Professional Documents

Culture Documents

Pile Structural Capacity

Uploaded by

jcc_vincentCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Structural Capacity

Uploaded by

jcc_vincentCopyright:

Available Formats

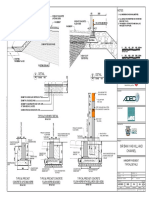

PRECAST RC SQUARE PILE

The aim of pile design is to provide a footing which will safely support the superstructure over its design life. The footing shall be durable, and of adequate strength and the footing performance shall be compatible with the superstructure so that it remains serviceable and can perform its intended function. Piles are considered of displacement type and they shall be designed for both structural and geotechnical strength requirements. As geotechnical design involves pile - soil interaction the capacity then shall be usually assessed vide static pile load testing. Once the piles are driven to their nal position the stresses caused by foundation loading are likely to be much lower than those caused by handling and driving. The reinforcement requirements are predominantly catered for handing during manufacture, storage, transport and on site as appropriate. SPECIFICATION AND DESIGN Piles shall be designed to BS 8110 or CP 116 and to MS 1314 (see table 1, 2 and 3). Any special design criteria or to other relevant codes, speci cations and requirements can be ful lled if required. The ultimate bearing capacity for a pile shall be calculated vide empirical dynamic pile formula or by a static formula and conclusively determined by test loading. APPLICATION Civil Engineering and building structures on land or immediate inshore locations intended for use as permanent structures. MANUFACTURE Steel forms are employed to manufacture the piles in a factory-controlled environment. After the concrete has been placed, vibrated by internal vibrators and cured the products are stripped from the stationery steel forms and the production cycle is then repeated. CONCRETE MATERIAL AGGREGATE Coarse aggregates shall comply with MS 29. The nominal maximum size shall not exceed 20mm. ADMIXTURES Admixtures when used shall comply with MS 922. Calcium choride or admixture based on calcium choride shall not be used. CONCRETE The fully compacted concrete shall have a minimum cement content of 350 kg/cu.m for normal and easy driving conditions and the characteristic strength of concrete shall be 45 N/sq.mm. However for hard and very hard driving condition and in marine works a minimum cement content of 400 Kg/cu.m is recommended to be used. REINFORCEMENT Reinforcing steel shall comply to MS 146 for main longitudinal bar and MS 144 for the lateral links. JOINTS In lengthening of piles the mild steel and plates are butt (blunt point), jointed centerally and axially and subjected to eld full penetration butt welding. Cast iron shoes are usually required only when driven into rocks, coarse gravel and othersoils liable to damage the concrete at the tip of the pile. ( g 1) LIFTING AND STORAGE ARRANGEMENTS Units shall be lifted at designated lifting points provided along the pile and preferably by means of a spreader beam to avoid and undue stresses. All units shall be stored on an unyielding ground and stacked with timber. SURFACE FINISH Small blemishes caused by entrapped air or water may be expected but the surface shall be free from voids, honey combing or other large blemishes. MARKING Each unit shall be clearly indenti ed and position for lifting as in use shall be indicated by lifting hooks. DIMENSION The maximum permissible derivations from the manufacturing mean dimension shall not exceed BS 8110:Pt 1:1985 requirements. QUALITY ASSURANCE Quality Assurance in the manufacture of the products is provided vide established MS ISO 9001 Quality Management System. PILE DRIVING Pile can be installed commonly by hammering, pushing, jacking, screwing, vibrating or other means to force them into the ground so as to transmit loads to the soil or rock. These piles can be easily extended by splicing additional length of piling. Pile preparation for testing shall generally involve all practical steps to ensure that the hammer and pile are aligned to prevent bending of the pile during the test blows, and that the hammer strikes a ush sound surface perpendicular to the pile axis. Test driving is recommended as it provides a clue to the strata, load bearing capacity leading to valuable informations for selection of the best pile driving plant and of the best pile type. As to stresses induced during installation they may be obtained from a wave equation analysis or directly measured during pile driving, using dynamic pile testing equipment. As a rule of thumb and from lessons of experience also from successful applications the maximum calculated stress in piles during driving shall not exceed 0.8fcu in compression and in tension 0.8sqrt(fcu) where fcu is the compressive strength of cube in MPa at the time of driving. Experience shows that even during properly executed driving of reinforced concrete piles, hair line cracks cannot always be avoided. They are unobjectionable as long as they do not exceed a certain number and a certain crack width. Relevant global industry standards permit cracks up to a width of 0.15mm which has proven, according to the present knowldge to be harmless.

