Professional Documents

Culture Documents

Angelina Beam: Angelina Transforms An Industrial Product Into An Innovative and Useful Solution For Architects

Uploaded by

Demçe FlorjanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angelina Beam: Angelina Transforms An Industrial Product Into An Innovative and Useful Solution For Architects

Uploaded by

Demçe FlorjanCopyright:

Available Formats

Long Carbon Europe

Sections and Merchant Bars

Angelina

beam

A successful combination of strength,

light weight, and transparency

Angelina

transforms an industrial product into

an innovative and useful solution for architects.

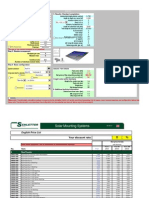

A load test was performed and validated at the University

of Lige based on a reference beam for an office

building having the following characteristics:

l a long span,

l a floor beam height of only 62 cm,

l high loads (dead weight + 100 kg/m of

partitions + 500 kg/m of service load),

l a distance between beams of 6.75 m through

the use of COFRADAL 200.

The test confirmed that the measured results were perfectly in

line with our numerical simulations performed using the design

software SAFIR, available from the University of Lige - Belgium.

This software is used to optimise beam and opening dimensions.

Tested and certified

1

7

,0

m

6

,7

5

m

0

,2

0

m

6

,7

5

m

Angelina

Made from environmentally-friendly electric

arc furnace steel in an ISO 14001 certified mill,

Angelina beams are 100% recyclable and

fully meet sustainable development criteria.

Angelina

, an

environmental

must

ArcelorMittal

Commercial Sections

66, rue de Luxembourg

L-4221 Esch-sur-Alzette

LUXEMBOURG

Tel. + 352 5313 3014

Fax + 352 5313 3087

www.arcelormittal.com/sections

0

-0.05

-0.1

-0.15

-0.2

-0.25

-0.3

0 200 400 600 800 1000 1200

Applied load (kN)

D

e

f

e

c

t

i

o

n

(

m

)

ANGELINA test curve

Numerical simulation

350%

300%

250%

200%

150%

100%

50%

0%

z ANGELINA beam

z Equivalent ACB

Inertia at right

angles to opening

Area of an

opening

Maximum possible

width of a 40 cm

high duct

* The values are based on

the17 metres Angelina

beam of the test, and

an equivalent ACB beam

(HD400x187;

D = diameter = 450 mm;

w = 150 mm;

Ht = 580 mm).

The Angelina beam offers substantial technical and economical advantages for floors.

21

4

0

1526.10

3

cm

4

*

1732.10

3

cm

4

*

0,40m

2

*

0,16m

2

*

70cm*

21cm*

70

4

0

Technical

assistance

Our engineers are at your disposal to provide

answers to all your technical questions,

with particular emphasis on the predesign

of structural components, construction

details, surface treatments, fire protection,

metallurgy and welding. They can also help in

the predesign of structures for new buildings

or in case of renovation. To help design your

projects, we also offer a range of software

programs as well as technical documentation

that can be consulted or downloaded from

www.arcelormittal.com/sections

At ArcelorMittal we also have a team of

multi-product professionals specialising in

the construction market: the Building and

Construction Support (BCS) division.

A complete range of products and

solutions dedicated to construction in all

its forms: structures, faades, roofing,

etc. is available from the website

www.constructalia.com

Building &

Construction

Support

V

e

r

s

i

o

n

2

0

0

8

-

1

COFRADAL 200

Angelina

beam

A clever idea applied to an industrial product

Sleek, open, transparent and fexible, the Angelina

beam

offers a new architectural dimension within an environmentally-

friendly approach. Thanks to a reduced production time and

substantial material savings, Angelina

meets the economic

requirements of your projects, while ensuring optimum safety

Aesthetic

With its large spans, its oblong, pleasing shapes

and its soft, gentle geometry, Angelina leaves

plenty of scope for design and imagination by

overcoming normal technical constraints.

Lightweight

Angelina uses the least amount of material to

be refined and light. It optimises construction

heights, the number of beams and columns,

the size of the foundations and many physical

constraints. It can thus reduce the steel weight

in the slabs of office buildings to less than

30 kg/m.

Economical

The weight saving, the optimization of the cuts,

the height and weld length reductions have a

beneficial influence on the fabrication costs. On

job site, the large openings allow for the fast

installation of pipes and ducts.

Flexible

All kind of fluids and even very large rectangular

ventilation ducts (0.7 m x 0.4 m) can be

easily integrated into the Angelina openings.

A simplified fabrication guarantees a Just in

time delivery to the site. The quick and easy

assembly ensure a flexible, economical and safe

construction.

An infnite number of permutations

for wide spans

Angelina allows for an infinite number of

possible geometries depending on the required

inertia, the resistance to high loads, or the

application. Indeed, using one or two base

A technical and industrial solution

meeting all your requirements

Made from H or I beams cut through the web

along a sinusoidal line with the two T-sections

then being offset and welded together, the

resulting Angelina beam is one and a half

times the height of the original profile.

profiles, Angelina beams can feature different

configurations with regard to layout, shape of

openings and distances between openings.

This manufacturing method allows the height

of the beam to be adjusted with precision

and minimizes offcuts during fabrication.

Floor

Production of an Angelina beam

ANGELINA floor beam

Technical data

b w b w

H

0

X

Y

t a

Sine equation of length

b and height a/2

A

L

= area to be painted per unit length

G = weight per unit length

4 2

3

sin

2

5 , 0

a

b

x a

y +

(

|

.

|

\

|

+

|

.

|

\

|

=

Ht a

l

h

Original profile (height h)

Angelina beam (height H

t

)

r = fllet radius

t

f

= fange thickness

a [mm] = 2h - 4(t

f

+ r + 20) H

t

= 1,4 to 1,7 h l = 3 to 5 a

Step 1 : flame cutting

Step 2 : separation of the tees

Step 3 : turning - assembly - welding

Step 4 : cutting to length - completion

To fulfil additional requirements, specific

finishing operations such as bending and

cambering, or the production of hybrid

beams are available upon request.

