Professional Documents

Culture Documents

Thermal Conductivities of Selected Materials: Appendix 5

Thermal Conductivities of Selected Materials: Appendix 5

Uploaded by

Benni WewokOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Conductivities of Selected Materials: Appendix 5

Thermal Conductivities of Selected Materials: Appendix 5

Uploaded by

Benni WewokCopyright:

Available Formats

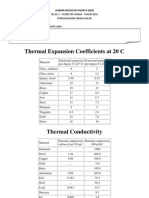

APPENDIX 5

Thermal Conductivities of Selected Materials

All values in units of W/m K. Divide by 1.73 to obtain values in Btu/hr/ft2 / F/ft. Divide by 419 to obtain values in cal/cm K s. Consult references for values at additional temperatures.

ELEMENTS, METALS, AND ALLOYS

190 C 0 C 20 C 100 C 1000 C

Source: Geankoplis, C. J., Transport Processes and Unit Operations, Prentice-Hall, Englewood Cliffs, 1993. Aluminum Copper Steel 202 388 377 45

Source: Kittel, C., Introduction to Solid State Physics, John Wiley and Sons, New York, 1957. Aluminum Cadmium (||hex. axis) Cadmium ( hex. axis) Copper Gold Iron Magnesium Nickel Silver Sodium 418 92.1 113 578 184 188 113 427 155 226 83.7 105 394 306 92.1 172 83.7 418 138

Source: Gaskell, D. R., Transport Phenomena in Materials Engineering, MacMillan, New York, 1992. 1% carbon steel 1% chrome steel 304 stainless steel (18% Cr, 8% Ni) 60% Pt, 40% Rh Al Bronze (90% Cu, 10% Al) Aluminum Beryllium Boron Brass (70% Cu, 30% Zn) 43 62 14 46 49 236 218 31.7 110

An Introduction to Materials Engineering and Science: For Chemical and Materials Engineers, by Brian S. Mitchell ISBN 0-471-43623-2 Copyright 2004 John Wiley & Sons, Inc.

874

CERAMICS

875

190 C Cadmium Cast iron Chromium Cobalt Constantan (55% Cu, 45% Ni) Copper Germanium Gold Iron Lead Lithium Magnesium Manganese Molybdenum Nichrome (80% Ni, 10% Cr) Nickel Platinum Rhenium Rhodium Silicon Silver Sodium Tin Titanium Tungsten Uranium Vanadium Wrought iron Zinc Zirconium

0 C

20 C 104 52 95 104 22 401 67 318 83 36 79 157 7.7 139 12 94 72 49 151 168 428 135 68 22 182 27 31 59 122 23

100 C

1000 C

CERAMICS

190 C 0 C 20 C 100 C 1000 C

Source: Kingery, W. D., H. K. Bowen and D. R. Uhlmann, Introduction to Ceramics, John Wiley and Sons, New York, 1976. Al2 O3 BeO Fire-clay refractory Fused silica glass Graphite MgAl2 O4 MgO Mullite Porcelain Soda-lime-silica glass ThO2 TiC TiC cermet 30.2 220 1.13 2.00 180 15.1 37.7 5.86 1.67 1.67 10.5 25.1 33.5 6.28 20.5 1.55 2.51 62.8 5.86 7.11 3.77 1.88 2.93 5.86 8.37

(continued )

876

THERMAL CONDUCTIVITIES OF SELECTED MATERIALS

190 C UO2.0 ZrO2 (stabilized)

0 C

20 C

100 C 10.0 1.97

1000 C 3.35 2.30

Source: Oxide Handbook, G. V. Samsanor, editor, Plenum, New York, 1973. CaO NiO TiO2 VO2 ZrO2 15.2 12.4 6.53 9.80 1.97 7.79 4.48 3.31 3.41 2.0

Source: Kittel, C., Introduction to Solid State Physics, John Wiley and Sons, New York, 1957. CaF2 KCl KF NaCl Source: Gaskell, D. R., Transport Phenomena in Materials Engineering, MacMillan, New York, 1992. Aluminum oxide Asbestos Beryllium oxide Bricks Chrome Common Fireclay Magnesite Masonry Silica Cement mortar Clay earth Coal Concrete Diatomaceous earth Fused quartz Granite Gypsum plaster Limestone Magnesium oxide Marble Rock wool Sand Sandstone 40 0.11 302 2.2 0.7 1.0 4.0 0.66 1.1 0.9 1.4 0.24 1.0 1.3 1.3 3.0 0.5 2.0 53 2.7 0.04 0.3 2.8