TABLE 1 ACP BRAND `STANDARD PRECAST REINFORCED CONCRETE SQUARE PILES - GRADE OF CONCRETE 45MPa PILE NOMINAL DIMENSIONS AND REINFORCEMENT DETAILS Nominal size (mmxmm) 150x150 175x175 200x200 225x225 250x250 300x300 350x350 380x380 400x400 Main Longitudinal Reinforcement No. Dia.(mm) 4 4 4 4 8 4 4 4 4 8 9 10 12 10 16 20 20 20 Mild Steel Wire Size (mm) 4 4 5 5 5 6 6 6 6 Lateral Reinforcement (Links) P S2 S1 (mm) (mm) (mm) 57 52 50 45 42 53 46 44 42 450 525 600 675 750 900 1050 1145 1200 57-72 52-85 50-100 45-112.5 42-125 53-145 46-145 44-125 42-125 Q (mm) 450 525 600 675 750 900 1050 1145 1200 S3 (mm) 72 85 100 112.5 125 145 145 125 125 R (mm) 4200 3900 6600 6300 9000 8400 7800 7420 7200

Note 1 : R - refer to recommended maximum length at middle transition section of pile. Mild Steel joint plate shall be in accordance with Table 2 for dierent application as approciate, other details remain unchanged as in Table 1. TABLE 3 TABLE 2 MILD STEEL JOINT PLATE THICKNESS (mm) TYPE Nominal Size ACP BRAND `STANDARD ACP BRAND `MS 1314 (mm) (mm) (mmxmm) 150x150 175x175 200x200 225x225 250x250 300x300 350x350 380x380 400x400 4.5 4.5 5 6 6 8 8 9 9 6 6 9 9 9 9 12 12 12 PILE STRUCTURAL CAPACITY Nominal Longitudinal Maximum Ulitimate Size Reinforcement Area Axial Working Load* Axial Load** (mmxmm) (mm2) (Tonnes) (Tonnes) 150x150 175x175 200x200 225x225 250x250 300x300 350x350 380x380 400x400 201 254 314 452 628 804 1256 1256 1256 31 42 55 71 88 125 173 200 219 47 64 83 107 134 190 264 303 331

Note 2: * Maximum Axial Working Load is in accordance with BS 8004/CP 116. ** Ultimate Axial Load2 is in accordance with BS 8110. Formula to determine maximum axial load working load* Formula to determine ultimate axial load** Reference 1. BS 8004 : 1986 Clause 7.4.2.3.2 2. CP 116, Clause 321.b, equation 17 & table 8 Po = Pcc Ac + PscAsc Where Po = Permissible axial load as a short column Pcc = Permissible stress for the concrete in direct compression (0.27fcu) Ac = Cross sectional area of concrete excluding accessories and reinforcing steel Psc = Permissible compressive stress for longitudinal steel (0.55fy and > 175 N/mm2) Asc = Cross sectional area of the longitudinal steel. fy = Guaranteed yield or proof stress. Where Reference 1. BS 8004 : 1986 Clause 7.4.2.3.2 2. BS 8110 : Pt 1 : 1985 clause 3.8.4, equation 38 N = 0.4fcuAc + 0.75fyAsc N = Ultimate Axial load fcu = Characteristic strength of concrete at 28 days. Ac = Cross sectional area of concrete excluding accessories and reinforing steel. fy = Characteristic yield strength of longitudinal steel Asc = Cross sectional area of the longitudinal steel.

Note : Speci cation and details shown in brochure subject to change without prior notice due to product development, changing customer and industry requirements.

