Professional Documents

Culture Documents

Saddle Support Calculation

Uploaded by

richardchiamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saddle Support Calculation

Uploaded by

richardchiamCopyright:

Available Formats

FILENAME : 693254684.

xls

DATE : 09/23/2023 SADDLE STRESS ANALYSIS - LP.ZICK - BS5500

PAGE : 1

SADDLE BENDING STRESS ANALYSIS - L.P. ZICK ANALYSIS

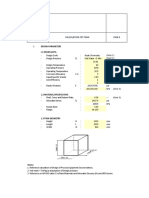

1 .0 REACTION AT SADDLE DUE TO EXTERNAL LOADING

1 .1 GEOMETRIC DATA OF VESSEL

Outside diameter of vessel, Do = 1238 mm

Overall vessel length, L = 5028 mm

Height of tank axis to bottom base plate, Hv = 1650 mm

Number of saddles, N = 2

Distance between saddles, Ls = 2150 mm

Base plate width, B = 200 mm

1 .2 FORCES AND MOMENTS

1 .2.1 Empty Condition

(a) Loading Combination

Erection weight, We (@ 8,986 kg ) = 88,156 N

Horizontal earthquake factor, Ch = 0

Vertical earthquake factor, Cv = 0

Longitudinal design wind force, Plh = 0 N

Transverse design wind force, Pth = 0 N

Horizontal transportation force, Th (@ 0.00 %We ) = 0 N

Vertical transportation force, Tv (@ 0.00 %We ) = 0 N

(b) Forces and Moments

(i) Earthquake Case

Horizontal shear, Vh = ( Ch.We ) = 0 N

Vertical shear per saddle, Vv = ( (1+Cv).We / N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vh.Hv/Ls ) ) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + ( 3.Vh.Hv/2B.N )) = 44,078 N

(ii) Wind Case

Horizontal longitudinal shear, Vlh = ( Plh ) = 0 N

Horizontal transverse shear, Vth = ( Pth ) = 0 N

Vertical shear per saddle, Vv = ( We / N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vlh.Hv/Ls ) ) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + ( 3.Vth.Hv/2B.N )) = 44,078 N

(iii) Transportation Case

Horizontal shear, Vh = ( Th ) = 0 N

Vertical shear per saddle, Vv = ( (Tv+We) / N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vh.Hv/Ls ) ) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + (3.Vh.Hv/2B.N) ) = 44,078 N

Maximum horizontal longitudinal shear, Flemax = 0 N

Maximum horizontal transverse shear, Ftemax = 0 N

Maximum reaction force per saddle, Qemax = 44,078 N

1 .2.2 Operating Condition

(a) Loading Combination

Operating weight, Wo (@ 8,986 kg ) = 88,156 N

Horizontal earthquake factor, Ch = 0

Vertical earthquake factor, Cv = 0

Longitudinal design wind force, Plh = 0 N

Transverse design wind force, Pth = 0 N

Total horizontal nozzle load in longitudinal direction, Nlh = 0 N

Total horizontal nozzle load in transverse direction, Nth = 0 N

Total vertical nozzle load, Nv = 0 N

(b) Forces and Moments

FILENAME : 693254684.xls

DATE : 09/23/2023 SADDLE STRESS ANALYSIS - LP.ZICK - BS5500

PAGE : 2

(i) Earthquake Case

Horizontal shear, Vh = ( Ch.Wo ) = 0 N

Vertical shear per saddle, Vv = ( (1+Cv).Wo / N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vh.Hv/Ls ) ) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + ( 3.Vh.Hv/2B.N )) = 44,078 N

(ii) Wind Case

Horizontal longitudinal shear, Vlh = ( Plh ) = 0 N

Horizontal transverse shear, Vth = ( Pth ) = 0 N

Vertical shear per saddle, Vv = ( Wo / N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vlh.Hv/Ls ) ) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + ( 3.Vth.Hv/2B.N )) = 44,078 N

(iii) External Nozzle Loading Case

Horizontal longitudinal shear, Vlh = ( Nlh ) = 0 N

Horizontal transverse shear, Vth = ( Nth ) = 0 N

Vertical shear per saddle, Vv = ( (Wo+Nv )/N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vlh.Hv/Ls )) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + (3.Vth.Hv/2B.N)) = 44,078 N

