Professional Documents

Culture Documents

Prevention & Repair of Cracks in Concrete Structures

Uploaded by

Suvin SadanandanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prevention & Repair of Cracks in Concrete Structures

Uploaded by

Suvin SadanandanCopyright:

Available Formats

PREVENTION & REPAIR OF

CRACKS IN CONCRETE

STRUCTURES

BY

B.B.GAMIT XEN( C) W.RLY.

K.S.KRISHNAN AEN (D) W.RLY.

S.C.NAG AEN(W) W.RLY.

G.K.SIROHI AEN ( C) W.RLY

GUIDED BY

SHRI.V.B.SOOD PT-2,IRICEN

BROAD CLASSIFICATION

STRUCTURAL CRACKS

DUE TO INCORRECT DESIGN, FAULTY

CONSTRUCTION OR OVER LOADING AND

THESE MAY ENDANGER THE SAFETY OF A

BUILDING

NON-STRUCTURAL CRACKS

DUE TO INTERNALLY INDUCED STRESSES IN

BUILDING MATERIALS AND DO NOT

ENDANGER SAFETY OF A BUILDING, BUT

MAY CREATE AN IMPRESSION OF FAULTY

WORK OR MAY GIVE A FEELING OF

INSTABILITY.

ORIGIN OF CRACKS

CRACKS MIGHT DEVELOP DUE TO -

1.DETERIORATION OF CONCRETE OR

CORROSION OF REBARS DUE TO POOR

CONSTRUCTION OR INAPPROPRIATE

SELECTION OF CONSTITUENT MATERIALS.

2..TEMPERATURE AND SHRINKAGE EFFECTS.

3. SETTLEMENT OF SUPPORTS.

4. NATURAL HAZARDS; ETC.

STRUCTURAL CRACKS

IN STRCTURAL MEMBERS LIKE BEAM, ,COLUMNS

AND SLABS

FLEXURAL CRACKS IN BEAM

OCCURE AT THE MAXIMUM MOMENT REGION

THE SECTION CAPACITY TO RESIST THE MOMENT

OF RESISTANCE IS LESS

THE REINFORCEMENT IS IN ADEQUATE

SECTION PROVIDED MAY NOT BE SUFFICIENT

BEAM JUNCTION WITH CONTINUITY

CHARACTERSTICS

OCCURS WHEN THERE IS FLEXURAL

STRENGTH DEFICIENCY

MAXIMUM WIDTH AT TENSION FACE

CONVERGES TOWARDS OTHER FACE

OCCURS EITHER SINGLY OR IN GROUP

EFFECTS

AFFECTS STRUCTURAL SOUNDNESS

ATTENDED TO AS EARLY AS POSSIBLE

SHEAR FLEXURE CRACKS IN

BEAM

COMBINATION OF SHEAR AND

MOMENT

DEFICIENCY OF SHEAR AND

MOMENT CAPACITY

CHARACTERSTICS

OCCURS WHEN THERE IS SHEAR ST.

