Professional Documents

Culture Documents

Thermo 5th Chap10 P046

Thermo 5th Chap10 P046

Uploaded by

Ahmad AlgarniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermo 5th Chap10 P046

Thermo 5th Chap10 P046

Uploaded by

Ahmad AlgarniCopyright:

Available Formats

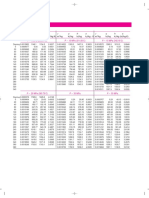

10-30

10-46 A steam power plant operates on an ideal regenerative Rankine cycle with two open feedwater

heaters. The net power output of the power plant and the thermal efficiency of the cycle are to be

determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis

P III P II P I

fwh

fwh I

Condenser

Boiler

Turbine

6

5

4

3

2

1

10

9

8

7

T

10 MPa

1 - y

8

5

6

3

y

4

0.2 MPa

5 kPa

0.6 MPa

9

1 - y - z

7

10

2

1

s

(a) From the steam tables (Tables A-4, A-5, and A-6),

( ) ( )( )

kJ/kg 95 . 137 20 . 0 75 . 137

kJ/kg 0 2 . 0

m kPa 1

kJ 1

kPa 5 200 /kg m 0.001005

/kg m 001005 . 0

kJ/kg 75 . 137

in , 1 2

3

3

1 2 1 in ,

3

kPa 5 @ 1

kPa 5 @ 1

= + = + =

=

|

|

.

|

\

|

= =

= =

= =

pI

pI

f

f

w h h

P P w

h h

v

v v

( ) ( )( )

( ) ( )( )

kJ/kg 10.35

m kPa 1

kJ 1

kPa 600 10,000 /kg m 0.001101

/kg m 001101 . 0

kJ/kg 38 . 670

liquid sat.

MPa 6 . 0

kJ/kg 13 . 505 42 . 0 71 . 504

kJ/kg 0.42

m kPa 1

kJ 1

kPa 200 600 /kg m 0.001061

/kg m 001061 . 0

kJ/kg 71 . 504

liquid sat.

MPa 2 . 0

3

3

5 6 5 in ,

3

MPa 6 . 0 @ 5

MPa 6 . 0 @ 5

5

in , 3 4

3

3

3 4 3 in ,

3

MPa 2 . 0 @ 3

MPa 2 . 0 @ 3

3

=

|

|

.

|

\

|

= =

= =

= =

)

`

=

= + = + =

=

|

|

.

|

\

|

= =

= =

= =

)

`

=

P P w

h h

P

w h h

P P w

h h

P

pIII

f

f

pII

pII

f

f

v

v v

v

v v

( )(

kJ/kg 7 . 2618

6 . 2201 9602 . 0 71 . 504

9602 . 0

5968 . 5

5302 . 1 9045 . 6

MPa 2 . 0

kJ/kg 8 . 2821

MPa 6 . 0

K kJ/kg 9045 . 6

kJ/kg 8 . 3625

C 600

MPa 10

kJ/kg 73 . 680 35 . 10 38 . 670

9 9

9

9

7 9

9

8

7 8

8

7

7

7

7

in , 5 6

=

+ = + =

=

=

)

`

=

=

=

)

`

=

=

=

=

)

`

=

=

)

= + = + =

fg f

fg

f

pIII

h x h h

s

s s

x

s s

P

h

s s

P

s

h

T

P

w h h

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-31

( )( ) kJ/kg 0 . 2105 0 . 2423 8119 . 0 75 . 137

8119 . 0

9176 . 7

4762 . 0 9045 . 6

kPa 5

10 10

10

10

7 10

10

= + = + =

=

=

)

`

=

=

fg f

fg

f

h x h h

s

s s

x

s s

P

The fraction of steam extracted is determined from the steady-flow energy balance equation applied to the

feedwater heaters. Noting that Q , 0 pe ke W

& &

FWH-2:

( ) (

5 4 8 5 5 4 4 8 8

out in

(steady) 0

out in

1 1

0

h h y yh h m h m h m h m h m

E E

E E E

e e i i

system

= + = + =

=

= =

& & & & &

& &

& & &

)

where y is the fraction of steam extracted from the turbine ( = & / & m m

8 5

). Solving for y,

07133 . 0

13 . 505 8 . 2821

13 . 505 38 . 670

4 8

4 5

=

=

h h

h h

y

FWH-1: ( ) ( )

3 2 9 3 3 2 2 9 9

1 1 h y h z y zh h m h m h m h m h m

e e i i

= + = + =

& & & & &

where z is the fraction of steam extracted from the turbine ( = & / & m m

9 5

) at the second stage. Solving for z,

( ) ( ) 1373 . 0 07136 . 0 1

95 . 137 7 . 2618

95 . 137 71 . 504

1

2 9

2 3

=

= y

h h

h h

z

Then,

( )( ) ( )( )

kJ/kg 2 . 1388 8 . 1556 0 . 2945

kJ/kg 1556.8 137.75 2105.0 1373 . 0 07133 . 0 1 1

kJ/kg 0 . 2945 73 . 680 8 . 3625

out in net

1 10 out

6 7 in

= = =

= = =

= = =

q q w

h h z y q

h h q

and

( )( ) MW 30.5 = = = kW 540 , 30 kJ/kg 1388.2 kg/s 22

net net

w m W &

&

(b) 47.1% = = =

kJ/kg 2945.0

kJ/kg 1556.8

1 1

in

out

th

q

q

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-32

10-47 [Also solved by EES on enclosed CD] A steam power plant operates on an ideal regenerative

Rankine cycle with two feedwater heaters, one closed and one open. The mass flow rate of steam through

the boiler for a net power output of 250 MW and the thermal efficiency of the cycle are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),

( )

( )( )

kJ/kg 10 . 192 29 . 0 81 . 191

kJ/kg 29 . 0

m kPa 1

kJ 1

kPa 10 300 /kg m 0.00101

/kg m 00101 . 0

kJ/kg 81 . 191

in , 1 2

3

3

1 2 1 in ,

3

kPa 10 @ 1

kPa 10 @ 1

= + = + =

=

|

|

.

|

\

|

=

=

= =

= =

pI

pI

f

f

w h h

P P w

h h

v

v v

( )

( )( )

( )( ) kJ/kg 0 . 2755 5 . 2047 9935 . 0 87 . 720

9935 . 0

6160 . 4

0457 . 2 6317 . 6

MPa 8 . 0

K kJ/kg 6317 . 6

kJ/kg 5 . 3476

C 550

MPa 5 . 12

kJ/kg 727.83 MPa 12.5 ,

C 4 . 170

/kg m 001115 . 0

kJ/kg 87 . 720

liquid sat.

MPa 8 . 0

kJ/kg 52 . 574 09 . 13 43 . 561

kJ/kg 13.09

m kPa 1

kJ 1

kPa 300 12,500 /kg m 0.001073

/kg m 001073 . 0

kJ/kg 43 . 561

liquid sat.

MPa 3 . 0

9 9

9

9

8 9

9

8

8

8

8

5 5 5 6

MPa 0.8 @ sat 6

3

MP 8 . 0 @ 6

MPa 8 . 0 @ 7 6

6

in , 3 4

3

3

3 4 3 in ,

3

MPa 3 . 0 @ 3

MPa 3 . 0 @ 3

3

= + = + =

=

=

)

`

=

=

=

=

)

`

=

=

= = =

= =

= =

= = =

)

`

=

= + = + =

=

|

|

.

|

\

|

=

=

= =

= =

)

`

=

fg f

fg

f

a f

f

pII

pII

f

f

h x h h

s

s s

x

s s

P

s

h

T

P

h P T T

T T

h h h

P

w h h

P P w

h h

P

v v

v

v v

1-y-z

z

y

3

Closed

fwh

P II

P I

Open

fwh

Condenser

Boiler

Turbine

5

6

4

7

2

1

11

10

9

8

T

7

9

5

6

3

4

0.3 MPa

z

10 kPa

0.8 MPa

12.5

MPa

y

10

1 - y - z

8

11

2

1

s

( )( )

( )( ) kJ/kg 0 . 2100 1 . 2392 7977 . 0 81 . 191

7977 . 0

4996 . 7

6492 . 0 6317 .

kPa 10

kJ/kg 5 . 2578 5 . 2163 9323 . 0 43 . 561

9323 . 0

3200 . 5

6717 . 1 6317 . 6

MPa 3 . 0

11 11

11

11

8 11

11

10 10

10

10

8 10

10

= + = + =

=

6

=

=

)

`

=

=

= + = + =

=

=

)

`

=

=

fg f

fg

f

fg f

fg

f

h x h h

s

s s

x

s s

P

h x h h

s

s s

x

s s

P

The fraction of steam extracted is determined from the steady-flow energy balance equation applied to the

feedwater heaters. Noting that Q , 0 pe ke W

& &

( ) ( ) ( ) (

4 5 6 9 4 5 5 6 9 9

out in

(steady) 0

system out in

0

h h h h y h h m h h m h m h m

E E

E E E

e e i i

= = =

=

= =

& & & &

& &

& & &

)

