH NEGATIVE REINFORCING)

SPAN

SLAB DEPTH (mm)

NEGATIVE EINFORCING DETAILS (SEE NOTE 3)

MESH

B8 (503mm2fm)

3. The negative reinforcing details indicated in Table 6 (b) are:

• for continuous slabs over internal supports

• based on the effective depth of the Condeck slab

• placed with 20mm cover to the top surface of the slab and is in addition to and placed above the secondary reinforcement as per Table 2

• based on the allowable superimposed load (with lighter loaded slabs probably containing less reinforcement; although a design check on the reinforcement requirement is necessary).

• based on a minimum yield stress of 450 N/mm2

4. Negative reinforcement is to extend past one quarter of the clear span on both sides of an interior support.

5. The arbitrary deflection limits are the maximum spans for the allowable superimposed loads indicated calculated on the deflection limitation of SPAN/480.

6. Table 6 (b) "Continuous Slabs" is applicable provided that the ratio of adjacent span lengths do not exceed 1.20. Adopt normal design procedure for higher ratios.

7. For details of negative reinforcement using stress relieved cold worked deformed bars refer to

the Technical Department Stramit (SEA) Pte. Ltd. .

9

CONDECK COMPOSITE

ALLOWABLE GRADE 30 CONCRETE TABLE 71a) SINGLE SPAN SLABS (SLABS WITHOUT NEGATIVE REINFORCING)

~~~~--~----+---~----~--,_~()~~4----+----~--4----+--~~--W~~-r--~----~---+----r_--~--~~~

C~~4---~----+- __ ~ ~ __ 4- __ -+ ~~

:Z~~-r __ ~ +- __ ~ ~ __ -r __ ~ +- _

()~~+---~---r---+---4~--r-~+---~---r~-()~~-r--~----+---~----~---r--~----+----r--~--~

E~~I----_ E ~~I-----PC--:~ a.n1---7~-r-----+--..... ~~~---+----+--=-=~

c)~==-r-----+----+---~-=~

~j----:':;';';'-+---~----+----+----r_---r-=O,__ ()~~4----+----r---4----+--~~--LUj----:~-+---~----+- __ -+ __ --r_--~--~~=-

C :z~~-r--~----+----r----r---~---T----+-~-

()~~+---~---r---+---4~--r---+---~---r--~

(J~~4----+----~--4----+--~~ __ +- __ ~ __ ~ +-~

,

E f.--=~+---E 1---=-=-=-+-----1--'-'-'-()I~~-r--~---() 1-7.,c.::..=.-r--~----+---'-'-'-~ ,..: ~~--I----~----+---.-+--.....":..:=----

No propping

-

One line of props

_ Two lines of props

-

Three lines of props

.____~----,I Arbitrary Deflection Lim its (See Note 5)

NOTES TO TABLES 7 la) and 7 Ibl

1. Propping recommendations in Tables 7 (a) and 7 (b) are as per Table 3 for single span and continuous span Condeck respectively.

2. No adjustment to the allowable superimposed load is required if "propping" or "non-propping" is undertaken in accordance with Tables 7 (a) and 7 (b).

However should a designer adopt a temporary prop for a span that Tables 7 (a) and 7 (b) indicates requires no such extra support, then the allowable superimposed load as indicated in Tables 7 (a) and 7 (b) has to be reduced by the slab's self weight

SLAB CAPACITIES

SUPERIMPOSED LOAD (kN/m2) (F'c = 30 N/mm2)

TABLE 7 (b) CONTINUOUS SLABS (SLABS WITH NEGATIVE REINFORCING)

SPAN

SLAB DEPTH (mm)

NEGATIVE REINFORCING DETAILS (SEE NOTE 3)

MESH

88 (503mm2/m)

e

E

E

0

0

·

,_

~

0

W (1131

C

Z

0

0 I--;;;-~-t-~:;-------i~~--t-~;---t~~+-:~~~~~m-+-:i::i;-~+-:i~-+~~+";:~-+~~ 88 (503mm2/m) 89 (636mm2/m)

