Professional Documents

Culture Documents

So LP For This Problem

Uploaded by

Özlem YurtseverOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

So LP For This Problem

Uploaded by

Özlem YurtseverCopyright:

Available Formats

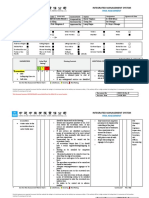

3.1-10 Weenies and Buns is a food processing plant which manufactures hot dogs and hot dog buns.

They grind their own flour for the hot dog buns at a maximum rate of 200 pounds per week. Each hot dog bun requires 0.1 pound of flour. They currently have a contract with Pigland, Inc., which specifies that a delivery of 800 pounds of pork product is delivered every Monday. Each hot dog requires pound of pork product. All the other ingredients in the hot dogs and hot dog buns are in plentiful supply. Finally, the labor force at Weenies and Buns consists of 5 employees working full time (40 hours per week each). Each hot dog requires 3 minutes of labor, and each hot dog bun requires 2 minutes of labor. Each hot dog yields a profit of $0.80, and each bun yields a profit of $0.30. Weenies and Buns would like to know how many hot dogs and how many hot dog buns they should produce each week so as to achieve the highest possible profit. (a) Formulate a linear programming model for this problem. (b) Use the graphical method to solve this model. a) x1: # hot dogs they should produce each week x2: # hot dog buns they should produce each week Objective is maximize the profit so; Max Z = 0,80 x1 + 0,30 x2 Flour constraint: 0,1 x2 200 Pork product constraints: x1 800 0,25 x1 800 Labor constraint: 3x1+2x2 12000 (40 hours = 2400 minutes, 2400 minutes per worker, so for 5 worker= 2400*5 =12000 minutes) Non-negativity; x1, x2 0 So LP for this problem: Max Z = 0,80 x1 + 0,30 x2 St; 0,1 x2 200 0,25 x1 800 3x1+2x2 12000 b) 1) 0,1 x2 = 200 x2 = 2000 2) 0,25 x1 = 800 x1 = 3200 3) 3x1+2x2 = 12000 (0, 6000 ) and (4000,0)

Optimal Solution: x1*=3200 , x2*=1200 and Z*=2920

3.1-11 The Omega Manufacturing Company has discontinued the production of a certain unprofitable product line. This act created considerable excess production capacity. Management is considering devoting this excess capacity to one or more of three products; call them products 1, 2, and 3. The available capacity on the machines that might limit output is summarized in the following table:

The number of machine hours required for each unit of the respective products is

The sales department indicates that the sales potential for products 1 and 2 exceeds the maximum production rate and that the sales potential for product 3 is 20 units per week. The unit profit would be $50, $20, and $25, respectively, on products 1, 2, and 3. The objective is to determine how much of each product Omega should produce to maximize profit. (a) Formulate a linear programming model for this problem. (b) Solve this model by the simplex method. axi =the number of units of product i produced for i=1,2,3 x1: # Product 1 x2: # Product 2 x3: # Product 3 Objective is to maximize the profit; Max Z = 50 x1 +20 x2 +25 x3 Constraints: Machine Hours for Milling Machine: 9 x1 +3 x2 +5 x3 500 Machine Hours for Lathe: 5 x1 +4 x2 350 Machine Hours for Grinder: 3 x1 + 2 x3 150 Sales Potential: x3 20 Non-negativity; x1, x2, x3 0

b- Simplex: Objective function: Z -50 x1 -20 x2 - 25 x3 St 9 x1 + 3 x2 +5 x3 + s1 5 x1 + 4 x2 + s2 3 x1 + +2 x3 + s3 x3 + s4 x1, x2, x3 s1 s2 s3 0 solution is on excel sheet Manuel solution: min ratio test 55,6 70,0 50,0 = 500 =350 = 150 = 20