(iv) Expanding/Contracting deflection; Pier deflection

Friction coefficient of 'base plate-foundation' , µ = 0.00

Pier deflection , y = 0.00 mm

Spring rate, K = 0.00 N/mm

Horizontal expanding/contracting force , Fhec ( = µ.Wo/N ) = 0 N

Horizontal pier deflection force , Fhp ( = K.y/ N ) = 0 N

Maximum horizontal longitudinal shear, Flomax = 0 N

Maximum horizontal transverse shear, Ftomax = 0 N

Maximum reaction force per saddle, Qomax = 44,078 N

1 .2.3 Hydrostatic Test Condition

(a) Loading Combination

Hydrostatic test weight, Wh ( 8,986 kg ) = 88,156 N

Horizontal earthquake factor, Ch = 0

Vertical earthquake factor, Cv = 0

Longitudinal design wind force, Plh = 0 N

Transverse design wind force, Pth = 0 N

(b) Forces and Moments

(i) Earthquake Case

Horizontal shear, Vh = ( Ch.We ) = 0 N

Vertical shear per saddle, Vv = ( (1+Cv).We / N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vh.Hv/Ls ) ) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + ( 3.Vh.Hv/2B.N )) = 44,078 N

(ii) Wind Case

Horizontal longitudinal shear, Vlh = ( Plh ) = 0 N

Horizontal transverse shear, Vth = ( Pth ) = 0 N

Vertical shear per saddle, Vv = ( We / N ) = 44,078 N

Reaction at saddle at longitudinal direction, Ql ( = Vv + ( Vlh.Hv/Ls) ) = 44,078 N

(Notes : This equation is only applicable for 2 saddles only )

Reaction at saddle at transverse direction, Qt ( = Vv + ( 3.Vth.Hv/2B.N)) = 44,078 N

Maximum horizontal longitudinal shear, Flhmax = 0 N

Maximum horizontal transverse shear, Fthmax = 0 N

FILENAME : 693254684.xls

DATE : 09/23/2023 SADDLE STRESS ANALYSIS - LP.ZICK - BS5500

PAGE : 3

Maximum reaction force per saddle, Qhmax = 44,078 N

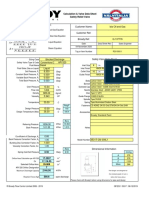

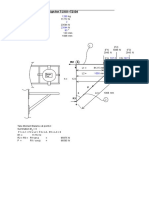

1 .3 SADDLE BENDING STRESS ANALYSIS - L.P. ZICK ANALYSIS

1 .3.1 GENERAL

Design code : BS 5500

Method used : L.P.ZICK

Type of support ( saddle / ring ) : saddle

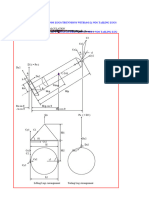

1 .3.2 GEOMETRIC DATA

L

Di

b2

b A b1

Cylindrical Shell

Inside diameter of cylindrical vessel, Dis = 1220 mm

Length of cylindrical shell, L ( tan/tan) = 4400 mm

Shell thickness, ts = 10.00 mm

Mean radius of shell, Rms = 615.00 mm

Head

Type of head used ( Hemi-spherical/Semi-ellipsoidal/Tori-spherical ) : Semi ellipsoidal

Inside diameter of head, Dih = 1220 mm

Depth of head, b ( outside ) = 314 mm

Head thickness, te = 9.00 mm

Mean radius of head, Rmh = 614.50 mm

Saddle and Wear Plate

Saddle welded to the vessel ? ( yes/no ) : no

Distance to saddle from end , A = 2500 mm

Angle of saddle support, g = 150 °xxxxx

Extended angle, ß = 6 °

Width of saddle, b1 (recommend use{30Dms}½ = 192 mm ) = 800 mmxxxxx

Width of wear plate , b2 = 1000 mmxxxxx

Wear plate thickness, t1 = 12.00 mmxxxxx

Stiffening Ring

Stiffening ring location ( unstiffened/plane/adjacent ) : unstiffened

Stiffener ring location ( internal/external ) : internal

( Location plane - internal, location adjacent - internal/external )

Stiffener ring dist. from saddle ctr., As-s = 0 mm******

Case 'adjacent' :

min. ring dist. from saddle ctr.(=(b1+10ts.cor)/2)= 450 mm

max. ring dist. from saddle ctr.( =Rms/2 ) = 308 mm

Type of ring ( rib/tee ) : tee

Web height, hw ( corroded ) 0 mm (New) = 0 mm (Cor.)

