Professional Documents

Culture Documents

Ade Lect4 Notes

Ade Lect4 Notes

Uploaded by

Madhur MayankCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ade Lect4 Notes

Ade Lect4 Notes

Uploaded by

Madhur MayankCopyright:

Available Formats

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Actuators

Actuators are devices used to produce action or motion. The input is generally electrical signal and output is linear or rotary motion. Electrical signal can be low power or high power. In case of low power signal, additional circuitry is required to drive the actuator otherwise it can be driven directly. Actuators output can be position or rate i.e. linear displacement or velocity. Actuation can be from few microns to few meters.

Actuators

Selection of actuator

Accuracy and resolution Prof. H. Arya DEPT. OF AEROSPACE ENGINEERING IIT BOMBAY Power required for actuation Cost of actuation device Dynamic response

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Actuators

Types of actuators : Electrical power, fluid power, piezoelectric, Shape Memory Alloys Linear : Solenoid, hydraulic/pneumatic jacks Rotary : Motors, hydraulic/pneumatic drives

Electrical Actuators

Rotary : Motors, to have continuous rotation or hold an angular position. AC motors: Works on AC power supply. Most household devices, industrial motors. DC motors: Small gadgets, due to availability of DC power source. Large DC motors are used in locomotive engines, easier to control.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Solenoids

When current flows in the coil, magnetic field is generated and it reduces the air gap. Generally spring is used to create gap when coil is not energised. Commonly used in relays to make/break circuit. Small signal can operate solenoids. Large back emf is generated when coil is switched off. Diode is used to suppress the back emf and it prevents the control electronics from damage.

Diode - Protection of circuit

Relay - Electromechanical device When disconnected back emf is generated, can damage components

Voltage change in an inductive coil

V=L

dI dt

In switched on mode diode is reverse biased During back emf diode is forward biased and it conducts and creates the alternative path for the current

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Voice coil

Electrical Motors

Operation principle is same as solenoid but in a controlled manner. The movement of the plunger is controlled by the coil current. Used in the speakers, control valve in hydraulic system etc. Generally response is linear and it is bidirectional.

Works on Lorentzs force law. When a conductor carrying current is in a orthogonal magnetic field, a force is generated which is perpendicular to the direction of current and magnetic field. In DC motors, stator coils produce constant magnetic field. The current in the rotor coil results in torque. For continuous rotation, current direction is to be changed. This is accomplished by commutator. Commutator is circular ring on the shaft connected to rotor coils and has many segments. Electric supply is fed to these segments by brushes (carbon). This mechanical-electrical contact requires frequent maintenance.

Voice Coil

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Electrical Motors

DC Shunt motor

In shunt motor, armature and filed windings are connected parallel and at same voltage. Field winding resistance is higher compared to armature winding. High torque characteristics for wide range of speed. Torque can be increased by increasing current in the motor. Generally field resistance is changed to achieve this. Starting torque is 1.5 times of rated torque. To reverse the direction of the rotor, armature or field polarity is to be reversed.

DC motors are classified based on the connection between field coil and armature coil. i) Series wound motor ii) Shunt wound motor iii) Compound wound motor iv) Separate wound motor

Applied Mechatronics - ADE

Applied Mechatronics - ADE

DC Series motor

Armature and field windings are connected in series. The current is same in both the windings. Very high starting torque compared to shunt motors and very high speed at no load. Series motor can fail on sudden removal of load and this condition is called run-away. Parabolic variation between speed and torque and nearly constant power output over a wide range. Reversing the supply voltage has no effect on the direction of motor rotation because both field direction and armature current directions are changed.

DC Compound motor

It is a combination of shunt and series motor. Contain two coils one in series and another in parallel. Maximum speed is limited, but the speed regulation is not as good as shunt motor.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

DC Motor Control

DC motor control is achieved by changing the armature current or field current. Control system is added in the low power part of the system. For example field coil of shunt motor. In a series motor, control resistor is put parallel to field coil to control current in it. To understand how these changes will effect the output detail study on DC motor operation is required. Braking: DC motor can be stopped by switching off the power supply and let it coast. Large motors may take lot of time due to large inertia. Electromechanical braking is used for quick slow down. In this case the stator is kept energised and it is used as generator. It means that the output of the rotor is given to resistor or fed back to the power supply. It is very effective at high speeds. Another method is armature current direction is changed and it is switched off when it comes to halt.