iteration Z s1 s2 s3 0 s4

x1 -50 9 5 3 0 x1 0 0 0 1 0 x1 0 0 0 1 0

x2 -20 3 4 0 0 x2 -20 3 4 0 0 x2 0 1 0 0 0

x3 -25 5 0 2 1 x3 8 1/3 -1 -3 1/3 2/3 1 x3 1 2/3 - 1/3 -2 2/3 1

s1 0 1 0 0 0 s1 0 1 0 0 0 s1 6 2/3 1/3 -1 1/3 0 0

s2 0 0 1 0 0 s2 0 0 1 0 0 s2 0 0 1 0 0

s3 0 0 0 1 0 s3 16 2/3 -3 -1 2/3 1/3 0 s3 -3 1/3 -1 2 1/3 1/3 0

s4 0 0 0 0 1 s4 0 0 0 0 1 s4 0 0 0 0 1

RHS 0 500 350 150 20 RHS 2500 50 100 50 20 RHS

Z s1 s2 x1 1 s4

min ratio test 16 2/3 25

Z x2 s2 x1 2 s4

min ratio 2833 1/3 test 16 2/3 33 1/3 14 2/7 50 150 20

Min ratio test= RHS values/coef. Of ent. Variable For the first iteration, we see that x1 is entering variable since -50 is the most minimum one. And s3 is the leaving variable since 50,from minimum ratio test, is the minimum one. We want the intersection of entering variable and leaving variable (pivot cell) is to be 1. So for that, we divide 3 to 3 and we get 1. And then we divide whole row to 3:

Z s1 s2 x1 1 s4

x1 0 0 0 1 (3/3) 0

x2 -20 3 4 0 (0/3) 0

x3 8 1/3 -1 -3 1/3 2/3(2/3) 1

s1 0 1 0 0 (0/3) 0

s2 0 0 1 0 (0/3) 0

s3 16 2/3 -3 -1 2/3 1/3(1/3) 0

s4 0 0 0 0 (0/3) 1

RHS 2500 50 100 50 (150/3) 20

You might also like

- Tugas Teknik Kuantitatif Linear Programming: DiketahuiDocument7 pagesTugas Teknik Kuantitatif Linear Programming: DiketahuiGustia AmeliaNo ratings yet

- MeraDocument11 pagesMeraShikhar Virmani100% (1)

- DDDA ISYE6189037 DeterministicOptimizationStochasticProcesses-QuestionDocument7 pagesDDDA ISYE6189037 DeterministicOptimizationStochasticProcesses-QuestionAyu Irma prasaktiNo ratings yet

- Quanti AssDocument27 pagesQuanti AssKricel Maquera100% (4)

- Ch. 2 - Practice ProblemsDocument3 pagesCh. 2 - Practice Problemsyay111100% (2)

- 5 - Project Management (S)Document7 pages5 - Project Management (S)Zakiah Abu Kasim100% (2)

- DGDA - STAT6174037 - ProbabilityTheoryandAppliedStatistics-Answer 2Document14 pagesDGDA - STAT6174037 - ProbabilityTheoryandAppliedStatistics-Answer 2calvin100% (1)

- Business Analytics ProblemDocument1 pageBusiness Analytics Problemrohit_kocharNo ratings yet

- Mossaic Tiles, LTD.: Case ProblemDocument10 pagesMossaic Tiles, LTD.: Case ProblemPrejit PillaiNo ratings yet

- SDocument6 pagesSAbhilasha BhaskarNo ratings yet

- TP1-W2-S3 YudhaDocument7 pagesTP1-W2-S3 YudhaKho Via0% (1)

- MexicanaDocument4 pagesMexicanaJD_04100% (12)

- Or Examples SolutionsDocument14 pagesOr Examples Solutionsmohamadalfar111100% (1)

- Ot (Unit I)Document19 pagesOt (Unit I)Dharani C KNo ratings yet

- LINEAR PROGRAMMING Formulation ExampleDocument40 pagesLINEAR PROGRAMMING Formulation ExampleAlyssa Audrey JamonNo ratings yet

- Operations Research: Text Book: Operations Research: An Introduction by Hamdy A.Taha (Pearson Education) 8 EditionDocument34 pagesOperations Research: Text Book: Operations Research: An Introduction by Hamdy A.Taha (Pearson Education) 8 Editionaditya balaNo ratings yet

- 2lp Modelinggraph SolnDocument56 pages2lp Modelinggraph SolnTanzeel HussainNo ratings yet