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- PilesDocument17 pagesPilesntah84No ratings yet

- Deep FoundationsDocument75 pagesDeep FoundationsMuhd SyahidNo ratings yet

- As-Built Pile Eccentricity and Penetration PlanDocument1 pageAs-Built Pile Eccentricity and Penetration PlanSanjay RajNo ratings yet

- PilingDocument34 pagesPilingHariz HilmanNo ratings yet

- IWK Guide On FeeDocument1 pageIWK Guide On FeeJohnyReubenNo ratings yet

- BQ PmuDocument5 pagesBQ PmuAzamOthman100% (1)

- Sheet Pile Brochure 2022Document8 pagesSheet Pile Brochure 2022bayzuraNo ratings yet

- S3 01concretedetails PDFDocument1 pageS3 01concretedetails PDFAmr HalabyNo ratings yet

- Cost For Each Pile CapDocument4 pagesCost For Each Pile CapGeetashree PaulNo ratings yet

- Construction and Design of MultistoreyDocument37 pagesConstruction and Design of MultistoreyFawadNo ratings yet

- 2018 19 LOKRITE Ironmongery CatalogueDocument98 pages2018 19 LOKRITE Ironmongery CatalogueKho Song YuanNo ratings yet

- Novospt enDocument29 pagesNovospt enSalvatore Miranda0% (1)

- ELS Sample Questions For 2010 HKPU T3 Top Up Course PDFDocument2 pagesELS Sample Questions For 2010 HKPU T3 Top Up Course PDFYu chung yinNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFLavanyan SatchithananthanNo ratings yet

- Esq 540 - Piling Operation-AssignmentDocument11 pagesEsq 540 - Piling Operation-AssignmentMoffat KangombeNo ratings yet

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- 11 HDB Requirements For A&a Work On HDB PremisesDocument16 pages11 HDB Requirements For A&a Work On HDB PremisesasdasNo ratings yet

- Notes On Hy-RibDocument20 pagesNotes On Hy-RibMohd Faizal100% (1)

- Dokumen - Tips Arahan Teknik Jalan 6 85 Guidelines For Presentation of Engineering DrawingDocument29 pagesDokumen - Tips Arahan Teknik Jalan 6 85 Guidelines For Presentation of Engineering Drawingiris engineeringNo ratings yet

- .. Power Points Impact HammersDocument26 pages.. Power Points Impact HammersmarklesterNo ratings yet

- Wiring Accessories CatalogueDocument88 pagesWiring Accessories CatalogueDhanushka RathnasooriyaNo ratings yet

- Schedule of Rates 2011-12Document149 pagesSchedule of Rates 2011-12Riazahemad B JagadalNo ratings yet

- Appendix H - TOR For Bridge and Viaducts StructureDocument11 pagesAppendix H - TOR For Bridge and Viaducts StructureSara Ikhwan Nor SalimNo ratings yet

- Method Statement For CoringDocument4 pagesMethod Statement For CoringNasir Nagoor PitchaiNo ratings yet

- Guard HouseDocument2 pagesGuard HouseKevin LowNo ratings yet

- JKR-Mackintosh Probe ChartDocument1 pageJKR-Mackintosh Probe ChartNurmuliana Abdul WahabNo ratings yet

- DDDDocument72 pagesDDDCallisto 1908No ratings yet

- Elastomeric Catalogue - Laminated BRG - WDocument16 pagesElastomeric Catalogue - Laminated BRG - WhassanNo ratings yet

- Placement of Main Reinforcement (Bar) of FootingDocument2 pagesPlacement of Main Reinforcement (Bar) of FootingBijaya RaulaNo ratings yet

- Sewerage Design Calculation For CO4Document6 pagesSewerage Design Calculation For CO4Mohd RafiqNo ratings yet

- Bill of Quantities: IndexDocument42 pagesBill of Quantities: IndexLe JennieNo ratings yet

- Fencing PriceDocument2 pagesFencing PriceAana SamsNo ratings yet

- Guidelines KL Bike Pedestrian 2019 2028Document88 pagesGuidelines KL Bike Pedestrian 2019 2028saraseeraNo ratings yet

- Bahagian 9 Spec 4 TurfingDocument1 pageBahagian 9 Spec 4 TurfingRahayu SuranNo ratings yet

- Lysaght Smartdek - Jan 2019Document2 pagesLysaght Smartdek - Jan 2019Chai Weng KuakNo ratings yet

- Steel Section PropertiesDocument2 pagesSteel Section Propertiesman.drakeNo ratings yet

- Bridge Bearings, Expansion Joints & ParapetsDocument81 pagesBridge Bearings, Expansion Joints & ParapetsSAMNo ratings yet

- Practical Task - Topic 4 Ibs Component InstallationDocument11 pagesPractical Task - Topic 4 Ibs Component InstallationtahirNo ratings yet

