Professional Documents

Culture Documents

284 - Profile On Timber Production

Uploaded by

big johnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

284 - Profile On Timber Production

Uploaded by

big johnCopyright:

Available Formats

284 .

PROFILE ON TIMBER PRODUCTION

284 - 2 TABLE OF CONTENTS

PAGE

I.

SUMMARY

284 - 3

II.

PRODUCT DESCRIPTION & APPLICATION

284 - 3

III.

MARKET STUDY AND PLANT CAPACITY A. MARKET STUDY B. PLANT CAPACITY & PRODUCTION PROGRAMME

284 - 4 284 - 4 284 - 7

IV.

RAW MATERIALS AND INPUTS A. RAW & AUXILIARY MATERIALS B. UTILITIES

284 - 8 284 - 8 284 - 9

V.

TECHNOLOGY & ENGINEERING A. TECHNOLOGY B. ENGINEERING

284 - 9 284 - 9 284 - 10

VI.

MANPOWER & TRAINING REQUIREMENT A. MANPOWER REQUIREMENT B. TRAINING REQUIREMENT

284 - 11 284 - 11 284 - 12

VII.

FINANCIAL ANLYSIS A. TOTAL INITIAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEFITS

284 - 14 284 - 14 284 - 15 284 - 16 284 - 17

284 - 3 I. SUMMARY

This profile envisages the establishment of a farm and processing plant for the production of timber with a capacity of 50,000 m3 per annum. The present demand for the proposed product is estimated at 790,200 m3 per annum. The demand is expected to reach at 1.1 million m3 by the year 2017.

The plant will create employment opportunities for 85 persons.

The total investment requirement is estimated at Birr 3.16 million, out of which Birr 1.59 million is required for plant and machinery.

The project is financially viable with an internal rate of return (IRR) of 27 % and a net present value (NPV) of Birr 2.35 million ,discounted at 8.5%.

II.

PRODUCTION DESCRIPTION AND APPLICATION

Timber production is the harvesting of logs of matured trees and preparing them for market. Appropriately produced timbers are used for the manufacturing of wood products such as household and office furniture, wooden ornaments, kitchen articles, etc., and the waste can be used as source of energy in households and industries. Logs of trees of different species can be used as raw materials.

284 - 4 III. MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past supply and Present Demand

Timber production is harvesting of matured trees' logs and preparing them for market. The product is used as industrial or construction wood. Accordingly, the demand for industrial and construction wood in SNNPRS is briefly assed below.

a)

Industrial Wood

The three principal types of primary industrial wood products are sawn wood, wood-based panels (including plywood, fiberboard and particleboard) and paper which are used in production of furniture, windows, doors, moldings, stairs, cabinets, and many other products. In Ethiopia industrial wood production (and consumption) per capita is one of the lowest in the world (EFAP, 1994).

Ethiopia's low level of consumption of sawn wood and other industrial wood products reflects the fact that the country's limited forest resource base has been and continues to be primarily exploited for fuel wood. The same it true for SNNPRS.

In SNNPRS, only sawn boards are produced. Products such as plywood, particle boards and the like are not produced in the Region at all. According to The Regional Forestry Action Plan of SSNPRS (RFAP) the volume harvested and the actual consumption do not much at all unless a proper measure is devised. The current (2007) demand for industrial wood in SNNPRS is estimated at 69,730 m3 by the regional RFAP.

284 - 5 b) Construction Wood

Construction wood, including poles, posts and lumber, is used by State Enterprises, small urban and rural enterprises and households. Construction poles with a length between 4 and 12 m are used for roofing, house framing and pillars. Split poles with a length of about 3m are used for house walls. Fence posts with a length of 1 to 3 m are normally of lower quality than construction poles. Both poles and posts are small sized wood with a diameter between 3 and 10 cm.

The sources of construction wood in the SNNPRS are mainly natural forests, plantations, farm forestry, woodlands, community and private wood lots.

