Professional Documents

Culture Documents

Simulation of UAV Systems

Uploaded by

Zain Ul AabidinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation of UAV Systems

Uploaded by

Zain Ul AabidinCopyright:

Available Formats

Czech Technical University in Prague

Acta Polytechnica Vol. 45 No. 4/2005

Simulation of UAV Systems

P. Kaovsk, L. Smrcek, C. Goodchild

The study described in this paper deals with the issue of a design tool for the autopilot of an Unmanned Aerial Vehicle (UAV) and the selection of the airdata and inertial system sensors. This project was processed in cooperation with VTUL a PVO o.z. [1]. The feature that distinguishes the autopilot requirements of a UAV (Figs. 1, 7, 8) from the flight systems of conventional manned aircraft is the paradox of controlling a high bandwidth dynamical system using sensors that are in harmony with the low cost low weight objectives that UAV designs are often expected to achieve. The principal function of the autopilot is flight stability, which establishes the UAV as a stable airborne platform that can operate at a precisely defined height. The main sensor for providing this height information is a barometric altimeter. The solution to the UAV autopilot design was realised with simulations using the facilities of Matlab and in particular Simulink[2]. Keywords: autopilot, modelling, Sojka, tools, UAV

Symbols

m V & a a b F, Q, Y u, v, w p, q, r CD CL CLF cl cn cm r Ix, Iy, Iz c S b g T Airplane mass Velocity Time derivation of a Angle of attack Angle of drift Euler angles (roll, pitch, yaw) Components of velocity of the airplane mass centre relative to atmosphere Components of the angular velocity of the airplane Drag coefficient Lift coefficient Lift coefficient of the vertical tail surface Rolling moment coefficient Yawing moment coefficient Pitching moment coefficient Air density Moments of inertia about (x, y, z) axes Length of mean aerodynamic chord Wing area Wing span Standard gravitational acceleration Engine thrust

1 Introduction

Civil and military usage of low cost UAVs is becoming more needed. Possibly the most expensive design items are the control and navigation systems. Therefore, one of main questions that each system designer has to face is the selection of appropriate sensors for a specific autopilot system. Such sensors should satisfy the main requirements without contravening their boundaries. Higher sensor quality can lead to a significant rise in costs. In aircraft design this kind of consideration is especially important due to the safety requirements expressed in airworthiness standards. Therefore question is how to determine the optimal solution. This problem is mostly solved by the designers experience and by thorough testing. However, this can be very expensive, and involves with many risks in relation to flight safety. The problem can be resolved by using a suitable simulation method, for example in the Matlab Simulink program environment. This program can be considered as a facility fully competent for this task. An important factor is what is done to manipulate the functions of the program to achieve the autopilot design. A computer only solves logical problems. It cannot implement practical real world entities, and a computer simulation only simulates what in a sense the designer already knows. For the precise design solution it is necessary to have a mathematical model of the aircraft or at least the basic con-

Wing span

Overall length MTOW Max. speed Payload Endurance Engine

Fig. 1: UAV Sojka III

Czech Technical University Publishing House http://ctn.cvut.cz/ap/

4.5 m 3.78 m 145 kg 210 km/hr 20 kg >4 hr 28.4 kW

109

Acta Polytechnica Vol. 45 No. 4/2005

Czech Technical University in Prague

Power

Pressure regulator Druck DPI 530

RS 232

Thermostatic box Labio LS80

Pressure

Measured pressure sensor

PC

RS 232 RS 232

Barometer Druck DPI 145

Temperature sensor (Pt100)

Data Acquisition Control Unit Agilent 34970A

HPIB

Fig. 2: Automatic measurement system

straints in its movement. By using suitable simulations it is possible not only to evaluate the sensors, but also to optimise their filters and control algorithms.