o I----=~~_:__;_-

~f----'-=-=-=---+-~---+:___-:=-O~~--+-~_+~~+-~_

W

Cl~==-r~~---~--+---_'~---

Z~=-=-=-~ __ ~ ~4- __ -4 4- __

O~~_+- __ ~ __ ~ +- __ ~ __ -4~~

O~~~--~----4----4----4----+--~

3. The negative reinforcing details indicated in Table 7 (a) are:

• for continuous slabs over internal supports

• based on the effective depth of the Condeck slab

• placed with 20mm cover to the top surface of the slab and is in addition to and placed above the secondary reinforcement as per Table 2

• based on the allowable superimposed load (with lighter loaded slabs probably containing less reinforcement; although a design check on the reinforcement requirement is necessary).

• basedon a minimum yield stress of 450 N/mm2

4. Negative reinforcement is to extend past one quarter of the clear span on both sides of an interior support

5. The arbitrary deflection limits are the maximum spans for the allowable superimposed loads indicated calculated on the deflection limitation of SPAN/480.

6. Table 7 (b) "Continuous Slabs" is applicable provided that the ratio of adjacent span lengths do not exceed 1.20. Adopt normal design procedure for higher ratios.

7. For details of negative reinforcement using_stress relieved cold worked deformed bars refer to the Technical Department Stramit (SEA) Pte. Ltd

11

DESIG N EXAM PLES

DESIGN PROCEDURE AND SAMPLE COMPUTATIONS

Normally once the design loadings and other parameters are known, reference to the preceding tables will enable a suitable Condeck and composite slab to be selected.

The design steps and formulae used to derive the figures in the tables are shown below by way of the "sample computations".

NOTES:

1. ·Condeck Bending moments and deflection values have been derived from a computer analysis which makes provision for varying section properties viz: Ip, In

2. For single span uncropped Condeck M= 0.125 WL2

S = 5 WL4

-----

Elp

E = 2 X 105 N/mm2

384

NEGATIVE REINFORCEMENT

3. For propped condition W = Ws + self Wt Slab.

4. The value of j (= 0.90) is only approximate and a check of Its value with the calculated reinforcement might be necessary.

5. Theleverarmdis calculated using a cover to reinforcement of

20 mm and distance to the centroid of the largest mesh available.

Fig. 2

STEPS· IN DESIGN FORMULAE SIMPLE SPAN SLAB CONTINUOUS SLAB

.,

Where l'-8inloTCing mash is used Where negative moment •

only.1Qr temperature Dr relnlorcsmelll is 'iJsed Over I

distribution steel SUPDO.rts

Span ··L" ~ 3000mm Span "L" - 2200mm

Loading & Parameters III Live load WL - 4.0 kN{m' III Live load WL - 8.0 kNtm2

{2) Floo, Finloh - 0.5 kNtm2 21 Floor FiniSh - 1.0 kNlm'

13) Suspended cailings - 0.5 kN{m' ~~:.a,::::~;d~·2..~N~~: 12.0 kN/m.

Superimpo •• d load W. - 5.0 kN/m2 Concrete- stfellgln F'c .. 25 N/mm?

Conot81e S1rSnglh Pc - 25 Nlmm' l a x 1.

, 3OIlO mm ~ Ie ,I( ,Ic ~

:I':2'og nco 2200

ConSUlt tabJes 0.75 Co.deck 110 mm slab

one tOw of ,prop, 0.75 Condeck - 100 mm slab

Wr slab - 264 xClim' NQ prop •

.& 1. A· Wt .Iab - 240 kCllm'

--RoIW01 IDIODI

(1) Che<:k Condeck (' ?-vA l< "I.~17 .. ,,,,.