Source: Materials Science & Engineering Handbook, J. Shackelford and W. Alexander, editors, CRC Press, Boca Raton, FL, 1992. Aluminum nitride Aluminum oxide Beryllium oxide Boron carbide Boron nitride (|| to a axis) Boron nitride (|| to c axis) Calcium oxide Chromium carbide Chromium diboride Chromium oxide Cordierite 30.2 25.1 15.919.7 27.228.9 190 20.531.8 10.033.0 3.2 15.5 5.96.7 12.4 26.7 7.96

POLYMERS

877

190 C Hafnium carbide Hafnium diboride Hafnium oxide Magnesium oxide Mullite Nickel oxide Silicon carbide Silicon nitride Sillimanite Spinel Tantalum carbide Tantalum diboride Thorium oxide Titanium carbide Titanium diboride Titanium nitride Titanium oxide Tungsten carbide Uranium dioxide Zircon Zirconium carbide Zirconium diboride Zirconium oxide

0 C

20 C 22.2 6.29 11.4 40.6 12.1 30.2 22.2 10.9 10.1 17.131.0 24.326.0 28.9 84.2 20.5 23.024.3

100 C 6.1 1.8 14.7 8.4 6.7 10.5 6.1 2.1

1000 C 3.8 21.4 2.9 3.4 3.4

GLASSES

190 C 0 C 20 C 100 C 1000 C

Source: Gaskell, D. R., Transport Phenomena in Materials Engineering, MacMillan, New York, 1992. Glass ber Glass wool Pyroceram Window glass 0.035 0.038 4.1 0.84

POLYMERS

190 C 0 C 20 C 100 C 1000 C

Source: Geankoplis, C. J., Transport Processes and Unit Operations, Prentice-Hall, Englewood Cliffs, 1992. Hard Rubber 0.15

Source: Materials Science & Engineering Handbook, J. Shackelford and W. Alexander, editors, CRC Press, Boca Raton, FL, 1992. ABS resins (molded, extruded) Heat resistant High impact Low temperature impact Medium impact 0.210.35 0.210.28 0.130.24 0.130.31

(continued )

878

THERMAL CONDUCTIVITIES OF SELECTED MATERIALS

190 C Very high impact Acrylics (cast, molded, extruded) Alkyds (molded) Allyl diglycol carbonate Cellulose acetate (molded, extruded) Cellulose acetate butyrate (molded, extruded) Cellulose acetate propionate (molded, extruded) Chlorinated polyether Chlorinated polyvinyl chloride Epoxies (cast, molded) Fluorinated ethylene propylene (FEP) Nylon 6 Nylon 66 Nylon 610 Phenylene oxides Polyacetal Polyarylsulfone Polycarbonate Polyester, thermoplastic Polyester, thermoset Polyethylene (all densities) Polyimides Polyphenylene sulde Polypropylene Polypropylene, high impact Polystyrene Polytetrauoroethylene (PTFE) Polytriuorochloroethylene (PTFCE) Polyvinyl chloride Polyvinylidene uoride (PVDF)

0 C

20 C 0.020.24 0.21 0.351.04 2.51 0.170.33 0.170.33 0.170.33 1.57 1.64 0.170.86 0.21 2.082.92 2.94 2.60 1.93.1 0.220.28 1.9 0.19 0.620.95 0.170.21 0.33 6.5811.7 3.46 2.12.35 2.98 0.040.16 0.24 0.25 0.120.17 0.24

100 C

1000 C

Source: Gaskell, D. R., Transport Phenomena in Materials Engineering, MacMillan, New York, 1992. Foam rubber Hard rubber Polystyrene insulation Teon 0.030 0.16 0.025 0.35

COMPOSITES

190 C 0 C 20 C 100 C 1000 C

Source: Gaskell, D. R., Transport Phenomena in Materials Engineering, MacMillan, New York, 1992. Plywood 0.12