There is no need to blank the openings at the ends using this manufacturing process.

Closure of the web using a welded plate (optional)

IPE

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

IPE A 200 18,4 316,0 238,0 429,5 250 0,764

IPE 200 22,4 319,0 238,0 433,6 250 0,768

IPE O 200 25,1 321,0 238,0 436,3 250 0,779

IPE A 220 22,2 354,6 275,2 482,0 250 0,843

IPE 220 26,2 357,6 275,2 486,1 250 0,848

IPE O 220 29,4 359,6 275,2 488,8 250 0,858

IPE A 240 26,2 387,4 300,8 526,6 250 0,918

IPE 240 30,7 390,4 300,8 530,6 250 0,922

IPE O 240 34,3 392,4 300,8 533,4 250 0,932

IPE A 270 30,7 446,6 359,2 607,0 250 1,037

IPE 270 36,1 449,6 359,2 611,1 250 1,041

IPE O 270 42,3 453,6 359,2 616,5 250 1,051

IPE A 300 36,5 505,6 417,2 687,2 250 1,156

IPE 300 42,2 508,6 417,2 691,3 250 1,16

IPE O 300 49,3 512,6 417,2 696,7 250 1,174

IPE A 330 43 558,0 462,0 758,4 250 1,25

IPE 330 49,1 561,0 462,0 762,5 250 1,254

IPE O 330 57 565,0 462,0 768,0 250 1,268

HD 260 x 54,1 54,1 381,0 274,0 517,9 250 1,47

HD 260 x 68,2 68,2 387,0 274,0 526,0 250 1,48

HD 260 x 93,0 93 397,0 274,0 539,6 250 1,50

HD 260 x 114 114 405,0 274,0 550,5 250 1,52

HD 260 x 142 142 415,0 274,0 564,1 250 1,54

HD 260 x 172 172 427,0 274,0 580,4 250 1,57

HD 320 x 74,2 74,2 486,0 370,0 660,6 250 1,74

HD 320 x 97,6 97,6 495,0 370,0 672,8 250 1,76

HD 320 x 127 127 505,0 370,0 686,4 250 1,77

HD 320 x 158 158 515,0 370,0 700,0 250 1,80

HD 320 x 198 198 528,0 370,0 717,7 250 1,83

HD 320 x 245 245 544,0 370,0 739,4 250 1,87

HD 320 x 300 300 560,0 370,0 761,2 250 1,90

HD 360 x 134 134 606,0 500,0 823,7 250 2,14

HD 360 x 147 147 610,4 500,8 829,7 250 2,15

HD 360 x 162 162 614,4 500,8 835,1 250 2,16

HD 360 x 179 179 618,2 500,4 840,3 250 2,17

HD 360 x 196 196 621,6 499,2 844,9 250 2,18

HD 400 x 187 187 618,0 500,0 840,0 250 2,24

HD 400 x 216 216 624,6 499,2 849,0 250 2,27

HD 400 x 237 237 629,6 499,2 855,8 250 2,28

HD 400 x 262 262 637,4 500,8 866,4 250 2,30

HD

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

HE

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

HE 260 AA 54,1 381,0 274,0 517,9 250 1,474

HE 260 A 68,2 387,0 274,0 526,0 250 1,484

HE 260 B 93 397,0 274,0 539,6 250 1,499

HE 260 M 172 427,0 274,0 580,4 250 1,575

HE 280 AA 61,2 420,0 312,0 570,9 250 1,593

HE 280 A 76,4 426,0 312,0 579,0 250 1,603

HE 280 B 103 436,0 312,0 592,6 250 1,618

HE 280 M 189 466,0 312,0 633,4 250 1,694

HE 300 AA 69,8 451,0 336,0 613,0 250 1,705

HE 300 A 88,3 458,0 336,0 622,5 250 1,717

HE 300 B 117 468,0 336,0 636,1 250 1,732

HE 300 M 238 508,0 336,0 690,5 250 1,832

HE 320 AA 74,2 486,0 370,0 660,6 250 1,74

HE 320 A 97,6 495,0 370,0 672,8 250 1,756

HE 320 B 127 505,0 370,0 686,4 250 1,771

HE 320 M 245 544,0 370,0 739,4 250 1,866

HE 340 AA 78,9 523,0 406,0 710,9 250 1,777

HE 340 A 105 533,0 406,0 724,5 250 1,795

HE 340 B 134 543,0 406,0 738,1 250 1,81

HE 340 M 248 580,0 406,0 788,3 250 1,902

HE 360 AA 83,7 560,0 442,0 761,2 250 1,814

HE 360 A 112 571,0 442,0 776,1 250 1,834

HE 360 B 142 581,0 442,0 789,7 250 1,849

HE 360 M 250 616,0 442,0 837,3 250 1,934

Angelina

beam

A clever idea applied to an industrial product

Sleek, open, transparent and fexible, the Angelina

beam

offers a new architectural dimension within an environmentally-

friendly approach. Thanks to a reduced production time and

substantial material savings, Angelina

meets the economic

requirements of your projects, while ensuring optimum safety

Aesthetic

With its large spans, its oblong, pleasing shapes

and its soft, gentle geometry, Angelina leaves

plenty of scope for design and imagination by

overcoming normal technical constraints.