memant (s'ress] dye 10 WElt W - 2.59 + 1.5 - 4.09 kN/m2 W - 2.35 + 1.$ - 3.85 kN/m'

concrete :plus ''''POS - 0.7 kNm c 3.30 kN.m ·Mpo. - i.e kNm < 3.30 kN.m

cans1ructionalload. 'Mneg - 0.9 kN.m c 2.06 kN.M 'Mneg - 1.0 kN.m < 2.06 kN.m

MPOO-

"'neg-

(2) Check Condock dslloclion W - 2.59 kNlm' W - 2.35 kNlm2

under wet concrete IDad. ".a: -1.01 mm .. '" -5.01 mm

6 .... Span and/or

- 24ii

3mm between props _6 __ ~ __ 1_ < _1_:.0.K. _' __ ~ __ 1_<_1_. OK.

(10,2 <)I' mora propel Span 1500 1485 24D Span 2200 439 240"·

C31 Calculala I - ~ TBktlsl '* 0 for ,propp{ .... g I., 0.98 X lOS

len""" 81.e •• at s. ZP! at m span. - 33.30 X 1()3

mH::lsJ)an under wet

concrnta. - 29.4 N/mm2

(4) Calculate sraal lensile' I 0.125WL2 lIZ _ 0.12515 + 2.58) x 3000' Is.- 0.091 X 12.0 X 2200' t

stress In composi.e _ s'--:z:r- 83.5 X ID3 74.1 X 10'

slab IJnl1er superimposed SI"IIleSpanl - 1 02.3 Ntmm2 ... 71,3 N/mm2

load.Un,pan) 1 .. - 9·09Z~·

(Plus slab self weighl;1

propped COndeck) Continuous Spans

whare

W-W.+SeIlWiSlab

For propped cDnditians

(5) Che<:k 101al len "'Ie I .. - 1$,+ 1$2 lOT - 0 + 102.3 /., - 29.4 .. 71.3

stress in Coodeck. - 102.3 Ntmm2 < 275 Nlmm2 ... 0.K- - 100.7 N/mm2

F ..... -~ - 275N/mm2

(I) Che<:k comp.essive .. ~ Ie_ 0.125 [5 + 2.511) X 3000' Ie_ 0.091 X 12.0X 22002

streu Fn concrete In ,pan - nZc as x 185.1 X 1()3 as X 157.5 X 1()3

Fe - 11.25 Nlmm2 for Si"gle Spanll - 5.43Ntmm2<11.25N1mm2;.0.K- _ 3.95N/mm'<11.25N1mm2;.O.K.

Fe - 25 N{mm2 O.og.WL'

n - 8.S Ie ---;;z;-

ConUnuous SiPan

whllre

W- W,+SelfWiSlab

Forproppod

condition

(7) Chick slab delleclion 5 W L' $X5 X 3000' 1 x 12.0 X 2200'

6 -384~ 6- 334X2X 105XB.3X lOB 6 - 145 x 2 X 105 X 5.0X 1011

under suparimposed Icad

6 .... __ SDan Single span - <l2mm - 1.9mm

480 6 -m- w~r

_, __ ~ _ -1- < _1_:. 0.K. _, __ ..1J!_ __ 1_ < _1_:. O.K.

Continuous Spa!'! Span 3000 714 480 Span 2200 1158 480

o.SWL 0.5 j5 + 2.59) x 3000 0.4 x 12.0 X 2200

(8) Check bond atre .. U u- u- 546.5 X 53.13

at ~(ee end supports- - ""Toib 548.5 X 62.40

Single Spans _ 0.33 N{mm' < 0.5 N/mm2 r. O.K. _ 0.38 N/mm' < 0.5 NImmo c. O.K.

u.. •. - 0.50N{mm2 u-~

J;otb

continuous Spans

"w- W," SelfWtSlab

lor propped

c{)ndihon.

(9) Check Raintorcemonl

raquirament. t Ast- 0.0015 X 45 x 1000 ~I-

.) Secondary Drdlstnbulion OJ) A.I - O.0015"b Atr- 0.0015 X 55 X 1000

rSimpl. & Cofltinuou:s where d - effecUv8 - 82.5 mm'/m - 67.5 mm2/m

Spans) deplh

b- 1DOO mm

bI Negallve b)A.l- ~

[Conlin~ou. Spano) jdF. Asl_ 0.'0 X 12 X 2200'

where 0.9 X 74X 230

Mnlll'-0.10Wl'

j - 0.90 [appro.) -- .. 379 n'lm2lm

d - 0-26

20mm Covet

12mmlmu!

diameler -

Fs "" 230 NImm2 t For a hre rated slab sae FIg.. 7b

You might also like

- Composite Beam Design ExampleDocument7 pagesComposite Beam Design Exampledgreally1gmailcom100% (1)

- Design of composite slabDocument7 pagesDesign of composite slabjonathanbido100% (4)

- Design Example-Beam Compact SectionDocument13 pagesDesign Example-Beam Compact SectionManoj RautNo ratings yet

- Example Composite Floor SlabDocument13 pagesExample Composite Floor SlabZamfira Octavian100% (2)