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-33

where y is the fraction of steam extracted from the turbine (

5 10

/ m m & & = ). Solving for y,

0753 . 0

87 . 720 0 . 2755

52 . 574 83 . 727

6 9

4 5

=

=

h h

h h

y

For the open FWH,

( ) (

3 10 2 7 3 3 10 10 2 2 7 7

out in

(steady) 0

system out in

1 1

0

h zh h z y yh h m h m h m h m h m h m

E E

E E E

e e i i

= + + = + + =

=

= =

& & & & & &

& &

& & &

)

where z is the fraction of steam extracted from the turbine ( = & / & m m

9 5

) at the second stage. Solving for z,

( ) ( ) ( )( )

1381 . 0

10 . 192 5 . 2578

10 . 192 87 . 720 0753 . 0 10 . 192 43 . 561

2 10

2 7 2 3

=

=

h h

h h y h h

z

Then,

( )( ) ( )( )

kJ/kg 1249 1 . 1500 1 . 2749

kJ/kg 1 . 1500 81 . 191 0 . 2100 1381 . 0 0753 . 0 1 1

kJ/kg 1 . 2749 36 . 727 5 . 3476

out in net

1 11 out

5 8 in

= = =

= = =

= = =

q q w

h h z y q

h h q

and

kg/s 200.2 = = =

kJ/kg 1249

kJ/s 250,000

net

net

w

W

m

&

&

(b) 45.4% = = =

kJ/kg 2749.1

kJ/kg 1500.1

1 1

in

out

th

q

q

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-34

10-48 EES Problem 10-47 is reconsidered. The effects of turbine and pump efficiencies on the mass flow

rate and thermal efficiency are to be investigated. Also, the T-s diagram is to be plotted.

Analysis The problem is solved using EES, and the solution is given below.

"Input Data"

P[8] = 12500 [kPa]

T[8] = 550 [C]

P[9] = 800 [kPa]

"P_cfwh=300 [kPa]"

P[10] = P_cfwh

P_cond=10 [kPa]

P[11] = P_cond

W_dot_net=250 [MW]*Convert(MW, kW)

Eta_turb= 100/100 "Turbine isentropic efficiency"

Eta_turb_hp = Eta_turb "Turbine isentropic efficiency for high pressure stages"

Eta_turb_ip = Eta_turb "Turbine isentropic efficiency for intermediate pressure stages"

Eta_turb_lp = Eta_turb "Turbine isentropic efficiency for low pressure stages"

Eta_pump = 100/100 "Pump isentropic efficiency"

"Condenser exit pump or Pump 1 analysis"

Fluid$='Steam_IAPWS'

P[1] = P[11]

P[2]=P[10]

h[1]=enthalpy(Fluid$,P=P[1],x=0) {Sat'd liquid}

v1=volume(Fluid$,P=P[1],x=0)

s[1]=entropy(Fluid$,P=P[1],x=0)

T[1]=temperature(Fluid$,P=P[1],x=0)

w_pump1_s=v1*(P[2]-P[1])"SSSF isentropic pump work assuming constant specific volume"

w_pump1=w_pump1_s/Eta_pump "Definition of pump efficiency"

h[1]+w_pump1= h[2] "Steady-flow conservation of energy"

s[2]=entropy(Fluid$,P=P[2],h=h[2])

T[2]=temperature(Fluid$,P=P[2],h=h[2])

"Open Feedwater Heater analysis"

z*h[10] + y*h[7] + (1-y-z)*h[2] = 1*h[3] "Steady-flow conservation of energy"

h[3]=enthalpy(Fluid$,P=P[3],x=0)

T[3]=temperature(Fluid$,P=P[3],x=0) "Condensate leaves heater as sat. liquid at P[3]"

s[3]=entropy(Fluid$,P=P[3],x=0)

"Boiler condensate pump or Pump 2 analysis"

P[5]=P[8]

P[4] = P[5]

P[3]=P[10]

v3=volume(Fluid$,P=P[3],x=0)

w_pump2_s=v3*(P[4]-P[3])"SSSF isentropic pump work assuming constant specific volume"

w_pump2=w_pump2_s/Eta_pump "Definition of pump efficiency"

h[3]+w_pump2= h[4] "Steady-flow conservation of energy"

s[4]=entropy(Fluid$,P=P[4],h=h[4])

T[4]=temperature(Fluid$,P=P[4],h=h[4])

"Closed Feedwater Heater analysis"

P[6]=P[9]

y*h[9] + 1*h[4] = 1*h[5] + y*h[6] "Steady-flow conservation of energy"

h[5]=enthalpy(Fluid$,P=P[6],x=0) "h[5] = h(T[5], P[5]) where T[5]=Tsat at P[9]"

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-35

T[5]=temperature(Fluid$,P=P[5],h=h[5]) "Condensate leaves heater as sat. liquid at P[6]"

s[5]=entropy(Fluid$,P=P[6],h=h[5])

h[6]=enthalpy(Fluid$,P=P[6],x=0)

T[6]=temperature(Fluid$,P=P[6],x=0) "Condensate leaves heater as sat. liquid at P[6]"

s[6]=entropy(Fluid$,P=P[6],x=0)

"Trap analysis"

P[7] = P[10]

y*h[6] = y*h[7] "Steady-flow conservation of energy for the trap operating as a throttle"

T[7]=temperature(Fluid$,P=P[7],h=h[7])

s[7]=entropy(Fluid$,P=P[7],h=h[7])

"Boiler analysis"

q_in + h[5]=h[8]"SSSF conservation of energy for the Boiler"

h[8]=enthalpy(Fluid$, T=T[8], P=P[8])

s[8]=entropy(Fluid$, T=T[8], P=P[8])

"Turbine analysis"

ss[9]=s[8]

hs[9]=enthalpy(Fluid$,s=ss[9],P=P[9])

Ts[9]=temperature(Fluid$,s=ss[9],P=P[9])

h[9]=h[8]-Eta_turb_hp*(h[8]-hs[9])"Definition of turbine efficiency for high pressure stages"

T[9]=temperature(Fluid$,P=P[9],h=h[9])

s[9]=entropy(Fluid$,P=P[9],h=h[9])

ss[10]=s[8]

hs[10]=enthalpy(Fluid$,s=ss[10],P=P[10])

Ts[10]=temperature(Fluid$,s=ss[10],P=P[10])

h[10]=h[9]-Eta_turb_ip*(h[9]-hs[10])"Definition of turbine efficiency for Intermediate pressure

stages"

T[10]=temperature(Fluid$,P=P[10],h=h[10])

s[10]=entropy(Fluid$,P=P[10],h=h[10])

ss[11]=s[8]

hs[11]=enthalpy(Fluid$,s=ss[11],P=P[11])

Ts[11]=temperature(Fluid$,s=ss[11],P=P[11])

h[11]=h[10]-Eta_turb_lp*(h[10]-hs[11])"Definition of turbine efficiency for low pressure stages"

T[11]=temperature(Fluid$,P=P[11],h=h[11])

s[11]=entropy(Fluid$,P=P[11],h=h[11])

h[8] =y*h[9] + z*h[10] + (1-y-z)*h[11] + w_turb "SSSF conservation of energy for turbine"

"Condenser analysis"

(1-y-z)*h[11]=q_out+(1-y-z)*h[1]"SSSF First Law for the Condenser"

"Cycle Statistics"

w_net=w_turb - ((1-y-z)*w_pump1+ w_pump2)

Eta_th=w_net/q_in

W_dot_net = m_dot * w_net

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-36

turb

turb

th

m[kg/s]

0.7 0.7 0.3916 231.6

0.75 0.75 0.4045 224.3

0.8 0.8 0.4161 218

0.85 0.85 0.4267 212.6

0.9 0.9 0.4363 207.9

0.95 0.95 0.4452 203.8

1 1 0.4535 200.1

0.7 0.75 0.8 0.85 0.9 0.95 1

0.39

0.4

0.41

0.42

0.43

0.44

0.45

0.46

200

205

210

215

220

225

230

235

turb

t

h

m

[

k

g

/

s

]

turb

=

pump

0 2 4 6 8 10 12

0

100

200

300

400

500

600

s [kJ/kg-K]

T

[

C

]

12500 kPa

800 kPa

300 kPa

10 kPa

Steam

1,2

3,4

5,6

7

8

9

10

11

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-37

10-49 A steam power plant operates on an ideal reheat-regenerative Rankine cycle with an open feedwater

heater. The mass flow rate of steam through the boiler and the thermal efficiency of the cycle are to be

determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),

( ) ( )( )

kJ/kg 61 . 192 80 . 0 81 . 191

kJ/kg 0.80

m kPa 1

kJ 1

kPa 10 800 /kg m 0.00101

/kg m 00101 . 0

kJ/kg 81 . 191

in , 1 2

3

3

1 2 1 in ,

3

kPa 10 @ 1

kPa 10 @ 1

= + = + =

=

|

|

.

|

\

|

= =

= =

= =

pI

pI

f

f

w h h

P P w

h h

v

v v

T

( ) ( )( )

( )( ) kJ/kg 7 . 2494 1 . 2392 9627 . 0 81 . 191

9627 . 0

4996 . 7

6492 . 0 8692 . 7

kPa 10

K kJ/kg 8692 . 7

kJ/kg 3 . 3481

C 500

MPa 8 . 0

kJ/kg 1 . 2812

MPa 8 . 0

K kJ/kg 7585 . 6

kJ/kg 0 . 3502

C 550

MPa 10

kJ/kg 12 . 731 26 . 10 87 . 720

kJ/kg 10.26

m kPa 1

kJ 1

kPa 800 10,000 /kg m 0.001115

/kg m 001115 . 0

kJ/kg 87 . 720

liquid sat.