Force equations & u = -qw + rv - CD 1 rV 2S T + - g sin Q, 2 m m 1 rV 2S T + g cos Q sin F, + m 2 m (1)

2 Experiment

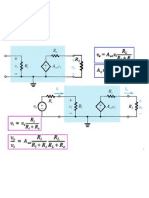

First phase of the project was to verify the sensor parameters declared by the manufacturer. In order to measure the sensor parameters (sensitivity, accuracy, stability, temperature dependence and hysteresis), it was necessary to adapt an existing automatic system by recording data into a file (see Fig. 2). The second phase in this project was to make a statistical evaluation of data obtained by the automatic measurement system. The validity of the measurements themselves was verified by an accuracy analysis of the measurement system and processing the statistical data. The most important quantity in the set of measured data was the pressure variation between two different altitudes, which could be measured very precisely. The entire evaluation of the measured data then helped to find sensor parameters and, consequently, to design a sensor model for the Matlab Simulink program. The designed model was a simplified version, because it reflected only parameters relevant for the specified UAV autopilot design. The sensor delay in this case could be ignored, because its value was negligible in comparison with the previously mentioned sensor parameters. The basic requirement for this project was to obtain data concerning the UAV design system. In this case, the UAV system was described in the following referential axes (Fig. 3) and by a set of differential equations (Equations 1, 2) [3, 4]:

& v = -ru + pw - CLF & w = qu - pv - CL

1 rV 2S T + + g cos Q cos F. m 2 m 1 rV 2Sb , 2 Ix

Moment equations & p=& q=& r =I y - Iz Ix qr + cl

1 rV 2Sc Ix - Iz , rp + cm 2 Iy Iy Iz - Ix 1 rV 2Sb pq + cn . 2 Iz Iz

(2)

Fig. 3: Main axes

All variables were calculated in a frame of differential equations. All aerodynamic parameters needed for these equations were obtained from wind tunnel experiments [4]. The airplane model in Simulink consists of partial blocks. These blocks represent basic mathematical operations or functions and tools that are necessary for modelling. For example, these could be memory, delay, signal sinks and sources (for an illustration, see Fig. 4). The mathematical model of the airplane was compiled as a continuous system, i.e., all calculations were not performed as a time defined sequence but the time interval changed due to the magnitude of the outcomes of the calculations. This solution guaranteed that all relevant quantities would be obtained. This was because the time between two calculations was in the order of milliseconds, which means more than two orders higher frequency than the highest own frequency of airplane movement. The model in Simulink was divided into subblocks representing the individual equations. The main initial conditions were defined in an external .m file, which had to be run before starting the main simulation in Simulink. The rest of the initial conditions and quantities could be set up directly in the Simulink scheme. These conditions were, for example, initial velocity, altitude and flight path. The input quantities to be modelled were: - elevator deflection - aileron deflection

Czech Technical University Publishing House http://ctn.cvut.cz/ap/

110

Czech Technical University in Prague

Acta Polytechnica Vol. 45 No. 4/2005

Fig. 4: Simulink scheme representing the calculation of the first equation from Equation 1

thrust wind as defined in MIL-F-8785C [6]

3 Results

The processed data from the automatic measurement system was used for designing a model corresponding to the basic parameters of the sensor. The results showed the significant temperature dependence. This dependence was easy to correct. However, taking into account the desired function of the sensor, this dependence could be ignored. Standard deviation was 0.031 By processing the 152 measured data items, the following results can be obtained:

-

All the calculated output quantities for visualisation could be shown in a graphical interface or saved. These quantities could be, for example, Euler angles and their derivations, translational and angular movements, speed, altitude, etc. Assuming that we had all necessary aerodynamic parameters, the design of a non-linear aircraft model was worked out. The model describes the aircraft behaviour in almost all standard phases of flight. Algorithms representing the autopilot control were also simulated. In order to make the simulation comprehensive, the model was extended by submodels of the wind and the actuators. A simplified diagram of the design simulation is shown in Fig. 5.