DEFICIENCY

OCCURS IN MAXIMUM SHEAR REGION

MAXIMUM WIDTH AT MID-DEPTH

CONVERGES TOWARDS TOP/BOTTOM

OCCURS EITHER SINGLY OR IN GROUP

EFFECTS

AFFECTS STRUCTURAL SOUNDNESS

NEEDS TO BE ATTENDED TO AS EARLY

AS POSSIBLE

TORSIONAL CRACK IN BEAM

INADEQUACY TO RESIST TORSION

BOND SLIP CRACK IN BEAMS

DUE TO ABRUPT CURTAILMENT OF

REINFORCEMENTS

INADEQUATE BOND

SLIPPING OF BARS

CHARACTERSTICS

OCCURS WHEN THERE IS TORSIONAL

STRENGTH DEFICIENCY

UNIFORM WIDTH THROUGHOUT

OCCURS IN THE FORM OF A SPIRAL

OCCURS SINGLY

EFFECTS

AFFECTS STRUCTURAL SOUNDNESS

NEEDS TO BE ATTENDED TO

IMMEDIATELY

DISTURBACE CRACKS IN BEAMS

CONSTRUCTIONAL PRACTICES

REMOVAL/STRIPPING OF

FORMWORK/SHUTTERING

SUPPORTING THE MEMBERS

TENSION CRACKS IN TIE BEAMS

IN ADEQUATE REINFORCEMENTS TO

RESIST TENSION

POOR QUALITY OF CONCRETE

HORIZONTAL CRACKS IN COLUMNS

CORROSION OF REINFORCEMENTS

COLUMN SECTION NOT DESIGNED

FOR MOMENT

DIAGONAL CRACKS IN COLUMNS

LATERAL FORCES NOT CONSIDERED

SECTON NOT ADEQUATE TO RESIST

AXIAL LOAD CARRYING CAPACITY

CORROSION/BOND CRACK IN COLUMNS

CORROSION OF REINFORCEMENTS

COVER NOT ADEQUATE

QUALITY OF CONCRETE

FLEXURE CRACKS IN SLABS

DEFICIENCY IN DESIGN

UNDER ASSESSMENT OF LOADING

OVER LOADING OF SECTION

POOR CONCRETE QUALITY

TOP FLEXURE CRACKS IN SLAB

MAIN REINFORCMENT INADEQUATE

DISTRIBUTION OF REINFORCEMENTS

NOT CONTINUOUS

SHRINKAGE CRACKS IN CANTILEVER

SLAB

W/C RATIO HIGH IN CONCRETE

IMPROPER CURING

NO RESTRAINTS AT CORNERS

CONSTRUCTION JOINT CRACKS IN

BEAMS

CRACKS DUE TO SETTLEMENT OF

FOUNDATION

DIRECTION OF CONCRETING

NON STRUCTURAL CRACKS

PLASTIC SETTLEMENT

PLASTIC SHRINKAGE

EARLY THERMAL CONTRACTION

LONG TERM DRYING SHRINKAGE

CRAZING

DUE TO CORROSION OF CONCRETE

DUE TO ALKALI- AGGREGATE REACTION

SULPHATE ATTACK

DUE TO CORROSION OF STEEL

PLASTIC SETTLEMENT

PLASTIC SETTLEMENT

PROBABLE AREA

OVER REINFORCEMENT, ARCHING, CHANGE

OF DEPTH

PROBABLE LOCATIONS

DEEP SECTIONS, TOP OF COLUMNS/

TROUGHS

CAUSE

EXCESS BLEEDING

RAPID EARLY DRYING

REMEDY

REDUCE BLEEDING

REVERBERATE MILDLY

TIME OF APPEARANCE

TEN MIN. TO THREE HOURS

PLASTIC SHRINKAGE

PROBABLE AREA

RANDOM OVER REINFORCEMENT MESH,

DIAGONAL, NORMAL TO WIND DIRECTION

PROBABLE LOCATIONS

RCC SLABS

CAUSE

RAPID EARLY DRYING

LOW BLEEDING AND FAST SURFACE

EVAPORATION

REMEDY

IMPROVE EARLY CURING AND TROWEL

TIME OF APPEARANCE

THIRTY MIN. TO SIX HOURS

PLASTIC SHRINKAGE

EARLY THERMAL EXPANSION

AND CONTRACTION

PROBABLE AREA

EXTERNAL/ INTERNAL RESTRAINT

PROBABLE LOCATIONS

THICK WALLS, THICK SLABS

CAUSE

EXCESS HEAT GENERATION, EXCESS TEMP.

GRADIENT

RAPID COOLING, CURING BY COLD WATER

REMEDY

REDUCE HEAT AND/OR INSULATE, COOL

CONCRETE, REDUCE SPACING OF STEEL

TIME OF APPEARANCE

ONE DAY TO 2-3 WEEKS

LONG TERM DRYING SHRINKAGE

PROBABLE AREA

PROBABLE LOCATIONS

THIN WALLS, THIN SLABS

CAUSE

ABSENCE OF MOVEMENT, INEFFICIENT

JOINTS

EXCESS SHRINKAGE, INEFFICIENT CURING

REMEDY

REDUCE W/C RATIO, IMPROVE CURING

TIME OF APPEARANCE

SEVERAL WEEKS OR MONTHS

CRAZING

PROBABLE AREA

AGAINST FORMWORK

PROBABLE LOCATIONS

FAIR FACED SLABS

CAUSE

IMPERMEABLE FORMWORK, OVER

TROWELLING

RICH MIXES, POOR CURING

REMEDY

IMPROVE CURING AND FINISHING

TIME OF APPEARANCE

1-7 DAYS, SOMETIMES LATER

CORROSION OF CONCRETE

PROBABLE AREA

NATURAL AND SLOW, FAST IF CACL IS PRESENT

PROBABLE LOCATIONS

ALTERNATE DRYING AND WETTING, HUMIDITY

CAUSE

LACK OF COVER AND DAMPNESS, CARBONATION,

CHLORIDES

POOR QUALITY CONCRETE

REMEDY

USE DENSE CONCRETE (PORTLAND BLAST FURNACE

SLAG CEMENT), DEHUMIDIFY, CATHODE PROTECTION

TIME OF APPEARANCE

MORE THAN TWO YEARS

CORROSION OF CONCRETE

CARBONATION

THE DIFFUSION OF ATMOSPHERIC CO

2

IN THE

GASEOUS PHASE OF THE CONCRETE PORES

AND REACTS IN FOLLOWING TWO WAYS.

THE DISSOLUTION OF SOLID CA(OH)

2

FROM

CEMENT GEL INTO THE PORE WATER AND

REACTION OF DISSOLVED CO

2

WITH

DISSOLVED CA(OH)

2

IN THE PORE WATER.

THE REACTION OF DISSOLVED CO2 WITH

CSH.

CORROSION OF CONCRETE-

CARBONATION

Ca(OH)

2

+ 2CO

3

> CaCO

+ 2H

2

O

3CaO-2SiO

2

-3H

2

O + 3CO

2

> 3CaCO

-2SiO

2

-3H

2

O

- The pH-value decreases to less than 9,

which normally is insufficient to protect

the reinforcement against corrosion.

CORROSION OF CONCRETE-

CARBONATION

X= K T

- Where X is measured in mm and T in years

- K is function of concrete strength

- Above relation is for RELATIVE HUMIDITY 50%

CORROSION OF CONCRETE-

CARBONATION

CORROSION OF CONCRETE-

CHLORIDES

MIXING WATER

AGGREGATES

ADMIXTURES (ACCELERATORS)

CURING WATER

SURROUNDING SOIL

SEA WATER

CORROSION OF CONCRETE-

CRITICAL CHLORIDE

CONTENT

ALKALI AGGREGATE REACTION

PROBABLE LOCATIONS

DAMP AREA, SHOWS GEL TYPE OR DRIED

RESIN TYPE DEPOSIT IN CRACKS

CAUSE

REACTIVE SILICATES AND CARBONATES IN

AGGREGATES REACTING WITH ALKALI IN

CEMENT

REMEDY

USE PROPER AGGREGATES, USE PORTLAND

BLAST FURNACE SLAG CEMENT, KEEP

WATER AWAY

TIME OF APPEARANCE

MORE THAN FIVE YEARS

ALKALI AGGREGATE REACTION

SULPHATE ATTACK

SULPHATE SALTS FROM SURROUNDING SOIL

REACT WITH C3A . NO DEPOSITS LIKE THOSE IN

ALKALI- AGGREGATE REACTION

USE LOW C3A CEMENT, PORTLAND BLAST

FURNACE SLAG CEMENT

TIME OF APPEARANCE

-AFTER TWO YEARS

SULPHATE ATTACK

HIGH CONCENTRATIONS OF SULPHATE IONS

(SO

4

--) + CA(OH)