Source: Materials Science & Engineering Handbook, J. Shackelford and W. Alexander, editors, CRC Press, Boca Raton, FL, 1992. Alkyd, glass-lled Polycarbonate, 40% glass-ber-lled High-strength epoxy laminate Melamine, glass-ber-lled Melamine, cellulose-lled Nylon 6, 30% glass-ber-lled 0.350.52 0.22 4.1 0.48 0.290.35 2.925.66

BIOLOGICS

879

190 C Nylon 6-6, glass-ber-lled Nylon 610, 30% glass-ber-lled Polyester, high-strength glass-ber-lled Polyimide, glass-lled Polyphenylene sulde, 40% glass-ber-lled Polystyrene, 30% glass-ber-lled Polyurea, cellulose-lled Phenolic, wood-our-lled Phenolic, glass-ber-lled

0 C

20 C 2.605.71 6.06 2.282.91 6.21 3.46 0.20 0.290.42 0.170.52 0.35

100 C

1000 C

BIOLOGICS

190 C 0 C 20 C 100 C 1000 C

Source: Gaskell, D. R., Transport Phenomena in Materials Engineering, MacMillan, New York, 1992. Human skin Balsa wood Cypress wood Fir wood Maple/Oak wood White pine wood Yellow pine wood Wool 0.37 0.55 0.097 0.11 0.17 0.11 0.15 0.038

Source: Johnson, A. T., Biological Process Engineering, John Wiley and Sons, New York, 1999. Animal skin Beeswax Bone Cat blood Dental amalgam Enamel Fleece Animal muscle Human blood Human skin Human fat Human muscle Kidney or liver Porcelain Pork fat Seal blubber Oyster shell Wool Cork Cotton Cypress wood Fir wood Leaves Animal coats Paper 0.50 0.40 0.533 23.0 0.59 0.82 0.140.21 0.430.50 0.507 0.210.63 0.210.33 0.410.50 0.498 1.00 0.187 0.190 1.952.27 0.036 0.045 0.061 0.097 0.17 0.240.50 0.030.15 0.13

You might also like

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Investment CastingDocument26 pagesInvestment CastingParesh Shrivastava100% (1)

- Solomons Organic Chemistry Module IR TableDocument1 pageSolomons Organic Chemistry Module IR TableBenni WewokNo ratings yet

- Acid ZincDocument27 pagesAcid ZincHacı OsmanNo ratings yet

- Chromium PlatingDocument66 pagesChromium PlatingManikandan SudharsanNo ratings yet

- Shell CorrosionDocument33 pagesShell CorrosionManekGorisNo ratings yet

- Semiconductor Materials and Process Technology HandbookDocument691 pagesSemiconductor Materials and Process Technology HandbookRika100% (8)

- Clay Seminar Tewei NDocument9 pagesClay Seminar Tewei NTewei ChiuNo ratings yet

- LKPD Suhu Dan Pemuaian 2013Document2 pagesLKPD Suhu Dan Pemuaian 2013rudyhilkyaNo ratings yet

- Cadmium Telluride Thin Films: Growth From Solution and CharacteristicsDocument4 pagesCadmium Telluride Thin Films: Growth From Solution and CharacteristicsZaraSaleemNo ratings yet

- 10.1016/j.tsf.2016.12.036: Thin Solid FilmsDocument34 pages10.1016/j.tsf.2016.12.036: Thin Solid FilmssecateNo ratings yet

- Synthesis of Caco3 Nanoparticles by Mechanochemical ProcessingDocument7 pagesSynthesis of Caco3 Nanoparticles by Mechanochemical ProcessingKaren JohannaNo ratings yet

- Hardening Due To Vanadium Carbides Formed During Short-Time Aging of Hadfield SteelsDocument10 pagesHardening Due To Vanadium Carbides Formed During Short-Time Aging of Hadfield SteelsinekNo ratings yet

- Tfug 2005 02 Uc DavisDocument21 pagesTfug 2005 02 Uc DavisHery Saragih AndyNo ratings yet

- IIT gUWAHATI NOTESDocument25 pagesIIT gUWAHATI NOTESआदेश मीणाNo ratings yet

- Acrylonitrile-Butadiene Elastomer: Parameter Unit Value ReferencesDocument3 pagesAcrylonitrile-Butadiene Elastomer: Parameter Unit Value ReferencesIlles AlinNo ratings yet

