Professional Documents

Culture Documents

A Cause - Effect Analysis of Furnace Heat Transfer

Uploaded by

Mallinatha PNOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Cause - Effect Analysis of Furnace Heat Transfer

Uploaded by

Mallinatha PNCopyright:

Available Formats

A Cause Effect Analysis of Furnace Heat Transfer

BY

P M V Subbarao

Associate Professor

Mechanical Engineering Department

I I T Delhi

Closed form solutions for performance analysis of complex heat

transfer devices..

Cause Effect Analysis

Combustion is a primary cause

Steam Generation is an ultimate effect.

Heat transfer is a mediation.

Combustion causes the generation of heat in side furnace volume.

Heat generation causes the production of high temperature gases.

These high temperature gases cause the Radiation and convection heat

transfer processes.

Heat Transfer processes carry the thermal energy to furnace wall &

steam tubes.

Conduction through the tubes and walls causes the convection inside

the tubes.

Convection Causes the generation of steam.

A cause effect analysis can simplify the design analysis of a furnace.

Analysis of the Primary Cause

Reactants Products

i j

j j i i

P Y R X

At a given temperature the Gibbs free energy of products is less

than Reactants.

Depending on the effectiveness of heat release rate, the sensible

energy of products will be higher than sensible energy of reactants.

Hence, the temperature of products of combustion is very high.

Chemical Energy Thermal (Sensible) Energy

exchange

i j

j j i i

Q h Y h X

+

The temperature of the gases in an adiabatic furnace attain a

maximum temperature called adiabatic flame temperature.

General Design Principles

The effective heat release rate is depends on the size of furnace.

The furnace should provide the required physical environment and the

time to complete the combustion of fuel.

The furnace should have adequate radiative heating surfaces to cool

the flue gas sufficiently to ensure safe operation of the downstream

convective heating surface.

Aerodynamics in the furnace should prevent impingement of flames on

the water wall and ensure uniform distribution of heat flux on the

water wall.

The furnace should provide conditions favoring reliable natural

circulation of water through water wall tubes.

The configuration of the furnace should be compact enough to

minimize the amount of steel and other construction material.

Determination of Furnace Size

What is the boundary of a furnace?

The boundary of a furnace is defined

by

Central horizontal plane of water wall

and roof tubes

Central horizontal lines of the first set

of super heater panels.

o = 30 to 50

O

| > 30

O

= 50 to 55

O

E = 0.8 to 1.6 m

d = 0.25 b to 0.33 b

Design Constrains:Heat Release Rate

Heat Release Rate per Unit Volume, q

v

, kW/m

3

Heat Release Rate per Unit Cross Sectional Area,q

a

,

kW/m

2

Heat Release Rate per Unit Wall Area of the Burner

Region, q

b

, kW/m

2

The maximum allowable heat flux of the water wall is

restricted by its water-side burnout (dryout) heat flux.

Heat Release Rate per Unit Volume, q

v

The amount of heat generated by combustion of fuel in a unit effective

volume of the furnace.

3

/ m kW

V

LHV m

q

c

v

-

=

-

s

r

c

v

Vt

LHV m

q

Where, m

c

= Design fuel(coal) consumption rate, kg/s.

V = Furnace volume, Cu. m.

LHV= Lower heating value of fuel kJ/kg.

A proper choice of volumetric heat release rate ensures the critical fuel

residence time.

Fuel particles are burnt substantially

The flue gas is cooled to the required safe temperature.

Heat Release Rate per Unit Cross Sectional Area,q

a

The amount of heat released per unit cross section of the furnace.

Also called as Grate heat release rate.

2

/ m kW

A

LHV m

q

grate

c

A

-

=

A

grate

is the cross sectional area or grate area of the furnace, Sq. m.

This indicates the temperature levels in the furnace.

An increase in q

a

, leads to a rise in temperature in burner region.

This helps in the stability of flame

Increases the possibility of slagging.

A

Heat Release Rate per Unit Wall Area of the Burner Region

The burner region of the furnace is the most intense heat zone.