MPa 8 . 0

8 8

8

8

7 8

8

7

7

7

7

6

5 6

6

5

5

5

5

in , 3 4

3

3

3 4 3 in ,

3

MPa 8 . 0 @ 3

MPa 8 . 0 @ 3

3

= + = + =

=

=

)

`

=

=

=

=

)

`

=

=

=

)

`

=

=

=

=

)

`

=

=

= + = + =

=

|

|

.

|

\

|

= =

= =

= =

)

`

=

fg f

fg

f

pII

pII

f

f

h x h h

s

s s

x

s s

P

s

h

T

P

h

s s

P

s

h

T

P

w h h

P P w

h h

P

v

v v

10 MPa

1 - y

6

3

4

y

10 kPa

0.8 MPa

7

5

8

2

1

s

6

1-y

7

6

P II P I

Open

fwh

Condenser

Boiler

Turbine

4

3

2

1

8

5

y

The fraction of steam extracted is determined from the steady-flow energy balance equation applied to the

feedwater heaters. Noting that Q , 0 pe ke W

& &

( ) (

3 2 6 3 3 2 2 6 6

out in

(steady) 0

system out in

1 1

0

h h y yh h m h m h m h m h m

E E E E E

e e i i

= + = + =

= = =

& & & & &

& & & & &

)

where y is the fraction of steam extracted from the turbine ( = & / & m m

6 3

). Solving for y,

2017 . 0

61 . 192 1 . 2812

61 . 192 87 . 720

2 6

2 3

=

=

h h

h h

y

Then, ( ) ( )( ) ( ) ( )( )

( )( ) ( )( )

kJ/kg 6 . 1466 5 . 1838 1 . 3305

kJ/kg 5 . 1838 81 . 191 7 . 2494 2017 . 0 1 1

kJ/kg 1 . 3305 1 . 2812 3 . 3481 2017 . 0 1 12 . 731 0 . 3502 1

out in net

1 8 out

6 7 4 5 in

= = =

= = =

= + = + =

q q w

h h y q

h h y h h q

and kg/s 54.5 = = =

kJ/kg 1466.1

kJ/s 80,000

net

net

w

W

m

&

&

(b) 44.4% = = =

kJ/kg 3305.1

kJ/kg 1466.1

in

net

th

q

w

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-38

10-50 A steam power plant operates on an ideal reheat-regenerative Rankine cycle with a closed feedwater

heater. The mass flow rate of steam through the boiler and the thermal efficiency of the cycle are to be

determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis

9

10

Mixing

chamber

1-y

7

y

P II P I

Closed

fwh

Condenser

Boiler

Turbine

4

3

2

1

8

5

6

T

10 MPa

1 - y

6

3

4

10

9

y

10 kPa

0.8 MPa

7

5

8

2

1

s

(a) From the steam tables (Tables A-4, A-5, and A-6),

( ) ( )( )

( ) ( )( )

kJ/kg 13 . 731 26 . 10 87 . 720

kJ/kg 10.26

m kPa 1

kJ 1

kPa 800 10,000 /kg m 0.001115

/kg m 001115 . 0

kJ/kg 87 . 720

liquid sat.

MPa 8 . 0

kJ/kg 90 . 201 09 . 10 81 . 191

kJ/kg 10.09

m kPa 1

kJ 1

kPa 10 10,000 /kg m 0.00101

/kg m 00101 . 0

kJ/kg 81 . 191

in , 3 4

3

3

3 4 3 in ,

3

MP 8 . 0 @ 3

MPa 8 . 0 @ 3

3

in , 1 2

3

3

1 2 1 in ,

3

kPa 10 @ 1

kPa 10 @ 1

= + = + =

=

|

|

.

|

\

|

= =

= =

= =

)

`

=

= + = + =

=

|

|

.

|

\

|

= =

= =

= =

pII

pII

a f

f

pI

pI

f

f

w h h

P P w

h h

P

w h h

P P w

h h

v

v v

v

v v

Also, h

4

= h

9

= h

10

= 731.12 kJ/kg since the two fluid streams that are being mixed have the same enthalpy.

( )( ) kJ/kg 7 . 2494 1 . 2392 9627 . 0 81 . 191

9627 . 0

4996 . 7

6492 . 0 8692 . 7

kPa 10

K kJ/kg 8692 . 7

kJ/kg 3 . 3481

C 500

MPa 8 . 0

kJ/kg 7 . 2812

MPa 8 . 0

K kJ/kg 7585 . 6

kJ/kg 0 . 3502

C 550

MPa 10

8 8

8

8

7 8

8

7

7

7

7

6

5 6

6

5

5

5

5

= + = + =

=

=

)

`

=

=

=

=

)

`

=

=

=

)

`

=

=

=

=

)

`

=

=

fg f

fg

f

h x h h

s

s s

x

s s

P

s

h

T

P

h

s s

P

s

h

T

P

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-39

The fraction of steam extracted is determined from the steady-flow energy balance equation applied to the

feedwater heaters. Noting that Q , 0 pe ke W

& &

( ) ( ) ( )( ) (

3 6 2 9 3 6 3 2 9 2

out in

(steady) 0

system out in

1

0

h h y h h y h h m h h m h m h m

E E

E E E

e e i i

= = =

=

= =

& & & &

& &

& & &

)

where y is the fraction of steam extracted from the turbine ( = & / & m m

3 4

). Solving for y,

( ) ( )

2019 . 0

90 . 201 13 . 731 87 . 720 7 . 2812

90 . 201 13 . 731

2 9 3 6

2 9

=

+

=

+

=

h h h h

h h

y

Then,

( ) ( )( ) ( ) ( )( )

( )( ) ( )( )

kJ/kg 6 . 1466 8 . 1837 5 . 3304

kJ/kg 9 . 1837 81 . 191 7 . 2494 2019 . 0 1 1

kJ/kg 5 . 3304 7 . 2812 3 . 3481 2019 . 0 1 13 . 731 0 . 3502 1

out in net

1 8 out

6 7 4 5 in

= = =

= = =

= + = + =

q q w

h h y q

h h y h h q

and

kg/s 54.5 = = =

kJ/kg 1467.1

kJ/s 80,000

net

net

w

W

m

&

&

(b) 44.4% = = =

kJ/kg 3304.5

kJ/kg 1837.8

1 1

in

out

th

q

q

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-40

10-51E A steam power plant operates on an ideal reheat-regenerative Rankine cycle with one reheater and

two open feedwater heaters. The mass flow rate of steam through the boiler, the net power output of the

plant, and the thermal efficiency of the cycle are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis

High-P

Turbine

5

P III

1-y-z

12

11

z

10

4

Open

fwh II

1-y

y

P II P I

Open

fwh I

Condenser

Boiler

Low-P

Turbine

6

3

2

1

8

7

9

T

9

10

z

1500

8

1 - y

5

6

3

y

4

250 psia

1 psia

40 psia

140 psia

1 - y - z

11

7

12

2

1

s

(a) From the steam tables (Tables A-4E, A-5E, and A-6E),

( )

( )( )

Btu/lbm 84 . 69 12 . 0 72 . 69

Btu/lbm 0.12

ft psia 5.4039

Btu 1

psia 1 40 /lbm ft 0.01614

/lbm ft 01614 . 0

Btu/lbm 72 . 69

in , 1 2

3

3

1 2 1 in ,

3

psia 1 @ 1

psia 1 @ 1

= + = + =

=

|

|

.

|

\

|

=

=

= =

= =

pI

pI

f

f

w h h

P P w

h h

v

v v

( )

( )( )

( )

( )( )

Btu/lbm 41 . 380 31 . 4 09 . 376

Btu/lbm 4.31

ft psia 5.4039

Btu 1

psia 250 1500 /lbm ft 0.01865

/lbm ft 01865 . 0

Btu/lbm 09 . 376

liquid sat.

psia 250

Btu/lbm 81 . 236 67 . 0 14 . 236

Btu/lbm 0.67

ft psia 5.4039

Btu 1

psia 40 250 /lbm ft 0.01715

/lbm ft 01715 . 0

Btu/lbm 14 . 236

liquid sat.

psia 40

in , 5 6

3

3

5 6 5 in ,

3

psia 250 @ 5

psia 250 @ 5

5

i , 3 4

3

3

3 4 3 in ,

3

psia 40 @ 3

psia 40 @ 3

3

= + = + =

=

|

|

.

|

\

|

=

=

= =

= =

)

`

=

= + = + =

=

|

|

.

|

\

|

=

=

= =

= =

)