Lightweight

Angelina uses the least amount of material to

be refined and light. It optimises construction

heights, the number of beams and columns,

the size of the foundations and many physical

constraints. It can thus reduce the steel weight

in the slabs of office buildings to less than

30 kg/m.

Economical

The weight saving, the optimization of the cuts,

the height and weld length reductions have a

beneficial influence on the fabrication costs. On

job site, the large openings allow for the fast

installation of pipes and ducts.

Flexible

All kind of fluids and even very large rectangular

ventilation ducts (0.7 m x 0.4 m) can be

easily integrated into the Angelina openings.

A simplified fabrication guarantees a Just in

time delivery to the site. The quick and easy

assembly ensure a flexible, economical and safe

construction.

An infnite number of permutations

for wide spans

Angelina allows for an infinite number of

possible geometries depending on the required

inertia, the resistance to high loads, or the

application. Indeed, using one or two base

A technical and industrial solution

meeting all your requirements

Made from H or I beams cut through the web

along a sinusoidal line with the two T-sections

then being offset and welded together, the

resulting Angelina beam is one and a half

times the height of the original profile.

profiles, Angelina beams can feature different

configurations with regard to layout, shape of

openings and distances between openings.

This manufacturing method allows the height

of the beam to be adjusted with precision

and minimizes offcuts during fabrication.

Floor

Production of an Angelina beam

ANGELINA floor beam

Technical data

b w b w

H

0

X

Y

t a

Sine equation of length

b and height a/2

A

L

= area to be painted per unit length

G = weight per unit length

4 2

3

sin

2

5 , 0

a

b

x a

y +

(

|

.

|

\

|

+

|

.

|

\

|

=

Ht a

l

h

Original profile (height h)

Angelina beam (height H

t

)

r = fllet radius

t

f

= fange thickness

a [mm] = 2h - 4(t

f

+ r + 20) H

t

= 1,4 to 1,7 h l = 3 to 5 a

Step 1 : flame cutting

Step 2 : separation of the tees

Step 3 : turning - assembly - welding

Step 4 : cutting to length - completion

To fulfil additional requirements, specific

finishing operations such as bending and

cambering, or the production of hybrid

beams are available upon request.

There is no need to blank the openings at the ends using this manufacturing process.

Closure of the web using a welded plate (optional)