- Composite Beam Simply Supported DesignDocument21 pagesComposite Beam Simply Supported DesignTharanga Pradeep100% (1)

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Document14 pagesSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNo ratings yet

- Steel-Concrete Composite Slab Design Using ExcelDocument9 pagesSteel-Concrete Composite Slab Design Using ExcelTasnuva NazmulNo ratings yet

- Minimum Edge Distances As Identified in BS 5950Document1 pageMinimum Edge Distances As Identified in BS 5950Jagdish DhanuskarNo ratings yet

- Worked Example 1 - Composite Beam - Normal DesignDocument26 pagesWorked Example 1 - Composite Beam - Normal DesignTudor Tudor100% (1)

- Example 1 - Staircase Design PDFDocument2 pagesExample 1 - Staircase Design PDFHaziq Senin80% (5)

- Design of DomeDocument5 pagesDesign of DomeAmarjeet SinghNo ratings yet

- Design of A Composite Bridge DeckDocument121 pagesDesign of A Composite Bridge DeckAnonymous JLaQiSNo ratings yet

- Design Shear Resistance (Beams EC2)Document2 pagesDesign Shear Resistance (Beams EC2)dhanya1995No ratings yet

- Basement Wall DesignDocument19 pagesBasement Wall DesignwaikenNo ratings yet

- Vertical reinforcement (Walls: BS 8110) guidelinesDocument4 pagesVertical reinforcement (Walls: BS 8110) guidelinesdhanya1995100% (1)

- RC Water Tank Design GuideDocument40 pagesRC Water Tank Design GuideAdil MansuriNo ratings yet

- Elastic Analysis of A Single Bay Portal FrameDocument31 pagesElastic Analysis of A Single Bay Portal Framelanmark100% (1)

- Design of Cantilever Retaining Wall in BS8110Document6 pagesDesign of Cantilever Retaining Wall in BS8110Teoh ChunliNo ratings yet

- Portal Frame Stablity CheckDocument2 pagesPortal Frame Stablity CheckAlma M. LaraNo ratings yet

- Staircase ExcelDocument5 pagesStaircase ExcelvishnuNo ratings yet

- Pad Foundation Design To Bs 81101997Document23 pagesPad Foundation Design To Bs 81101997Anonymous 66uWhphVNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNo ratings yet

- Composite Column DesignDocument3 pagesComposite Column DesignEngDbt50% (2)

- Composite Beams & Columns To Eurocode 4Document155 pagesComposite Beams & Columns To Eurocode 4dfdfdfasd324sad100% (2)

- Wind load design data for 72m buildingDocument12 pagesWind load design data for 72m buildingதமிழ்மகன் ஜெகதீஷ் தாமோதரன்100% (2)

- Composite Slab DesignDocument13 pagesComposite Slab Design_jesseca100% (2)

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Document1 page16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriNo ratings yet

- Prestressed Concrete Design (SAB 4323) : Dr. Roslli Noor MohamedDocument22 pagesPrestressed Concrete Design (SAB 4323) : Dr. Roslli Noor MohamedJerryYanNo ratings yet

- RCD Course Work PDFDocument60 pagesRCD Course Work PDFSaciid LaafaNo ratings yet

- Chap 7 Foundation DesignDocument36 pagesChap 7 Foundation DesignZulhasri WahapNo ratings yet

- Composite Beam DesignDocument4 pagesComposite Beam DesignSunil PulikkalNo ratings yet

- Abutment Design Example To BD 30Document16 pagesAbutment Design Example To BD 30Muzammil Moosafeer100% (1)