The RFAP of SNNPRS calculated the demand for construction wood in SNNPRS based on the following assumptions. New houses to be built due to population growth (3m3 per annum) Rebuilding of existing houses assuming houses have a 30 year life span: (3m3 per annum) Annual renovation of houses over, 10 years old: (0.05m3 per annum) 20% of the houses have wooden fences which consume 2m3 per annum) Fences are replaced every ten years. Demand from all sources is expected to grow at 2.9 per annum

Based on the above assumptions the current (2007) demand for construction wood is estimated at 720,470 which are adopted for the purpose of this study.

Accordingly the total current demand for timber which is the total industrial and construction wood demand in SNNPRS is estimated at 790,200 m3

284 - 6 2. Projected Demand

The demand for timber is going to increase with the expansion of the wood and wooden product industry and the construction sector. At present, the sub-sectors are growing at a faster rate owing to the expansion of schools, clinics, the bureaucracy apparatus and increase in population size.

In projecting the regional demand for timber, projection made by the RFAP of SNNPRS is adopted. Accordingly, the total demand for timber in the region increases from 810,730 m3 in 2008 to 1.1 million m3 in 2020. (See Table 3.1.) Table 3.1 PROJECTED DEMAND FOR TIMBER IN SNNPRS ( m3)

Industrial Construction Year 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 Wood 72,750 75,430 78,460 81,610 84,890 88,300 91850 95,550 99,400 10 3,410 107,580 111,930 116,450 Wood 737,980 755,950 774,380 793,280 812,670 832,560 852,970 873,900 895,370 917,400 940,010 963,210 987,010 Total 810,730 831,380 852,840 874,890 897,560 920,860 944,820 969,450 994,770 1,020,810 1,047,590 1,075,140 1,103,460

284 - 7 3. Pricing and Distribution

The price of timber varies considerably with the type of tree species used. Allowing a profit margin for retailers and distribution costs, factory-gate price of recommended. Birr 150 per m3 is

The products could be distributed to the end-users through existing distributing agents and retailers.

B.

PLANT CAPACITY AND PRODUCTION PROGRAMME

1.

Plant Capacity

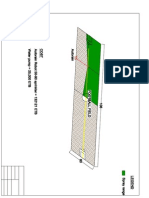

Accordingly to market study shown above, the projected demand of timber for the year 2008 will be 810,730 m3. This figure will grow to 969,450 m3 and 1,103,460 m3 in 2015 and 2020, respectively. As timber is required for different economic sectors such as construction sector, industrial sector, house hold and office furniture sector, the demand of the product would substantially grow as these economic sectors grow in the country. On the other hand timber production will have to be carried out without affecting the environment by way of depleting the forest in the region. Thus, the most appropriate approach will be to start timber production at a small scale level and gradually raise capacity by future expansion. The envisaged plant understudy will therefore have annual production capacity of 50,000 m3 of timber. The total land area required for full capacity production is estimated to be 200

hectares. This new farm area to be developed by the envisaged plant.

2.

Farming and Production Programme

At the initial stage, Pines tree shall be grown in the area of 200 hectares of land. Experience indicates that the first cutting shall be carried out after five years of growing. In some localities first cutting can stay from six to seven years. The longer pine trees stay in the farm, the longer will be their height, the thicker will be their stems, and the greater will be the volume of timber that can be harvested.

284 - 8

Production can be started at 60% of annual capacity, and gradually raise production to75%, 90% and finally to 100% in the succeeding years. Production might be started on the third year of pine tree plantation. It is assumed that timber will be harvested when the plant reaches production at 75% of capacity.

IV.

MATERIALS AND INPUTS

A.

RAW AND AUXILIARY MATERIALS

Sources of raw material are assumed to be already existing forests in the region, particularly the Kaffa, Sheka and Benchmaji zones, and the area of 300 hectares of land to be covered by pinus tree in the coming five to six years. This project study assumes that there is high forest potential is the SNNPRS, and supply of raw material will not be a hindrance to the operation of the envisaged plant.

The major raw material required by the plant is seed, poly propylene sheets and other auxiliary materials. Table 4.1 below indicates annual requirement of raw and auxiliary materials.