IPE

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

IPE A 200 18,4 316,0 238,0 429,5 250 0,764

IPE 200 22,4 319,0 238,0 433,6 250 0,768

IPE O 200 25,1 321,0 238,0 436,3 250 0,779

IPE A 220 22,2 354,6 275,2 482,0 250 0,843

IPE 220 26,2 357,6 275,2 486,1 250 0,848

IPE O 220 29,4 359,6 275,2 488,8 250 0,858

IPE A 240 26,2 387,4 300,8 526,6 250 0,918

IPE 240 30,7 390,4 300,8 530,6 250 0,922

IPE O 240 34,3 392,4 300,8 533,4 250 0,932

IPE A 270 30,7 446,6 359,2 607,0 250 1,037

IPE 270 36,1 449,6 359,2 611,1 250 1,041

IPE O 270 42,3 453,6 359,2 616,5 250 1,051

IPE A 300 36,5 505,6 417,2 687,2 250 1,156

IPE 300 42,2 508,6 417,2 691,3 250 1,16

IPE O 300 49,3 512,6 417,2 696,7 250 1,174

IPE A 330 43 558,0 462,0 758,4 250 1,25

IPE 330 49,1 561,0 462,0 762,5 250 1,254

IPE O 330 57 565,0 462,0 768,0 250 1,268

HD 260 x 54,1 54,1 381,0 274,0 517,9 250 1,47

HD 260 x 68,2 68,2 387,0 274,0 526,0 250 1,48

HD 260 x 93,0 93 397,0 274,0 539,6 250 1,50

HD 260 x 114 114 405,0 274,0 550,5 250 1,52

HD 260 x 142 142 415,0 274,0 564,1 250 1,54

HD 260 x 172 172 427,0 274,0 580,4 250 1,57

HD 320 x 74,2 74,2 486,0 370,0 660,6 250 1,74

HD 320 x 97,6 97,6 495,0 370,0 672,8 250 1,76

HD 320 x 127 127 505,0 370,0 686,4 250 1,77

HD 320 x 158 158 515,0 370,0 700,0 250 1,80

HD 320 x 198 198 528,0 370,0 717,7 250 1,83

HD 320 x 245 245 544,0 370,0 739,4 250 1,87

HD 320 x 300 300 560,0 370,0 761,2 250 1,90

HD 360 x 134 134 606,0 500,0 823,7 250 2,14

HD 360 x 147 147 610,4 500,8 829,7 250 2,15

HD 360 x 162 162 614,4 500,8 835,1 250 2,16

HD 360 x 179 179 618,2 500,4 840,3 250 2,17

HD 360 x 196 196 621,6 499,2 844,9 250 2,18

HD 400 x 187 187 618,0 500,0 840,0 250 2,24

HD 400 x 216 216 624,6 499,2 849,0 250 2,27

HD 400 x 237 237 629,6 499,2 855,8 250 2,28

HD 400 x 262 262 637,4 500,8 866,4 250 2,30

HD

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

HE

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

HE 260 AA 54,1 381,0 274,0 517,9 250 1,474

HE 260 A 68,2 387,0 274,0 526,0 250 1,484

HE 260 B 93 397,0 274,0 539,6 250 1,499

HE 260 M 172 427,0 274,0 580,4 250 1,575

HE 280 AA 61,2 420,0 312,0 570,9 250 1,593

HE 280 A 76,4 426,0 312,0 579,0 250 1,603

HE 280 B 103 436,0 312,0 592,6 250 1,618

HE 280 M 189 466,0 312,0 633,4 250 1,694

HE 300 AA 69,8 451,0 336,0 613,0 250 1,705

HE 300 A 88,3 458,0 336,0 622,5 250 1,717

HE 300 B 117 468,0 336,0 636,1 250 1,732

HE 300 M 238 508,0 336,0 690,5 250 1,832

HE 320 AA 74,2 486,0 370,0 660,6 250 1,74

HE 320 A 97,6 495,0 370,0 672,8 250 1,756

HE 320 B 127 505,0 370,0 686,4 250 1,771

HE 320 M 245 544,0 370,0 739,4 250 1,866

HE 340 AA 78,9 523,0 406,0 710,9 250 1,777

HE 340 A 105 533,0 406,0 724,5 250 1,795

HE 340 B 134 543,0 406,0 738,1 250 1,81

HE 340 M 248 580,0 406,0 788,3 250 1,902

HE 360 AA 83,7 560,0 442,0 761,2 250 1,814

HE 360 A 112 571,0 442,0 776,1 250 1,834

HE 360 B 142 581,0 442,0 789,7 250 1,849

HE 360 M 250 616,0 442,0 837,3 250 1,934

Angelina

beam

A clever idea applied to an industrial product

Sleek, open, transparent and fexible, the Angelina

beam

offers a new architectural dimension within an environmentally-

friendly approach. Thanks to a reduced production time and

substantial material savings, Angelina

meets the economic

requirements of your projects, while ensuring optimum safety

Aesthetic

With its large spans, its oblong, pleasing shapes

and its soft, gentle geometry, Angelina leaves

plenty of scope for design and imagination by

overcoming normal technical constraints.

Lightweight

Angelina uses the least amount of material to

be refined and light. It optimises construction

heights, the number of beams and columns,

the size of the foundations and many physical

constraints. It can thus reduce the steel weight

in the slabs of office buildings to less than

30 kg/m.

Economical

The weight saving, the optimization of the cuts,

the height and weld length reductions have a

beneficial influence on the fabrication costs. On

job site, the large openings allow for the fast

installation of pipes and ducts.

Flexible

All kind of fluids and even very large rectangular

ventilation ducts (0.7 m x 0.4 m) can be

easily integrated into the Angelina openings.

A simplified fabrication guarantees a Just in

time delivery to the site. The quick and easy

assembly ensure a flexible, economical and safe

construction.

An infnite number of permutations

for wide spans

Angelina allows for an infinite number of

possible geometries depending on the required

inertia, the resistance to high loads, or the

application. Indeed, using one or two base

A technical and industrial solution

meeting all your requirements

Made from H or I beams cut through the web

along a sinusoidal line with the two T-sections

then being offset and welded together, the

resulting Angelina beam is one and a half

times the height of the original profile.

profiles, Angelina beams can feature different

configurations with regard to layout, shape of

openings and distances between openings.

This manufacturing method allows the height

of the beam to be adjusted with precision

and minimizes offcuts during fabrication.

Floor

Production of an Angelina beam

ANGELINA floor beam

Technical data

b w b w

H

0

X

Y

t a

Sine equation of length

b and height a/2

A

L

= area to be painted per unit length

G = weight per unit length

4 2

3

sin

2

5 , 0

a

b

x a

y +

(

|

.

|

\

|

+

|

.

|

\

|

=

Ht a

l

h

Original profile (height h)

Angelina beam (height H

t

)

r = fllet radius

t

f

= fange thickness

a [mm] = 2h - 4(t

f

+ r + 20) H

t

= 1,4 to 1,7 h l = 3 to 5 a

Step 1 : flame cutting

Step 2 : separation of the tees

Step 3 : turning - assembly - welding

Step 4 : cutting to length - completion

To fulfil additional requirements, specific

finishing operations such as bending and

cambering, or the production of hybrid

beams are available upon request.

There is no need to blank the openings at the ends using this manufacturing process.

Closure of the web using a welded plate (optional)