80 % of the results were within the interval 0.5m 60 % of the results were within the interval 0.3m 20 % of the results were within the interval 0.1m

Pitch autopilot

Actuators

Airplane Mathematical model

Sensor models + algorithm of filtration

Data visualisation

Roll autopilot

Fig. 5: Simulink block scheme

Czech Technical University Publishing House http://ctn.cvut.cz/ap/

111

Acta Polytechnica Vol. 45 No. 4/2005

Czech Technical University in Prague

A decision on the suitability of using the sensor as an altimeter could have been made on the basis of the stated manufacturers data, from the supplied datasheets. Unfortunately this method was inapplicable in the case of using the pressure sensor as a vertical speedometer. The definition for calculating vertical speed is obvious from Fig. 6. and Eq. 3. Vertical speed is defined as change of altitude in time. Dh Vertical speed = (3) Dt It is evident from Graph 1. that the steps of discrete time derivation of altitude can cause undesirable step changing in measurement of vertical speed. These steps could be elimi-

Dt

Altitude Dh

Time

Fig. 6: Calculating the vertical speed

Graph 1

Graph 2

112

Czech Technical University Publishing House

http://ctn.cvut.cz/ap/

Czech Technical University in Prague

Acta Polytechnica Vol. 45 No. 4/2005

nated by implementing a filter, but this would involve unacceptable time delays. Surprisingly, thanks to the robustness of the system, the system itself was resistant to sharp and large steps of indicated vertical speed. Graph 2 shows the resultant change of altitude. The control mechanism is made by keeping the vertical speed value (in this case 0) and keeping the set altitude value.

who designed the basic version of the automatic measurement system for pressure measurement.

References

[1] VTUL a PVO o. z. (Air Force Research Institute), Czech Republic, http://www.vtul.cz/. [2] http://www.mathworks.com/. [3] Etkin, B., Reid, L. D.: Dynamics of Flight Stability and rd Control, John Wiley & Sons, Inc. 1996, 3 ed. [4] Cech, Z.: Vyuit magnetickho pole Zem ke stabilizaci bezpilotnch prostedk (Usage of the Earths Magnetic Field for Stabilising UAV Flight)(in Czech), dissertation work, Military Academy Antonina Zapotockeho, Brno, CZ, 1989. [5] Proks, M.: Men modelu letounu Sojka-M4 v aerodynamickm tunelu. Technical report Z-3763/02, Aeronautical Research and Test Institute in Prague 2002. [6] http://www.pdiaero.com/downloads/download_files/MIL -F-8785C. pdf, section 3.7 Ing. Petr Kaovsk e-mail: kanovsp@fel.cvut.cz Department of Measurements Czech Technical University in Prague Faculty of Electrical Engineering Technick 2 166 27 Prague 6, Czech Republic Dr. Ladislav Smrcek Dr. Colin Goodchild Aerospace Engineering Department James Watt Building University of Glasgow Glasgow, G12 8QQ Scotland, U.K.

4 Conclusion

Simulated flight quantities were evaluated with comparing with real flight records and submitted by real Sojka operators. This correspondence certifies the correctness of the Simulink airplane model. The model of the UAV design system helps to create a powerful tool for a suitability testing of the autopilot and its sensors. This procedure can speed up the choice of sensors which makes a price reduction of their implementation into the UAV autopilot. Particular result from this study is a decision to use a low-cost altimeter for vertical speed measurements. This design method is also suitable for further utilisation in UAV design system simulation. Another possible utilisation of the method is in evaluating of sensor quality in ageing, for the purposes of flight safety.

5 Acknowledgment

The author thanks Mr. Z. Cech, from Delong Instruments Ltd. Brno, Czech Republic, who described the mathematical model of UAV Sojka, and Mr. V. Dvorak from CTU Prague,

Fig. 7

Fig. 8

Czech Technical University Publishing House http://ctn.cvut.cz/ap/

113

You might also like

- Aviation CNS Systems OverviewDocument219 pagesAviation CNS Systems OverviewAngijad MesicNo ratings yet

- Integrated Avionics SystemsDocument13 pagesIntegrated Avionics SystemsvasanthNo ratings yet

- Evaluating Response Robot Capabilities: Standard Terminology ForDocument3 pagesEvaluating Response Robot Capabilities: Standard Terminology ForAlevj DbNo ratings yet