2

+ 2H

2

O ->

CASO

4

2H

2

O + 2OH- + EXPANSION

LOW SULPHATE ION CONCENTRATION

CALCIUM ALUMINATE HYDRATE + CASO

4

2H

2

O ->

3CAOAL

2

O

3

CASO

4

32H

2

O (ETTRINGITE)

+EXPANSION

MAGNESIUM AND AMMONIUM

SULPHATE(SERIOUS)

MGSO

4

REACTS WITH CALCIUM ALUMINATE

HYDRATE MGSO

4

+ CA(OH)

2

->

CASO

4

+ MG(OH)

2

+ VOLUME EXPANSION

CORROSION OF STEEL

ELECTROCHEMICAL CORROSION

GALVANIC CORROSION

ATMOSPHERIC CORROSION

CORROSION OF STEEL

Fe

Fe(OH)

2

Fe

3

O

4

Fe(OH)

3

Fe(OH).3nH

2

O

1 2 3 4 5 6

Volume

ELECTROCHEMICAL

CORROSION

Iron reacts as

Fe >> Fe

++

+ 2e

-

(Anode process)

Water takes oxygen from Atmosphere

2H

2

O + O

2

+ 4e

-

>>> 4 OH

-

(Cathode Process)

Fe

++

and OH

-

creates Fe(OH)

2

Fe(OH)

2

is not stable, oxidises to form Fe(OH)

3

Takes water to form Fe(OH)

3

nH

2

O (Rust)

ELECTROCHEMICAL

CORROSION

GALVANIC CORROSION

MORE ANODIC METAL RELEASES IONS WHEN

TWO DIFFERENT METALS ARE IN ELECTRICAL

CONTACT IN MOIST ATMOSPHERE

ATMOSPHERIC CORROSION

HIGH HUMIDITY LEVEL ( > 65 %)

THE CORROSION VELOCITY IS DOUBLED FOR

EVERY 10

O

C INCREASE IN TEMPERATURE.

AIR POLLUTION

SO

2

IN AIR

THE SULPHUR DIOXIDE CREATES H

2

SO

3

WHICH IS OXIDIZED TO SULPHURIC ACID

(H

2

SO

4

) WHICH INCREASES THE

CORROSION VELOCITY.

TIMING OF CRACK

FORMATION

BEFORE SETTING

PLASTIC

SHRINKAGE*

PLASTIC

SETTLEMENT*

DIFFERENTIAL

SETTLEMENT OF

SUPPORTS

HARDENING PHASE

CONSTRAINT TO

EARLY THERMAL

MOVEMENT*

CONSTRAINT TO

EARLY DRYING

SHRINKAGE*

DIFFERENTIAL

SETTLEMENT OF

SUPPORTS

* Non- Structural

TIMING OF CRACK

FORMATION

IN HARDENED STATE

OVERLOADING/ UNDER

DESIGN

INADEQUATE CONST./

DETAILING

DIFFERENTIAL

SETTLEMENT

SULPHATE ATTACK*

RUSTING

CHLORIDE ATTACK

CARBONATION

SIMPLE OXIDATION

ALKALI AGGREGATE

REACTION

HANDLING CRACKS IN

PRE-CAST MEMBERS

CRAZING

WEATHERING CRACKS

LONG TERM DRYING AND

SHRINKAGE*

ALLOWABLE CRACK WIDTHS

THE MINIMUIM WIDTH OF CRACK THAT CAN BE

SEEN BY NAKED EYE IS GENERALY ABOUT 1.3 MM

INTERIOR MEMBERS 0.35 MM

EXTERIOR MEMBERS 0.25 MM

(Normal Exposure)

EXTERIOR MEMBERS 0.15 MM

(Aggressive Exposure)

LIMIT STATE OF CRACKING, AS PER IS 456 : 2000

NOT TO AFFECT ADVERSELY THE APPEARANCE

AND DURABILITY OF STRUCTURES.

ALLOWABLE CRACK WIDTHS CONTD;

CODE SPECIFIES MAX ALLOWABLE

WIDTH AS 0. 3 MM IN GENERAL

DEPENDS ON TYPE OF STRUCTURE AND

EXPOSURE CONDITIONS

ON AGGRESSIVE ENVIRONMENT THE

COMPUTED CRACK WIDTH ON THE

SURFACE NEAREST TO REINFORCEMENT

BARS SHOULD NOT EXCEED 0.1MM

IT IS DESIRABLE TO CONTROL CRACKS

THROUGH GOOD DETAILING PRACTICES,

RATHER THAN RELY ON COMPUTATIONS

FOR CRACK WIDTHS

MEASUREMENT

MEASURING MAGNIFIER

CRACK SCOPE

DIGITAL CRACK GAUGE

LOMARO MICROSCOPE

Measuring Magnifier - Proceq

CRACKSCOPE - GERMANN INSTRUMENTS

DIGITAL CRACK GUAGE - ELE

LOMARO MICROSCOPE- ELE

GENERAL MEASURES FOR

PREVENTION OF CRACKS

BROADLY CASSIFIED UNDER THE

FOLLOWING HEADS

CHOICE OF MATERIAL

SPECIFICATION FOR CONCRETE

DESIGN OF STRUCTURES

CONSTRUCTION TECHNIQUES AND

PRACTICES

CHOICE OF MATERIALS

FINE AGGREGATE

AVOID USE OF TOO FINE OR

CONTAINS TOO MUCH OF CLAY OR

SILT AND NOT WELL GRADED.