IPE

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

IPE A 200 18,4 316,0 238,0 429,5 250 0,764

IPE 200 22,4 319,0 238,0 433,6 250 0,768

IPE O 200 25,1 321,0 238,0 436,3 250 0,779

IPE A 220 22,2 354,6 275,2 482,0 250 0,843

IPE 220 26,2 357,6 275,2 486,1 250 0,848

IPE O 220 29,4 359,6 275,2 488,8 250 0,858

IPE A 240 26,2 387,4 300,8 526,6 250 0,918

IPE 240 30,7 390,4 300,8 530,6 250 0,922

IPE O 240 34,3 392,4 300,8 533,4 250 0,932

IPE A 270 30,7 446,6 359,2 607,0 250 1,037

IPE 270 36,1 449,6 359,2 611,1 250 1,041

IPE O 270 42,3 453,6 359,2 616,5 250 1,051

IPE A 300 36,5 505,6 417,2 687,2 250 1,156

IPE 300 42,2 508,6 417,2 691,3 250 1,16

IPE O 300 49,3 512,6 417,2 696,7 250 1,174

IPE A 330 43 558,0 462,0 758,4 250 1,25

IPE 330 49,1 561,0 462,0 762,5 250 1,254

IPE O 330 57 565,0 462,0 768,0 250 1,268

HD 260 x 54,1 54,1 381,0 274,0 517,9 250 1,47

HD 260 x 68,2 68,2 387,0 274,0 526,0 250 1,48

HD 260 x 93,0 93 397,0 274,0 539,6 250 1,50

HD 260 x 114 114 405,0 274,0 550,5 250 1,52

HD 260 x 142 142 415,0 274,0 564,1 250 1,54

HD 260 x 172 172 427,0 274,0 580,4 250 1,57

HD 320 x 74,2 74,2 486,0 370,0 660,6 250 1,74

HD 320 x 97,6 97,6 495,0 370,0 672,8 250 1,76

HD 320 x 127 127 505,0 370,0 686,4 250 1,77

HD 320 x 158 158 515,0 370,0 700,0 250 1,80

HD 320 x 198 198 528,0 370,0 717,7 250 1,83

HD 320 x 245 245 544,0 370,0 739,4 250 1,87

HD 320 x 300 300 560,0 370,0 761,2 250 1,90

HD 360 x 134 134 606,0 500,0 823,7 250 2,14

HD 360 x 147 147 610,4 500,8 829,7 250 2,15

HD 360 x 162 162 614,4 500,8 835,1 250 2,16

HD 360 x 179 179 618,2 500,4 840,3 250 2,17

HD 360 x 196 196 621,6 499,2 844,9 250 2,18

HD 400 x 187 187 618,0 500,0 840,0 250 2,24

HD 400 x 216 216 624,6 499,2 849,0 250 2,27

HD 400 x 237 237 629,6 499,2 855,8 250 2,28

HD 400 x 262 262 637,4 500,8 866,4 250 2,30

HD

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

HE

Base profle

Angelina beam parameters

G H

t

a b w A

L

kg/m mm mm mm mm m

2

/m

HE 260 AA 54,1 381,0 274,0 517,9 250 1,474

HE 260 A 68,2 387,0 274,0 526,0 250 1,484

HE 260 B 93 397,0 274,0 539,6 250 1,499

HE 260 M 172 427,0 274,0 580,4 250 1,575

HE 280 AA 61,2 420,0 312,0 570,9 250 1,593

HE 280 A 76,4 426,0 312,0 579,0 250 1,603

HE 280 B 103 436,0 312,0 592,6 250 1,618

HE 280 M 189 466,0 312,0 633,4 250 1,694

HE 300 AA 69,8 451,0 336,0 613,0 250 1,705

HE 300 A 88,3 458,0 336,0 622,5 250 1,717

HE 300 B 117 468,0 336,0 636,1 250 1,732

HE 300 M 238 508,0 336,0 690,5 250 1,832

HE 320 AA 74,2 486,0 370,0 660,6 250 1,74

HE 320 A 97,6 495,0 370,0 672,8 250 1,756

HE 320 B 127 505,0 370,0 686,4 250 1,771

HE 320 M 245 544,0 370,0 739,4 250 1,866

HE 340 AA 78,9 523,0 406,0 710,9 250 1,777

HE 340 A 105 533,0 406,0 724,5 250 1,795

HE 340 B 134 543,0 406,0 738,1 250 1,81

HE 340 M 248 580,0 406,0 788,3 250 1,902

HE 360 AA 83,7 560,0 442,0 761,2 250 1,814

HE 360 A 112 571,0 442,0 776,1 250 1,834

HE 360 B 142 581,0 442,0 789,7 250 1,849

HE 360 M 250 616,0 442,0 837,3 250 1,934

Long Carbon Europe

Sections and Merchant Bars

Angelina

beam

A successful combination of strength,

light weight, and transparency

Angelina

transforms an industrial product into

an innovative and useful solution for architects.

A load test was performed and validated at the University

of Lige based on a reference beam for an office

building having the following characteristics:

l a long span,

l a floor beam height of only 62 cm,

l high loads (dead weight + 100 kg/m of

partitions + 500 kg/m of service load),

l a distance between beams of 6.75 m through

the use of COFRADAL 200.

The test confirmed that the measured results were perfectly in

line with our numerical simulations performed using the design

software SAFIR, available from the University of Lige - Belgium.

This software is used to optimise beam and opening dimensions.

Tested and certified

1

7

,0

m

6

,7

5

m

0

,2

0

m

6

,7

5

m

Angelina

Made from environmentally-friendly electric

arc furnace steel in an ISO 14001 certified mill,

Angelina beams are 100% recyclable and

fully meet sustainable development criteria.

Angelina

, an

environmental

must

ArcelorMittal

Commercial Sections

66, rue de Luxembourg

L-4221 Esch-sur-Alzette

LUXEMBOURG

Tel. + 352 5313 3014

Fax + 352 5313 3087

www.arcelormittal.com/sections

0

-0.05

-0.1

-0.15

-0.2

-0.25

-0.3

0 200 400 600 800 1000 1200

Applied load (kN)

D

e

f

e

c

t

i

o

n

(

m

)

ANGELINA test curve

Numerical simulation

350%

300%

250%

200%

150%

100%

50%

0%

z ANGELINA beam

z Equivalent ACB

Inertia at right

angles to opening

Area of an

opening

Maximum possible

width of a 40 cm

high duct

* The values are based on

the17 metres Angelina

beam of the test, and

an equivalent ACB beam

(HD400x187;

D = diameter = 450 mm;

w = 150 mm;

Ht = 580 mm).

The Angelina beam offers substantial technical and economical advantages for floors.

21

4

0

1526.10

3

cm

4

*

1732.10

3

cm

4

*

0,40m

2

*

0,16m

2

*

70cm*

21cm*

70

4

0

Technical

assistance

Our engineers are at your disposal to provide

answers to all your technical questions,

with particular emphasis on the predesign

of structural components, construction

details, surface treatments, fire protection,

metallurgy and welding. They can also help in

the predesign of structures for new buildings

or in case of renovation. To help design your

projects, we also offer a range of software

programs as well as technical documentation

that can be consulted or downloaded from

www.arcelormittal.com/sections

At ArcelorMittal we also have a team of

multi-product professionals specialising in

the construction market: the Building and

Construction Support (BCS) division.