Table 4.1 RAW AND AUXILIARY MATERIALS REQUIREMENT

Sr. No. 1 2 3 Seed (kg)

Description

Qty 200 Reqd. Reqd. -

Cost (000 Birr) 350 150.0 75.0 575

Fertilizer (quintal) Auxiliary materials Total

284 - 9 B. UTILITIES

Electricity, water, fuel and lubricant are utilities required for the timber production plant. Table 4.2 below shows estimates of annual requirement of utilities.

Table 4.2 ANNUAL REQUIREMENT OF UTILITIES

Sr. No. 1 2 3 4

Description

Qty

Cost (000 Birr)

Electricity (kWh) Water (m3) Fuel (litres) Lubricant (Litre) Total

20,000 200 6,000 200 -

9.48 2.00 32.94 22.00 66.42

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

1.

Production Process

Inorder to produce the required size and quality of timber for various economic sectors, it would be necessary to carryout good timber management programme. This is the process of improving, protecting and managing forest lands for the production of timber. These

include: tree planting; timber stand improvement; protection of forests from fire and insects; felling or cutting down the timber; cutting it into lengths; and transporting it usually by truck to the point of end-use.

In a well-planned harvest, before the timber is felled, the forester the person in charge of managing the forest decides which trees will be cut and when. These decisions must be

284 - 10 made within the context of the foresters overall responsibility for maintaining the quality of the forest as an ongoing resource.

Loggers employed by the envisaged plant generally fell trees with gasoline powered chain saws. When cutting and felling trees care has to be taken to avoid smashing and scarring trees that are to be left standing. Once the tree is down the logger removes its limbs to make easier to transport the stem.

After the trees are felled and trimmed, the logs are skidded to landings where they can be put on trucks and hauled to the mill or a place where the timber is required. Skidding involves raising one end of the leg and dragging it across the ground. Animal skidding can be applied in case wheeled or tracked vehicles are not available. Cable skidders with vehicles can be used to pull logs behind them with steel ropes.

2.

Source of Technology

Yongkang Anluda Co., Ltd No. 23, Yinchua East Road Hardware Science and Technology Industrial zone, Yongkang City, Zhejiang Province, China, Yongkang, Zhejiang, China

B.

ENGINEERING

1.

Plant Machinery and Equipment

The list of machinery and equipment required for timber production is shown in Table 5.1 below.

284 - 11 Table 5.1 MACHINERY AND EQUIPMENT AND COST

Sr. No. 1 2 3 4 5 6 7 8 9

Description

Qty LC

Cost (000 Birr) FC 50 450 10 350 250 160 60 60 50 1440 150 50 450 10 350 250 160 60 60 50 1440 TC

Gasoline- powered chain saw Truck-mounted crane Hand tools Tractor (110-125 HP) Vehicle Trailor Generator Motor cycle Workshop equipment FOB price Freight, insurance, customs, book charges, etc. CIF landed cost

10 1 2 sets 1 1 4 1 2 LS

150

1440

1590

2.

Land, building and Civil Works

Timber production plant requires land for tree plantation, and an area for preparation of timber suitable for marketing. Moreover, land is required for building that would be used as offices for management, for laborers to serve for social activities. At the initial stage land area of 200 hectares will be required for planting pine and eucalyptus trees. The envisaged plant will, however, require more land for future expansion. Timber production is preceded by tree plantation and conserving the environment. This activity will have to be encourage by the regional government. One approach of encouragement is the provision of land free of lease value. The study therefore proposes that the regional government provide enough land area to investors that would be engaged in timber production. As indicated above a total area

284 - 12 of 400 m2 will be required for building. At the rate of Birr 2000 per m2, the investment on building will be Birr 800,000.

3.

Proposed Location

Location of a plant is determined on the basis of proximity to raw materials, distance to potential market outlets, and the availability of infrastructure. Consideration is also given to fair distribution of projects among the woredas of SNNPRS. In view of these three zones namely Kaffa, Sheka and Benchamji were identified. The three woredas that are believed to be potential areas for timber production are Bonga Zuria, Andricha and Mizanteferi zuria. Of these woredas Andricha is selected to be an appropriate one. Therefore, it is proposed that the Timber production plant will be established in Gucha town.