DC Motor Control

Braking: In dynamic braking the current generated due to generator action is used for braking, no external power supply. In plugging the polarity of armature coil is reversed and the torque is generated in opposite direction. Quick braking and needs automatic switching off when motor comes to halt.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Permanent magnet DC Motors

In this motor stator is constructed out of permanent magnet. This gives constant flux in the stator. Magnetic properties are lost with time. The rotor construction is similar to conventional DC motors. Rotating magnetic field is generated by commutator. Motor output is controlled by rotor current. No issue of heating in the stator field winding.

Brushless DC Motors

In this motor permanent magnet is used for construction of rotor. Inertia of the rotor increases. Magnetic field is rotated in the stator by energising the coils using electronics. This eliminates brushes and commutator. Sensors are required to identify the location of rotor and based on this information coils are switched. This is equivalent to mechanical commutator.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

DC Motor Control Permanent magnet DC Motor Characteristics

Field flux is constant. Torque is proportional to armature current. For a given armature current, speed varies linearly with torque. Max power output is at 50% of no load speed. Armature current is limited by the coil characteristics. DC motor is controlled by controlling energy input in the system. Power supply to the DC motor is given in form high frequency pulses, 1kHz. By changing the duty cycle the input energy is controlled or average voltage in the armature coil is controlled. Variable duty cycle pulse are fed to power electronics circuit.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

H-bridge

Four power transistors are used in bridge configuration. Transistors can be switched on low power signal. When Q1 and Q3 are on the current in the motor flows in the direction shown. Similarly when Q2 and Q4 are on the direction of the current flow reverses and hence the direction. Can be controlled easily using micro-controller. Inputs can be in the form of PWM.

DC Motor Control

Example : A sensor is used to determine the output of the rotor. The rotor output is compared with the desired set speed. Based on the error PWM is generated.

H-bridge for motor control

Applied Mechatronics - ADE

Applied Mechatronics - ADE

RC servos

These are servo motors used for position control. Very popularly used in hobby. Feed back circuit, power electronics all are packed in a single unit. Highly optimised circuit, very compact for the given performance. Generally three input gadget. Two for power supply and third for control signal. Control signal is low power and the width of the pulse decided the rotary position of the servo.

AC Electrical Motors

Two types - single phase or polyphase (3-phase) Both can be - induction and Synchronous Single phase motors are common in household equipment. Domestic power supply is single phase 230 V, 50 Hz. Capacity from < 1 hp to 10 hp. 3-phase motors are common in industry. Industrial power supply is 3-phase and at different voltage levels. 440 V to few kV.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

AC Electrical Motors

Simplest AC motor is single phase squirrel cage induction motor. Maximum number of motors in use. Simple construction, maintenance free, low cost etc are the attractive features of this motor. Rotor is in the form of squirrel cage. No separate power for rotor. Rotor gets energised by induction due to AC supply in the stator coil. This induced voltage produces current in the rotor coil and hence magnetic field. The interaction between stator and rotor magnetic field produces torque. For continuous rotary motion the magnetic field in stator coil should be rotating. This is achieved by sequencing the peak current in the coils along the circumference. In case of single phase supply external aid like a capacitor is required to create phase difference between two coil supply.

AC Electrical Motors

Rotor conductors are heavy gage copper. These bars are the current path. Core of the rotor is made of iron. The air gap between rotor and stator is kept low. The torque depends on the slip. Slip is the difference between the rotor speed and the stator field speed. Slip necessary for the operation of the motor. Current in rotor is proportional to slip. Torque is dependent on the rotor current.

Squirrel-cage rotor construction

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Electrical Motors Three phase input 120 degree phase shift 3-phase Electrical Motors

Three phase power supply generates a rotating magnetic field

Direction of rotation can be changed by swapping one of the phase.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Synchronous AC Motors

Induction motor works only when slip exist. Constant speed is not possible and depends on load. Synchronous AC motors works without slip. The rotor is energised by DC supply to have fixed magnetic field with respect to rotor winding. This magnetic field gets locked with the rotating magnetic field and the motor rotates at constant synchronous speed. To achieve higher torque, rotor coil current is increased. The rotor is supplied DC by slip rings. Starting torque is a problem. Synchronous motors will always have methods to achieve synchronous speed. Squirrel cage motor is also used for this purpose, once the synchronous speed is reached no current flows in squirrel cage. This motor can only run at synchronous speed.