A complete range of products and

solutions dedicated to construction in all

its forms: structures, faades, roofing,

etc. is available from the website

www.constructalia.com

Building &

Construction

Support

V

e

r

s

i

o

n

2

0

0

8

-

1

COFRADAL 200

Long Carbon Europe

Sections and Merchant Bars

Angelina

beam

A successful combination of strength,

light weight, and transparency

Angelina

transforms an industrial product into

an innovative and useful solution for architects.

A load test was performed and validated at the University

of Lige based on a reference beam for an office

building having the following characteristics:

l a long span,

l a floor beam height of only 62 cm,

l high loads (dead weight + 100 kg/m of

partitions + 500 kg/m of service load),

l a distance between beams of 6.75 m through

the use of COFRADAL 200.

The test confirmed that the measured results were perfectly in

line with our numerical simulations performed using the design

software SAFIR, available from the University of Lige - Belgium.

This software is used to optimise beam and opening dimensions.

Tested and certified

1

7

,0

m

6

,7

5

m

0

,2

0

m

6

,7

5

m

Angelina

Made from environmentally-friendly electric

arc furnace steel in an ISO 14001 certified mill,

Angelina beams are 100% recyclable and

fully meet sustainable development criteria.

Angelina

, an

environmental

must

ArcelorMittal

Commercial Sections

66, rue de Luxembourg

L-4221 Esch-sur-Alzette

LUXEMBOURG

Tel. + 352 5313 3014

Fax + 352 5313 3087

www.arcelormittal.com/sections

0

-0.05

-0.1

-0.15

-0.2

-0.25

-0.3

0 200 400 600 800 1000 1200

Applied load (kN)

D

e

f

e

c

t

i

o

n

(

m

)

ANGELINA test curve

Numerical simulation

350%

300%

250%

200%

150%

100%

50%

0%

z ANGELINA beam

z Equivalent ACB

Inertia at right

angles to opening

Area of an

opening

Maximum possible

width of a 40 cm

high duct

* The values are based on

the17 metres Angelina

beam of the test, and

an equivalent ACB beam

(HD400x187;

D = diameter = 450 mm;

w = 150 mm;

Ht = 580 mm).

The Angelina beam offers substantial technical and economical advantages for floors.

21

4

0

1526.10

3

cm

4

*

1732.10

3

cm

4

*

0,40m

2

*

0,16m

2

*

70cm*

21cm*

70

4

0

Technical

assistance

Our engineers are at your disposal to provide

answers to all your technical questions,

with particular emphasis on the predesign

of structural components, construction

details, surface treatments, fire protection,

metallurgy and welding. They can also help in

the predesign of structures for new buildings

or in case of renovation. To help design your

projects, we also offer a range of software

programs as well as technical documentation

that can be consulted or downloaded from

www.arcelormittal.com/sections

At ArcelorMittal we also have a team of

multi-product professionals specialising in

the construction market: the Building and

Construction Support (BCS) division.

A complete range of products and

solutions dedicated to construction in all

its forms: structures, faades, roofing,

etc. is available from the website

www.constructalia.com

Building &

Construction

Support

V

e

r

s

i

o

n

2

0

0

8

-

1

COFRADAL 200

You might also like

- Busducts: Low and Medium VoltageDocument14 pagesBusducts: Low and Medium VoltagesaturasatuNo ratings yet

- SADEF-Standard Building ProfilesDocument15 pagesSADEF-Standard Building ProfilesJosé OliveiraNo ratings yet

- Knauf PartitionSystemDocument2 pagesKnauf PartitionSystemBoy GalihNo ratings yet

- Autocalculator v. 16.00 i113001ENDocument224 pagesAutocalculator v. 16.00 i113001ENstikssNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Monolithic Insulating JointsDocument5 pagesMonolithic Insulating JointsTran Thanh TungNo ratings yet

- GE Evolve LED Roadway Medium Cobra Head ERMC DataSheet LowRes 032511Document4 pagesGE Evolve LED Roadway Medium Cobra Head ERMC DataSheet LowRes 032511wmesa777No ratings yet

- Hadley Group Ultrazed and Ultrabeam 63mm System ManualDocument68 pagesHadley Group Ultrazed and Ultrabeam 63mm System ManualTarek-Aziz BihiNo ratings yet

- PurlinsDocument9 pagesPurlinsrocky_oquendoNo ratings yet

- Acoustic CatalogDocument12 pagesAcoustic CatalogrohizatNo ratings yet

- Components Overview - Brochures V11 I400003GBDocument80 pagesComponents Overview - Brochures V11 I400003GBKirsten HernandezNo ratings yet

- IGBT and Diode Chips From ABB Switzerland LTD, SemiconductorsDocument4 pagesIGBT and Diode Chips From ABB Switzerland LTD, Semiconductorsbacuoc.nguyen356No ratings yet

- ITECH Subsea Bullseye Slope IndicatorsDocument1 pageITECH Subsea Bullseye Slope Indicatorssheila3898No ratings yet

- HeliCoil CatalogueDocument34 pagesHeliCoil Cataloguejarv7910No ratings yet

- WavePro LT Busway GE CatalogDocument40 pagesWavePro LT Busway GE CatalogWei Jiang NgNo ratings yet

- Industrial Enclosures Catalogue Oct 10 Complete - 2Document88 pagesIndustrial Enclosures Catalogue Oct 10 Complete - 2Harsha Jayanath GajanayakaNo ratings yet