- Act3 LFVPDocument11 pagesAct3 LFVPluis vazquezNo ratings yet

- A Company Manufactures Four Products ADocument4 pagesA Company Manufactures Four Products AHaile SimachewNo ratings yet

- Formulation of Linear Programming Model - UpdatedDocument13 pagesFormulation of Linear Programming Model - UpdatedArslan HamidNo ratings yet

- Q1: A Company Engaged in Producing Tinned Food Has 300 Trained Employee On The Rolls Each of WhonDocument24 pagesQ1: A Company Engaged in Producing Tinned Food Has 300 Trained Employee On The Rolls Each of WhonsjthankiNo ratings yet

- Exam Review - Module 3Document7 pagesExam Review - Module 3Cameron BelangerNo ratings yet

- Assignment B TechDocument5 pagesAssignment B TechAbhishekKumarNo ratings yet

- Production Management A.) Economic Order Quantity Problems and SolutionsDocument27 pagesProduction Management A.) Economic Order Quantity Problems and SolutionsI AM NOT CHINESENo ratings yet

- F21110217 Dounia Bouchahab Big AssignmentDocument10 pagesF21110217 Dounia Bouchahab Big AssignmentDouniacdouniaNo ratings yet

- L01 - Formulation of LPPsDocument36 pagesL01 - Formulation of LPPsAmey ShitoleNo ratings yet

- 01 Formulation of LPPsDocument36 pages01 Formulation of LPPsMeghashyam SandeepNo ratings yet

- Operational ResearchDocument5 pagesOperational ResearchDhananjay ChauhanNo ratings yet

- Test Bank For Chapter 3Document36 pagesTest Bank For Chapter 3Laya ElianeNo ratings yet

- FormulationDocument9 pagesFormulationdipnisNo ratings yet

- LP, IpDocument38 pagesLP, IpUMANG JAGADNo ratings yet

- Linear Programming ExamplesDocument5 pagesLinear Programming ExamplesEdlyn PangilinanNo ratings yet

- Solution of AssignmenDocument38 pagesSolution of AssignmenNikunj Patel75% (8)

- Test Bank For Introduction To Operations Research 10Th Edition Hillier 0073523453 9780073523453 Full Chapter PDFDocument36 pagesTest Bank For Introduction To Operations Research 10Th Edition Hillier 0073523453 9780073523453 Full Chapter PDFmarie.miller469100% (16)

- Introduction To Operations Research 10th Edition Hillier Test BankDocument36 pagesIntroduction To Operations Research 10th Edition Hillier Test Bankdorothy100% (14)

- Ques 2.20Document46 pagesQues 2.20AkshatAgarwal0% (1)

- Analisis RegresiDocument24 pagesAnalisis RegresiElvaa Riannaa Msr100% (2)

- Introduction To Operations Research: Batch 2020-22Document5 pagesIntroduction To Operations Research: Batch 2020-22Shweta SolankiNo ratings yet

- Taree A AaaaaaaDocument13 pagesTaree A AaaaaaaJhon Ambrosio NayraNo ratings yet

- Mt1 Slides FullDocument119 pagesMt1 Slides FullmilkersaracNo ratings yet

- Question Bank On Operations Research UniDocument39 pagesQuestion Bank On Operations Research UniManiranjan KumarNo ratings yet

- Midterms Reviewer - No Northwest Corner Least Cost Method Vogels MethodDocument24 pagesMidterms Reviewer - No Northwest Corner Least Cost Method Vogels MethodJinx Cyrus RodilloNo ratings yet

- 2 Modeling Graphical-SolutionDocument32 pages2 Modeling Graphical-SolutionanindyataminNo ratings yet

- Tutorial 3Document4 pagesTutorial 3Asmidar HaniNo ratings yet

- Linear Programming: I Sem LPP Quant-IDocument27 pagesLinear Programming: I Sem LPP Quant-IBabitha RaghuNo ratings yet

- LP GraphDocument55 pagesLP GraphMizanur Rahaman ShamimNo ratings yet

- Linear - Prog Q 3 4Document12 pagesLinear - Prog Q 3 4Aatif_Saif_80No ratings yet

- QA Second AssagnmentDocument8 pagesQA Second Assagnmentyohanis meleseNo ratings yet