- Beam-Column Connection To BS5950Document6 pagesBeam-Column Connection To BS5950Mitra RampersadNo ratings yet

- Example Calculation of Alpha-Cr PDFDocument9 pagesExample Calculation of Alpha-Cr PDFHerdean RemusNo ratings yet

- Z Purlin DesignDocument22 pagesZ Purlin DesignGautam PaulNo ratings yet

- Design of WingwallDocument29 pagesDesign of WingwallMar MartillanoNo ratings yet

- Tapered I-Section Design in StaadproDocument1 pageTapered I-Section Design in StaadproMichael DixonNo ratings yet

- Composite BeamDocument7 pagesComposite Beamsaif.mullaNo ratings yet

- Bridge Loading Idealisation For Grillage AnalysisDocument8 pagesBridge Loading Idealisation For Grillage AnalysisHarold Jackson MtyanaNo ratings yet

- River Banks Design PDFDocument15 pagesRiver Banks Design PDFpk100% (1)

- MS PurliDocument4 pagesMS PurliJennifer PearsonNo ratings yet

- Composite Steel DesignDocument33 pagesComposite Steel DesignscegtsNo ratings yet

- Slab With OpeningDocument16 pagesSlab With OpeningTomislav Šimag100% (1)

- BS5950 Vs EC3Document146 pagesBS5950 Vs EC3Ali Gaffar100% (1)

- TCC33 Flat Slabs (A&D)Document47 pagesTCC33 Flat Slabs (A&D)Nazar Shafiq100% (1)

- Beam-Column Using Double Angle CleatDocument7 pagesBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Slab DesignDocument87 pagesSlab Designshamen amarasekaraNo ratings yet

- Example Flat Slab Design - CarDocument31 pagesExample Flat Slab Design - CarRayGaintNo ratings yet

- Portal Frames DDocument48 pagesPortal Frames DMukonyora SirMartinNo ratings yet

- Reynolds's Reinforced Concrete Designer's Handbook: Charles E. Reynolds James C. SteedmanDocument2 pagesReynolds's Reinforced Concrete Designer's Handbook: Charles E. Reynolds James C. SteedmanMuhammad Irfan Khan0% (1)

- Example of Structural CalculationDocument18 pagesExample of Structural Calculationdeua2004No ratings yet

- Raft Slab DesignDocument5 pagesRaft Slab DesignLekins Sefiu Yekini100% (2)

- Structural Analysis and Design Report of Proposed Two Storey CafeDocument55 pagesStructural Analysis and Design Report of Proposed Two Storey CafedasmindpcqboNo ratings yet

- Lastra Singola - It.enDocument4 pagesLastra Singola - It.enyogeshNo ratings yet

- Rcc95 Continuous Beams (Tables)Document8 pagesRcc95 Continuous Beams (Tables)Steve JsobNo ratings yet

- STRUCT ANALfront4 19Document5 pagesSTRUCT ANALfront4 19Jaybert DumaranNo ratings yet

- RECONSTRUCTION OF BRIDGEDocument152 pagesRECONSTRUCTION OF BRIDGERamachandran SingaraveluNo ratings yet

- Advances in Rigid Pavement DesignDocument108 pagesAdvances in Rigid Pavement Designdhanush gtNo ratings yet

- Design TemplateDocument19 pagesDesign TemplatePaul AlcantaraNo ratings yet

- Model Estimate DPRCDocument63 pagesModel Estimate DPRCD.V.Srinivasa Rao100% (2)

- Stair Detail PDFDocument1 pageStair Detail PDFManish AgrawalNo ratings yet

- Madhya Pradesh Public Works Department: Office of The Engineer-In-ChiefDocument3 pagesMadhya Pradesh Public Works Department: Office of The Engineer-In-Chiefabhijeet sahuNo ratings yet

- Precast - A Competetive AdvantageDocument41 pagesPrecast - A Competetive AdvantageSony JsdNo ratings yet