- Gue & Partner Geotechnical 5Document9 pagesGue & Partner Geotechnical 5Muhammad RoslanNo ratings yet

- Road Gully For Malaysian Roads. Type 'Grating'Document1 pageRoad Gully For Malaysian Roads. Type 'Grating'LMBong8881No ratings yet

- Sample Civil BoqDocument57 pagesSample Civil Boqkvamshi_1971No ratings yet

- Cost Estimation BundDocument26 pagesCost Estimation BundAnonymous UUw70xirbl100% (1)

- Design Calculation (Structural Data Sheet)Document1 pageDesign Calculation (Structural Data Sheet)vasinopNo ratings yet

- Sika Viscoflow®-3880 LV: Product Data SheetDocument3 pagesSika Viscoflow®-3880 LV: Product Data Sheetedars08100% (1)

- Method Statement Horizontal DrainDocument1 pageMethod Statement Horizontal DrainAlsonChin100% (1)

- Castellated Beams STAAD-Pro2004Document13 pagesCastellated Beams STAAD-Pro2004Lukman Nul HakimNo ratings yet

- OKA G45 RC - Square PilesDocument4 pagesOKA G45 RC - Square PilesTee Bun PinNo ratings yet

- The Proposed Dualization of Road Kotangora Auto Saved)Document6 pagesThe Proposed Dualization of Road Kotangora Auto Saved)Felix IdeboghieNo ratings yet

- AGPT04E-09 Guide To Pavement Technology Part 4E PDFDocument32 pagesAGPT04E-09 Guide To Pavement Technology Part 4E PDFWawan FadelNo ratings yet

- Specification For Precast Concrete WorksDocument39 pagesSpecification For Precast Concrete Worksm.nurhishammNo ratings yet

- Pile Data and Hammer TableDocument9 pagesPile Data and Hammer TableGULF PILING LLC100% (1)

- Comperative Study of RCC and SteelDocument6 pagesComperative Study of RCC and Steelvenu manikantaNo ratings yet

- Pile Driving Inspection Manual - Gem-26b - NydotDocument97 pagesPile Driving Inspection Manual - Gem-26b - Nydotullwn100% (1)

- Ibs CalculationDocument5 pagesIbs CalculationSiongyung KongNo ratings yet

- Liebherr Casing Oscillator Deep Foundation enDocument4 pagesLiebherr Casing Oscillator Deep Foundation enNararya Muh Pratito Anditya100% (1)

- Pile CatalogueDocument8 pagesPile CatalogueMohamad AmirulbaharudinNo ratings yet

- DPC - Brochure 3 HCSDocument26 pagesDPC - Brochure 3 HCSNagendra BurabattulaNo ratings yet

- Initial Design Reinforced Concrete - Concrete Building StructuresDocument4 pagesInitial Design Reinforced Concrete - Concrete Building StructuresNoel FernandineNo ratings yet

- T150mm - Beam and Blocks PDFDocument2 pagesT150mm - Beam and Blocks PDFErnie ErnieNo ratings yet

- Crawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, ChinaDocument10 pagesCrawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, Chinadepi_rachmanNo ratings yet

- GFRC Admix Mix DesignDocument5 pagesGFRC Admix Mix Designdepi_rachmanNo ratings yet

- (PDS) Lokfix EpDocument2 pages(PDS) Lokfix Epdepi_rachman100% (1)

- LTM1200 en PDFDocument10 pagesLTM1200 en PDFdepi_rachmanNo ratings yet

- Cebex Cable Grout-1Document4 pagesCebex Cable Grout-1depi_rachmanNo ratings yet

- Steel Bars: High Yield DeformedDocument1 pageSteel Bars: High Yield Deformeddepi_rachmanNo ratings yet

- SF Marina English Brochure 2015-04-30Document16 pagesSF Marina English Brochure 2015-04-30depi_rachmanNo ratings yet

- Method Statement - Sikagard 670 W MYDocument1 pageMethod Statement - Sikagard 670 W MYdepi_rachman100% (1)

- Sheet and Plate - Steel DataDocument1 pageSheet and Plate - Steel Datadepi_rachmanNo ratings yet

- 1 - (Rev3) Casting and Forging, PC AC BoQ Price Breakdown - CIVIL BUILDINGDocument25 pages1 - (Rev3) Casting and Forging, PC AC BoQ Price Breakdown - CIVIL BUILDINGMohammed Mostafa El HaddadNo ratings yet

