Professional Documents

Culture Documents

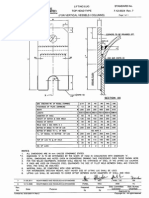

Tank Saddle Analysis

Uploaded by

WONG TSOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tank Saddle Analysis

Uploaded by

WONG TSCopyright:

Available Formats

Horizontal Tank.xls 1) INPUT: 2) Cylinder thickness, in 3) SSL , in 4) Diameter, in 5) S.G.

6) Saddle spacing, in 7) Width of build up ring, in 8) Overlay ring thickness, in 9) Head thickness, in 10) Pressure above head, psi 11) Axial Modulus E, psi 12) Hoop Modulus E, psi 1.53 Shell stress, psi 1461 Allowable stress, psi 787.4 (Head height is . 17 X diameter) 173.23 1.54 512.00 (Use tools, solver to find optimum) 8.00 1.75 Ring stress, psi 11,376 (12,500 allow. for FW) 1.53 Min head thick, in 1.515 29.01 1.64E+06 1.76E+06 2200

13) OUTPUT: 14) Total length, in 874.02 (Straight side + 2X the head height) 15) Total gallons 86215 16) Pressure at bottom, psi 38.638 17) Head thickness min., in 1.531 18) Distance saddle to end, in 181.01 B18/B14= 0.2071 19) Hoop stress, psi 1461.41 (B18/B14 Should be.2071 for optimum) 20) Fluid weight, lb 1107196 21) FRP weight, lb 66,870 (cylinder, heads, and support rings only) 22) Total weight, lb 1174066 23) Line load, lb/in 1353.60 24) Bend. moment at saddle, in/lb 22174510 25) Bend moment at center, in/lb 22180199 26) Axial stress at saddle, psi 1141.55 27) Axial stress at center, psi 1141.66 28) Deflection at center, in 0.0607 29) Deflection % at center 0.0119 30) Effective width of support ring, in 37.11 31) Moments, forces, and stresses away from the saddle tip (120 degree saddles and shear ply) 32) Moment, in lb 1129777 (Max moment at 2D*pi/48) 33) Vertical force, lb 99700 34) Tangential force, lb 96300 35) Normal force, lb 36) Bending stress, psi 11376 (Tension side) 37) -11004 (Compression side) 38) Shear stress, psi 0 40) 39) Moments, forces, and stresses at the saddle tip (120 degree saddles and rigid connection) 41) Moment, in lb 2715489 42) Vertical force, lb 237886 43) Tangential force, lb 206009 44) Normal force, lb 118943 45) Bending stress, psi 26351 (Tension side) 46) -27442 (Compression side) 47) Shear stress, psi 793 48) Saddle weight each, lb 533.3

Rick Van Name

Page 1

1/21/2004

You might also like

- Diffuser Pipe CalculationDocument15 pagesDiffuser Pipe Calculationmano_gceNo ratings yet

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNo ratings yet

- Hinge For Cover CalculationDocument2 pagesHinge For Cover CalculationamaNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- MD He Tema Asme v0.1Document31 pagesMD He Tema Asme v0.1Sharon Lambert100% (1)

- Fuel Injection Equipment: EspecificacionesDocument29 pagesFuel Injection Equipment: EspecificacionesSergio Ricardo Ibañez100% (1)

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcsjnmanivannan100% (4)

- Honda Wave 100Document2 pagesHonda Wave 100Arif Paktam63% (8)

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533No ratings yet

- HAT Horiz Vessel VolDocument1 pageHAT Horiz Vessel VolJ.SIVIRANo ratings yet

- Saddle Support CalculationDocument7 pagesSaddle Support CalculationrichardchiamNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- M 269-96 (2008) (Turnbuckles and Shackles)Document25 pagesM 269-96 (2008) (Turnbuckles and Shackles)tran_lamNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Nozzle Interference Error SolvingDocument2 pagesNozzle Interference Error SolvingSakthi VelNo ratings yet

- Specification Description Design Code ContentDocument1 pageSpecification Description Design Code Contentsushant_jhawerNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- NDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12Document7 pagesNDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12ravivarmadatla2011No ratings yet

- Denso Quantity Estimate Sheet PDFDocument2 pagesDenso Quantity Estimate Sheet PDFIvan RocoNo ratings yet