- The Effect of Tio Addition On Glass Ceramic PropertiesDocument6 pagesThe Effect of Tio Addition On Glass Ceramic PropertiesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Lecture 6Document17 pagesLecture 6Rigved kokaneNo ratings yet

- Thin Films Deposited by Femtosecond Pulsed Laser Ablation of Tungsten CarbideDocument4 pagesThin Films Deposited by Femtosecond Pulsed Laser Ablation of Tungsten CarbideBosco BeloNo ratings yet

- Ceramics IntroductionDocument35 pagesCeramics IntroductionSaptarshi SenguptaNo ratings yet

- 2020-Effects of Aluminum Doping in CDS Thin Films Prepared by CBD and The Performance On Schottky Diodes TCO - CDS - Al - CDocument21 pages2020-Effects of Aluminum Doping in CDS Thin Films Prepared by CBD and The Performance On Schottky Diodes TCO - CDS - Al - CEdgar E Mosquera VargasNo ratings yet

- Optical and Structural Characterization of Air-Annealed Cds Film Prepared by Chemical Bath Deposition (CBD) Technique - Rizawan & JafariDocument6 pagesOptical and Structural Characterization of Air-Annealed Cds Film Prepared by Chemical Bath Deposition (CBD) Technique - Rizawan & JafariSuresh LakhanpalNo ratings yet

- CIM 20 21 Ord InglésDocument8 pagesCIM 20 21 Ord InglésIñigoNo ratings yet

- Ceramics International: SciencedirectDocument7 pagesCeramics International: SciencedirectBabcsánné Kiss JuditNo ratings yet

- Fire Behavior of Ethylene Vinyl Acetate/Kaolinite CompositesDocument18 pagesFire Behavior of Ethylene Vinyl Acetate/Kaolinite Compositestoloco1977No ratings yet

- Co2 CaptureDocument24 pagesCo2 CaptureWade ColemanNo ratings yet

- Effect of Temperature in The Tubular Ceramic Membrane Sintering Obtained With Kaolin and Ball ClayDocument8 pagesEffect of Temperature in The Tubular Ceramic Membrane Sintering Obtained With Kaolin and Ball ClayBenilton OliveiraNo ratings yet

- The Effect of Sodium Citrate As An Additive On Properties of ElectroplatedDocument7 pagesThe Effect of Sodium Citrate As An Additive On Properties of ElectroplatedCzzhhNo ratings yet

- Electroplating PowerpointDocument18 pagesElectroplating PowerpointPutradhana Setihadi50% (2)

- Ukrainczyk06 PDFDocument7 pagesUkrainczyk06 PDFyinglvNo ratings yet

- Tabelas - IncroperaDocument31 pagesTabelas - IncroperaOliveira74No ratings yet

- HASTELLOY® C-22HS™alloyDocument16 pagesHASTELLOY® C-22HS™alloyYudha SatriaNo ratings yet

- Appendix 4: Permeability of Polychlorotrifluoroethylene (PCTFE)Document3 pagesAppendix 4: Permeability of Polychlorotrifluoroethylene (PCTFE)jonasNo ratings yet

- CVD Diamond BookletDocument28 pagesCVD Diamond BookletАндрей ВольхинNo ratings yet

- Fire and Mechancial Properties of PA6/kaolinite CompositesDocument13 pagesFire and Mechancial Properties of PA6/kaolinite CompositesMarcos BatistellaNo ratings yet

- Atlas of Polarization DataDocument90 pagesAtlas of Polarization Datarajarajeswaran100387No ratings yet

- Comparative Properties of MetalsDocument2 pagesComparative Properties of MetalsAjay AgrawalNo ratings yet

- Materials 1Document8 pagesMaterials 1Harriprashanth ShanmugavelNo ratings yet

- Me 4210 Manufacturing Processes and EngineeringDocument4 pagesMe 4210 Manufacturing Processes and EngineeringAli ŞimşekNo ratings yet

- Electrodeposition of Nanocrystalline Nickel by Using Rotating Cylindrical ElectrodesDocument6 pagesElectrodeposition of Nanocrystalline Nickel by Using Rotating Cylindrical ElectrodesAsandulesa AndreeaNo ratings yet