- Midwaymetals Steel Selection GuideDocument100 pagesMidwaymetals Steel Selection GuidegarrybieberNo ratings yet

- Final Idler and Roller CatalogDocument6 pagesFinal Idler and Roller CatalogShubham Khurana100% (1)

- Industrial Penstocks GuideDocument19 pagesIndustrial Penstocks Guidedundee2012No ratings yet

- 05 50 00csbDocument9 pages05 50 00csbJerico NamucoNo ratings yet

- G3 60827Document2 pagesG3 60827api-3805767No ratings yet

- AMS XT66 Casement & Tilt Turn Window System Thermal PerformanceDocument35 pagesAMS XT66 Casement & Tilt Turn Window System Thermal PerformanceBranZzZzZNo ratings yet

- Mid GridDocument16 pagesMid GridnunosobralNo ratings yet

- Dracast Led2000 Studio Series Info SheetDocument2 pagesDracast Led2000 Studio Series Info SheetJohnNo ratings yet

- Igus E-Chain For CranesDocument28 pagesIgus E-Chain For CranesigusukNo ratings yet

- 04 Heg en 0703Document0 pages04 Heg en 0703aditgroupNo ratings yet

- Sai Extrumech Alias Sai EngineeringDocument18 pagesSai Extrumech Alias Sai EngineeringsaiextrumechNo ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- Aurora Commercial Outdoor Lighting V1Document320 pagesAurora Commercial Outdoor Lighting V1Aurora LightingNo ratings yet

- Cooling TowerDocument72 pagesCooling TowerRobert Nixon100% (1)

- TESEO Triptico PDFDocument5 pagesTESEO Triptico PDFLuis Felipe ZuñigaNo ratings yet

- Deltabeam Brochure EngDocument20 pagesDeltabeam Brochure EngymitevNo ratings yet

- 1STC007003D0201Document294 pages1STC007003D0201Niamat KhanNo ratings yet

- Steelaris CatalogueDocument150 pagesSteelaris CatalogueadnanraisahmedNo ratings yet

- EgyluxDocument13 pagesEgyluxayie5550% (2)

- Dry Pin Mill Ecutec NutzschDocument4 pagesDry Pin Mill Ecutec NutzschJohan ConradieNo ratings yet

- Industrial Ethernet Cables Cat 5 / Cat 6Document12 pagesIndustrial Ethernet Cables Cat 5 / Cat 6Cristian Alberto Oyarzo CalistoNo ratings yet

- Ruukki C Purlins PDFDocument4 pagesRuukki C Purlins PDFRicardo NovondoNo ratings yet

- Ultra Mag enDocument8 pagesUltra Mag enAdmir TalicNo ratings yet

- Catalogo Huck C50L PDFDocument8 pagesCatalogo Huck C50L PDFVladimir SepulvedaNo ratings yet

- WallDocument0 pagesWallgks6043No ratings yet

- 8645 enDocument2 pages8645 enhoangmy0106No ratings yet

- High Voltage Cable Catalog Cutting ToolsDocument57 pagesHigh Voltage Cable Catalog Cutting ToolssalvgranNo ratings yet

- 2010walkway Expanded MetalDocument2 pages2010walkway Expanded MetalthorenNo ratings yet

- ARCELOR CATALOG TechnicalDocument47 pagesARCELOR CATALOG TechnicalRadu MateiNo ratings yet

- BW Drum+Systems+Cost+Efficient+Welding en 2018 GL 092 WEBDocument16 pagesBW Drum+Systems+Cost+Efficient+Welding en 2018 GL 092 WEBpeterbirtatNo ratings yet

- Kathrein 2002Document179 pagesKathrein 2002MasTomNo ratings yet

- Origo™ Mig 320: Powerful and FlexibleDocument2 pagesOrigo™ Mig 320: Powerful and FlexiblehelderfsnNo ratings yet

- l10752 4000 Series Cement Plant Elevator Chain BrochureDocument4 pagesl10752 4000 Series Cement Plant Elevator Chain BrochureUrip S. SetyadjiNo ratings yet

- Edge illumination signsDocument2 pagesEdge illumination signsWaleed Mohammed FekryNo ratings yet

- Autocalculator v. 16.00 i113001ENDocument53 pagesAutocalculator v. 16.00 i113001ENstikss100% (1)

- Cavity ShaftwallDocument14 pagesCavity Shaftwallatac101No ratings yet

- Acesian Ducting Catalogue (111121)Document20 pagesAcesian Ducting Catalogue (111121)Matthew Ho Choon LimNo ratings yet

- 12.construction Catalogue en LeicaDocument44 pages12.construction Catalogue en LeicaLădaru-Baricz HajnalkaNo ratings yet

- SINO - KA300 - Scale ManualDocument21 pagesSINO - KA300 - Scale ManualAnonymous jW9BkgbQmE100% (1)

- Oglaend System Smart Cleat 1113Document12 pagesOglaend System Smart Cleat 1113sourcNo ratings yet

- Additive Manufacturing and Strategic Technologies in Advanced CeramicsFrom EverandAdditive Manufacturing and Strategic Technologies in Advanced CeramicsKiyoshi ShimamuraNo ratings yet

- 2306 Overview of Seismic Loads and Application of Local Code Provisions For Tall Buildings in Baku Azerbaijan PDFDocument8 pages2306 Overview of Seismic Loads and Application of Local Code Provisions For Tall Buildings in Baku Azerbaijan PDFDemçe FlorjanNo ratings yet