The amount of heat released per unit water wall area in the burner

region.

( )

2

/

2

m kW

H b a

LHV m

q

b

b

+

=

-

a and b are width and depth of furnace, and H

b

is the height of burner

region.

This represents the temperature level and heat flux in the burner

region.

Used to judge the general condition of the burner region.

Its value depends on Fuel ignition characteristics, ash characteristics,

firing method and arrangement of the burners.

Furnace Depth & Height

Depth to breadth ratio is an important parameter from both combustion

and heat absorption standpoint.

Following factors influence the minimum value of breadth.

Capacity of the boiler

Type of fuel

Arrangement of burners

Heat release rate per unit furnace area

Capacity of each burner

The furnace should be sufficiently high so that the flame does not hit

the super heater tubes.

The minimum height depends on type of coal and capacity of burner.

Lower the value of height the worse the natural circulation.

Furnace Depth & Height

Basic Geometry of A Furnace

safe v

c

q

LHV m

V

,

-

=

safe A

c

grate

q

LHV m

b a A

,

-

= =

( )

safe b

b

q

LHV m

H b a

,

2

-

= +

safe f f

h h

,

>

safe

b b >

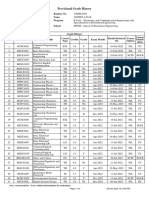

Dimensions of A 500 MW(e) Plant Furnace

HT Areas of A 500 MW(e) Plant Furnace

Analysis of the Secondary Cause

Emissive power of flame:

| | kW T A Q

fl flame emi

4

oc =

-

How to find the area of a Flame ?

Where c

flame

is the emissivity of flame.

How to Find the Emissivity of A Flame

Flame Length, m

Analysis of the Tertiary Cause

Radiation heat transfer

Where c

eff

is the emissivity of flame and water wall system.

| | kW T T AF Q

wa fl eff rad

4 4

=

-

oc

( )( )

wa fl

wa fl

eff

c c

c c

c

=

1 1 1

Heat flux is non uniform.

Wall temperature is non uniform.

This effect is another cause for further analysis.

Distribution of Heat Flux on Furnace Walls

| | kW T T F t z y x q

wa fl eff

) : , , ( ' '

4 4

= c o

Analysis of the Last but One Effect

Final effect : T

fl

gets changed to Furnace Exit

GasTemperature.

Due to energy lost by hot gases.

Loss due to Environment

Energy absorbed by water walls

Energy lost by hot gasses from flame to exit.

{ } kW T T C m Q

FEGT ad p

g

loss g

,

=

- -

{ } kW T T C

F

A

m Q

FEGT ad p

act

fuel

loss g

1

,

|

.

|

\

|

+ =

- -

T

flame

T

fe

(

=

- - -

fe ad loss g

Q Q Q

,

i j

Pj Pj Ri Ri

h Y h X

Mixed Adiabatic Temperature of the Gases

i j

Pj Pj Ri Ri

h Y h X

} }

i j

T

T

P Pi p Pj

T

T

R Ri p Ri

ad

ref

R

ref

dT c Y dT c X

, ,

kgK kJ

T

C

T

C

T

C C c

p

/

1000 1000 1000

3

3

2

2 1 0

|

.

|

\

|

+

|

.

|

\

|

+ + =

You might also like

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Design Steps: Furnace of A Steam Generator: Selection of Geometric ParametersDocument21 pagesDesign Steps: Furnace of A Steam Generator: Selection of Geometric Parametersank_mehraNo ratings yet

- Structure of A Two in One Device - Combustor and Heat ExchangerDocument35 pagesStructure of A Two in One Device - Combustor and Heat ExchangerMadhur SherawatNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Lect-5 FurnaceDocument60 pagesLect-5 FurnaceIffat0% (1)

- 2 BoilersDocument58 pages2 BoilersParameswararao BillaNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Heatoptimisation PDFDocument76 pagesHeatoptimisation PDFChandra Sekar100% (2)

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsFrom EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNo ratings yet