- 7-12-0024 Rev 7Document1 page7-12-0024 Rev 7cynideNo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- Piping Wind LoadsDocument2 pagesPiping Wind LoadsAbhishek GorkarNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Jeddah South Thermal Power Plant Stage-I: ProjectDocument18 pagesJeddah South Thermal Power Plant Stage-I: ProjectAmr AbdeinNo ratings yet

- Seismic Load Calculation of The Tank As Per IS 1893Document1 pageSeismic Load Calculation of The Tank As Per IS 1893ParthibanNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Cpp-Tank DSGN Calc-Rev CDocument42 pagesCpp-Tank DSGN Calc-Rev CnamasralNo ratings yet

- Calculation For Sight Glass FlangeDocument4 pagesCalculation For Sight Glass FlangeOmil Rastogi0% (2)

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Gasket Dimension (ASME B16.5 & B16.47)Document4 pagesGasket Dimension (ASME B16.5 & B16.47)ama100% (1)

- Base Plate CalculationDocument7 pagesBase Plate CalculationLcm TnlNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- 16 Preiss Study en 13445 Asme ViiiDocument26 pages16 Preiss Study en 13445 Asme ViiiDubaiHMARNo ratings yet

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- Ladder Rung Calc.Document1 pageLadder Rung Calc.Azwan ShahNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal Sattu100% (1)

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- Chibro Press Fit Piping Data SheetDocument5 pagesChibro Press Fit Piping Data SheetBoyd Johnston100% (1)

- Curb AngleDocument1 pageCurb Angle940623015859No ratings yet

- Vessel Calculation 200Document37 pagesVessel Calculation 200Phát NguyễnNo ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- Conversion ASME Unit ConversionDocument3 pagesConversion ASME Unit ConversionMohdBadruddinKarimNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Hydraulic Pump (8J6730) (Part of 8J6731 Pump Group) : SpecificationsDocument7 pagesHydraulic Pump (8J6730) (Part of 8J6731 Pump Group) : SpecificationsJohn Fredy Palacio G.No ratings yet

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- (B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationDocument7 pages(B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationArt G. Enzi100% (1)

- 2-Critical Speed of ShaftDocument5 pages2-Critical Speed of ShaftRidani Faulika Amma100% (3)

- Bridge Bearing Main - 2 Design Calculation (R-0)Document27 pagesBridge Bearing Main - 2 Design Calculation (R-0)mohan1441No ratings yet

- Monorail Overhead CraneDocument8 pagesMonorail Overhead Cranesherwinpons2003100% (1)

- Chain DesignDocument6 pagesChain Designशशांक तिवारीNo ratings yet

- R1 - Design of Pier LP1 RP1 With Open FN MJB CH-88+095Document212 pagesR1 - Design of Pier LP1 RP1 With Open FN MJB CH-88+095chiranjeevimd2991 MDNo ratings yet

- Nozzle Cal - 05Document1 pageNozzle Cal - 05whngomjNo ratings yet

- Tank Design PDFDocument89 pagesTank Design PDFcecgootyNo ratings yet

- Tank DesignDocument89 pagesTank DesignRafael ReyesNo ratings yet

- Tank DesignDocument89 pagesTank DesignDietrich von BismarckNo ratings yet

- Lifting LugDocument17 pagesLifting LugbkprodhNo ratings yet

- Techdoc Print PageDocument3 pagesTechdoc Print PageBuku DigitalNo ratings yet

- Solvents AlternativesDocument8 pagesSolvents AlternativesWONG TSNo ratings yet

- Sodium Determination ComparisonDocument8 pagesSodium Determination ComparisonWONG TSNo ratings yet

- Field Measurement of ORPDocument21 pagesField Measurement of ORPWONG TSNo ratings yet

- Mine Process Waste - Several Metals: ConclusionDocument2 pagesMine Process Waste - Several Metals: ConclusionWONG TSNo ratings yet

- Four Questions Centrifuge SelectionDocument4 pagesFour Questions Centrifuge SelectionWONG TSNo ratings yet

- Chapter 1: General ApplicabilityDocument19 pagesChapter 1: General ApplicabilityWONG TSNo ratings yet

- Addressing Water DiscolorationDocument24 pagesAddressing Water DiscolorationWONG TSNo ratings yet

- Chromium Treatment: ConclusionDocument4 pagesChromium Treatment: ConclusionWONG TSNo ratings yet

- Fan Selection Total PressureDocument4 pagesFan Selection Total PressureWONG TSNo ratings yet

- PH and TemperatureDocument4 pagesPH and TemperatureWONG TSNo ratings yet