VI .

MANPOWER AND TRAINING REQUIREMENT

A.

MANPOWER REQUIREMENT

Timber production plant requires wood technologist, workers to handle the chain saws and laborers. The details of manpower with wages are given in Table 6 .1 below.

284 - 13 Table 6.1 MANPOWER REQUIREMENT AND SALARY OF EMPLOYEES(BIRR)

Sr. No.

Job Title Req.No A. Administration

Monthly Salary

Annual Salary

1 2 3 4 5 6

Plant manager Secretary Sales man Personnel Guard Store keeper Sub total B. Production

1 1 1 1 4 2 10

2,000 600 800 1,000 350 600 -

24,000 7,200 9,600 12,000 16,800 14,400 84,000

Production technologist)

head

(wood

1500

18,000

2 3 4 5

Operators Laborers Production clerk Mechanics Sub total Workers benefit (25% BS) Total

10 60 2 2 75 85

600 350 500 700

72,000 252,000 12,000 16,800 370,800 113,700 568,500

B.

TRAINING REQUIREMENT

Timber production does not require specialized skill, except that experienced workers on wood working can handle the work.

284 - 14

VII.

FINANCIAL ANALYSIS

The financial analysis of the timber project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

1 year 30 % equity 70 % loan

Tax holidays Bank interest Discount cash flow Accounts receivable Raw material local Work in progress Finished products Cash in hand Accounts payable

3 years 8% 8.5% 30 days 30days 2 days 30 days 5 days 30 days

A.

TOTAL INITIAL INVESTMENT COST

The total investment cost of the project including working capital is estimated at Birr 3.16 million, of which 51 per cent will be required in foreign currency.

The major breakdown of the total initial investment cost is shown in Table 7.1.

284 - 15

Table 7.1 INITIAL INVESTMENT COST

Sr. No. 1 2 3 4 5 6 7 Cost Items Land lease value Building and Civil Work Plant Machinery and Equipment Office Furniture and Equipment Vehicle Pre-production Expenditure* Working Capital Total Investment cost Foreign Share

Total Cost (000 Birr) 800.00 1,590.00 75 200 368.87 131.22 3,165.1 51

* N.B Pre-production expenditure includes interest during construction ( Birr 218.87 thousand ) and Birr 200 thousand costs of registration, licensing and formation of the company including legal fees, commissioning expenses, etc.

B.

PRODUCTION COST

The annual production cost at full operation capacity is estimated at Birr 1.98 million (see Table 7.2). The material and utility cost accounts for 36.36 per cent, while repair and

maintenance take 7.57 per cent of the production cost.

284 - 16 Table 7.2 ANNUAL PRODUCTION COST AT FULL CAPACITY ('000 BIRR)

Items Raw Material and Inputs Utilities Maintenance and repair Labour direct Factory overheads Administration Costs Total Operating Costs Depreciation Cost of Finance Total Production Cost

Cost 575.00 66.42 150 341.1 142.13 227.4 1,502.05 276.5 203.72 1,982.27

% 29.01 3.35 7.57 17.21 7.17 11.47 75.77 13.95 10.28 100

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the first year of operation. Important ratios such as profit to total sales, net profit to equity total investment (return on total

(Return on equity) and net profit plus interest on

investment) show an increasing trend during the life-time of the project.

The income statement and the other indicators of profitability show that the project is viable.

284 - 17

2.

Break-even Analysis

The break-even point of the project including cost of finance when it starts to operate at full capacity ( year 3) is estimated by using income statement projection.

BE =

Fixed Cost Sales Variable Cost

= 28 %

3.

Pay Back Period

The investment cost and income statement projection are used to project the pay-back period. The projects initial investment will be fully recovered within 4 years.

4.

Internal Rate of Return and Net Present Value

Based on the cash flow statement, the calculated IRR of the project is 27 % and the net present value at 8.5% discount rate is Birr 2.35 million.