MAX CLA AND SILT LIMITTED TO

3 %

CHOICE OF MATERIALS CONTD.

COARSE AGGREGATE

WELL GRADED TO OBTAIN DENSE

CONCRETE

MAX SIZE SHOULD BE LARGEST POSSIBLE

CONSISTENT WITH THE JOB

REQUIREMENT

POROUS AND HAVING HIGH SHRINKAGE

PROPERTIES SHOULD BE AVOIDED

CHOICE OF MATERIALS CONTD.

CEMENT

IF USE ALKALI REACTIVE AGGREGATE IS

UNAVOIDABLE, ALKALI CONTENT OF

CEMENT SHOULD NOT EXCEED 0.6 %

USE OF POZZOLANA SHOULD BE MADE TO

CHECK ALKAI-AGGREGATE REACTION

LOW HEAT CEMENT SHOULD BE USED IN

MASSIVE STRUCTURES TO LIMIT HEAT OF

HYDRATION

SPECIFICATION FOR

CONCRETE

MIX SHOULD NOT BE RICHER THAN

WHAT IS REQUIRED FROM

STRENGTH CONSIDERATION

AIM SHOULD BE TO OBTAIN STRONG

AND DURABLE CONCRETE BY

CAREFUL MIX DESIGN, THOROUGH

MIXING , POROPER COMPACTION

AND ADEQUATE CURING

QTY. OF WATER USED SHOULD BE

MINIMUM CONSISTENT WITH

REQUIREMENTS FOR PROPER

LAYING AND COMPACTION. THIS IS

THE ONE OF THE MOST IMPORTANT

SINGLE FACTOR RESPONSIBLE FOR

SHRINKAGE AND CONSEQUENT

CRACKS IN CONCRETE

STRUCTURAL DESIGN CONTD.

IN EXPANSIVE CLAYEY SOIL

MOVEMENT DUE TO ALTERNATE

WETTING AND DRYING AND

CONSEQUENT SWELLING AND

SHRINKAGE SHOULD BE TAKEN

CARE BY

TAKING THE FOUNDATION DEEP

AND USING MOORUM, GRANULAR

SOIL OR QUARRY DUST IN FILLING

IN FOUNDATION TRENCHES AND

PLINTH

USING UNDER REAMED PILES

CONSTRUCTION PRACTICES

AND TECHIQUES

IN CASE CANTILEVER BEAMS AND

SLABS, REMOVAL OF CENTERING

AND IMPOSITION OF LOAD SHOULD

BE DIFFERED AT LEAST ONE MONTH

SO THAT SUFFICIENT STRENGTH IS

ATTAINED BEFORE IT BEARS THE

LOAD

CONSTRUCTION PRACTICES AND TECHIQUES CONTD.

AVOID CONCRETING IF IT IS VERY HOT, DRY

AND WINDY. IF UNAVOIDABLE, SHOULD BE

DONE DURING EARLY HOURS OF THE DAY.

PRECAUTION SHOULD BE TAKEN TO KEEP DOWN

THE TEMPERATURE OF FRESH CONCRETE AND

TO PREVENT QUICK DRYING.

PART OF MIXING WATER SHALL BE REPLACED

WITH ICE

RE-TROWELLING THE CONCRETE SURFACE

SLIGHTLY, BEFORE ITS INITIAL SETTING, TO

MITIGATE PLASTIC AND SHRINKAGE CRACKS

PROVISION OF ADEQUATE TEMPERATURE

REINFORCEMENTS TO CONTROL THE CRACK DUE

TO SHRINKAGE AS WELL AS TEMP. EFFECT

ENVIRONMENT

CONSTRUCTION IN COLD WEATHER

LESS LIABLE TO SHRINKAGE

CRACKING THAN THAT IN HOT

WEATHER

REPAIR PLAN

CRACKS

LIVE CRACKS

DORMANT CRACKS

REPAIR PLAN

OTHER DAMAGE

VOIDS, HOLLOWS AND HONEYCOMBS

SCALING DAMAGE

SPALLING DAMAGE

REPAIR PLAN

CARBONATED OR CHLORIDE CONTAMINATED

CONCRETE- REPAIR PLAN

LIVE CRACKS

CAULKING

ELASTOMERIC SEALER

PRESSURE INJECTION WITH FLEXIBLE FILLER

EPOXY GROUTING

CONBEXTRA UR63 BY FOSROC

JACKETING

STRAPPING OR OVERLAYING

STRENGTHENING

STEEL PLATE, POST TENSIONING, STITCHING

ETC

DORMANT CRACKS

CAULKING

CEMENT MORTAR

PRESSURE INJECTION WITH RIGID FILLER

CONBEXTRA EPLV BY FOSROC

COATING

BITUMINOUS, TAR

OVERLAYS

ASPHALT WITH MEMBRANE

GRINDING AND OVERLAY

LATEX MODIFIED CONCRETE, HIGHLY

DENSE CONCRETE

DRY PACK

DORMANT CRACKS ( CONT.)

SHOTCRETE/ GUNITE

PATCHING

CEMENT MORTAR, EPOXY OR

POLYMER CONCRETE

JACKETING

STEEL ROD

STRENGTHENING

POST TENSIONING, STITCHING ETC

CRACK REPAIR PLAN

CRACK WITH STRUCTURAL

IMPLICATION

RISK OF

CORROSION

INJECT WITH

CEMENT GROUT, IF CRACK > .5MM

EPOXY RESIGN, IF CRACK < .5MM

LEAKINESS

NO INJECTION

CRACKS WITH MINOR MOVEMENTS

INJECT WITH

POLYURETHANE RESIN

ACRYLIC RESIN

POLYMER IMPREGNATION

SURFACE TREATMENT

OVERLAYS

YES

No

Yes

Yes

Yes

No

No

CEMENT PRESSURE

GROUTING

MATERIAL

ORDINARY PORTLAND CEMENT AS PER

IS 269

ADMIXTURE WITH APPROVAL OF DIV.