- 2016 RF Sputtering of ZnO (002) Thin Films On Top of 3C-SiC-On-Si (100) Substrates For Low Cost Piezoelectric DevicesDocument4 pages2016 RF Sputtering of ZnO (002) Thin Films On Top of 3C-SiC-On-Si (100) Substrates For Low Cost Piezoelectric DevicesAbid IqbalNo ratings yet

- Anie202014384 Sup 0001 Misc - InformationDocument13 pagesAnie202014384 Sup 0001 Misc - InformationswapnilNo ratings yet

- NanoparticlesDocument25 pagesNanoparticlesAnonymous oVd3php100% (1)

- Materials and Equipment Design: PETR 350Document26 pagesMaterials and Equipment Design: PETR 350Yassir HindiNo ratings yet

- Kim2016 SonoDocument7 pagesKim2016 Sonozmaxprom5No ratings yet

- Lecture 1 2014Document23 pagesLecture 1 2014Fadhil Muhammad Al-fachriNo ratings yet

- Sanchez2016 - Ultrasonic Spray-Pyrolyzed CuCrO2 Thin FilmsDocument8 pagesSanchez2016 - Ultrasonic Spray-Pyrolyzed CuCrO2 Thin FilmsHeraclioNo ratings yet

- Artigo 6Document8 pagesArtigo 6Kaori OubaNo ratings yet

- ManualDocument14 pagesManualaryan_bhardwaj047No ratings yet

- The Future of Thin-Film Solar CellsDocument25 pagesThe Future of Thin-Film Solar CellsRay DanielNo ratings yet

- Deposicion de VaporDocument4 pagesDeposicion de VaporDavid RomeroNo ratings yet

- Chong 2010 NgembanTiO2Document10 pagesChong 2010 NgembanTiO2setyosulaksonoNo ratings yet

- Microwave-Assisted Synthesis and Characterization of Cao NanoparticlesDocument7 pagesMicrowave-Assisted Synthesis and Characterization of Cao NanoparticlesBeth JiménezNo ratings yet

- Bio-Functionalization of Silicon Nitride-Based Piezo-Resistive MicrocantileversDocument7 pagesBio-Functionalization of Silicon Nitride-Based Piezo-Resistive MicrocantileversNitin KaleNo ratings yet

- Rahul Vyas NotesDocument19 pagesRahul Vyas NotesMechanical HODNo ratings yet

- Electroplating PowerpointDocument18 pagesElectroplating PowerpointAMIR SURYA HIDAYAHNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Emerging Technologies: ASTM Methods For Fluid Ingress November 2010 Concrete InternationalDocument7 pagesEmerging Technologies: ASTM Methods For Fluid Ingress November 2010 Concrete InternationalmasteriragaNo ratings yet

- Fluid Dynamics & Thermal Performance of NanofluidsDocument73 pagesFluid Dynamics & Thermal Performance of Nanofluidsmind2008No ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument9 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringMARCOS ABRAHAM ALEJANDRO BALDOCEDA HUAYASNo ratings yet

- Introduction To Interpretation of Infrared SpectraDocument3 pagesIntroduction To Interpretation of Infrared SpectraBenni WewokNo ratings yet

- Ionic ConductorsDocument20 pagesIonic ConductorsGregorio GuzmanNo ratings yet

- IR Absorption TableDocument2 pagesIR Absorption TablefikrifazNo ratings yet

- Pyrolysis - Wikipedia, The Free EncyclopediaDocument9 pagesPyrolysis - Wikipedia, The Free EncyclopediaBenni WewokNo ratings yet

- Polymer BiodegradationDocument12 pagesPolymer BiodegradationBenni WewokNo ratings yet

- RejangDocument1 pageRejangBenni WewokNo ratings yet

- What Is CivilizationDocument1 pageWhat Is CivilizationBenni WewokNo ratings yet

- Examples of Stokes' Theorem and Gauss' Divergence TheoremDocument6 pagesExamples of Stokes' Theorem and Gauss' Divergence TheoremBenni WewokNo ratings yet

- Lorentz-Lorenz Equation - Wikipedia, The Free EncyclopediaDocument1 pageLorentz-Lorenz Equation - Wikipedia, The Free EncyclopediaBenni WewokNo ratings yet