D.

ECONOMIC BENEFITS

The project can create employment for 85 persons.

In addition to supply of the domestic

needs, the project will generate Birr 1.43 million in terms of tax revenue. The establishment of such factory will have a foreign exchange saving effect to the country by substituting the current imports.

You might also like

- Bati-Rési Suite PDFDocument16 pagesBati-Rési Suite PDFgfgfNo ratings yet

- Profile On The Production of Refractory BricksDocument26 pagesProfile On The Production of Refractory BricksTewfic SeidNo ratings yet

- Corrugated Paper BoxDocument13 pagesCorrugated Paper BoxhibadaNo ratings yet

- Straw BoardDocument25 pagesStraw BoardEsayas Mekonnen100% (1)

- Production of Plaster of Paris Using Solar EnergyDocument4 pagesProduction of Plaster of Paris Using Solar EnergyesatjournalsNo ratings yet

- Mineral Processing OverviewDocument12 pagesMineral Processing OverviewBima AbdillahNo ratings yet

- Bed CoverDocument19 pagesBed Coverabel_kayel100% (1)

- Broom Corn Production FarmDocument25 pagesBroom Corn Production FarmEsayas MekonnenNo ratings yet

- Small Scale Cement Plants A Study in EconomicsDocument33 pagesSmall Scale Cement Plants A Study in EconomicsplutocowNo ratings yet

- Dextrin From Starch Project Report PDFDocument14 pagesDextrin From Starch Project Report PDFAnonymous vFwQuKrtSNo ratings yet

- Alkyd ResinDocument19 pagesAlkyd Resinyenealem100% (1)

- Profile On Dairy Processing EquipmentDocument20 pagesProfile On Dairy Processing Equipmentbiniam meazaneh100% (1)

- Investment Office ANRS: Project Profile On The Establishment of Absorbent Cotton Making PlantDocument29 pagesInvestment Office ANRS: Project Profile On The Establishment of Absorbent Cotton Making Plantabel_kayelNo ratings yet

- Investment Office ANRS: Project Profile On The Establishment of Absorbent Cotton Making PlantDocument28 pagesInvestment Office ANRS: Project Profile On The Establishment of Absorbent Cotton Making PlantLakewNo ratings yet

- Profile On Woolen FabricsDocument21 pagesProfile On Woolen FabricsAhmad Daood100% (1)

- Polyester Fibre ManufacturingDocument16 pagesPolyester Fibre ManufacturinghaishpithadiyaNo ratings yet

- Mapping and Characterization of Industrial Minerals in Dilla, EthiopiaDocument27 pagesMapping and Characterization of Industrial Minerals in Dilla, Ethiopiachalachew k/mariam tesemaNo ratings yet

- EIA Improved SeedDocument76 pagesEIA Improved SeedTesfaye DegefaNo ratings yet

- Profile On Production of Socks & StockingDocument17 pagesProfile On Production of Socks & Stockinggetachew liger100% (1)

- 1.1 Background of The Problem Task UndertakenDocument47 pages1.1 Background of The Problem Task UndertakenraahoulNo ratings yet

- Project Profile On Leather Shoes PDFDocument5 pagesProject Profile On Leather Shoes PDFFaraz JiNo ratings yet

- Company InformationDocument36 pagesCompany InformationAnaruzzaman SheikhNo ratings yet

- Cotton and Synthetic HoseDocument20 pagesCotton and Synthetic Hoseabel_kayelNo ratings yet

- Agricultural Development PlanDocument26 pagesAgricultural Development Planmadawe adem100% (1)

- Environmental and Social Impact Assessment Report For Fuel Station Environmental and Social Management PlanDocument36 pagesEnvironmental and Social Impact Assessment Report For Fuel Station Environmental and Social Management PlanMohammed hussenNo ratings yet

- Seminar 03Document67 pagesSeminar 03lamaNo ratings yet

- Cotton Ginning Male-2Document32 pagesCotton Ginning Male-2Tesfaye DegefaNo ratings yet