ENGINEER

PROPORTION

W /C RATIO 0.4 TO 0.5

PRESSURE FOR GROUTING

3 TO 4 KG PER SQ CM

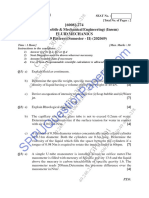

CEMENT PRESSURE GROUTING

EQUIPMENT

DRILLING EQUIPMENT FOR HOLES UPTO

25MM DIA

GROUT INJECTING MACHINE

AIR COMPRESSOR OF 3 TO 4 CUBIC M/MIN

AND PRESSURE 3-4 KG/SQ CM

12- 20 MM DIA GI PIPES WITH COUPLERS

a

a

a a a

a = 500 to /50 mm

- HOLE OF 25 NN D!A.

- G! P!PE P!ECES 12 / 20 NN D!A X 200 NN W!TH THREADED END.

- SEAL ALL CRACKS AND ANNULAR SPACE AROUND G! P!PES.

- FLUSH ALL HOLES W!TH CONPRESSED A!R.

- GROUT START!NG W!TH BOTTON NOST HOLE.

- CURE FOR 1+ DAYS.

- USE GROUT N!XTURE W!TH!N 15 N!NUTES.

- CLEAN GROUT EOU!PNENT THOROUGHLY.

CENENT GROUT!NG

EPOXY GROUTING

EPOXY SYSTEM

RESIN AND HARDENER ( THINNER IF NECESSARY)

FILLER ( DRY SILICA FLOUR) FOR WIDE CRACKS

MANUFACTURERS SPECIFICATION

CONDITION OF APPLICATION

PROPORTIONS

POT LIFE

APPLICATION PROCEDURE

EPOXY GROUTING

BASIC REQUIREMENTS

SUFFICIENT POT LIFE ( 60 MIN AT 30

0

C)

COMPRESSIVE STRENGTH OF EPOXY ( NOT LESS

THAN CONCRETE)

SHEAR STRENGTH ( NOT LESS THAN 100 KG/CM

2

)

VISCOSITY - DEPENDING ON CRACK WIDTH

STABLE SYSTEM ( CLIMATIC CONDITION )

NON SUSCEPTIBLE TO FIRE / EXPLOSION DURING

PROCESS OF INJECTION

EPOXY GROUTING

EQUIPMENTS FOR EPOXY GROUTING

DRILLING EQUIPMENT (PNEUMATIC OR

ELECTRICAL)

PRESSURE INJECTING EQUIPMENT

AIR COMPRESSOR 3-4 M

3

/ MIN, 10 KG / CM

2

POLYTHENE / METAL PIPE PIECES 6-9 MM

DIA.

POLYTHENE PLASTIC CONTAINER

PORTABLE GENERATOR

EPOXY GROUTING

AREA TO BE GROUTED SHOULD BE DRY, CLEAN WITH AIR

JET

CRACK TO BE PREFERABLY DRY

ALL CRACKS TO BE CUT OPEN TO A V GROOVE, 10MM DEEP

DRILLING , CLEANING LOOSE MATERIAL AND SEALING THE

GROOVE

HOLE OF 7-10MM DIA DRILLED AND GROUT NIPPLES FIXED.

FULL PENETRATION DOUBTFUL IF CRACKS > 0.6 M DEEP

PORTS ON BOTH SIDE

MEMBERS < 0.3 M , PORTS ON ONE SIDE ONLY

FIRST / LAST PORT TO BE AT OR NEAR BOTTOM / TOP

EPOXY GROUTING

PRECAUTIONS

FOLLOW MANUFACTURES INSTRUCTIONS

DIRECT SKIN CONTACT SHOULD BE AVOIDED

THE GREASE GUN SYRINGE SHOULD BE

WASHED WITH ACETONE IMMEDIATELY AFTER

USE.

REPAIR OF CARBONATED/CHLORIDE

CONTAMINATED CONCRETE

BREAK AFFECTED CONCRETE

FOSROC PRODUCTS AND METHOD

USE NITOPRIME ZINCRICH PRIMER OVER

REINFORCEMENT

USE NITOBOND AR (NITOBOND EP) AS

BONDING AGENT

REPAIR WITH RENDEROC TG POLYMER

MODIFIED REPAIR MORTAR

APPLY NITOCOTE DEKGUARD PRIMER

APPLY TWO COATS OF NITOCOTE DEKGUARD

PIGMENTED TOPCOAT

CONCLUSION -

THE INDIVIDUAL CRACKS IN R.C. MEMBERS ARE

UNIQUE BY THEMSELVES.

THEY ARE VERSATILE DIAGNOSTIC DEVICES, CLEARLY

INDICATING THE SPECIFIC PROBLEMS IN THE

CONCERNED R.C. MEMBERS. IN ADDITION, THEY ALSO

INDICATE THE DEGREE OF SERIOUSNESS OF THE

PROBLEM.

THE CRACKS THROW LIGHT ON THE

DISCIPLINE IN THE ASSOCIATED STRUCTURAL DESIGNS

AND CONSTRUCTION QUALITY.

THE CORRECTIVE MEASURES TO BE IMPLEMENTED

ARE CLEARLY INDICATED BY THESE CRACKS.