Web thickness, tw ( corroded ) 0 mm (New) = 0 mm (Cor.)

Flange width, wf ( corroded ) 0 mm (New) = 0 mm (Cor.)

Flange thickness, tf ( corroded ) 0 mm (New) = 0 mm (Cor.)

Cross sectional area of stiffener ring, As 0 mm² (New) = 0 mm² (Cor.)

Material and Mechanical Properties

Material used : BS1501-224-GR430A

Specified minimum yield stress , Sy = 275.00 N/mm²

Specified minimum tensile stress , Ss = 430.00 N/mm²

Allowable design stress at 38 °C , Srt = 183.00 N/mm²

Allowable design stress at 38.00 °C , Sdt = 183.00 N/mm²

Modulus of elasticity at 38.00 °C , E = 200000 N/mm²

FILENAME : 693254684.xls

DATE : 09/23/2023 SADDLE STRESS ANALYSIS - LP.ZICK - BS5500

PAGE : 4

( Notes : E shall be taken from the applicable materials chart in Subpart 3

of Section II Part D )

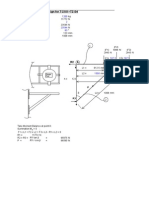

Stiffener Ring Sizing

wf = wf =

tf = 0 0 2 tf = 0 0 2

d d

tw = 0 tw = 0

hw = 0 hw = 0 Neutral axis

1 c 1 c

3 3

Le = 100.00 ts = 10.00 Le = 100.00 ts.cor = 10.00

NEW CONDITION CORRODED CONDITION

Determine Combine Shell-Stiffener Ring Properties ( New Condition )

Effective length of shell, Le ( = tw + 10ts ) = 100.00 mm

A Y AY h A.h² I = (bd³)/12

(mm²) (mm) (mm³) (mm) (mm4) (mm4)

1 0 10.00 0 5.00 0 0

2 0 10.00 0 5.00 0 0

3 1000 5.00 5000 0.00 0 8,333

TOTAL 1000 5000 0 8,333

Neutral axis of stiffener ring from shell, c ( = AY/A ) = 5.00 mm

Neutral axis of stiffener ring from tip of ring, d = 5.00 mm

Cross sectional area o 1 stiffener rings, A = 1000 mm²

Moment of inertia of combined 1 stiffener rings-shell,Isr = 8,333 mm4

Determine Combine Shell-Stiffener Ring Properties ( Corroded Condition )

Effective length of shell, Le ( = tw + 10ts.cor ) = 100.00 mm

A Y AY h A.h² I = (bd³)/12

(mm²) (mm) (mm³) (mm) (mm4) (mm4)

1 0 10.00 0 5.00 0 0

2 0 10.00 0 5.00 0 0

3 1000 5.00 5000 0.00 0 8,333

TOTAL 1000 5000 0 8,333

Neutral axis of stiffener ring from shell, c ( = AY/A ) = 5.00 mm

Neutral axis of stiffener ring from tip of ring, d = 5.00 mm

Cross sectional area o 1 stiffener rings, A = 1000 mm²

Moment of inertia of combined 1 stiffener rings-shell,Isr = 8,333 mm4

1 .3.3 PRESSURE, TEMPERATURE & CONTENT

Internal design pressure, Pi = 0.00 N/mm²

Hydrostatic test pressure, Ph (@ 1.50 Pi ) = 0.000 N/mm²

Design temperature, T = 38 °C

Specific gravity of liquid ( operating ) = 0.00

Specific gravity of water ( hydrostatic ) = 0.00

1 .3.4 SHELL MATERIAL AND MECHANICAL PROPERITIES

Material : SS 240 304L

Specified minimum yield stress at 38.00 °C, Sy = 206.70 N/mm²

Specified minimum tensile stress a 38.00 °C, St = 482.30 N/mm²

Allowable tensile stress at 38.00 °C, fdt = 172.30 N/mm²

Allowable tensile stress at 38.00 °C, frt = 172.30 N/mm²

Modulus of elasticity at 38.00 °C, Edt = 200000 N/mm²

FILENAME : 693254684.xls

DATE : 09/23/2023 SADDLE STRESS ANALYSIS - LP.ZICK - BS5500

PAGE : 5

Modulus of elasticity at 38.00 °C, Ert = 200000 N/mm²

Stress factor, s = 1.4

Corrosion allowance, c.a. = 0 mm

1 .4 STRESS ANALYSIS

EMPTY OPERATING FIELD HYDROSTATIC

No. Press. No. Press. With Press. No. Press. With Press.