- Guide To Certification of - Shotcrete Nozzlemen - Aci - 506 - 3R - 91Document13 pagesGuide To Certification of - Shotcrete Nozzlemen - Aci - 506 - 3R - 91Tansel YılmazNo ratings yet

- Types of Concrete - WikipediaDocument11 pagesTypes of Concrete - WikipediaAndi SilalahiNo ratings yet

- Trial Mix Data Sheet - M50Document1 pageTrial Mix Data Sheet - M50kiranrvgowdaNo ratings yet

- Durability of ConcreteDocument33 pagesDurability of Concreteabdulwahab11No ratings yet

- BID Data Sheet RBC-pk-19Document1 pageBID Data Sheet RBC-pk-19JND LogisticNo ratings yet

- Vision Mission Objectives: Ordinary Portland Cement 43 Grade Cement (OPC 43 Grade)Document2 pagesVision Mission Objectives: Ordinary Portland Cement 43 Grade Cement (OPC 43 Grade)M. HaripriyaNo ratings yet

- Visvesvaraya Technological University Jnanasangama, Belagavi-590018Document40 pagesVisvesvaraya Technological University Jnanasangama, Belagavi-590018Srinivas JNo ratings yet

- Generalizing Abrams' Law for Mortar StrengthDocument8 pagesGeneralizing Abrams' Law for Mortar StrengthNico YamatoNo ratings yet

- MEKA Concrete Batching TechnologiesDocument31 pagesMEKA Concrete Batching TechnologiesSaad SaadNo ratings yet

- Bijan Khaleghi 6ADocument56 pagesBijan Khaleghi 6AKY PengNo ratings yet

- 017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFDocument9 pages017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFMohammad Hadoumi Saldan100% (1)

- Design of Isolated FootingsDocument13 pagesDesign of Isolated FootingsMohamedNo ratings yet

- 1179 FinalDocument21 pages1179 Finaltsitsi bizaNo ratings yet

- Read MeDocument2 pagesRead MeLoren ViejayNo ratings yet

- Partial Replacement of Cement by Ggbs MiniDocument15 pagesPartial Replacement of Cement by Ggbs MiniSai RamNo ratings yet

- Technical Report TR 5 Conc Mix DesignDocument18 pagesTechnical Report TR 5 Conc Mix DesignSunil ReddyNo ratings yet

- Rate Analysis FinalDocument14 pagesRate Analysis FinalSakar ShresthaNo ratings yet

- Lysaght Smartdek - Jan 2019Document2 pagesLysaght Smartdek - Jan 2019Chai Weng KuakNo ratings yet

- Aci CCS-3 (1989)Document104 pagesAci CCS-3 (1989)Sino hydro0% (1)

- 10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDocument3 pages10.14 Mva Transformer Foundation: Input Data Rebar Work Footing SizeDesign explorer olomizanaNo ratings yet

- Self-Healing Concrete: A Revolutionary MaterialDocument15 pagesSelf-Healing Concrete: A Revolutionary MaterialHARIS ALI100% (1)

- Estimates - FajardoDocument4 pagesEstimates - FajardoGenesis Castro (Engr. Pianista)No ratings yet

- Shotcrete Concrete Technical Data SheetDocument2 pagesShotcrete Concrete Technical Data SheetRavi SinghNo ratings yet

- Experimental Investigation On Eggshell Powder Blended ConcreteDocument97 pagesExperimental Investigation On Eggshell Powder Blended ConcreteSamsouma BkNo ratings yet

- Conplast sp495Document2 pagesConplast sp495Vincent JavateNo ratings yet

- Concrete Mix Design Calculation For M20Document25 pagesConcrete Mix Design Calculation For M20Kosygin Leishangthem100% (2)

- BT 5Document3 pagesBT 5Earl UbiñaNo ratings yet