- Heat Recovery Steam Generator 5Document29 pagesHeat Recovery Steam Generator 5Hitesh SinglaNo ratings yet

- High Flux Steam Reforming Design Lowers CostDocument6 pagesHigh Flux Steam Reforming Design Lowers CostAnissa Nurul BadriyahNo ratings yet

- Module 4 - Boiler Accessories, Super HeaterDocument74 pagesModule 4 - Boiler Accessories, Super Heaterkngkng100% (1)

- Boiler and FurnaceDocument42 pagesBoiler and FurnaceEr Bali PandhareNo ratings yet

- Soot Blower PresentationDocument26 pagesSoot Blower PresentationVishal ModiNo ratings yet

- Heat Exchanger 2Document64 pagesHeat Exchanger 2John Louie GresulaNo ratings yet

- Coeficien Heat Tranfer Boiler Fire Tube1Document8 pagesCoeficien Heat Tranfer Boiler Fire Tube1กี๋ แต่งงาม100% (1)

- Radiant Tube Heating StripDocument9 pagesRadiant Tube Heating StripSajib Chandra RoyNo ratings yet

- Mel713 37Document46 pagesMel713 37Rudresh AnandNo ratings yet

- Fuels: o Sanskar Jain o Chetan Bhardwaj o Shivendra Singh o Naman Jindal o Vinay KumarDocument20 pagesFuels: o Sanskar Jain o Chetan Bhardwaj o Shivendra Singh o Naman Jindal o Vinay KumarNaman JindalNo ratings yet

- Encon Thermal Engineers: Answer To The Continued Need For Energy ConservationDocument73 pagesEncon Thermal Engineers: Answer To The Continued Need For Energy Conservationdawit mesfinNo ratings yet

- Heat Transfre Subsea PipelinesDocument34 pagesHeat Transfre Subsea Pipelinesatils100% (1)

- Increase Boiler Efficiency with an EconomiserDocument15 pagesIncrease Boiler Efficiency with an EconomiserjadgugNo ratings yet

- Heat Exchanger Network OptimizationDocument76 pagesHeat Exchanger Network Optimizationarun aryaNo ratings yet

- An and de PresentationDocument31 pagesAn and de PresentationKirubel MogesNo ratings yet

- Waste heat recovery saves energy costsDocument6 pagesWaste heat recovery saves energy costsHassan MehrizNo ratings yet

- Heat and Mass TransferDocument29 pagesHeat and Mass TransferAllyzon MejiaNo ratings yet

- Design Analysis of Furnace of A Steam Generator: Perfection of Primary Cause For All That Continues .Document21 pagesDesign Analysis of Furnace of A Steam Generator: Perfection of Primary Cause For All That Continues .Ramesh kumarNo ratings yet

- 04 BoilersDocument59 pages04 BoilersMHD Abdi MuttaqinNo ratings yet

- Thermosyphons and Heat PipeDocument14 pagesThermosyphons and Heat PipespurwonofjpNo ratings yet

- Insulation Thickness in Subsea FlowlineDocument34 pagesInsulation Thickness in Subsea FlowlineJOhn2No ratings yet

- Heat Exchange in Subsea Flowline PDFDocument34 pagesHeat Exchange in Subsea Flowline PDFPrasanna KumariNo ratings yet

- Heat Exchange in Subsea Flowline PDFDocument34 pagesHeat Exchange in Subsea Flowline PDFPrasanna KumariNo ratings yet

- Heat Transfer and U-ValuesDocument35 pagesHeat Transfer and U-ValuesaliNo ratings yet

- Principle Heat TransferDocument34 pagesPrinciple Heat TransferZick HaziqNo ratings yet

- Heat Transfer via Compact Heat ExchangersDocument42 pagesHeat Transfer via Compact Heat ExchangersRodrigo BondocNo ratings yet

- Enhancing The Circulation Analysis of A Recovery Boiler Through The Incorporation of 3-D Furnace Heat Transfer Results From COMO™Document5 pagesEnhancing The Circulation Analysis of A Recovery Boiler Through The Incorporation of 3-D Furnace Heat Transfer Results From COMO™Surasan ThepsiriNo ratings yet