(A) REACTION FORCE & DATA

Max. Reaction Force W1 (N) 44078 44078 44078 44078 44078

Mean radius of vesse Rms (mm) 615.00 615.00 615.00 615.00 615.00

Shell thickness ts (mm) 10.00 10.00 10.00 10.00 10.00

Mean radius of head Rmh (mm) 614.50 614.50 614.50 614.50 614.50

Head thickness te (mm) 9.00 9.00 9.00 9.00 9.00

Internal pressure Pi (N/mm²) 0.00 0.00 0.00 0.00 0.00

Inside dia. of vessel Ri (mm) 610.00 610.00 610.00 610.00 610.00

Condition :

CASE A > Rm/2 ( Shell is NOT STIFFENED by proximity of the ends )

CASE 'unstiffened' ( Shell is NOT STIFFENED by stiffener rings )

FOR ß = 150 °

K1 = 0.1610 K3 = 0.7990 K5 = 0.6730 K7 = -

K2 = 0.2790 K4 = - K6 = 0.0316 K8 = -

C4 = - C5 = -

FOR ß = 162 °

K5 = 0.6506

K6 = 0.0254

C4 = - C5 = -

REMARK :-

Off hand calcs. for ß 162 °, for K6

A/Rms 120.0 NIL 135.0 NIL 150.0 162.0 165.0

NIL

0.500 0.0132 NIL 0.0103 NIL 0.0079 0.0063 0.0059

NIL NIL NIL NIL NIL NIL NIL NIL

1.000 0.0528 NIL 0.0413 NIL 0.0316 0.0254 0.0238

4.065

(B) LONGITUDINAL BENDING STRESSES

AT MID-SPAN

Longitudinal Moment M3 (Nmm) -64643210 -64643210 -64643210 -64643210 -64643210

Longitudinal Stress at

Highest Point f1 (N/mm²) 5.44 5.44 5.44 5.44 5.44

Lowest Point f2 (N/mm²) -5.44 -5.44 -5.44 -5.44 -5.44

Primary Membrane Cir. Stress

Highest Point sq (N/mm²) 0.00 0.00 0.00 0.00 0.00

Lowest Point sq (N/mm²) 0.00 0.00 0.00 0.00 0.00

Stress Intensities

Primary Membrane Stress Intensities

Highest Point S (N/mm²) 5.44 5.44 5.44 5.44 5.44

Lowest Point S (N/mm²) 5.44 5.44 5.44 5.44 5.44

Allowable ten. stress f (N/mm²) 172.30 172.30 172.30 186.03 186.03

Condition OK ! OK ! OK ! OK ! OK !

Longitudinal Compressive Stress

FILENAME : 693254684.xls

DATE : 09/23/2023 SADDLE STRESS ANALYSIS - LP.ZICK - BS5500

PAGE : 6

Longitudinal compressive stress

Highest/Lowest Point sc (N/mm²) 5.44 5.44 5.44 5.44 5.44

Allowable comp. stresSc (N/mm²) 120.85 120.85 120.85 120.85 120.85

Condition OK ! OK ! OK ! OK ! OK !

AT SUPPORT

Longitudinal Moment M4 (Nmm) -65466474 -65466474 -65466474 -65466474 -65466474

Longitudinal Stress at

Equator f3 (N/mm²) 34.22 34.22 34.22 34.22 34.22

Lowest Point f4 (N/mm²) -19.75 -19.75 -19.75 -19.75 -19.75

Primary Membrane Cir. Stress

Equator sq (N/mm²) 0.00 0.00 0.00 0.00 0.00

Lowest Point sq (N/mm²) 0.00 0.00 0.00 0.00 0.00

Stress Intensities

Primary Membrane Stress Intensities

Equator S (N/mm²) 34.22 34.22 34.22 34.22 34.22

Lowest Point S (N/mm²) 19.75 19.75 19.75 19.75 19.75

Allowable stress f (N/mm²) 172.30 172.30 172.30 186.03 186.03

Condition OK ! OK ! OK ! OK ! OK !