*****

You might also like

- Prevention & Repair of Cracks in Concrete StructuresDocument98 pagesPrevention & Repair of Cracks in Concrete StructuresDeepum HalloomanNo ratings yet

- Structures: Prevention & Repair of Cracks in ConcreteDocument148 pagesStructures: Prevention & Repair of Cracks in ConcreteDeepum HalloomanNo ratings yet

- Che 431 Group 7Document15 pagesChe 431 Group 7Stephen JagunNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Causes and Prevention of Cracks in BuildingsDocument41 pagesCauses and Prevention of Cracks in BuildingsTim PassNo ratings yet

- Hot Cracking: Craking in Austenitic SsDocument36 pagesHot Cracking: Craking in Austenitic SsMidhun K ChandraboseNo ratings yet

- Corrosion PresentationDocument22 pagesCorrosion PresentationIshu Attri100% (1)

- Steel Making Axle Forging Heat Treatment MachiningDocument41 pagesSteel Making Axle Forging Heat Treatment MachiningAsif Ali PCNo ratings yet

- Abdulrhman Mohamd Rock MassDocument56 pagesAbdulrhman Mohamd Rock Massmina redaNo ratings yet

- Corrosion ProcessDocument42 pagesCorrosion Processmujeebmehar100% (2)

- Applied Met - Fartiliser IndustryDocument77 pagesApplied Met - Fartiliser IndustryRajneesh PatelNo ratings yet

- Corrosion PresentationDocument22 pagesCorrosion PresentationIshu AttriNo ratings yet

- Causes and Prevention of Cracks in BuildingDocument47 pagesCauses and Prevention of Cracks in BuildingvishalgoreNo ratings yet

- Soil NailingDocument10 pagesSoil NailingSamirsinh ParmarNo ratings yet

- Soil NailingDocument10 pagesSoil NailingSamirsinh ParmarNo ratings yet

- Chloride Induced Corrosion CorrosionDocument32 pagesChloride Induced Corrosion Corrosionapoorv mishraNo ratings yet

- Corrosion Presentation 1Document27 pagesCorrosion Presentation 1Ishu AttriNo ratings yet

- Temporary StructuresDocument11 pagesTemporary StructuresSuraj WankhedeNo ratings yet

- Bridge Foundations: Vineet Gupta Senior Prof Bridge - IDocument175 pagesBridge Foundations: Vineet Gupta Senior Prof Bridge - Isajid alam100% (1)

- Presentation On HardwareDocument48 pagesPresentation On HardwareNaresh kumarNo ratings yet

- Piers and AbutmentsDocument19 pagesPiers and AbutmentsHAyath KNo ratings yet

- Strat 7Document33 pagesStrat 7abdounouNo ratings yet

- A Simple View On A Complex MatterDocument18 pagesA Simple View On A Complex MatterFadlanbunglonNo ratings yet

- Concrete Amran.Document45 pagesConcrete Amran.SHAHUL HAMEEDNo ratings yet

- Amalgm 090714061748 Phpapp02Document91 pagesAmalgm 090714061748 Phpapp02Hafsa AzharNo ratings yet

- AmalgamDocument91 pagesAmalgamsunithabanavathNo ratings yet

- How To Select The Right Paint SystemDocument33 pagesHow To Select The Right Paint SystemFernandoNo ratings yet

- What Is Sulfate AttackDocument17 pagesWhat Is Sulfate AttackForood TorabianNo ratings yet

- IDOT 2020 Bridge Design Updates - Structure Coating PolicyDocument74 pagesIDOT 2020 Bridge Design Updates - Structure Coating PolicyJoe AndrewsNo ratings yet

- Types of CorrosionDocument53 pagesTypes of CorrosionFelix Julio Céspedes Soto100% (3)

- 00.1.corrosion Control Jetty PileDocument48 pages00.1.corrosion Control Jetty PileSyafrudin MegnumzNo ratings yet

- Light Weight concrete-BTM IVDocument21 pagesLight Weight concrete-BTM IVvedangidNo ratings yet

- Ce12-Some Problems Encounter in Construction Site Align To..Document48 pagesCe12-Some Problems Encounter in Construction Site Align To..Jovin ManarinNo ratings yet

- MCE328 - Pipeline CorrosionDocument74 pagesMCE328 - Pipeline CorrosionM PNo ratings yet

- Alloying in Steel: Alloy Steel High Strength, Low Alloy (Hsla)Document12 pagesAlloying in Steel: Alloy Steel High Strength, Low Alloy (Hsla)Dhesa HidayatNo ratings yet

- CladDocument27 pagesCladbaluNo ratings yet

- Hull Structures - For SessionDocument111 pagesHull Structures - For Sessionsumit kumarNo ratings yet

- Inaugural AddrssDocument67 pagesInaugural AddrssMurthy BabuNo ratings yet

- 7 - Material Selection For Urea ServiceDocument17 pages7 - Material Selection For Urea ServicedennykvgNo ratings yet

- Corrosive Damage in Metals and Its PreventionDocument36 pagesCorrosive Damage in Metals and Its Preventionsamurai7_7783% (6)

- 4.durability and Concrete CoverDocument46 pages4.durability and Concrete CoverNH PNo ratings yet

- Types of Corrosion: Dr. Hamdy A. KandilDocument53 pagesTypes of Corrosion: Dr. Hamdy A. KandilAmyNo ratings yet

- CFRD 05 - BayardoDocument23 pagesCFRD 05 - BayardodiegofernandodiazsepNo ratings yet

- Stainless Steel Storage & Handling IN WorkshopDocument50 pagesStainless Steel Storage & Handling IN Workshopyashaswi kumarNo ratings yet

- Welding Metallurgy and Weldability of MetalsDocument134 pagesWelding Metallurgy and Weldability of MetalsAkash Kumar DevNo ratings yet

- CIV5887 Chemical AttackDocument59 pagesCIV5887 Chemical AttackgoogkitNo ratings yet

- Controlled BLASTINGDocument11 pagesControlled BLASTINGABHIJEET ROUTNo ratings yet

- Crevice Corrosion PDFDocument3 pagesCrevice Corrosion PDFPDF_user_blue0% (1)