- Quantitative Method For MGT DecisionDocument9 pagesQuantitative Method For MGT DecisionAgat0% (1)

- BIT 2212: Business Systems ModelingDocument9 pagesBIT 2212: Business Systems Modelingbeldon musauNo ratings yet

- NotesDocument34 pagesNotesAmmunitionsNo ratings yet

- Answer:Since The Decisions To Be Made Are X Production Level of Product, For 1, 2Document3 pagesAnswer:Since The Decisions To Be Made Are X Production Level of Product, For 1, 2ThegoatNo ratings yet

- A1 10BM60005Document13 pagesA1 10BM60005amit_dce100% (2)

- Z X y X y X Y: Linear ProgrammingDocument22 pagesZ X y X y X Y: Linear Programmingguptamaths8676No ratings yet

- AlgbraDocument40 pagesAlgbraMohye AuobNo ratings yet

- CH 2 Linear Programming in SpreadsheetsDocument63 pagesCH 2 Linear Programming in SpreadsheetsBilalNo ratings yet

- BMath3 ProjectDocument6 pagesBMath3 ProjectRainbow VillanuevaNo ratings yet

- Test Bank Introduction To Operations Research 10th Edition Fred HillierDocument36 pagesTest Bank Introduction To Operations Research 10th Edition Fred Hilliernick200808No ratings yet

- Exercise 12.2: Linear Programming 519Document10 pagesExercise 12.2: Linear Programming 519Sandeep TyagiNo ratings yet

- Linear Programming 1Document5 pagesLinear Programming 1Özlem YurtseverNo ratings yet

- Homework From The ClassDocument23 pagesHomework From The ClassÖzlem YurtseverNo ratings yet

- Linear Programming 1Document6 pagesLinear Programming 1Özlem YurtseverNo ratings yet

- Frame Parts (Unit) Electrical Components (Unit) Profit ($) Max Number To Be Produced Product 1 Product 2 AvailabilityDocument4 pagesFrame Parts (Unit) Electrical Components (Unit) Profit ($) Max Number To Be Produced Product 1 Product 2 AvailabilityÖzlem YurtseverNo ratings yet

- First Cargo Scond Cargo Third Cargo Fourth CargoDocument2 pagesFirst Cargo Scond Cargo Third Cargo Fourth CargoÖzlem YurtseverNo ratings yet

- Continuing The Problem: Homework 6Document3 pagesContinuing The Problem: Homework 6Özlem YurtseverNo ratings yet

- Standard Form: Iteration1 MRT 2 4 5Document6 pagesStandard Form: Iteration1 MRT 2 4 5Özlem YurtseverNo ratings yet

- Linear Programming 1Document4 pagesLinear Programming 1Özlem YurtseverNo ratings yet

- Linear Programming 1Document11 pagesLinear Programming 1Özlem YurtseverNo ratings yet

- 1 Iteration: - Continuing The ProblemDocument19 pages1 Iteration: - Continuing The ProblemÖzlem YurtseverNo ratings yet

- SM 12 16eDocument26 pagesSM 12 16ebebo3usaNo ratings yet

- ComputerGraphics CS602 1 SOL - DoDocument3 pagesComputerGraphics CS602 1 SOL - DoÖzlem YurtseverNo ratings yet

- Proof Proof 1: Every Hyper Plane Is Convex: Homework 3Document8 pagesProof Proof 1: Every Hyper Plane Is Convex: Homework 3Özlem YurtseverNo ratings yet

- Linear Programming 1Document5 pagesLinear Programming 1Özlem YurtseverNo ratings yet

- MGMT 405 Operations and Production Management Answer Set 5 (Reference Chapters 12 - William J. Stevenson-2007, Ninth Edition) ProblemsDocument13 pagesMGMT 405 Operations and Production Management Answer Set 5 (Reference Chapters 12 - William J. Stevenson-2007, Ninth Edition) ProblemsÖzlem YurtseverNo ratings yet

- Homework 1: ST NDDocument13 pagesHomework 1: ST NDÖzlem YurtseverNo ratings yet