Longitudinal Compressive Stress

Longitudinal compressive stress

Highest/Lowest Point sc (N/mm²) 19.75 19.75 19.75 19.75 19.75

Allowable comp. stresSc (N/mm²) 120.85 120.85 120.85 120.85 120.85

Condition OK ! OK ! OK ! OK ! OK !

(C) TANGENTIAL SHEARING STRESSES

AT SUPPORT

Tangential shearing streses in the

Shell qs (N/mm²) -0.71 -0.71 -0.71 -0.71 -0.71

- - - - - - -

- - - - - -

- -

- - - - - -

- - - - - -

- 0.012 0.012 0.012 0.012 0.012

- - - - - -

Allow. tangential shearing stress

Shell Sqs (N/mm²) 137.84 137.84 137.84 137.84 137.84

- - - - - - -

Condition OK ! OK ! OK ! OK ! OK !

(D) CIRCUMFERENTIAL STRESSES

Condition :

Shell not stiffened by rings.

Saddle not welded to the vessel. Hence, K5'' = K5.

Since ß >= 6° and b2>= ( b1+10ts ), therefore t = ( ts + tw ).

AT SUPPORT ( At the edge of saddle, ß = 150 °)

Circumferential stresses

Lowest Point f5 (N/mm²) -1.35 -1.35 -1.35 -1.35 -1.35

At the Horn of the Saddle

For L / Rms < 8 f6 (N/mm²) -5.33 -5.33 -5.33 -5.33 -5.33

- - - - - - -

Allowable circumferential stress

FILENAME : 693254684.xls

DATE : 09/23/2023 SADDLE STRESS ANALYSIS - LP.ZICK - BS5500

PAGE : 7

Lowest Point Sci5 (N/mm²) 120.85 120.85 120.85 120.85 120.85

At the Horn of the Saddle

For L / Rms < 8 Sci6(N/mm² 215.38 215.38 215.38 215.38 215.38

- - - - - - -

Condition OK ! OK ! OK ! OK ! OK !

AT SUPPORT ( At the edge of saddle plate, ß = 162 °)

Circumferential stresses

Lowest Point f5 (N/mm²) -2.87 -2.87 -2.87 -2.87 -2.87

At the edge of the Saddle plate

For L / Rms < 8 f6 (N/mm²) -19.85 -19.85 -19.85 -19.85 -19.85

Allowable circumferential stress

Lowest Point Sci5 (N/mm² 120.85 120.85 120.85 120.85 120.85

At the edge of the Saddle plate

For L / Rms < 8 Sci6 (N/mm² 215.38 215.38 215.38 215.38 215.38

Condition OK ! OK ! OK ! OK ! OK !

You might also like

- Large Horizontal Vessel Supported by Two Saddles Stress AnalysisDocument7 pagesLarge Horizontal Vessel Supported by Two Saddles Stress AnalysisSiva baalanNo ratings yet

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDocument9 pagesPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie MartinezNo ratings yet

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNo ratings yet

- 50KL Tank - API CalcDocument1 page50KL Tank - API CalcRathikaNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- PSV Reaction Force CalculationDocument2 pagesPSV Reaction Force CalculationSuthanNo ratings yet

- Cummins C400D5 Sound Data SheetDocument4 pagesCummins C400D5 Sound Data SheetLeonel Molina AlvaradoNo ratings yet

- Ellipsoidal Flange to Circular Conversion DimensionsDocument3 pagesEllipsoidal Flange to Circular Conversion Dimensionsnaveenkumar_madasettNo ratings yet

- 1607pras PDFDocument4 pages1607pras PDFDana GuerreroNo ratings yet

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDocument5 pagesBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Tailing Lifting Lug Design 57 V 202 r2Document10 pagesTailing Lifting Lug Design 57 V 202 r2Dinesh KhaparkarNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Specification Description Design Code ContentDocument1 pageSpecification Description Design Code Contentsushant_jhawerNo ratings yet