`

=

pIII

pIII

f

f

n pII

pII

f

f

w h h

P P w

h h

P

w h h

P P w

h h

P

v

v v

v

v v

Btu/lbm 5 . 1308

psia 250

R Btu/lbm 6402 . 1

Btu/lbm 5 . 1550

F 1100

psia 1500

8

7 8

8

7

7

7

7

=

)

`

=

=

=

=

)

`

=

=

h

s s

P

s

h

T

P

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-41

( )(

Btu/lbm 4 . 1052

7 . 1035 9488 . 0 72 . 69

9488 . 0

84495 . 1

13262 . 0 8832 . 1

psia 1

Btu/lbm 0 . 1356

psia 40

R Btu/lbm 8832 . 1

Btu/lbm 3 . 1531

F 1000

psia 140

Btu/lbm 8 . 1248

psia 140

12 12

12

12

10 12

12

11

10 11

11

10

10

10

10

9

7 9

9

=

+ = + =

=

=

)

`

=

=

=

)

`

=

=

=

=

)

`

=

=

=

)

`

=

=

fg f

fg

f

h x h h

s

s s

x

s s

P

h

s s

P

s

h

T

P

h

s s

P

)

)

The fraction of steam extracted is determined from the steady-flow energy balance equation applied to the

feedwater heaters. Noting that Q , 0 pe ke W

& &

FWH-2:

( ) (

5 4 8 5 5 4 4 8 8

out in

(steady) 0

system out in

1 1

0

h h y yh h m h m h m h m h m

E E

E E E

e e i i

= + = + =

=

= =

& & & & &

& &

& & &

where y is the fraction of steam extracted from the turbine ( = & / & m m

8 5

). Solving for y,

1300 . 0

81 . 236 5 . 1308

81 . 236 09 . 376

4 8

4 5

=

=

h h

h h

y

FWH-1

( ) (

3 2 11 3 3 2 2 11 11

out in

(steady) 0

system out in

1 1

0

h y h z y zh h m h m h m h m h m

E E

E E E

e e i i

= + = + =

=

= =

& & & & &

& &

& & &

)

where z is the fraction of steam extracted from the turbine ( = & / & m m

9 5

) at the second stage. Solving for z,

( ) ( ) 1125 . 0 1300 . 0 1

84 . 69 0 . 1356

84 . 69 14 . 236

1

2 11

2 3

=

= y

h h

h h

z

Then,

( )( ) ( )( )

( )( ) ( )( )

Btu/lbm 4 . 671 4 . 744 8 . 1415

Btu/lbm 744.4 69.72 1052.4 1125 . 0 1300 . 0 1 1

Btu/lbm 8 . 1415 8 . 1248 3 . 1531 1300 . 0 1 41 . 380 5 . 1550 1

out in net

1 12 out

9 10 6 7 in

= = =

= = =

= + = + =

q q w

h h z y q

h h y h h q

and

lbm/s 282.5 =

= =

Btu/lbm 1415.8

Btu/s 10 4

5

in

in

q

Q

m

&

&

(b) ( )( ) MW 200.1 =

|

|

.

|

\

|

= =

Btu 1

kJ 1.055

Btu/lbm 671.4 lbm/s 282.5

net net

w m W &

&

(c) 47.4% = = =

Btu/lbm 1415.8

Btu/lbm 744.4

1 1

in

out

th

q

q

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-42

10-52 A steam power plant that operates on an ideal regenerative Rankine cycle with a closed feedwater

heater is considered. The temperature of the steam at the inlet of the closed feedwater heater, the mass flow

rate of the steam extracted from the turbine for the closed feedwater heater, the net power output, and the

thermal efficiency are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),

( )

kJ/kg 85 . 265 43 . 14 42 . 251

kJ/kg .43 14

88 . 0 / ) kPa 20 12,500 )( /kg m 0.001017 (

/

/kg m 001017 . 0

kJ/kg 42 . 251

in , 1 2

3

1 2 1 in ,

3

kPa 20 @ 1

kPa 20 @ 1

= + = + =

=

=

=

= =

= =

pI

p pI

f

f

w h h

P P w

h h

v

v v

Low-P

turbine

9

10

11

Mixing

Cham.

1-y

7

y

PII PI

Closed

fwh

Cond.

Boiler

High-P

turbine

4

3

2

1

8

5

6

/kg m 001127 . 0

kJ/kg 51 . 762

liquid sat.

MPa 1

3

MPa 1 @ 3

MPa 1 @ 3

3

= =

= =

)

`

=

f

f

h h

P

v v

( )

kJ/kg 25 . 777 73 . 14 51 . 762

kJ/kg 73 . 14

88 . 0 / ) kPa 00 10 12,500 )( /kg m 001127 . 0 (

/

in , 3 11

3

3 11 3 in ,

= + = + =

=

=

=

pII

p pII

w h h

P P w v

Also, h

4

= h

10

= h

11

= 777.25 kJ/kg since the two fluid streams which are being mixed have the same

enthalpy.

( )

( )( ) kJ/kg 5 . 3220 6 . 3185 5 . 3476 88 . 0 5 . 3476

kJ/kg 6 . 3185

MPa 5

K kJ/kg 6317 . 6

kJ/kg 5 . 3476

C 550

MPa 5 . 12

6 5 5 6

6 5

6 5

6

5 6

6

5

5

5

5

= =

=

=

=

)

`

=

=

=

=

)

`

=

=

s T

s

T

s

h h h h

h h

h h

h

s s

P

s

h

T

P

( )

( )( )

C 328 =

)

`

=

=

= =

=

=

=

)

`

=

=

=

=

)

`

=

=

8

8

8

8 7 7 8

8 7

8 7

8

7 8

8

7

7

7

7

kJ/kg 1 . 3111

MPa 1

kJ/kg 1 . 3111 1 . 3051 9 . 3550 88 . 0 9 . 3550

kJ/kg 1 . 3051

MPa 1

K kJ/kg 1238 . 7

kJ/kg 9 . 3550

C 550

MPa 5

T

h

P

h h h h

h h

h h

h

s s

P

s

h

T

P

s T

s

T

s

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-43

( )

( )( ) kJ/kg 2 . 2492 9 . 2347 9 . 3550 88 . 0 9 . 3550

kJ/kg 9 . 2347

kPa 20

9 7 7 9

9 7

9 7

9

7 9

9

= =

=

=

=

)

`

=

=

s T

s

T

s

h h h h

h h

h h

h

s s

P

The fraction of steam extracted from the low pressure turbine for closed feedwater heater is determined

from the steady-flow energy balance equation applied to the feedwater heater. Noting that

,

& &

Q W ke pe 0

( )( ) ( )

1788 . 0 ) 51 . 762 1 . 3111 ( ) 85 . 265 25 . 777 )( 1 (

1

3 8 2 10

= =

=

y y y

h h y h h y

The corresponding mass flow rate is

kg/s 4.29 = = = kg/s) 24 )( 1788 . 0 (

5 8

m y m & &

(c) Then,

( )( ) ( )( ) kJ/kg 1 . 1840 42 . 251 2 . 2492 1788 . 0 1 1

kJ/kg 7 . 3029 5 . 3220 9 . 3550 25 . 777 5 . 3476

1 9 out

6 7 4 5 in

= = =

= + = + =

h h y q

h h h h q

and

kW 28,550 = = = kJ/kg ) 1 . 1840 7 . 3029 )( kg/s 24 ( ) (

out in net

q q m W &

&

(b) The thermal efficiency is determined from

39.3% = = = = 393 . 0

kJ/kg 3029.7

kJ/kg 1840.1

1 1

in

out

th

q

q

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-44

Second-Law Analysis of Vapor Power Cycles

10-53C In the simple ideal Rankine cycle, irreversibilities occur during heat addition and heat rejection

processes in the boiler and the condenser, respectively, and both are due to temperature difference.

Therefore, the irreversibilities can be decreased and thus the 2

nd

law efficiency can be increased by

minimizing the temperature differences during heat transfer in the boiler and the condenser. One way of

doing that is regeneration.