- Ground Improvement TechniquesDocument14 pagesGround Improvement Techniqueskrunalshah1987No ratings yet

- 5 - Durability and Concrete Cover - 2020 PDFDocument46 pages5 - Durability and Concrete Cover - 2020 PDFIrma MedomNo ratings yet

- Chapter 3. Corrosion of MetalsDocument48 pagesChapter 3. Corrosion of MetalsEjaj Siddiqui100% (2)

- Rusting of Reinforcemen T Bars: A Challenge To OvercomeDocument13 pagesRusting of Reinforcemen T Bars: A Challenge To OvercomeOchini ChandrasenaNo ratings yet

- RCC Structures in Coastal AreasDocument4 pagesRCC Structures in Coastal AreasMahibul HasanNo ratings yet

- Fero-Cement As Bldg. Mat.Document30 pagesFero-Cement As Bldg. Mat.Adarsh PatilNo ratings yet

- Underwater Inspection of Bridges Illustrated With Case StudyDocument35 pagesUnderwater Inspection of Bridges Illustrated With Case StudysuhailenggNo ratings yet

- Cathodic PresentDocument51 pagesCathodic Presentravi chandra mavuri100% (1)

- Name: Utkarsha Bhujbal. Roll No: 06 Sem: Iv Topic: Soil MechanicsDocument17 pagesName: Utkarsha Bhujbal. Roll No: 06 Sem: Iv Topic: Soil MechanicsNikhilNo ratings yet

- The Story of A Luxury Villa at Pattom, Trivandrum, As Told by Icloud HomesDocument26 pagesThe Story of A Luxury Villa at Pattom, Trivandrum, As Told by Icloud HomesvinujohnpanickerNo ratings yet

- Sl. No. Particulars Cost % of Cost Summary of CostDocument1 pageSl. No. Particulars Cost % of Cost Summary of CostvinujohnpanickerNo ratings yet

- Ariyoor BridgeDocument1 pageAriyoor BridgevinujohnpanickerNo ratings yet

- Price: Public Works DepartmentDocument1 pagePrice: Public Works DepartmentvinujohnpanickerNo ratings yet

- Schedule of BTech Admission 2018Document3 pagesSchedule of BTech Admission 2018vinujohnpanickerNo ratings yet

- Form For Nomination / Cancellation of Nomination: (To Be Filled in by Individual Applying Singly or Jointly)Document2 pagesForm For Nomination / Cancellation of Nomination: (To Be Filled in by Individual Applying Singly or Jointly)vinujohnpanickerNo ratings yet

- Regdoc 0 TRSCDocument193 pagesRegdoc 0 TRSCAnil MehtaNo ratings yet

- Hydraulic Calculation Ariyoor BridgeDocument3 pagesHydraulic Calculation Ariyoor Bridgevinujohnpanicker100% (1)

- Chainage DetailsDocument3 pagesChainage DetailsvinujohnpanickerNo ratings yet

- How To Make Adobe Acrobat PDF Files From Autocad Drawings and MW Word Files, and Excel FilesDocument18 pagesHow To Make Adobe Acrobat PDF Files From Autocad Drawings and MW Word Files, and Excel FilesvinujohnpanickerNo ratings yet

- Existing Road OVERLAY & WIDENING KM 60+000-km 70+000 Reconstruction OVERLAY & WIDENING KM 75+000 - KM 82+173Document1 pageExisting Road OVERLAY & WIDENING KM 60+000-km 70+000 Reconstruction OVERLAY & WIDENING KM 75+000 - KM 82+173vinujohnpanickerNo ratings yet

- Annexure V 16 - 17Document3 pagesAnnexure V 16 - 17vinujohnpanickerNo ratings yet

- Long Span Bridges BrochureDocument2 pagesLong Span Bridges BrochurepeterNo ratings yet

- ASD - Webinar Foundations of Buildings May.20 ASDDocument166 pagesASD - Webinar Foundations of Buildings May.20 ASDvinujohnpanickerNo ratings yet

- ASD - Webinar Foundations of Buildings May.20 ASDDocument166 pagesASD - Webinar Foundations of Buildings May.20 ASDvinujohnpanickerNo ratings yet

- LUSAS RC Frame Design OptionDocument2 pagesLUSAS RC Frame Design OptionvinujohnpanickerNo ratings yet

- Machamthode Hydraulic CalculationDocument3 pagesMachamthode Hydraulic CalculationvinujohnpanickerNo ratings yet

- Schedule of Slabs at Level - 4500: Ajay Kadam AssociatesDocument1 pageSchedule of Slabs at Level - 4500: Ajay Kadam AssociatesvinujohnpanickerNo ratings yet

- CE 382 L6 - Shear and Moment Diagrams PDFDocument42 pagesCE 382 L6 - Shear and Moment Diagrams PDFparamarthasom1974No ratings yet

- Motivation LetterDocument1 pageMotivation Lettervinujohnpanicker100% (1)

- P & P 2 - Excel SheetDocument18 pagesP & P 2 - Excel SheetvinujohnpanickerNo ratings yet

- Schedule of Beams at Level - 4500: Ajay Kadam AssociatesDocument1 pageSchedule of Beams at Level - 4500: Ajay Kadam AssociatesvinujohnpanickerNo ratings yet

- Motivation LetterDocument1 pageMotivation Lettervinujohnpanicker100% (1)

- Item Unit Qty Rate AmountDocument17 pagesItem Unit Qty Rate AmountvinujohnpanickerNo ratings yet

- How To Generate Your Own Column Interaction DiagramDocument81 pagesHow To Generate Your Own Column Interaction DiagramMarlo AristorenasNo ratings yet

- Cover Page - GFC A3 PDFDocument1 pageCover Page - GFC A3 PDFvinujohnpanickerNo ratings yet