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- Welding 12Document21 pagesWelding 12AhmedNo ratings yet

- F921 Storage Tanks: Standard FeaturesDocument2 pagesF921 Storage Tanks: Standard Featuresminov minovitchNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- 201804-Cummins PowerHour - Sound Attenuation and Test StrategiesDocument44 pages201804-Cummins PowerHour - Sound Attenuation and Test StrategiesOsama QureshiNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- Reduce Engine Noise with Exhaust SilencersDocument4 pagesReduce Engine Noise with Exhaust Silencersjessito2No ratings yet

- (Pressure Safety Valve Kick Force On Gas Relief) : Technip Geoproduction (M) Sdn. Bhd. Stress Standard ProcedureDocument7 pages(Pressure Safety Valve Kick Force On Gas Relief) : Technip Geoproduction (M) Sdn. Bhd. Stress Standard ProcedurecelonevesNo ratings yet

- Variable Speed Drive - Economic Comparison: LocationDocument3 pagesVariable Speed Drive - Economic Comparison: LocationNiket MankadNo ratings yet

- Tidy-Aboveground Fabrication StandardsDocument40 pagesTidy-Aboveground Fabrication StandardsarisandiyusufNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542No ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Section VIII CalDocument22 pagesSection VIII CalthodathersNo ratings yet

- Tank FixturesDocument21 pagesTank FixturesASSSSSSSSSSSSNo ratings yet

- Fan Noise EstimateDocument5 pagesFan Noise EstimateBen ClackNo ratings yet

- Design Calculations of Storage Tank: According To API 650 Code, 11 EditionDocument3 pagesDesign Calculations of Storage Tank: According To API 650 Code, 11 EditionAkash KazamaNo ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- HT Aboveground Horizontal PDFDocument4 pagesHT Aboveground Horizontal PDFSenthil KumarNo ratings yet

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocument4 pagesWI06-0260 Calculations For Obround Nozzle ConnectionskumarNo ratings yet

- Rect TankDocument6 pagesRect TankSasikumar JothiNo ratings yet

- Pipe Davit & Guide & Support Calculation 1/3) : (For Pressure Vessel Design Manual Procedure 6-1 (Type-B) )Document4 pagesPipe Davit & Guide & Support Calculation 1/3) : (For Pressure Vessel Design Manual Procedure 6-1 (Type-B) )vamsiNo ratings yet

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaNo ratings yet

- IS.5216 1982part2Document27 pagesIS.5216 1982part2Mahendra SuryavanshiNo ratings yet

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinNo ratings yet

- Sound Data: Sound Pressure Levels at 7 Meters DB (A)Document1 pageSound Data: Sound Pressure Levels at 7 Meters DB (A)Anonymous 4Pq2vhjWLVNo ratings yet

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- Calculation Cpi Tank: I. Design Parameters I.1 Design DataDocument5 pagesCalculation Cpi Tank: I. Design Parameters I.1 Design DataikramNo ratings yet

- Air Blowers Data SheetDocument9 pagesAir Blowers Data Sheetgharsallah mounaNo ratings yet

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- Lifting - Lug (Modification)Document11 pagesLifting - Lug (Modification)Sam LowNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- EN13445 TWR OutDocument124 pagesEN13445 TWR OutCosimoNo ratings yet

- Holset - Dresden Technical Paper - New Range of Turbochargers For Light Commercial Vehicle MarketsDocument17 pagesHolset - Dresden Technical Paper - New Range of Turbochargers For Light Commercial Vehicle MarketsPetter LonningNo ratings yet

- Pressure Safety Valve DatasheetDocument10 pagesPressure Safety Valve DatasheetsithulibraNo ratings yet

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- LiftingLugStress Rev 1.5Document20 pagesLiftingLugStress Rev 1.5ilijarskNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Calculation of Required Bollard Pull: BV Rules and FormulasDocument2 pagesCalculation of Required Bollard Pull: BV Rules and FormulasRahul JagdaleNo ratings yet

- DAM LOADING CALCULATIONS AND ANALYSISDocument9 pagesDAM LOADING CALCULATIONS AND ANALYSISIsmail BmlNo ratings yet