- Profile On Production of Grape Juice PDFDocument16 pagesProfile On Production of Grape Juice PDFPradeepMathad100% (1)

- Mineral Mining IndustryDocument9 pagesMineral Mining Industrypankaj455No ratings yet

- Cardava and Chips PlantDocument14 pagesCardava and Chips PlantArmando SansoNo ratings yet

- Profile On The Production of Children's ClothDocument28 pagesProfile On The Production of Children's Clothmeskerem gizawNo ratings yet

- Edible Vegetable Fats & OilDocument21 pagesEdible Vegetable Fats & OilMelakuaccess100% (1)

- Construction and DemolitionDocument6 pagesConstruction and DemolitionTara MiltonNo ratings yet

- Inner FabricsDocument19 pagesInner Fabricsabel_kayelNo ratings yet

- Sunflower OilDocument17 pagesSunflower Oilgauti113No ratings yet

- Sheep and Goat Farming Business PlanDocument14 pagesSheep and Goat Farming Business PlanEsubalew Enquahone100% (1)

- Profile on Varnish and Lacquers Production in EthiopiaDocument20 pagesProfile on Varnish and Lacquers Production in Ethiopiaabel_kayelNo ratings yet

- Remedan SherifDocument16 pagesRemedan SherifAbduselam AhmedNo ratings yet

- Ground NutDocument19 pagesGround Nutabel_kayel100% (1)

- Textile WicksDocument15 pagesTextile Wicksbig john100% (1)

- Lecture Eight Primary TillageDocument35 pagesLecture Eight Primary Tillagehusni ahmed100% (1)

- ANRS Chaff Cutter Fabrication Plant ProfileDocument23 pagesANRS Chaff Cutter Fabrication Plant ProfileFekadie TesfaNo ratings yet

- Electronics ManufacturingDocument53 pagesElectronics ManufacturingTesfaye DegefaNo ratings yet

- Project Profile On The Establishment of Soybean Production Farm PDFDocument24 pagesProject Profile On The Establishment of Soybean Production Farm PDFyohannes meazaneh100% (1)

- Jharkhand Food Processing Industries Policies 2015 - DraftDocument76 pagesJharkhand Food Processing Industries Policies 2015 - DraftManu030150% (2)

- VSK process specification for small cement plantsDocument3 pagesVSK process specification for small cement plantsArjun Chetri BhandariNo ratings yet

- Composite FLourDocument27 pagesComposite FLouryenealem AbebeNo ratings yet

- By: Mahadi Barkatle Abdi: Project Proposal For Packed Tomato Paste Manufacturing ProjectDocument25 pagesBy: Mahadi Barkatle Abdi: Project Proposal For Packed Tomato Paste Manufacturing Projectabebech ar100% (1)

- Profile on fattening farm market and production analysisDocument15 pagesProfile on fattening farm market and production analysistaposhmamaNo ratings yet

- Final EIA Project Report For Exploratory Drilling in Block 10baDocument607 pagesFinal EIA Project Report For Exploratory Drilling in Block 10baEzzadin Baban0% (1)

- Evo StoveDocument6 pagesEvo StoveAnonymous Te9zvf0k0No ratings yet

- Feasibility Report For Production & Supply/Sale of Fly Ash Bricks in PakistanDocument5 pagesFeasibility Report For Production & Supply/Sale of Fly Ash Bricks in PakistanUmar YaqoobNo ratings yet

- Profile On CarbondioxideDocument20 pagesProfile On CarbondioxidetadiyosNo ratings yet

- Moringa Oil Business Plan and BudgetDocument15 pagesMoringa Oil Business Plan and BudgetMoringaidNo ratings yet

- Template Business PlanDocument17 pagesTemplate Business PlanMelesse AlemayehuNo ratings yet

- Particle BoardDocument19 pagesParticle Boardbig johnNo ratings yet

- Profile On BeehivesDocument18 pagesProfile On BeehivesKaramara Training & ConsultancyNo ratings yet