- Simplex Method For Bounded Variables: Linear Programming Problems With Lower and Upper BoundsDocument11 pagesSimplex Method For Bounded Variables: Linear Programming Problems With Lower and Upper BoundsÖzlem YurtseverNo ratings yet

- Industrial Drive and Application PDFDocument90 pagesIndustrial Drive and Application PDFGOUTHAM A.R coorgNo ratings yet

- Agilent Phase-Noise-Measurement TES-E5052B DatasheetDocument21 pagesAgilent Phase-Noise-Measurement TES-E5052B DatasheetTeq ShoNo ratings yet

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocument16 pagesInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeLucía MitchellNo ratings yet

- ACCF - CSR Reconciliation-Darrang-18-08-20Document7 pagesACCF - CSR Reconciliation-Darrang-18-08-20Hunny VermaNo ratings yet

- AC DisconnectsDocument2 pagesAC DisconnectsFidel CastroNo ratings yet

- THHN TC FuerzaDocument2 pagesTHHN TC Fuerzajuan pablo castro gallegoNo ratings yet

- ArçelikDocument36 pagesArçelikchampion93No ratings yet

- Secutec Binder Ds UkDocument2 pagesSecutec Binder Ds UkSuresh RaoNo ratings yet

- 3948Document20 pages3948Jigneshkumar PatelNo ratings yet

- A Ground-Motion Transfer Function Matrix Between Two Nearby Rock and Soil Sites: A System Identification ProblemDocument13 pagesA Ground-Motion Transfer Function Matrix Between Two Nearby Rock and Soil Sites: A System Identification ProblemRicardo Angelo Quispe MendizábalNo ratings yet

- Digital Time StampingDocument22 pagesDigital Time StampingSunil Vicky VohraNo ratings yet

- Overall Heat Transfer CoefficientDocument4 pagesOverall Heat Transfer Coefficientvenka07No ratings yet

- Handling Tickets Is Called Issue Tracking System.: Sap SDDocument6 pagesHandling Tickets Is Called Issue Tracking System.: Sap SDNaveen KumarNo ratings yet

- Startup ShutdownDocument4 pagesStartup ShutdownPit_mkluNo ratings yet

- Curs HPLCDocument132 pagesCurs HPLCSimon RobertaNo ratings yet

- Revisd Load Calculations Orchid HospitalDocument11 pagesRevisd Load Calculations Orchid Hospitalsubstationlover100% (1)

- Laser G-Code Processing ExampleDocument5 pagesLaser G-Code Processing ExampleYakov ZinovievNo ratings yet

- Open Foundation With Eccentric Loading and Moments-FinalDocument6 pagesOpen Foundation With Eccentric Loading and Moments-FinalMahadev Sastry100% (1)

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- Technical ManualDocument48 pagesTechnical ManualStewart BenNo ratings yet

- MBA Project On CRMDocument40 pagesMBA Project On CRMsrikanthmogilla1250% (2)

- Valvulas Moog Hoja de DatosDocument24 pagesValvulas Moog Hoja de DatosLuis Alberto RamosNo ratings yet

- Toyota Truck SequoiaDocument16 pagesToyota Truck SequoiaD3NYNo ratings yet

- Math Samples PDFDocument1 pageMath Samples PDFArwin VillegasNo ratings yet

- Setup and Hold Time - Static Timing Analysis (STA) Basic (Part 3a) - VLSI ConceptsDocument3 pagesSetup and Hold Time - Static Timing Analysis (STA) Basic (Part 3a) - VLSI ConceptsRakesh KumarNo ratings yet

- 2011-10-23 Slipstream Service Pack 2 For Forefront TMG 2010Document7 pages2011-10-23 Slipstream Service Pack 2 For Forefront TMG 2010crisao23No ratings yet

- Deck Machinery PartsDocument3 pagesDeck Machinery Partsmihat jasneyNo ratings yet

- DDJ-RR Update Manual e PDFDocument8 pagesDDJ-RR Update Manual e PDFgusycaroNo ratings yet

- English For LogisticsDocument25 pagesEnglish For LogisticsRolando Nunez100% (1)

- 6R80L 6R100 Zip inDocument12 pages6R80L 6R100 Zip inYisus 616No ratings yet