- Foundation Example of Multi Story A New Era of Women - 222s Health For Central Florida) PDFDocument6 pagesFoundation Example of Multi Story A New Era of Women - 222s Health For Central Florida) PDFDemçe FlorjanNo ratings yet

- Earth - Quack Learning India PDFDocument32 pagesEarth - Quack Learning India PDFDemçe FlorjanNo ratings yet

- Column Base Design Using Component Method and CBFEMDocument83 pagesColumn Base Design Using Component Method and CBFEMrk0001No ratings yet

- Foundation On The Displacements of A Mat Foundation PDFDocument6 pagesFoundation On The Displacements of A Mat Foundation PDFDemçe FlorjanNo ratings yet

- Final Paper-Libre PDFDocument20 pagesFinal Paper-Libre PDFDemçe FlorjanNo ratings yet

- 1st ECEES Paper63 A COMPARATIVE STUDY OF SEISMIC ISOLATION CODES WORLDWIDE - I-Libre PDFDocument10 pages1st ECEES Paper63 A COMPARATIVE STUDY OF SEISMIC ISOLATION CODES WORLDWIDE - I-Libre PDFDemçe FlorjanNo ratings yet

- 7 - Subgrade CharacterizationDocument18 pages7 - Subgrade CharacterizationOkondu ChieduNo ratings yet

- Chapter 2 - Measuring and Recording - Intensity, Magnitude and EnergyDocument11 pagesChapter 2 - Measuring and Recording - Intensity, Magnitude and EnergyselcukxNo ratings yet

- 2283 Study On Structural Efficiency of Supertall Buildings PDFDocument7 pages2283 Study On Structural Efficiency of Supertall Buildings PDFDemçe FlorjanNo ratings yet

- 2282 Structural Design of Nakanoshima Festival Tower PDFDocument12 pages2282 Structural Design of Nakanoshima Festival Tower PDFDemçe Florjan100% (1)

- 2304 Performance Based Design of 300 M Vertical City Abeno Harukas PDFDocument15 pages2304 Performance Based Design of 300 M Vertical City Abeno Harukas PDFDemçe FlorjanNo ratings yet

- 2008 Drift Control For Multistory Moment Frames Under Lateral Loading PDFDocument12 pages2008 Drift Control For Multistory Moment Frames Under Lateral Loading PDFDemçe FlorjanNo ratings yet

- 1 French 8NCEE-001072 Subgrade Modulus PDFDocument10 pages1 French 8NCEE-001072 Subgrade Modulus PDFDemçe FlorjanNo ratings yet

- 2250 Smart System Identification of Supertall Buildings Using Limited Vibration Data During The Tohoku Earthquake PDFDocument18 pages2250 Smart System Identification of Supertall Buildings Using Limited Vibration Data During The Tohoku Earthquake PDFDemçe FlorjanNo ratings yet

- 2002 Human Induced Vibrations in Buildings PDFDocument6 pages2002 Human Induced Vibrations in Buildings PDFDemçe FlorjanNo ratings yet

- Sloping GroundDocument11 pagesSloping Groundmdirfanullah36No ratings yet

- 2279 Performance Based Wind Resistant Design For High Rise Structures in Japan PDFDocument14 pages2279 Performance Based Wind Resistant Design For High Rise Structures in Japan PDFDemçe FlorjanNo ratings yet

- 2000 Amplitude Dependency of Damping in Buildings and Critical Tip Drift Ratio PDFDocument14 pages2000 Amplitude Dependency of Damping in Buildings and Critical Tip Drift Ratio PDFDemçe FlorjanNo ratings yet

- TBI Task12 Report Appendices PDFDocument392 pagesTBI Task12 Report Appendices PDFDemçe FlorjanNo ratings yet

- 2255 Assessment On Natural Frequencies of Structures Using Field Measurement and Fe Analysis PDFDocument7 pages2255 Assessment On Natural Frequencies of Structures Using Field Measurement and Fe Analysis PDFDemçe FlorjanNo ratings yet

- Effect of Irregular Configurations On Seismic Vulnerability of RC BuildingsDocument7 pagesEffect of Irregular Configurations On Seismic Vulnerability of RC BuildingsSowmya HanumanthaiahNo ratings yet

- Seismic Soil Structure Interaction of Buildings On Hill SlopesDocument12 pagesSeismic Soil Structure Interaction of Buildings On Hill SlopesPrabhat KumarNo ratings yet

- SEISMIC ANALYSIS AND DESIGN OF HOSPITAL BUILDING-libre PDFDocument79 pagesSEISMIC ANALYSIS AND DESIGN OF HOSPITAL BUILDING-libre PDFDemçe Florjan100% (1)

- Effect of Irregular Configurations On Seismic Vulnerability of RC BuildingsDocument7 pagesEffect of Irregular Configurations On Seismic Vulnerability of RC BuildingsSowmya HanumanthaiahNo ratings yet

- Seismic Performance of Multi-Storeyed Building On Sloping Ground PDFDocument3 pagesSeismic Performance of Multi-Storeyed Building On Sloping Ground PDFDemçe FlorjanNo ratings yet

- Effect of Irregular Configurations On Seismic Vulnerability of RC BuildingsDocument7 pagesEffect of Irregular Configurations On Seismic Vulnerability of RC BuildingsSowmya HanumanthaiahNo ratings yet

- Santo Domingo SpeakersDocument5 pagesSanto Domingo SpeakersDemçe FlorjanNo ratings yet

- Vol 1 S4Document21 pagesVol 1 S4Demçe FlorjanNo ratings yet

- TBI Task12 Report Appendices PDFDocument392 pagesTBI Task12 Report Appendices PDFDemçe FlorjanNo ratings yet