- Receipt No Paid On Paid Amount Payment ModeDocument5 pagesReceipt No Paid On Paid Amount Payment ModevinujohnpanickerNo ratings yet

- Upgrading Punalur To Ponkunnam Road (SH 8) Package 8C: KM 60+000 (Placherry) To KM 82+173 (Ponkunnam) On Engineering, Procurement, Construction (Epc)Document1 pageUpgrading Punalur To Ponkunnam Road (SH 8) Package 8C: KM 60+000 (Placherry) To KM 82+173 (Ponkunnam) On Engineering, Procurement, Construction (Epc)vinujohnpanickerNo ratings yet

- Item Unit Qty Rate AmountDocument17 pagesItem Unit Qty Rate AmountvinujohnpanickerNo ratings yet

- 1278 - 2013 03 08 16 26 40 - 1362740200 PDFDocument198 pages1278 - 2013 03 08 16 26 40 - 1362740200 PDFvinujohnpanickerNo ratings yet

- IGBC Green Homes Ver 2 Precertification Preliminary Review - Shivram CHS LTD, MumbaiDocument29 pagesIGBC Green Homes Ver 2 Precertification Preliminary Review - Shivram CHS LTD, MumbaiaalekhchandanNo ratings yet

- Bearing CapacityDocument28 pagesBearing CapacityTejeshwini SNo ratings yet

- Slope Stability Analysis: 7.1 OverviewDocument6 pagesSlope Stability Analysis: 7.1 OverviewGustiTeguhNo ratings yet

- memoriaDeCalculoDeInst TermomecánicaDocument135 pagesmemoriaDeCalculoDeInst TermomecánicaESTUDIO GF INSTALACIONES S.R.LNo ratings yet

- Assignment OneDocument2 pagesAssignment OneARNo ratings yet

- Concrete TechnologyDocument16 pagesConcrete Technologysefatwrdk21No ratings yet

- FilesDocument104 pagesFilesjpantazis1975No ratings yet

- Cálculo HidraulicoDocument9 pagesCálculo HidraulicoTuco MlmNo ratings yet

- Orifice MeterDocument8 pagesOrifice MeterRanjith KrishnaaNo ratings yet

- M1A120014 - Pria Abdillah Hendra - Uts BingDocument9 pagesM1A120014 - Pria Abdillah Hendra - Uts BingPriaNo ratings yet

- Immediate Deflection in Concrete BeamsDocument11 pagesImmediate Deflection in Concrete BeamsSeifeldin Ali MarzoukNo ratings yet

- Astm-53-A-53m-07Document22 pagesAstm-53-A-53m-07Allen EspeletaNo ratings yet

- Geotechnical Engineering - Ii (Foundation Engineering) : Standard Penetration TestDocument14 pagesGeotechnical Engineering - Ii (Foundation Engineering) : Standard Penetration TestPascasio PascasioNo ratings yet

- Mechanics: by Dr. Sara Shah Department of OrthodonticsDocument11 pagesMechanics: by Dr. Sara Shah Department of OrthodonticsayeshaNo ratings yet

- Standard Specification: Tecnicas Reunidas, S.ADocument8 pagesStandard Specification: Tecnicas Reunidas, S.AaquilesanchezNo ratings yet

- International Airport at Hyderabad: Simplex Concrete Piles (India) LimitedDocument21 pagesInternational Airport at Hyderabad: Simplex Concrete Piles (India) LimitedKoshy ThankachenNo ratings yet

- Be - Mechanical Engineering - Semester 4 - 2023 - February - Fluid Mechanics FM Pattern 2019Document2 pagesBe - Mechanical Engineering - Semester 4 - 2023 - February - Fluid Mechanics FM Pattern 2019loharjay772No ratings yet

- Design of High Strength Concrete Using deDocument3 pagesDesign of High Strength Concrete Using deNabilah HashimNo ratings yet

- C45 Pb-44SMnPb28 - EN8M-F114SDocument7 pagesC45 Pb-44SMnPb28 - EN8M-F114Samh.fpdNo ratings yet

- UCE 806 Design of Hydraulic Structure: Course Objective: The Objective of This Subject Is To Focus OnDocument23 pagesUCE 806 Design of Hydraulic Structure: Course Objective: The Objective of This Subject Is To Focus OnBhabani Shankar DasNo ratings yet

- Ground Improvement Using Stone Column: Rohit Kumar PGRPE 2014Document20 pagesGround Improvement Using Stone Column: Rohit Kumar PGRPE 2014pranja9999No ratings yet

- Cold Form Inspector ChecklistDocument16 pagesCold Form Inspector ChecklistbooboosdadNo ratings yet

- Chapter 2 B 1 Arch ButressDocument19 pagesChapter 2 B 1 Arch ButressYasin Mohamed BulqaazNo ratings yet

- Tempered Glass: MACARAMPAT, Johainah S. Bsa 4Document17 pagesTempered Glass: MACARAMPAT, Johainah S. Bsa 4Kristine JadeNo ratings yet

- Seismic Analysis of Concrete Gravity Dam (Using ABAQUS) : Course Project ReportDocument26 pagesSeismic Analysis of Concrete Gravity Dam (Using ABAQUS) : Course Project ReportKalyaniNo ratings yet

- KBR InsulationDocument8 pagesKBR InsulationkennethNo ratings yet

- Tugas Daftar PustakaDocument19 pagesTugas Daftar PustakaKsatria ArfaNo ratings yet

- NSCP Timber Beam DesignDocument27 pagesNSCP Timber Beam DesignDiztrict GarageNo ratings yet

- Engineering Failure Analysis: SciencedirectDocument17 pagesEngineering Failure Analysis: SciencedirectMohammad Ali RashidNo ratings yet

- Slab/Mat Panels StaticDocument13 pagesSlab/Mat Panels StaticDavid JohnNo ratings yet