- Abma 9 00Document11 pagesAbma 9 00Matias MancillaNo ratings yet

- Module 5Document58 pagesModule 5Aaditya NegiNo ratings yet

- Chemistry CompiledDocument95 pagesChemistry CompiledNaveen Kumar NNo ratings yet

- Chemistry CompiledDocument98 pagesChemistry CompiledYatesh SkNo ratings yet

- Generation of Entropy To Generate Most Eligible Steam .Document36 pagesGeneration of Entropy To Generate Most Eligible Steam .Apocalypse GuptaNo ratings yet

- Heat Recovery MechanismsDocument13 pagesHeat Recovery MechanismsSuhailSharmaNo ratings yet

- Process Equipment Design-06Document25 pagesProcess Equipment Design-06PARAG DAHARWAL 20CH10020No ratings yet

- Designing of Steam Reformer& Heat Recovery Unit in Direct Reduced Iron Production (DRI)Document71 pagesDesigning of Steam Reformer& Heat Recovery Unit in Direct Reduced Iron Production (DRI)Engr Faiq Chauhdary100% (2)

- Boiler Functions and Main Categories: 3. BoilersDocument17 pagesBoiler Functions and Main Categories: 3. BoilersMusa KaleemNo ratings yet

- HJD Institute of Tech Edu & Research Mechanical Engg DeptDocument6 pagesHJD Institute of Tech Edu & Research Mechanical Engg DeptM Hamza NadeemNo ratings yet

- Monitoring Power Plant Performance MetricsDocument9 pagesMonitoring Power Plant Performance Metricsshobhan1984No ratings yet

- Boiler PerformanceDocument31 pagesBoiler PerformanceIrfan ShaikhNo ratings yet

- Electric Heating and WeldingDocument61 pagesElectric Heating and Weldingshuva rajNo ratings yet

- unitiveam-140916060902-phpapp02Document56 pagesunitiveam-140916060902-phpapp02BRAHIMNo ratings yet

- Coal To ElectricityDocument72 pagesCoal To Electricityrawat_jyotiNo ratings yet

- 12.0 Cooling Towers and LightingDocument55 pages12.0 Cooling Towers and LightingNesarkiran BagadeNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat Exchangerdieuhien0210No ratings yet

- Overall Heat Transfer CoefficientDocument15 pagesOverall Heat Transfer CoefficientPrashant PatelNo ratings yet

- Heat Transfer Lab ManualDocument40 pagesHeat Transfer Lab ManualRachit_Goyal25_10No ratings yet

- The Application Aspects of Self-Recuperative and Self-Regenerative Burners in Thermal DevicesDocument7 pagesThe Application Aspects of Self-Recuperative and Self-Regenerative Burners in Thermal DevicesGerardo LopezNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat Exchangererdev_sawle@yahoo.comNo ratings yet

- Plate and Frame Heat ExchangerDocument53 pagesPlate and Frame Heat ExchangerMohammed BaquarNo ratings yet

- Performance of Turbines, Similarity LawsDocument9 pagesPerformance of Turbines, Similarity LawsDheeraj KumarNo ratings yet

- Method Statement For The Installation of Water Treatment PlantDocument12 pagesMethod Statement For The Installation of Water Treatment Plantafraz_xec89% (18)

- White Paper On Irrigation DepartmentDocument9 pagesWhite Paper On Irrigation DepartmentgangarajuNo ratings yet

- Method Statement From Contractors PDFDocument2 pagesMethod Statement From Contractors PDFMallinatha PNNo ratings yet

- Disaster Management Plan: WAPCOS LimitedDocument11 pagesDisaster Management Plan: WAPCOS LimitedMallinatha PNNo ratings yet

- Design Manual Pump StationDocument127 pagesDesign Manual Pump Stationtsraj10100% (3)