Stepper Motor

Stepper motor is a truly digital motor. Always moves by one step when ever input signal is given. It also means that rotor stop moving until it receives the next signal. It is a series of electromagnets arranged in a circle. When energised in sequence it moves rotor. Rotor can be a permanent magnet. Motor torque is directly related to magnetic field strength of electromagnets and rotor.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Stepper Motor

Stepper motors have a oscillatory response. This can be controlled by damping but this demands more torque. In locked step mode motor can be stopped, reversed instantaneously. In slewing mode the rotor is in synch but cannot be stopped instantaneously. It may loose step integrity.

Stepper Motor

Full step motion is achieved by energising two coils at a time (1,4; 4,2; 2,3 and 3,1. Angular rotation of 90 degrees per step.

At higher speed available torque is reduced.

Half step is achieved by energising two coils first and next only one coil and repeating the sequence. Angular step is half of full step in present case is 45 degrees.

Four phase unipolar stepper motor

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Stepper Motor

Stepper Motor

For clockwise motion sequence of steps is 1 to 4 and for anti clockwise it is 4 to 1 in case of full step. Similarly for half step. The phase sequencing can be obtained by counter circuits and logic gates.

Typically a stepper motor driver circuit involves a Schmitt trigger to shape the input pulse. A count up/down counter and XOR gates to create properly phased output for stepper motor. The example given is a discrete device circuit. Stepper motor driver chips are available which will contain all these devices.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Variable reluctance Stepper Motor

This type of stepper motor contains a ferromagnetic toothed rotor and a electromagnetic stator similar to permanent magnet stepper motor. The example given is 3 phase design having 12 stator poles 30o apart and eight rotor poles 45o apart. When phase 1 is energised rotor tooth align with the magnetised poles in the position of least magnetic reluctance. Other teeth remain inbetween the non energised poles.

Hydraulic actuators

In these actuators high pressure fluid is used. The fluid is pressurised using electrical pumps. Fluid used is non corrosive and if possible self lubricating. It is more of mechanical system having valves, cylinders, pumps etc. Commonly used fluid is air and oil. When air is used it is called pneumatic system. Air is freely available, leakage is not hazardous, stored in big tanks and distributed where ever required. Very common in packaging industry. When oil is used it is called hydraulic system. High power to weight ratio. Hydraulic pumps are attached to the machinery. Leakage is not permitted. Used where ever heavy duty performance is required.

In the next step energising phase 2, the rotor will move anti clockwise and again the teeth closest to the poles will align. Repeating this action will produce the motion in the desired direction. The step size is equal to difference between the pitch of rotor and stator. In the present case is 15o.

Applied Mechatronics - ADE

Applied Mechatronics - ADE

Hydraulic actuators

Hydraulic actuators

A very simple hydraulic system is shown. It consist of 4/3 valve system, it means that P is connected to T; P can connect to A and T can connect to B; P and T are cross connected to A and B. The different connections can give forward and backward motion.

Some common example of hydraulic driven mechanisms.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Assignment On PLCDocument4 pagesAssignment On PLCNirman ParasharNo ratings yet

- Nature of JobDocument2 pagesNature of JobNirman ParasharNo ratings yet

- Indian Navy - An Ocean of OpportunitiesDocument1 pageIndian Navy - An Ocean of OpportunitiesNirman ParasharNo ratings yet

- PGP I Final ListDocument8 pagesPGP I Final ListNirman ParasharNo ratings yet

- School of Mechanical and Building Sciences Mee 301 Dynamics of MachineryDocument4 pagesSchool of Mechanical and Building Sciences Mee 301 Dynamics of MachineryNirman ParasharNo ratings yet

- For Quadrant DC Motor ControlDocument43 pagesFor Quadrant DC Motor ControlDarshanRupani100% (1)

- Programmable Digital Ignition CDI / TCI: IndexDocument8 pagesProgrammable Digital Ignition CDI / TCI: IndexAnonymous Oh6az4No ratings yet