10-54 The exergy destructions associated with each of the processes of the Rankine cycle described in

Prob. 10-15 are to be determined for the specified source and sink temperatures.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From Problem 10-15,

kJ/kg 8 . 1931

kJ/kg 72 . 2650

K kJ/kg 5412 . 6

K kJ/kg 0912 . 1

out

4 3

kPa 50 @ 2 1

=

=

= =

= = =

q

q

s s

s s s

in

f

Processes 1-2 and 3-4 are isentropic. Thus, i

12

= 0 and i

34

= 0. Also,

( )

( ) kJ/kg 351.3

kJ/kg 1068

=

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

=

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

K 290

kJ/kg 1931.8

5412 . 6 0912 . 1 K 290

K 1500

kJ/kg 2650.8

0912 . 1 5412 . 6 K 290

41 ,

4 1 0 41 destroyed,

23 ,

2 3 0 23 destroyed,

R

R

R

R

T

q

s s T x

T

q

s s T x

10-55 The exergy destructions associated with each of the processes of the Rankine cycle described in

Prob. 10-16 are to be determined for the specified source and sink temperatures.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From Problem 10-16,

kJ/kg 9 . 1897

kJ/kg 2 . 3173

K kJ/kg 5995 . 6

K kJ/kg 6492 . 0

out

in

4 3

kPa 10 @ 2 1

=

=

= =

= = =

q

q

s s

s s s

f

Processes 1-2 and 3-4 are isentropic. Thus, i

12

= 0 and i

34

= 0. Also,

( )

( ) kJ/kg 172.3

kJ/kg 1112.1

=

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

=

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

K 290

kJ/kg 1897.9

5995 . 6 6492 . 0 K 290

K 1500

kJ/kg 3173.2

6492 . 0 5995 . 6 K 290

41 ,

4 1 0 41 destroyed,

23 ,

2 3 0 23 destroyed,

R

R

R

R

T

q

s s T x

T

q

s s T x

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-45

10-56 The exergy destruction associated with the heat rejection process in Prob. 10-22 is to be determined

for the specified source and sink temperatures. The exergy of the steam at the boiler exit is also to be

determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From Problem 10-22,

kJ/kg 8 . 1961

kJ/kg 4 . 3411

K kJ/kg 8000 . 6

K kJ/kg 6492 . 0

out

3

4 3

kPa 10 @ 2 1

=

=

= =

= = =

q

h

s s

s s s

f

The exergy destruction associated with the heat rejection process is

( ) kJ/kg 178.0 =

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

K 290

kJ/kg 1961.8

8000 . 6 6492 . 0 K 290

41 ,

4 1 0 41 destroyed,

R

R

T

q

s s T x

The exergy of the steam at the boiler exit is simply the flow exergy,

( ) ( )

( ) ( )

0 3 0 0 3

0

3

0

2

3

0 3 0 0 3 3

2

s s T h h

qz s s T h h

=

+ + =

where

( )

( )

K kJ/kg 2533 . 0

kJ/kg 95 . 71

K 290 @ kPa 100 , K 290 @ 0

K 290 @ kPa 100 , K 290 @ 0

= =

= =

f

f

s s s

h h h

Thus, ( ) ( )( ) kJ/kg 1440.9 = = K kJ/kg 2532 . 0 800 . 6 K 290 kJ/kg 95 . 71 4 . 3411

3

10-57 The exergy destructions associated with each of the processes of the reheat Rankine cycle described

in Prob. 10-32 are to be determined for the specified source and sink temperatures.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From Problem 10-32,

kJ/kg 8 . 2133 42 . 251 2 . 2385

kJ/kg 1 . 352 1 . 3105 2 . 3457

kJ/kg 0 . 3140 54 . 259 5 . 3399

K kJ/kg 2359 . 7

K kJ/kg 7266 . 6

K kJ/kg 8320 . 0

1 6 out

in , 45

in , 23

6 5

4 3

kPa 20 @ 2 1

= = =

= =

= =

= =

= =

= = =

h h q

q

q

s s

s s

s s s

f

Processes 1-2, 3-4, and 5-6 are isentropic. Thus, i

12

= i

34

= i

56

= 0. Also,

( )

( )

( ) kJ/kg 212.6

kJ/kg 94.1

kJ/kg 1245.0

= |

.

|

\

|

+ =

|

|

.

|

\

|

+ =

=

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

= |

.

|

\

|

+ =

|

|

.

|

\

|

+ =

K 300

kJ/kg 2133.8

2359 . 7 8320 . 0 K 300

K 1800

kJ/kg 352.5

7266 . 6 2359 . 7 K 300

K 1800

kJ/kg 3140.0

8320 . 0 7266 . 6 K 300

61 ,

6 1 0 61 destroyed,

45 ,

4 5 0 45 destroyed,

23 ,

2 3 0 23 destroyed,

R

R

R

R

R

R

T

q

s s T x

T

q

s s T x

T

q

s s T x

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-46

10-58 EES Problem 10-57 is reconsidered. The problem is to be solved by the diagram window data entry

feature of EES by including the effects of the turbine and pump efficiencies. Also, the T-s diagram is to be

plotted.

Analysis The problem is solved using EES, and the solution is given below.

function x6$(x6) "this function returns a string to indicate the state of steam at point 6"

x6$=''

if (x6>1) then x6$='(superheated)'

if (x6<0) then x6$='(subcooled)'

end

"Input Data - from diagram window"

{P[6] = 20 [kPa]

P[3] = 8000 [kPa]

T[3] = 500 [C]

P[4] = 3000 [kPa]

T[5] = 500 [C]

Eta_t = 100/100 "Turbine isentropic efficiency"

Eta_p = 100/100 "Pump isentropic efficiency"}

"Data for the irreversibility calculations:"

T_o = 300 [K]

T_R_L = 300 [K]

T_R_H = 1800 [K]

"Pump analysis"

Fluid$='Steam_IAPWS'

P[1] = P[6]

P[2]=P[3]

x[1]=0 "Sat'd liquid"

h[1]=enthalpy(Fluid$,P=P[1],x=x[1])

v[1]=volume(Fluid$,P=P[1],x=x[1])

s[1]=entropy(Fluid$,P=P[1],x=x[1])

T[1]=temperature(Fluid$,P=P[1],x=x[1])

W_p_s=v[1]*(P[2]-P[1])"SSSF isentropic pump work assuming constant specific volume"

W_p=W_p_s/Eta_p

h[2]=h[1]+W_p "SSSF First Law for the pump"

v[2]=volume(Fluid$,P=P[2],h=h[2])

s[2]=entropy(Fluid$,P=P[2],h=h[2])

T[2]=temperature(Fluid$,P=P[2],h=h[2])

"High Pressure Turbine analysis"

h[3]=enthalpy(Fluid$,T=T[3],P=P[3])

s[3]=entropy(Fluid$,T=T[3],P=P[3])

v[3]=volume(Fluid$,T=T[3],P=P[3])

s_s[4]=s[3]

hs[4]=enthalpy(Fluid$,s=s_s[4],P=P[4])

Ts[4]=temperature(Fluid$,s=s_s[4],P=P[4])

Eta_t=(h[3]-h[4])/(h[3]-hs[4])"Definition of turbine efficiency"

T[4]=temperature(Fluid$,P=P[4],h=h[4])

s[4]=entropy(Fluid$,T=T[4],P=P[4])

v[4]=volume(Fluid$,s=s[4],P=P[4])

h[3] =W_t_hp+h[4]"SSSF First Law for the high pressure turbine"

"Low Pressure Turbine analysis"

P[5]=P[4]

s[5]=entropy(Fluid$,T=T[5],P=P[5])

h[5]=enthalpy(Fluid$,T=T[5],P=P[5])

s_s[6]=s[5]

hs[6]=enthalpy(Fluid$,s=s_s[6],P=P[6])

Ts[6]=temperature(Fluid$,s=s_s[6],P=P[6])

vs[6]=volume(Fluid$,s=s_s[6],P=P[6])

Eta_t=(h[5]-h[6])/(h[5]-hs[6])"Definition of turbine efficiency"

h[5]=W_t_lp+h[6]"SSSF First Law for the low pressure turbine"

x[6]=QUALITY(Fluid$,h=h[6],P=P[6])

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-47

"Boiler analysis"

Q_in + h[2]+h[4]=h[3]+h[5]"SSSF First Law for the Boiler"

"Condenser analysis"

h[6]=Q_out+h[1]"SSSF First Law for the Condenser"

T[6]=temperature(Fluid$,h=h[6],P=P[6])

s[6]=entropy(Fluid$,h=h[6],P=P[6])

x6s$=x6$(x[6])

"Cycle Statistics"

W_net=W_t_hp+W_t_lp-W_p

Eff=W_net/Q_in

"The irreversibilities (or exergy destruction) for each of the processes are:"

q_R_23 = - (h[3] - h[2]) "Heat transfer for the high temperature reservoir to process 2-3"

i_23 = T_o*(s[3] -s[2] + q_R_23/T_R_H)

q_R_45 = - (h[5] - h[4]) "Heat transfer for the high temperature reservoir to process 4-5"

i_45 = T_o*(s[5] -s[4] + q_R_45/T_R_H)

q_R_61 = (h[6] - h[1]) "Heat transfer to the low temperature reservoir in process 6-1"

i_61 = T_o*(s[1] -s[6] + q_R_61/T_R_L)

i_34 = T_o*(s[4] -s[3])

i_56 = T_o*(s[6] -s[5])

i_12 = T_o*(s[2] -s[1])

0.0 1.1 2.2 3.3 4.4 5.5 6.6 7.7 8.8 9.9 11.0

0

100

200

300

400

500

600

700

s [kJ/kg-K]

T

[

C

]

8000 kPa

3000 kPa

20 kPa

3

4

5

6

Ideal Rankine cycle with reheat

1,2

SOLUTION

Eff=0.389

Eta_p=1

Eta_t=1

Fluid$='Steam_IAPWS'

h[1]=251.4[kJ/kg]

h[2]=259.5[kJ/kg]

h[3]=3400[kJ/kg]

h[4]=3105[kJ/kg]

h[5]=3457[kJ/kg]

h[6]=2385[kJ/kg]

hs[4]=3105[kJ/kg]

hs[6]=2385[kJ/kg]

i_12=0.012[kJ/kg]

i_23=1245.038[kJ/kg]

i_34=-0.000[kJ/kg]

i_45=94.028[kJ/kg]

i_56=0.000[kJ/kg]

i_61=212.659[kJ/kg]