- Base Plate DesignDocument4 pagesBase Plate DesignrichardchiamNo ratings yet

- LiftingDocument13 pagesLiftingrichardchiamNo ratings yet

- Wind OpeartingDocument3 pagesWind OpeartingrichardchiamNo ratings yet

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDocument32 pagesKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamNo ratings yet

- Gen Conversion TableDocument3 pagesGen Conversion TablerichardchiamNo ratings yet

- Pipe Specification Api5lDocument1 pagePipe Specification Api5lmrzodNo ratings yet

- List To Be Follow For TenderDocument2 pagesList To Be Follow For TenderrichardchiamNo ratings yet

- LiftingLug TrunnionDocument22 pagesLiftingLug Trunnionrichardchiam100% (2)

- Seismic Hazard Map of Western IndonesiaDocument1 pageSeismic Hazard Map of Western IndonesiarichardchiamNo ratings yet

- Forging SDocument93 pagesForging SrichardchiamNo ratings yet

- Qty of PlatsDocument2 pagesQty of PlatsRichard Chiam Heng KuangNo ratings yet

- Calculation For Gauge Pole SupportsDocument7 pagesCalculation For Gauge Pole SupportsrichardchiamNo ratings yet

- Fund for World Indices Futures/CFD Risk and Return AnalysisDocument19 pagesFund for World Indices Futures/CFD Risk and Return AnalysisrichardchiamNo ratings yet

- Center Vent & Peripheral Vent CalDocument1 pageCenter Vent & Peripheral Vent CalrichardchiamNo ratings yet

- Center Vent & Peripheral Vent CalDocument1 pageCenter Vent & Peripheral Vent CalrichardchiamNo ratings yet

- Calculation For Gauge Pole SupportsDocument7 pagesCalculation For Gauge Pole SupportsrichardchiamNo ratings yet

- Ring Cutting PlanDocument1 pageRing Cutting PlanrichardchiamNo ratings yet

- Angle Clip Stress Calculation For Inlet Nozzle Part 1001Document2 pagesAngle Clip Stress Calculation For Inlet Nozzle Part 1001richardchiamNo ratings yet

- Gas and Oil Pipeline Project SkidsDocument18 pagesGas and Oil Pipeline Project SkidsrichardchiamNo ratings yet

- Angle Clip Stress Calculation For Inlet Nozzle Part 1001Document2 pagesAngle Clip Stress Calculation For Inlet Nozzle Part 1001richardchiamNo ratings yet

- Qty of Plats LATESTDocument6 pagesQty of Plats LATESTrichardchiamNo ratings yet

- Calculation For Gauge Pole SupportsDocument7 pagesCalculation For Gauge Pole SupportsrichardchiamNo ratings yet

- NozloadDocument1 pageNozloadrichardchiamNo ratings yet

- Floater Weight CalculationDocument10 pagesFloater Weight CalculationrichardchiamNo ratings yet

- Calculation For Gauge Pole SupportsDocument7 pagesCalculation For Gauge Pole SupportsrichardchiamNo ratings yet

- Figure - Ci Vs HDDocument3 pagesFigure - Ci Vs HDrichardchiamNo ratings yet

- Floater Weight CalculationDocument10 pagesFloater Weight CalculationrichardchiamNo ratings yet

- Shell Cutting PlanDocument2 pagesShell Cutting PlanrichardchiamNo ratings yet

- Slope Shell Course CalculationDocument2 pagesSlope Shell Course CalculationrichardchiamNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesFrom EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraRating: 4.5 out of 5 stars4.5/5 (4)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Advanced Design Examples of Seismic Retrofit of StructuresFrom EverandAdvanced Design Examples of Seismic Retrofit of StructuresRating: 1 out of 5 stars1/5 (1)

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesFrom EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesRating: 5 out of 5 stars5/5 (2)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksFrom EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksRating: 3 out of 5 stars3/5 (2)

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringFrom EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringNo ratings yet

- Natural Ventilation of Buildings: Theory, Measurement and DesignFrom EverandNatural Ventilation of Buildings: Theory, Measurement and DesignNo ratings yet

- Design and Construction of Soil Anchor PlatesFrom EverandDesign and Construction of Soil Anchor PlatesRating: 5 out of 5 stars5/5 (1)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Pipeline Planning and Construction Field ManualFrom EverandPipeline Planning and Construction Field ManualRating: 5 out of 5 stars5/5 (3)