- Autopilot 31Document51 pagesAutopilot 31Pramod Kumar100% (1)

- Avionics-Ae 2401: Unit - 1 Prepared by Rajarajeswari.M Mohammed Sathak Eng CollegeDocument129 pagesAvionics-Ae 2401: Unit - 1 Prepared by Rajarajeswari.M Mohammed Sathak Eng CollegeGaneshVijay0% (1)

- Avionics SystemsDocument5 pagesAvionics SystemsLalith KumarNo ratings yet

- c1 Integrated CircuitDocument19 pagesc1 Integrated CircuitMohammad SyaharinNo ratings yet

- Spec 04 Atc RadarsDocument3 pagesSpec 04 Atc Radarsgabriel99669966No ratings yet

- Introduction to the History of UAVsDocument44 pagesIntroduction to the History of UAVsAswin BalasubramaniamNo ratings yet

- TYPES OF TRANSDUCERSDocument129 pagesTYPES OF TRANSDUCERSUr dad Big dadNo ratings yet

- Protocols For Aerospace Control Systems: A Comparison of Afdx, Arinc 429, Can, and TTPDocument10 pagesProtocols For Aerospace Control Systems: A Comparison of Afdx, Arinc 429, Can, and TTPManoj GuptaNo ratings yet

- MODE S TranspondersDocument5 pagesMODE S TranspondersJoão Pedro AlmeidaNo ratings yet

- Bibliography Report Quadrotor Control MethodsDocument47 pagesBibliography Report Quadrotor Control MethodsPablo Fernández de la Granja100% (2)

- Aircraft Airborne Navigation IDocument104 pagesAircraft Airborne Navigation IRifki FirnandoTPPU 1No ratings yet

- RCMP Drone Privacy Impact AssessmentDocument33 pagesRCMP Drone Privacy Impact AssessmentNational Security Oversight Institute of CanadaNo ratings yet

- Synthetic Vision System: January 2009Document15 pagesSynthetic Vision System: January 2009bskanwar6376No ratings yet

- Aircraft AutopilotDocument21 pagesAircraft Autopilotdev achandyNo ratings yet

- Aircraft Avionics4Document15 pagesAircraft Avionics4Amjed MhmdNo ratings yet

- Avionics Architecture Growth and Integrated Modular ApproachDocument12 pagesAvionics Architecture Growth and Integrated Modular ApproachMeng KeeNo ratings yet

- ASI Full NotesDocument171 pagesASI Full NotesmuthumariNo ratings yet

- Avionics Refers To Electronic Systems On AircraftDocument7 pagesAvionics Refers To Electronic Systems On Aircraftadithya2103No ratings yet

- Ourania Chatzialekou Atco: March 2014Document32 pagesOurania Chatzialekou Atco: March 2014ΣΧΟΛΗ ΠΟΛΙΤΙΚΗΣ ΑΕΡΟΠΟΡΙΑΣNo ratings yet

- Need For Avionics in Civil, Military and Space SystemsDocument2 pagesNeed For Avionics in Civil, Military and Space Systemskannanemail100% (1)

- Synchronous Data-Transmission SystemsDocument24 pagesSynchronous Data-Transmission SystemsbharathshajiNo ratings yet

- Unmanned Aerial VehicleDocument178 pagesUnmanned Aerial Vehicletanveershariff13No ratings yet

- RPAS integration and regional developmentsDocument15 pagesRPAS integration and regional developmentsJuan C. MoñinoNo ratings yet

- Fly by WireDocument20 pagesFly by WireAnurag RanaNo ratings yet

- Computational Modelling and Simulation of Aircraft and the Environment, Volume 1: Platform Kinematics and Synthetic EnvironmentFrom EverandComputational Modelling and Simulation of Aircraft and the Environment, Volume 1: Platform Kinematics and Synthetic EnvironmentNo ratings yet

- Unit3 Avionics ModDocument91 pagesUnit3 Avionics ModVignesh Moorthy100% (1)