P[1]=20[kPa]

P[2]=8000[kPa]

P[3]=8000[kPa]

P[4]=3000[kPa]

P[5]=3000[kPa]

P[6]=20[kPa]

Q_in=3493[kJ/kg]

Q_out=2134[kJ/kg]

q_R_23=-3140[kJ/kg]

q_R_45=-352.5[kJ/kg]

q_R_61=2134[kJ/kg]

s[1]=0.832[kJ/kg-K]

s[2]=0.8321[kJ/kg-K]

s[3]=6.727[kJ/kg-K]

s[4]=6.727[kJ/kg-K]

s[5]=7.236[kJ/kg-K]

s[6]=7.236[kJ/kg-K]

s_s[4]=6.727[kJ/kg-K]

s_s[6]=7.236[kJ/kg-K]

T[1]=60.06[C]

T[2]=60.4[C]

T[3]=500[C]

T[4]=345.2[C]

T[5]=500[C]

T[6]=60.06[C]

Ts[4]=345.2[C]

Ts[6]=60.06[C]

T_o=300[K]

T_R_H=1800[K]

T_R_L=300[K]

v[1]=0.001017[m^3/kg]

v[2]=0.001014[m^3/kg]

v[3]=0.04177[m^3/kg]

v[4]=0.08968[m^3/kg]

vs[6]=6.922[m^3/kg]

W_net=1359[kJ/kg]

W_p=8.117[kJ/kg]

W_p_s=8.117[kJ/kg]

W_t_hp=294.8[kJ/kg]

W_t_lp=1072[kJ/kg]

x6s$=''

x[1]=0

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-31

x[6]=0.9051

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-48

10-59 The exergy destruction associated with the heat addition process and the expansion process in Prob.

10-34 are to be determined for the specified source and sink temperatures. The exergy of the steam at the

boiler exit is also to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From Problem 10-34,

( )

( )

kJ/kg 8 . 3749

kJ/kg 1 . 3375

kJ/kg 8 . 2664 , kPa 10 K kJ/kg 3870 . 8

K kJ/kg 7642 . 7

kJ/kg 0 . 2902 , MPa 1 K kJ/kg 8464 . 6

K kJ/kg 5995 . 6

K kJ/kg 6492 . 0

in

3

6 6 6

5

4 4 4

3

kPa 10 @ 2 1

=

=

= = =

=

= = =

=

= = =

q

h

h P s

s

h P s

s

s s s

f

The exergy destruction associated with the combined pumping and the heat addition processes is

( ) kJ/kg 5 . 1289

K 1600

kJ/kg 3749.8

8464 . 6 7642 . 7 6492 . 0 5995 . 6 K 285

15 ,

4 5 1 3 0 destroyed

=

|

|

.

|

\

|

+ + =

|

|

.

|

\

|

+ + =

R

R

T

q

s s s s T x

The exergy destruction associated with the pumping process is

Thus,

kJ/kg 1289 = = =

= = =

5 . 0 5 . 1289

kJ/kg 53 . 0 09 . 10 62 . 10

12 destroyed, destroyed heating destroyed,

, , , 12 destroyed,

x x x

P v w w w x

a p s p a p

The exergy destruction associated with the expansion process is

( ) ( )

( )( ) kJ/kg 247.9 = + =

|

|

.

|

\

|

+ + =

K kJ/kg 7642 . 7 3870 . 8 5995 . 6 8464 . 6 K 285

0

36 ,

5 6 3 4 0 34 destroyed,

R

R

T

q

s s s s T x

The exergy of the steam at the boiler exit is determined from

( ) ( )

( ) ( )

0 3 0 0 3

0

3

0

2

3

0 3 0 0 3 3

2

s s T h h

qz

V

s s T h h

=

+ + =

where

( )

( )

K kJ/kg 1806 . 0

kJ/kg 51 . 50

K 285 @ kPa 100 K, 285 @ 0

K 285 @ kPa 100 K, 285 @ 0

= =

= =

f

f

s s s

h h h

Thus,

( ) ( )( ) kJ/kg 1495 = = K kJ/kg 1806 . 0 5995 . 6 K 285 kJ/kg 51 . 50 1 . 3375

3

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-49

10-60 The exergy destruction associated with the regenerative cycle described in Prob. 10-44 is to be

determined for the specified source and sink temperatures.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From Problem 10-44, q

in

= 2692.2 kJ/kg and q

out

= 1675.7 kJ/kg. Then the exergy destruction

associated with this regenerative cycle is

( ) kJ/kg 1155 =

|

|

.

|

\

|

=

|

|

.

|

\

|

=

K 1500

kJ/kg 2692.2

K 290

kJ/kg 1675.7

K 290

in out

0 destroyed,

H L

cycle

T

q

T

q

T x

10-61 The exergy destruction associated with the reheating and regeneration processes described in Prob.

10-49 are to be determined for the specified source and sink temperatures.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis From Problem 10-49 and the steam tables,

kJ/kg 6 . 668 7 . 2812 3 . 3481

K kJ/kg 6492 . 0

K kJ/kg 8692 . 7

K kJ/kg 7585 . 6

K kJ/kg 0457 . 2

2016 . 0

6 7 reheat

kPa 10 @ 2 1

7

6 5

MPa 8 . 0 @ 3

= = =

= = =

=

= =

= =

=

h h q

s s s

s

s s

s s

y

f

f

Then the exergy destruction associated with reheat and regeneration processes are

( )

( ) ( )

( ) ( )( ) ( )( ) | | kJ/kg 47.8

kJ/kg 214.3

= =

=

|

|

.

|

\

|

+ = =

=

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+ =

6492 . 0 2016 . 0 1 7585 . 6 2016 . 0 0457 . 2 K 290

1

K 1800

kJ/kg 668.6

7585 . 6 8692 . 7 K 290

2 6 3 0

0

0

surr

0 gen 0 regen destroyed,

67 ,

6 7 0 reheat destroyed,

s y ys s T

T

q

s m s m T s T x

T

q

s s T x

i i e e

R

R

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-50

10-62 A single-flash geothermal power plant uses hot geothermal water at 230C as the heat source. The

power output from the turbine, the thermal efficiency of the plant, the exergy of the geothermal liquid at

the exit of the flash chamber, and the exergy destructions and exergy efficiencies for the flash chamber, the

turbine, and the entire plant are to be determined.

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.

Analysis (a) We use properties of water for

geothermal water (Tables A-4, A-5, and A-6)

kJ/kg.K 6841 . 2

1661 . 0

kJ/kg 14 . 990

kPa 500

kJ/kg.K 6100 . 2

kJ/kg 14 . 990

0

C 230

2

2

1 2

2

1

1

1

1

=

=

)

`

= =

=

=

=

)

`

=

=

s

x

h h

P

s

h

x

T

kg/s 38.19 kg/s) 230 )( 1661 . 0 (

1 2 3

= =

= m x m & &

K kJ/kg 7739 . 7

kJ/kg 3 . 2464

95 . 0

kPa 10

K kJ/kg 8207 . 6

kJ/kg 1 . 2748

1

kPa 500

4

4

4

4

3

3

3

3

=

=

)

`

=

=

=

=

)

`

=

=

s

h

x

P

s

h

x

P

K kJ/kg 8604 . 1

kJ/kg 09 . 640

0

kPa 500

6

6

6

6

=

=

)

`

=

=

s

h

x

P

kg/s 81 . 191 19 . 38 230

3 1 6

= = = m m m & & &

2

production

well

reinjection

well

separator

steam

turbine

1

Flash

chamber

6

5

4

3

condenser

The power output from the turbine is

kW 10,842 = = = kJ/kg ) 3 . 2464 8.1 kJ/kg)(274 38.19 ( ) (

4 3 3 T

h h m W &

&

We use saturated liquid state at the standard temperature for dead state properties

kJ/kg 3672 . 0

kJ/kg 83 . 104

0

C 25

0

0

0

0

=

=

)