- 91.veneer SheetDocument20 pages91.veneer SheetShewaye NegussieNo ratings yet

- Bamboo FurnituresDocument12 pagesBamboo FurnituresElnathan SamsonNo ratings yet

- Profile On The Production of ChipboardDocument24 pagesProfile On The Production of ChipboardTeferi100% (5)

- Nursery Manual For Native Plants PDFDocument309 pagesNursery Manual For Native Plants PDFbig john100% (1)

- Lowland OilcropsDocument14 pagesLowland Oilcropsbig johnNo ratings yet

- PomegranatesDocument5 pagesPomegranatesbig johnNo ratings yet

- Tea and IrrigationDocument14 pagesTea and Irrigationbig johnNo ratings yet

- The Date Palm Journal PDFDocument240 pagesThe Date Palm Journal PDFbig johnNo ratings yet

- Herb Production OrganicDocument20 pagesHerb Production OrganicShoshannah33% (3)

- Co-Op Bulk Spice List in Order by Alphabetic Spice NameDocument3 pagesCo-Op Bulk Spice List in Order by Alphabetic Spice Namebig johnNo ratings yet

- Jam and JellyDocument28 pagesJam and Jellybig johnNo ratings yet

- Horticulture Report FinalDocument57 pagesHorticulture Report Finalbig john100% (1)

- Grape JuiceDocument16 pagesGrape Juicebig johnNo ratings yet

- BS Year1 No14 - Apr.02 1925Document4 pagesBS Year1 No14 - Apr.02 1925big johnNo ratings yet

- Chewaka Store ModelDocument1 pageChewaka Store Modelbig johnNo ratings yet

- Football Field Layout1Document1 pageFootball Field Layout1big johnNo ratings yet

- Tea and IrrigationDocument14 pagesTea and Irrigationbig johnNo ratings yet

- FCKupload File FAO Syria Crisis Report enDocument106 pagesFCKupload File FAO Syria Crisis Report enbig johnNo ratings yet

- Commodity TeaDocument4 pagesCommodity Teabig johnNo ratings yet

- OrangeDocument23 pagesOrangebig john100% (1)

- CIB, ContractDocument89 pagesCIB, Contractbig johnNo ratings yet

- Tuta AbsolutaDocument25 pagesTuta Absolutabig johnNo ratings yet

- CIB, ContractDocument89 pagesCIB, Contractbig johnNo ratings yet

- Final EgyptDocument258 pagesFinal Egyptbig johnNo ratings yet

- Ethiopia Irrigation Diagnostic July 2010 2Document59 pagesEthiopia Irrigation Diagnostic July 2010 2big john100% (1)

- 36 Tomato Sauce, Ketchup and PureesDocument9 pages36 Tomato Sauce, Ketchup and Pureesbig johnNo ratings yet

- Tomato Paste and JuiceDocument14 pagesTomato Paste and JuiceRamanathan Meyyappan100% (1)

- Unu Strategic Plan 2011-2014 enDocument20 pagesUnu Strategic Plan 2011-2014 enbig johnNo ratings yet

- Participatory Irrigation Management in AlbaniaDocument25 pagesParticipatory Irrigation Management in Albaniabig johnNo ratings yet

- Tomato MarketingDocument8 pagesTomato Marketingbig johnNo ratings yet

- Dried Spray FruitDocument130 pagesDried Spray Fruitbig john100% (2)

- 101 Iced Tea RecipesDocument109 pages101 Iced Tea RecipesNessa Santiago100% (3)

- Agribusiness Organization and Management SeminarDocument24 pagesAgribusiness Organization and Management Seminarbig john100% (2)

- Land-Acquisition-and-Resettlement-Action-Plan Timor LesteDocument195 pagesLand-Acquisition-and-Resettlement-Action-Plan Timor LesteBudhi Darmawan100% (1)

- Icaew Cfab Mi 2018 Sample Exam 3Document30 pagesIcaew Cfab Mi 2018 Sample Exam 3Anonymous ulFku1v100% (2)