- Motor and Inertia LoadDocument4 pagesMotor and Inertia LoadKiran Kumar K TNo ratings yet

- Development of A Francis Turbine TestDocument146 pagesDevelopment of A Francis Turbine TestMallinatha PN100% (1)

- Vol2 3Document43 pagesVol2 3Ravneet BanyalNo ratings yet

- Strainer GuideDocument26 pagesStrainer Guidemudrijasm100% (1)

- MoEF - Report-Teesta Hydro PowerDocument22 pagesMoEF - Report-Teesta Hydro PowerMallinatha PNNo ratings yet

- Flow Control Devices for Water Management ProjectsDocument49 pagesFlow Control Devices for Water Management ProjectsPrem Singh RawatNo ratings yet

- Project ManagementDocument2 pagesProject ManagementMallinatha PNNo ratings yet

- The Choice of Materials For Hydraulic TurbinesDocument29 pagesThe Choice of Materials For Hydraulic TurbinesNIKHIL VERMA50% (2)

- Project ManagementDocument56 pagesProject ManagementMallinatha PNNo ratings yet

- Vol III Rate Schedule For Chimney-BhelDocument18 pagesVol III Rate Schedule For Chimney-BhelMallinatha PNNo ratings yet

- Booster Pumps MANUAL PDFDocument70 pagesBooster Pumps MANUAL PDFMallinatha PNNo ratings yet

- Model Testing of Francis-Type Hydraulic TurbinesDocument4 pagesModel Testing of Francis-Type Hydraulic TurbinesAjay KumarNo ratings yet

- 1320 MW Specifications For Electrical PackagesDocument272 pages1320 MW Specifications For Electrical PackagesMallinatha PNNo ratings yet

- Electrical Single Line DiagramDocument14 pagesElectrical Single Line DiagramPaw Tar100% (2)

- Word Parts Dictionary, Prefixes, Suffixes, Roots and Combining FormsDocument237 pagesWord Parts Dictionary, Prefixes, Suffixes, Roots and Combining Formslaukings100% (9)

- Formulas and calculations for drilling, production and workoverDocument62 pagesFormulas and calculations for drilling, production and workoverMallinatha PN100% (4)

- Hydro DefinitionDocument13 pagesHydro DefinitionHrishikesh DasNo ratings yet

- ABB Softstarter HandbookDocument92 pagesABB Softstarter HandbookAffan ZainunNo ratings yet

- Study of Equipment Prices in The Power SectorDocument121 pagesStudy of Equipment Prices in The Power Sector이주성100% (1)

- Anti Lock BrakesDocument44 pagesAnti Lock BrakesyogendranathbommuNo ratings yet

- Manual For Preparing Scoping DocumentDocument61 pagesManual For Preparing Scoping DocumentDinesh TimalsinaNo ratings yet

- Santhosh ConstructionsDocument25 pagesSanthosh ConstructionsMallinatha PNNo ratings yet

- Using MS Word For Drafting A ReportDocument5 pagesUsing MS Word For Drafting A ReportMallinatha PNNo ratings yet

- Labour Output On PaintingDocument6 pagesLabour Output On PaintingMallinatha PNNo ratings yet

- Asahi/America Life Science Application and Validation GuideDocument51 pagesAsahi/America Life Science Application and Validation GuideMiguel Egas LoorNo ratings yet

- 5977c GC MSD AgilentDocument5 pages5977c GC MSD Agilentashton.selokaNo ratings yet

- Infinite Selectivity of Wet Sio Etching in Respect To Al: MicromachinesDocument7 pagesInfinite Selectivity of Wet Sio Etching in Respect To Al: MicromachinesÖzgür GüngörNo ratings yet

- 1 s2.0 S2666330921000467 MainDocument15 pages1 s2.0 S2666330921000467 MainMUHAMMAD ILYAS PAKPAHANNo ratings yet

- ASTM A513-T5 DOM Mechanical Properties and SpecificationsDocument3 pagesASTM A513-T5 DOM Mechanical Properties and SpecificationsOscar JuárezNo ratings yet