`

=

=

s

h

x

T

kW 622 , 203 kJ/kg ) 83 . 104 .14 kJ/kg)(990 230 ( ) (

0 1 1 in

= = = h h m E &

&

5.3% = = = = 0.0532

622 , 203

842 , 10

in

out T,

th

E

W

&

&

(b) The specific exergies at various states are

kJ/kg 53 . 216 kJ/kg.K ) 3672 . 0 K)(2.6100 (298 kJ/kg ) 83 . 104 (990.14 ) (

0 1 0 0 1 1

= = = s s T h h

kJ/kg 44 . 194 kJ/kg.K ) 3672 . 0 K)(2.6841 (298 kJ/kg ) 83 . 104 (990.14 ) (

0 2 0 0 2 2

= = = s s T h h

kJ/kg 10 . 719 kJ/kg.K ) 3672 . 0 K)(6.8207 (298 kJ/kg ) 83 . 104 (2748.1 ) (

0 3 0 0 3 3

= = = s s T h h

kJ/kg 05 . 151 kJ/kg.K ) 3672 . 0 K)(7.7739 (298 kJ/kg ) 83 . 104 (2464.3 ) (

0 4 0 0 4 4

= = = s s T h h

kJ/kg 97 . 89 kJ/kg.K ) 3672 . 0 K)(1.8604 (298 kJ/kg ) 83 . 104 (640.09 ) (

0 6 0 0 6 6

= = = s s T h h

The exergy of geothermal water at state 6 is

kW 17,257 = = = kJ/kg) 7 kg/s)(89.9 .81 191 (

6 6 6

m X &

&

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

10-51

(c) Flash chamber:

kW 5080 = = = kJ/kg ) 44 . 194 53 kg/s)(216. 230 ( ) (

2 1 1 FC dest,

m X &

&

89.8% = = = = 0.898

53 . 216

44 . 194

1

2

FC II,

(d) Turbine:

kW 10,854 = = = kW 10,842 - kJ/kg ) 05 . 151 10 kg/s)(719. 19 . 38 ( ) (

T 4 3 3 T dest,

W m X

&

&

&

50.0% = =

= 0.500

)kJ/kg 05 . 151 10 kg/s)(719. 19 . 38 (

kW 842 , 10

) (

4 3 3

T

T II,

m

W

&

&

(e) Plant:

kW 802 , 49 kJ/kg) 53 kg/s)(216. 230 (

1 1 Plant in,

= = = m X &

&

kW 38,960 = = = 842 , 10 802 , 49

T Plant in, Plant dest,

W X X

& & &

21.8% = = = = 0.2177

kW 802 , 49

kW 842 , 10

Plant in,

T

Plant II,

X

W

&

&

Cogeneration

10-63C The utilization factor of a cogeneration plant is the ratio of the energy utilized for a useful purpose

to the total energy supplied. It could be unity for a plant that does not produce any power.

10-64C No. A cogeneration plant may involve throttling, friction, and heat transfer through a finite

temperature difference, and still have a utilization factor of unity.

10-65C Yes, if the cycle involves no irreversibilities such as throttling, friction, and heat transfer through a

finite temperature difference.

10-66C Cogeneration is the production of more than one useful form of energy from the same energy

source. Regeneration is the transfer of heat from the working fluid at some stage to the working fluid at

some other stage.

PROPRIETARY MATERIAL. 2006 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

You might also like

- JHU Pre-Med Resume Template PDFDocument2 pagesJHU Pre-Med Resume Template PDFZahida AsifNo ratings yet

- Solutions Manual For Thermodynamics and Chemistry: Howard DevoeDocument110 pagesSolutions Manual For Thermodynamics and Chemistry: Howard DevoeAshna GautamNo ratings yet

- Divorce Should Not Be Legalized in The PhilippinesDocument3 pagesDivorce Should Not Be Legalized in The Philippinesfrangkiepoop91% (44)

- Topic 7 - Reheat-Regenerative Power Cycle and PlantDocument11 pagesTopic 7 - Reheat-Regenerative Power Cycle and PlantMike MikeNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Jotun Jota Ep Mastic 66Document4 pagesJotun Jota Ep Mastic 66Abi PutraNo ratings yet

- Heat Transfer EngineeringDocument14 pagesHeat Transfer EngineeringAhmedAdrarNo ratings yet

- The Village of Round and Square HousesDocument1 pageThe Village of Round and Square Housesmaricon elle100% (2)

- Journal Pre-Proofs: Applied Thermal EngineeringDocument40 pagesJournal Pre-Proofs: Applied Thermal EngineeringDedi AfandiNo ratings yet

- ENSC 461 Tutorial, Week#4 - IC EnginesDocument8 pagesENSC 461 Tutorial, Week#4 - IC Enginesandres179No ratings yet

- 5 Controlled Rectifier DC Drives-Closed Loop - PpsDocument41 pages5 Controlled Rectifier DC Drives-Closed Loop - PpsRanjan KumarNo ratings yet

- DL-SCAN-10 Automated Sampling Instrument Operation ManualDocument10 pagesDL-SCAN-10 Automated Sampling Instrument Operation ManualNoé NK100% (1)

- Me 409 Compressible Fluid Flow: Tutorial 3: Numerical Problems On One Dimensional Isentropic FlowDocument8 pagesMe 409 Compressible Fluid Flow: Tutorial 3: Numerical Problems On One Dimensional Isentropic FlowVenkitaraj K PNo ratings yet

- Slides of All TurboDocument383 pagesSlides of All TurboDeivid William TorresNo ratings yet

- Middle East Technical University Mechanical Engineering Department ME 485 CFD With Finite Volume Method Spring 2017 (Dr. Sert)Document34 pagesMiddle East Technical University Mechanical Engineering Department ME 485 CFD With Finite Volume Method Spring 2017 (Dr. Sert)Kwanchai Choicharoen100% (1)

- MA2007 Summary Cycles Processes Part 2 FormulasDocument15 pagesMA2007 Summary Cycles Processes Part 2 FormulasYap Gee ShiuanNo ratings yet

- T3d TutorialDocument28 pagesT3d TutoriallitosfearNo ratings yet

- TD Physique NuageDocument3 pagesTD Physique Nuageelsa olive ze100% (1)

- 05 - Thermodynamic - Cycles - (Rankine) PDFDocument6 pages05 - Thermodynamic - Cycles - (Rankine) PDFAntonio Di FioreNo ratings yet

- Chapter1: Introduction To TurbomachinesDocument21 pagesChapter1: Introduction To TurbomachinesBinay Ranjan ChaudharyNo ratings yet

- TF06 Convection 03Document2 pagesTF06 Convection 03thekrumpNo ratings yet

- Rankine ReheatDocument2 pagesRankine ReheatManik SinghNo ratings yet

- Heat Exchanger Tutorial No 2 PDFDocument2 pagesHeat Exchanger Tutorial No 2 PDFNitin BuZzNo ratings yet

- Tutorial C5 AnswerDocument7 pagesTutorial C5 AnswerAustin Phua Yun HockNo ratings yet

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Document11 pages(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifNo ratings yet

- TP Turbomachine1 Pelton Wheel Lab SheetDocument7 pagesTP Turbomachine1 Pelton Wheel Lab SheetAbdelwahab.gfNo ratings yet

- Tutorial - 6 - EntropyDocument7 pagesTutorial - 6 - EntropyanotherdeobiNo ratings yet

- Slide Chapter 2 Measurement of PressureDocument29 pagesSlide Chapter 2 Measurement of PressureMuhd FareezNo ratings yet

- Thermo Calc Console ExamplesDocument523 pagesThermo Calc Console ExamplesKarthi KeyanNo ratings yet

- Performance Evaluation of A Air Conditioner According To Different Test Standards PDFDocument9 pagesPerformance Evaluation of A Air Conditioner According To Different Test Standards PDFIAEME PublicationNo ratings yet

- WIEN2k Getting StartedDocument58 pagesWIEN2k Getting StartedbatistaufrnNo ratings yet

- Sample Calculation-BDocument14 pagesSample Calculation-BEdrielleNo ratings yet

- EX-Radial Temperature Distribution For SteadyDocument11 pagesEX-Radial Temperature Distribution For SteadyRasoul MohsenNo ratings yet

- Fluent-Intro 14.5 WS02 Discrete Phase PDFDocument32 pagesFluent-Intro 14.5 WS02 Discrete Phase PDFHaider AliNo ratings yet

- Thermotables Part16Document1 pageThermotables Part16Alberto GutierrezNo ratings yet

- ME6301 Part A Q&ADocument31 pagesME6301 Part A Q&ASuseel Jai Krishnan100% (1)

- Apsley-Turbulence Modelling in CFDDocument17 pagesApsley-Turbulence Modelling in CFDjuanarcos_778612No ratings yet

- Matlab ExerciseDocument8 pagesMatlab ExerciseabvibNo ratings yet

- Technical Manual: Uv Photometric Ozone AnalyzerDocument118 pagesTechnical Manual: Uv Photometric Ozone AnalyzerYean-San LongNo ratings yet

- Anki A Unified Control Strategy For Three-Phase Inverter PDFDocument16 pagesAnki A Unified Control Strategy For Three-Phase Inverter PDFRavi KumarNo ratings yet

- Pdetool TutorialDocument12 pagesPdetool TutorialOluwaseun AweNo ratings yet

- History of PLCDocument4 pagesHistory of PLCREyma JOy Solivio Sipat100% (1)

- Aspenplustm IbuprofenDocument10 pagesAspenplustm IbuprofensinghuchNo ratings yet

- Advanced Heat Transfer: Theory & ApplicationDocument34 pagesAdvanced Heat Transfer: Theory & ApplicationImran Sajid ShahidNo ratings yet

- Photovoltaic Water Pumping System With Three-Level NPC InverterDocument10 pagesPhotovoltaic Water Pumping System With Three-Level NPC InverterTI Journals PublishingNo ratings yet

- Fluid Mechanics ReviewDocument17 pagesFluid Mechanics ReviewquanNo ratings yet

- 3.6. The System Shown in Fig.: Problems 121Document4 pages3.6. The System Shown in Fig.: Problems 121Nicolae0% (1)