- OM8373 78 N3 v1.0 PDFDocument108 pagesOM8373 78 N3 v1.0 PDFJulio Alberto Cabrera Rodriguez100% (1)

- Techtopics No. 125Document2 pagesTechtopics No. 125paijo klimpritNo ratings yet

- Power Systems K-NotesDocument36 pagesPower Systems K-NotesAkashGaurav100% (1)

- Method Statement LV Switchgear T&CDocument3 pagesMethod Statement LV Switchgear T&CphilipyongNo ratings yet

- Generation of ComputerDocument6 pagesGeneration of ComputerPratik KhadkaNo ratings yet

- Aieee 2002 QDocument33 pagesAieee 2002 Qsiddharth1996No ratings yet

- Energy-Efficient Solutions For Led Lighting: StmicroelectronicsDocument60 pagesEnergy-Efficient Solutions For Led Lighting: StmicroelectronicsJay KarnikNo ratings yet

- Ceramic ApplicationDocument12 pagesCeramic ApplicationAmalendu Sundar MandalNo ratings yet

- The Silicon Controlled Rectifier: ThyristorDocument6 pagesThe Silicon Controlled Rectifier: ThyristorAngelo Paulo Gonzales OnteNo ratings yet

- Analog and Digital Electronics (Subject Code: 17CS32) Lecturer NotesDocument59 pagesAnalog and Digital Electronics (Subject Code: 17CS32) Lecturer NotesKarthik v BhatNo ratings yet

- Development of Multi-Mode Step Down DC/DC Converters With Fault-Tolerant CapabilityDocument7 pagesDevelopment of Multi-Mode Step Down DC/DC Converters With Fault-Tolerant Capabilityjeos20132013No ratings yet

- Logic GatesDocument9 pagesLogic GatesIbz AjagbeNo ratings yet

- EC2354 NotesDocument3 pagesEC2354 NotesASDFGHJNNo ratings yet

- Writing A Scientific Paper (Introduction)Document2 pagesWriting A Scientific Paper (Introduction)nivram alindayuNo ratings yet

- Exercises Lectures1!7!2016 UpdatedDocument51 pagesExercises Lectures1!7!2016 UpdatedLydia BummNo ratings yet

- Fundamentals of Transistors by Leonard M. KrugmanDocument145 pagesFundamentals of Transistors by Leonard M. KrugmanRavinduNo ratings yet

- Light Intensity Control Using Diac and Triac 1Document12 pagesLight Intensity Control Using Diac and Triac 1Prathamesh KaleNo ratings yet

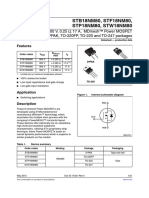

- STB18NM80, STF18NM80, STP18NM80, STW18NM80Document21 pagesSTB18NM80, STF18NM80, STP18NM80, STW18NM80Gilvana Cristina FerreiraNo ratings yet

- Cable Design PPT LatestDocument18 pagesCable Design PPT LatestjishnusajiNo ratings yet

- Passive Electronic Components: Resistor Capacitor InductorDocument16 pagesPassive Electronic Components: Resistor Capacitor InductorSukrat SharmaNo ratings yet

- Guide To The Installation of Photovoltaic SystemsDocument124 pagesGuide To The Installation of Photovoltaic SystemsWorcester Renewables100% (20)

- Amp ExpandibletranslatedDocument21 pagesAmp Expandibletranslatedvinxy beeNo ratings yet

- Hanwha Q CELLS Data Sheet QPEAK DUO-G5 315-330 2017-07 Rev01 EN PDFDocument2 pagesHanwha Q CELLS Data Sheet QPEAK DUO-G5 315-330 2017-07 Rev01 EN PDFDumitru GigiNo ratings yet

- Battery StudyDocument155 pagesBattery StudykarumaNo ratings yet

- Questions Old 2066 & 2068 NTC Level - 7 (Elx & Comm)Document4 pagesQuestions Old 2066 & 2068 NTC Level - 7 (Elx & Comm)Prashant McFc AdhikaryNo ratings yet

- Experiment Data of Mos and PNDocument17 pagesExperiment Data of Mos and PNrrahuldalal10No ratings yet

- TOP244Document52 pagesTOP244Rimla OtenNo ratings yet

- Tda 1548Document20 pagesTda 1548Jennifer NealNo ratings yet