- Reformer Convection Coils Explained PT 1 X 0Document7 pagesReformer Convection Coils Explained PT 1 X 0David PierreNo ratings yet

- ProMax 4.0 BrochureDocument20 pagesProMax 4.0 Brochureheiner Joned Guzman RiveraNo ratings yet

- Chemistry A Molecular Approach 2nd Edition Tro Test BankDocument35 pagesChemistry A Molecular Approach 2nd Edition Tro Test Bankstrewmerils1ej3n100% (25)

- ENPH 131 Assignment #1: SolutionsDocument4 pagesENPH 131 Assignment #1: SolutionsVien CruzNo ratings yet

- Report Standard Compaction TestDocument14 pagesReport Standard Compaction TestLuqman Yusof100% (1)

- Material Balance in Unit OperationsDocument75 pagesMaterial Balance in Unit OperationsAcademicBMNo ratings yet

- Appendix B: Descriptions of Computer Programs and Computer Aids For Use With This BookDocument15 pagesAppendix B: Descriptions of Computer Programs and Computer Aids For Use With This BookLorena Vivas100% (1)

- IMWA1995 Vandersluis PDFDocument16 pagesIMWA1995 Vandersluis PDFAbie BadhurahmanNo ratings yet

- Shuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development ChallengesDocument12 pagesShuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development Challengesari_siNo ratings yet

- EXPERIMENT 3: AAS Determination of Calcium in Commercial Supplement TabletsDocument11 pagesEXPERIMENT 3: AAS Determination of Calcium in Commercial Supplement Tabletsdjambulaziz100% (3)

- Revision Schedule of Xii - Neet (CF) (2021-2022) (29.11.2021)Document2 pagesRevision Schedule of Xii - Neet (CF) (2021-2022) (29.11.2021)AssishNo ratings yet

- Testing Water QualityDocument13 pagesTesting Water QualitySHIWANG SHARMA100% (4)

- cls9 qp1Document22 pagescls9 qp1Shebin PaulNo ratings yet

- BookDocument44 pagesBookDr-Mandeep SinghNo ratings yet

- Tecnologia de Separacion Liquido Gas - Separsol PlusDocument4 pagesTecnologia de Separacion Liquido Gas - Separsol PlusLuis Alejandro Mariño - RamguzNo ratings yet

- Metallurgical Engineering Scheme of Teaching and ExamDocument12 pagesMetallurgical Engineering Scheme of Teaching and ExamSuraj KumarNo ratings yet

- StudentGradeHistory 21BML0190Document3 pagesStudentGradeHistory 21BML0190brotin2002No ratings yet

- Presented To:: Dr. Manisha Bhardwaj Presented By: Prerna (M.SC Biochemistry)Document15 pagesPresented To:: Dr. Manisha Bhardwaj Presented By: Prerna (M.SC Biochemistry)Anubhuti JhaNo ratings yet

- Yay OFFLINEDocument6 pagesYay OFFLINEmichellaineNo ratings yet

- Lifetime prediction methods for polymersDocument19 pagesLifetime prediction methods for polymersLucas MlbNo ratings yet

- William Herschel's Double Star CatalogDocument15 pagesWilliam Herschel's Double Star CatalogGiannis TheodorouNo ratings yet

- Biochemistry Fluroscence Spectroscopy 27-Jan-2022Document23 pagesBiochemistry Fluroscence Spectroscopy 27-Jan-2022AyeshaNo ratings yet

- CME 200 Introduction To Chemical Engineering: Dr. Hadil Abu KhalifehDocument17 pagesCME 200 Introduction To Chemical Engineering: Dr. Hadil Abu KhalifehNajmul Puda PappadamNo ratings yet

- Registration Certificate for Talon 0.005 BB RodenticideDocument17 pagesRegistration Certificate for Talon 0.005 BB RodenticidepurwadiNo ratings yet

- FD&C Yellow 6 MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesFD&C Yellow 6 MSDS: Section 1: Chemical Product and Company Identificationzubair1951No ratings yet