- R-723 - An Azeotrope On The Basis of AmmoniaDocument6 pagesR-723 - An Azeotrope On The Basis of AmmoniaevrimkNo ratings yet

- Experiment No 8. Diesel Engine PerformanceDocument4 pagesExperiment No 8. Diesel Engine PerformanceMariel MirafloresNo ratings yet

- Common PDE ProblemsDocument28 pagesCommon PDE Problemsأبو كعب علاء الدينNo ratings yet

- More ExercisesDocument3 pagesMore ExercisesAnas Shatnawi100% (1)

- Control of Inverted PendulumDocument33 pagesControl of Inverted PendulumMohammad Umar RehmanNo ratings yet

- Class Exercise 1 - OttoDocument1 pageClass Exercise 1 - OttoHaziq MansorNo ratings yet

- Aircraft Propulsion Systems: Dr. Anmar H. AliDocument10 pagesAircraft Propulsion Systems: Dr. Anmar H. AliAlmukhtar AlkinanyNo ratings yet

- The Secant MethodDocument6 pagesThe Secant MethodAYU JANNATULNo ratings yet

- JJ207 Thermodynamic Topic 4 Second Law of ThermodynamicsDocument15 pagesJJ207 Thermodynamic Topic 4 Second Law of ThermodynamicsAh TiangNo ratings yet

- Assignment 1Document2 pagesAssignment 1Zulkarnain Bin ZainudinNo ratings yet

- 2.3 - Solar Collector CalculationsDocument11 pages2.3 - Solar Collector CalculationsHEI532532No ratings yet

- Refrigeration and Air ConditioningDocument25 pagesRefrigeration and Air ConditioningVitthawat STNo ratings yet

- Current Sensor Ic 4017Document55 pagesCurrent Sensor Ic 4017Alan RejiNo ratings yet

- ES311 Assignment & Tutorial 6Document7 pagesES311 Assignment & Tutorial 6HemanthSurya0% (1)

- Finite Physical Dimensions Optimal Thermodynamics 2: Complex SystemsFrom EverandFinite Physical Dimensions Optimal Thermodynamics 2: Complex SystemsNo ratings yet

- Assumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. Analysis (A) From The Steam Tables (Tables A-4, A-5, and A-6)Document1 pageAssumptions 1 Steady Operating Conditions Exist. 2 Kinetic and Potential Energy Changes Are Negligible. Analysis (A) From The Steam Tables (Tables A-4, A-5, and A-6)Juan Andres Barragan ZabalaNo ratings yet

- Problem21 p104Document1 pageProblem21 p104IENCSNo ratings yet

- Problem21 p102Document1 pageProblem21 p102IENCSNo ratings yet

- Problem21 p105Document1 pageProblem21 p105IENCSNo ratings yet

- Problem21 93Document1 pageProblem21 93IENCSNo ratings yet

- Problem21 p100Document1 pageProblem21 p100IENCSNo ratings yet

- Problem21 89Document1 pageProblem21 89IENCSNo ratings yet

- Problem21 95Document1 pageProblem21 95IENCSNo ratings yet

- Problem21 88Document1 pageProblem21 88IENCSNo ratings yet

- Problem21 p101Document1 pageProblem21 p101IENCSNo ratings yet

- Problem21 99Document1 pageProblem21 99IENCSNo ratings yet

- Problem21 91Document1 pageProblem21 91IENCSNo ratings yet

- Problem21 94Document1 pageProblem21 94IENCSNo ratings yet

- Problem21 98Document1 pageProblem21 98IENCSNo ratings yet

- Problem21 82Document1 pageProblem21 82IENCSNo ratings yet

- Problem21 87Document1 pageProblem21 87IENCSNo ratings yet

- Problem21 86Document1 pageProblem21 86IENCSNo ratings yet

- Problem21 80Document1 pageProblem21 80IENCSNo ratings yet

- Problem21 79Document1 pageProblem21 79IENCSNo ratings yet

- Problem21 85Document1 pageProblem21 85IENCSNo ratings yet

- Problem21 75Document1 pageProblem21 75IENCSNo ratings yet

- Problem21 73Document1 pageProblem21 73IENCSNo ratings yet

- Problem21 66Document1 pageProblem21 66IENCSNo ratings yet

- Problem21 77Document1 pageProblem21 77IENCSNo ratings yet

- Problem21 74Document1 pageProblem21 74IENCSNo ratings yet

- Problem21 71Document1 pageProblem21 71IENCSNo ratings yet

- Problem21 72Document1 pageProblem21 72IENCSNo ratings yet

- Problem21 68Document1 pageProblem21 68IENCSNo ratings yet

- Problem21 70Document1 pageProblem21 70IENCSNo ratings yet

- Problem21 69Document1 pageProblem21 69IENCSNo ratings yet

- Problem21 64Document1 pageProblem21 64IENCSNo ratings yet

- United States v. Jorge Balbuena MacHado, 25 F.3d 1042, 4th Cir. (1994)Document3 pagesUnited States v. Jorge Balbuena MacHado, 25 F.3d 1042, 4th Cir. (1994)Scribd Government DocsNo ratings yet

- 1 Psych 111 Introduction To Psychology PDFDocument11 pages1 Psych 111 Introduction To Psychology PDFcham chamNo ratings yet

- Tatalaksana Dan Prognosis Severe Visual Impairment Pada Miopia Patologi - Nikho Melga ShalimDocument14 pagesTatalaksana Dan Prognosis Severe Visual Impairment Pada Miopia Patologi - Nikho Melga ShalimOt PtkNo ratings yet

- Family in Colombia AND Family in IndiaDocument20 pagesFamily in Colombia AND Family in IndiaALISON ALBAN LIZARAZONo ratings yet

- Opel MotronicML4.1 PDFDocument4 pagesOpel MotronicML4.1 PDFRafael RosasNo ratings yet

- Re-Hiring Challenges For Employer and Boomerang EmployeeDocument4 pagesRe-Hiring Challenges For Employer and Boomerang Employeececil_brittoNo ratings yet

- Clinical Procedures For Medical AssistantDocument40 pagesClinical Procedures For Medical AssistantStudent1010No ratings yet

- NestleDocument16 pagesNestleAunto P PonnachanNo ratings yet

- Module 5 ExpressiveDocument16 pagesModule 5 Expressiveshubhiisharmaa25No ratings yet

- Specific Heat CapacityDocument2 pagesSpecific Heat CapacitysagesethNo ratings yet

- Architects-Behaving-Badly3 Harvard Design MagazineDocument3 pagesArchitects-Behaving-Badly3 Harvard Design MagazineJelena SavicNo ratings yet

- RF Cable and Cable Accessories CatalogueDocument59 pagesRF Cable and Cable Accessories Catalogueahm_shaabanNo ratings yet

- Corporate Social Responsibility ("CSR") Policy BMW India Private LimitedDocument7 pagesCorporate Social Responsibility ("CSR") Policy BMW India Private LimitednehaNo ratings yet

- LBYCH32 - Formal Laboratory Report 1 - Experiment 2Document9 pagesLBYCH32 - Formal Laboratory Report 1 - Experiment 2Charmaine MaghirangNo ratings yet

- Oak Steakhouse Atlanta MenuDocument1 pageOak Steakhouse Atlanta MenuchrisfuhrmeisterNo ratings yet

- Kami Export - Patrick McKeown - 10punnett-Squares-WorksheetDocument10 pagesKami Export - Patrick McKeown - 10punnett-Squares-WorksheetPatrick McKeownNo ratings yet

- COD Testing - LovibondDocument2 pagesCOD Testing - LovibondHasbi Ashidiqi PNo ratings yet

- J-STD-607-A: Commercial Building Grounding and Bonding Requirements For TelecommunicationsDocument14 pagesJ-STD-607-A: Commercial Building Grounding and Bonding Requirements For Telecommunicationsgava garcia valdesNo ratings yet

- Yamaha XVS 650 A Dragstar Classic 2005 2006 Manual WWW - Manualedereparatie.info PDFDocument86 pagesYamaha XVS 650 A Dragstar Classic 2005 2006 Manual WWW - Manualedereparatie.info PDFJavid CamposNo ratings yet

- Maize Starch Increase 2012Document25 pagesMaize Starch Increase 2012cafebuenoNo ratings yet

- Computer - Shopper July.2020Document134 pagesComputer - Shopper July.2020Rai MondNo ratings yet

- Cooling Tower PowerPointDocument12 pagesCooling Tower PowerPointHaerNo ratings yet

- Chapter 5 Hydropower - Arun KumarDocument60 pagesChapter 5 Hydropower - Arun KumarSu Crez No AtmajaNo ratings yet

- Anh 11. Midterm 1 Test. 2021 2022. Đề Chính Thức. Đáp ÁnDocument5 pagesAnh 11. Midterm 1 Test. 2021 2022. Đề Chính Thức. Đáp ÁnĐỗ PhongNo ratings yet

- Natural Convection: Amit KakkarDocument5 pagesNatural Convection: Amit KakkarRupesh TiwariNo ratings yet

- Trace Metal AnalysisDocument32 pagesTrace Metal AnalysisEssam Eldin Metwally AhmedNo ratings yet