- Combining ModelSim and Simulink With SystemVision in An Integrated Simulation EnvironmentDocument5 pagesCombining ModelSim and Simulink With SystemVision in An Integrated Simulation Environmentleo3001No ratings yet

- Design and Development of The Hardware For Vision Based UAV AutopilotDocument6 pagesDesign and Development of The Hardware For Vision Based UAV AutopilotJoshua DanielNo ratings yet

- R ProgramsDocument30 pagesR ProgramsRanga SwamyNo ratings yet

- Topic 1 - Typical Electronic Digital Aircraft System PDFDocument34 pagesTopic 1 - Typical Electronic Digital Aircraft System PDFnjnvsrNo ratings yet

- UAV Course SyllabusDocument3 pagesUAV Course Syllabushindaputra374100% (3)

- Selective CallingDocument6 pagesSelective CallingHimanshu HaldarNo ratings yet

- Unit 1 Avionics ModifiedDocument127 pagesUnit 1 Avionics ModifiedparantnNo ratings yet

- Aircraft Instrument Systems GuideDocument34 pagesAircraft Instrument Systems GuideArun Vinthan100% (1)

- Aircraft Attitude Indication SystemDocument69 pagesAircraft Attitude Indication SystemdinNo ratings yet

- Typical Avionics Sub SystemsWorld Sensor and Task AutomationDocument3 pagesTypical Avionics Sub SystemsWorld Sensor and Task AutomationvickyNo ratings yet

- A UAV Detection Algorithm Based On An Artificial Neural NetworkDocument9 pagesA UAV Detection Algorithm Based On An Artificial Neural NetworkanjulNo ratings yet

- Aircraft Marshalling TrainerDocument2 pagesAircraft Marshalling TrainerhennrynsNo ratings yet

- Avionics Question Bank and NotesDocument15 pagesAvionics Question Bank and NotesFaisal Muhammed MavathuNo ratings yet

- Vccs StudyDocument100 pagesVccs Studyoicfbd100% (1)

- Fly by Wire ConceptDocument20 pagesFly by Wire ConceptSanjay RameshNo ratings yet

- Curriculum of Ms in Avionics EngineeringDocument34 pagesCurriculum of Ms in Avionics EngineeringUfi70No ratings yet

- Avionics 2marks 1Document46 pagesAvionics 2marks 1Ar JunNo ratings yet

- Basic Autopilot SystemsDocument4 pagesBasic Autopilot SystemsSonali Srivastava100% (1)

- ERA - Technical ManualDocument87 pagesERA - Technical ManualTran DuyNo ratings yet

- National Aerospace Laboratories (Nal)Document52 pagesNational Aerospace Laboratories (Nal)EdwinRativaNo ratings yet

- Secondary Surveillance Radar (SSR)Document18 pagesSecondary Surveillance Radar (SSR)Ye Min OoNo ratings yet

- Radar Altimeter AssignmentDocument11 pagesRadar Altimeter Assignmentsajid93No ratings yet

- Gpws ModesDocument10 pagesGpws Modesjay_sidNo ratings yet

- AC 21-99 Aircraft Wiring Inspection GuideDocument8 pagesAC 21-99 Aircraft Wiring Inspection GuideShakil MahmudNo ratings yet

- Unmanned Aircraft SystemsFrom EverandUnmanned Aircraft SystemsElla AtkinsNo ratings yet

- Railroad Signal Specialist: Passbooks Study GuideFrom EverandRailroad Signal Specialist: Passbooks Study GuideNo ratings yet

- Laplace Transform and MapleDocument4 pagesLaplace Transform and MapleZain Ul AabidinNo ratings yet

- Cse-Lec 01Document47 pagesCse-Lec 01Zain Ul AabidinNo ratings yet

- 11Document2 pages11Liz AñazcoNo ratings yet

- Uav Autopilot ModelDocument2 pagesUav Autopilot ModelZain Ul AabidinNo ratings yet