- Experiment No. 1 Consistency Test On CementDocument8 pagesExperiment No. 1 Consistency Test On CementAjinkya Shendarkar0% (1)

- Ground ImprovementDocument47 pagesGround ImprovementCharlotte TilburyNo ratings yet

- Civil WorkDocument80 pagesCivil WorkMilind JadhavNo ratings yet

- Epilux Concrete PrimerDocument3 pagesEpilux Concrete PrimerTejinder KumarNo ratings yet

- Sportzentrum Mulimattt1Document12 pagesSportzentrum Mulimattt1mi biNo ratings yet

- Small Dams - Cap 6,7 - Earthfill and Rockfill DamsDocument127 pagesSmall Dams - Cap 6,7 - Earthfill and Rockfill Damsina_cri0% (1)

- Supercast SW30 (UK)Document2 pagesSupercast SW30 (UK)Gry ArdiansyahNo ratings yet

- Cristex Concentrate En-SDocument2 pagesCristex Concentrate En-Semam2405No ratings yet

- Ms - Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMs - Installation of Electric PVC Conduits and AccessoriesDuel TimeNo ratings yet

- DR - MAJID AL-BANA KARADA Structural-1 - 221108 - 213032Document16 pagesDR - MAJID AL-BANA KARADA Structural-1 - 221108 - 213032Bahaa AldeenNo ratings yet

- 33-F09221S-T0501-A6C-001 003 Calculations and Appendix PDFDocument190 pages33-F09221S-T0501-A6C-001 003 Calculations and Appendix PDFUzair Maqbool KhanNo ratings yet

- Prof. A.M.GalagaliDocument21 pagesProf. A.M.Galagalibemd_aliNo ratings yet

- ADC20023-DWG-PAV-404 - Hangar Pavement Typical DetailsDocument1 pageADC20023-DWG-PAV-404 - Hangar Pavement Typical DetailsAhmed SalahNo ratings yet

- Supergrout NDocument1 pageSupergrout NvasantsunerkarNo ratings yet

- BP QuoteExampleDocument80 pagesBP QuoteExampleNur IrawanNo ratings yet

- Construction LogbookDocument2 pagesConstruction LogbookGerard BorbonNo ratings yet

- Is 14242Document8 pagesIs 14242mohan890No ratings yet

- Revitalizing Abandoned Mills in India The Case of Tamil Nadu IJERTV10IS110184Document8 pagesRevitalizing Abandoned Mills in India The Case of Tamil Nadu IJERTV10IS110184SuyashNo ratings yet

- IT ReportDocument32 pagesIT ReportVictor EmmanuelNo ratings yet

- Sika Monotop®-610: Product Data SheetDocument3 pagesSika Monotop®-610: Product Data SheetVirah Sammy ChandraNo ratings yet

- Pola Seismic Code 2010Document39 pagesPola Seismic Code 2010nguyenvanduyetNo ratings yet

- Rosetta Retaining Wall CatalogDocument55 pagesRosetta Retaining Wall CatalogWorld Outdoor Emporium0% (1)

- MonolithicDocument1 pageMonolithicVishnu Teja Reddy100% (2)

- TCVN 9888-3 - 2013 - IEC 62305-3 - 2010 - 1049711 EN VerDocument137 pagesTCVN 9888-3 - 2013 - IEC 62305-3 - 2010 - 1049711 EN VerNam NguyenNo ratings yet

- Construction Specification 356 - Dike: 1. ScopeDocument8 pagesConstruction Specification 356 - Dike: 1. ScopeRenan YanzonNo ratings yet

- Industrial Coating ApplicationDocument22 pagesIndustrial Coating ApplicationaamirsaddiqNo ratings yet

- Fitzpatrick Product Catalogue 2020 - Steel Doors-Frames (DS) (ITB)Document46 pagesFitzpatrick Product Catalogue 2020 - Steel Doors-Frames (DS) (ITB)Ramez Bou-RizkNo ratings yet

- 01 Lowcosthousing 181224175137Document42 pages01 Lowcosthousing 181224175137Damanpreet DandiwalNo ratings yet

- 1 s2.0 S223878542300652X MainDocument14 pages1 s2.0 S223878542300652X MainFahra Aqilla AzzurahNo ratings yet