- History Quality Movements ConceptsDocument181 pagesHistory Quality Movements ConceptsJhonrick MagtibayNo ratings yet

- AbsorptionDocument29 pagesAbsorptionRavi KatiyarNo ratings yet

- Cost Management Concepts ExplainedDocument13 pagesCost Management Concepts Explainedestihdaf استهدافNo ratings yet

- Dwnload Full Managerial Accounting 2nd Edition Whitecotton Test Bank PDFDocument35 pagesDwnload Full Managerial Accounting 2nd Edition Whitecotton Test Bank PDFthomasacjen100% (8)

- Assets: Inventory and Operations ManagementDocument40 pagesAssets: Inventory and Operations ManagementMahmoud Abdullah100% (1)

- IAS 40 Investment Property GuideDocument29 pagesIAS 40 Investment Property GuideNollecy Takudzwa BereNo ratings yet

- Agricultural Projects Evaluation PDFDocument79 pagesAgricultural Projects Evaluation PDFGangadhar100% (1)

- Supplies Estimating Needs 1. Analyzing Program NeedsDocument9 pagesSupplies Estimating Needs 1. Analyzing Program Needsloveseeker06No ratings yet

- Chapter 5 Standardization of RecipeDocument10 pagesChapter 5 Standardization of RecipeChristella Margarejo Delos ReyesNo ratings yet

- Cost Accounting Prelims Practice Solving 1 50 1Document24 pagesCost Accounting Prelims Practice Solving 1 50 1Marjorie PalmaNo ratings yet

- Cost Accounting System - E-Notes - Udesh Regular - Group 1Document53 pagesCost Accounting System - E-Notes - Udesh Regular - Group 1r79qwkxcfjNo ratings yet

- ABC Lecture NotesDocument8 pagesABC Lecture Notessudeis omaryNo ratings yet

- MAS 1 1st Long QuizDocument6 pagesMAS 1 1st Long QuizHanna Lyn BaliscoNo ratings yet

- Pas 2 Common AssignmentDocument4 pagesPas 2 Common AssignmentTimothy james PalermoNo ratings yet

- Magerial Economics Ms 09Document271 pagesMagerial Economics Ms 09smartsatish100% (1)

- Group II - June 2010 Cost and Management Accounting: The Figures in The Margin On The Right Side Indicate Full MarksDocument23 pagesGroup II - June 2010 Cost and Management Accounting: The Figures in The Margin On The Right Side Indicate Full MarksMahesh BabuNo ratings yet

- BS Accountancy Qualifying Exam: Management Advisory ServicesDocument7 pagesBS Accountancy Qualifying Exam: Management Advisory ServicesMae Ann RaquinNo ratings yet

- Study On The Rework Activities That Lead To Unnecessary Costs in Construction ProjectsDocument4 pagesStudy On The Rework Activities That Lead To Unnecessary Costs in Construction ProjectsMansa ArthurNo ratings yet

- Eco-10 em PDFDocument11 pagesEco-10 em PDFAnilLalvaniNo ratings yet

- 10 Job Order CostingDocument5 pages10 Job Order CostingAllegria AlamoNo ratings yet

- Cost AccountingDocument8 pagesCost AccountingKim Nicole ReyesNo ratings yet

- Math Exam 18 Icse 10Document158 pagesMath Exam 18 Icse 10subhasedu100% (1)

- Production KPIsDocument29 pagesProduction KPIsNovalonNo ratings yet

- Ojas FR Module 1Document280 pagesOjas FR Module 1AnupNo ratings yet

- Cost Accounting Assignment BreakdownDocument10 pagesCost Accounting Assignment BreakdownlifernNo ratings yet

- Ijmet 09 11 051Document14 pagesIjmet 09 11 051bhupNo ratings yet

- Samcis - Ae212 - Module 7 Process Costing Lost UnitsDocument17 pagesSamcis - Ae212 - Module 7 Process Costing Lost UnitsMamaril John NathanielNo ratings yet

- Cost Plus PriceDocument3 pagesCost Plus PricenituljyotidasNo ratings yet