- White Paper Designed For Quality AssuranceDocument11 pagesWhite Paper Designed For Quality AssuranceZain Ul AabidinNo ratings yet

- Lec1 BDocument26 pagesLec1 BZain Ul AabidinNo ratings yet

- Ford Eectch98Document79 pagesFord Eectch98jockerNo ratings yet

- Service Manual (V1.22)Document529 pagesService Manual (V1.22)JensNo ratings yet

- Battery Testing, Test Methods and ProceduresDocument8 pagesBattery Testing, Test Methods and ProceduresMuraliKrishnaNo ratings yet

- ASME - Performance Test CodesDocument1 pageASME - Performance Test CodesanoopkntpcNo ratings yet

- Powered Acoustimass - 30 Speaker System AM-30P: Service ManualDocument48 pagesPowered Acoustimass - 30 Speaker System AM-30P: Service ManualHama Aiea100% (1)

- 100 People Who Changed History and The WorldDocument400 pages100 People Who Changed History and The WorldManjunath.RNo ratings yet

- Maintenance Recommendations: Operation and Maintenance ManualDocument10 pagesMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SNo ratings yet

- Calentador Catalitico de TuberíasDocument2 pagesCalentador Catalitico de TuberíasDavid RomeroNo ratings yet

- THPS DegradationDocument5 pagesTHPS DegradationAhmad Naim KhairudinNo ratings yet

- UMTS Chap6Document33 pagesUMTS Chap6NguyenDucTaiNo ratings yet

- Dimensional Analysis AND Similarity: Chapter-5. (Frank White)Document46 pagesDimensional Analysis AND Similarity: Chapter-5. (Frank White)ShujaAmjadNo ratings yet

- Kidney AnatomyDocument55 pagesKidney AnatomyMohammad zreadNo ratings yet

- Guaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39Document2 pagesGuaranteed Restore Points Oracle 11g - Flash Back to SCN or RP (39PraveenNo ratings yet

- Weld CheckDocument6 pagesWeld CheckArnold c ElverNo ratings yet

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDocument45 pagesAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamNo ratings yet

- Calculation For Short Circuit Current Calculation Using IEC / IEEE StandardDocument11 pagesCalculation For Short Circuit Current Calculation Using IEC / IEEE StandardibmmoizNo ratings yet

- Mathematics Class 10 CBSE (NCERT)Document369 pagesMathematics Class 10 CBSE (NCERT)LinoNo ratings yet

- 4MA0 4HR Que 20140115Document24 pages4MA0 4HR Que 20140115Lalith77No ratings yet

- 2021 Book AppliedAdvancedAnalyticsDocument236 pages2021 Book AppliedAdvancedAnalyticsKitykatmely LoveNo ratings yet

- Loan PredictionDocument3 pagesLoan PredictionShreyansh JainNo ratings yet

- Alcohols, Phenols and Ethers Worksheet Answer Grade 12Document6 pagesAlcohols, Phenols and Ethers Worksheet Answer Grade 12sethu100% (1)

- Mic 2282Document10 pagesMic 2282mariusz sNo ratings yet

- Formulas For Thermodynamics 1Document2 pagesFormulas For Thermodynamics 1Stefani Ann CabalzaNo ratings yet

- Renormalization Group: Applications in Statistical PhysicsDocument37 pagesRenormalization Group: Applications in Statistical PhysicsJaime Feliciano HernándezNo ratings yet

- Knight Boiler ManualDocument80 pagesKnight Boiler ManualAnonymous 7xHNgoKE6eNo ratings yet

- Solidworks Flow SimulationDocument7 pagesSolidworks Flow SimulationpatrickNX94200% (1)

- BS 2995-1966 PDFDocument15 pagesBS 2995-1966 PDF윤규섭No ratings yet

- 1-Newton Second Law-ForMATDocument5 pages1-Newton Second Law-ForMATVAIBHAV KUMARNo ratings yet

- Flow Chart SymbolsDocument7 pagesFlow Chart SymbolsAbhishekNo ratings yet

- Ch01Document33 pagesCh01sakali aliNo ratings yet