Professional Documents

Culture Documents

Data Rates 07 08 Canal

Data Rates 07 08 Canal

Uploaded by

Om Prakash JakharCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Rates 07 08 Canal

Data Rates 07 08 Canal

Uploaded by

Om Prakash JakharCopyright:

Available Formats

CANAL AND ALLIED WORKS

WATER RESOURCES DEPARTMENT

SCHEDULE OF RATES

CANAL AND ALLIED WORKS

FOR THE YEAR : 2007-08

CONTENTS REFERENCE DATA NOTES ON BASIC RATES DATA FOR SCHEDULE OF RATES DATA FOR ENABLING WORKS

PAGES 3 -- 5 6 -- 6 7 -- 152 153--156

REVISED BY SCHEDULE OF RATES COMMITTEE

CANAL AND ALLIED WORKS

CANAL AND ALLIED WORKS - REFERENCE DATA FOR THE YEAR: 2007-08 COST OF MATERIALS : 1 Air hose 25 mm dia per Rm 2 Air hose 50 mm dia per Rm 3 Asphalt 80 / 100 and 85 / 25 Gr per kg 4 Binding wire per kg 5 Cement per kg 6 Coarse aggregate 10-4.75 mm per cum ( at quarry ) 7 Coarse aggregate 20-10 mm per cum ( at quarry ) 8 Coarse aggregate 40-20 mm per cum ( at quarry ) 9 Curing Compound per ltr 10 D - cord per Rm 11 Detonating fuse coil per Rm 14 Detonator delay type per No. 15 Detonator electric per No. 16 Detonator ordinary per No. 17 Diesel oil per ltr 18 Empty cement bags per No. 19 Explosive ANFO high strength booster per kg 20 Explosive ANFO per kg 21 Explosive small dia.( Kelvex-220 ) per kg 22 Extension rod with coupling sleeve per Rm 23 Filter fabric 200 gsm per sqm 24 Filter fabric 250 gsm per sqm 25 Fine aggregate / Sand per cum ( Un-screened at quarry ) 26 Fine aggregate per cum ( Screened at quarry ) 27 G I pipe 50 mm dia A class per Rm 28 Jack hammer Drill rod 1.5 m length per No. 29 LDPE sheet 500 micron thick per sqm 30 LDPE sheet 750 micron thick per sqm 31 LDPE sheet 1000 micron thick per sqm 32 Murum per cum ( at quarry ) 33 Paving Cylinder per Each 34 PVC sealing strip per Rm 35 Reinforcement steel per kg 36 Rough stone 200 x 200 x 750 mm per No. ( at quarry ) 37 Shahabad stone slab per sqm 38 Shutter oil per ltr 39 Size stone 150 - 200 mm height per No. ( at quarry ) 40 Size stone 200 - 250 mm height per No. ( at quarry ) 41 Size stone 250 - 300 mm height per No. ( at quarry ) 42 Stone chips per cum ( at dump yard ) 43 Stone chips per cum ( at quarry ) 44 Structural steel angle / beam / channel / bar per kg 45 Structural steel plate / flat per kg 45 Super Plasticiser per ltr 47 Tarfelt jointer filler board 12 mm thick per sqm 48 Tarfelt jointer filler board 20 mm thick per sqm 49 T.C Cross bit 100 mm dia per No.

Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs:

130.00 170.00 24.00 32.00 3.80 554.00 431.00 316.00 84.00 7.00 5.00 15.00 8.00 4.50 38.00 1.00 50.00 21.00 44.00 3000.00 96.00 115.00 115.00 147.00 150.00 3000.00 52.00 80.00 98.00 52.00 19400.00 27.00 27.75 10.00 150.00 22.00 4.00 5.00 7.00 130.00 200.00 29.75 36.00 55.00 280.00 456.00 8500.00

CANAL AND ALLIED WORKS

50 51 52 53 54 55

Through stone 200 x 200 x 300 mm per No. ( at quarry ) Through stones 250 x 250 x 450 mm per No. ( at quarry ) Turfing sods per sqm Un-coursed rubble stones per cum ( at dump yard ) Un-coursed rubble stones per cum ( at quarry ) Wire mesh 50 x 50 mm 20 guage per sqm 1 km lead Rs: 29.30 Rs: 39.90 Rs: 30.90 Rs: 30.90

Rs: Rs: Rs: Rs: Rs: Rs: Loading 29.10 34.40 32.10 32.10

7.00 10.00 12.50 110.00 165.00 120.00 Unloading 6.90 17.20 32.10 32.10 Per tonne 5.00 15.00 25.00

LEAD CHARGES FOR 1 km REHANDLING LEAD: 1 Earth/ Sand 2 Stone/ Coarse aggregates 3 Cement 4 Reinforcement steel ROYALTY CHARGES: 1 Earth / Soil / Murum 2 Stone / Coarse aggregate 3 Fine aggregate / Sand HIRE CHARGES OF MACHINERY : 1 Air compressor 8.5 cmm ( diesel ) / hour 2 Angle dozer 90 hp per hour 3 Batching plant 15 cum / hr rated capacity 4 Concrete hand mixer 45 / 30 ltr per hour 5 Concrete mixer 300 / 200 ( diesel ) / hour 6 Concrete mixer 600 / 400 ( diesel ) / hour 7 Diesel generating set 30 KVA per hour 8 Diesel generating set 50 KVA per hour 9 Diesel road roller per hour 10 Jack hammer per hour 11 Mechanical concrete paver per hour 12 Needle Vibrator 40 mm ( petrol ) per hour 13 Pump 5 hp ( diesel ) per hour 14 Shovel 0.85 cum per hour 15 Shovel 0.50 cum per hour 16 Tipper 5 cum per hour 17 Transit mixer 2 cum per hour 18 Vibratory pad foot roller per hour 19 Waggon drill per hour 20 Water tanker per hour

Rs: Rs: Rs:

Hire charge Fuel charge Crew charge Rs: 185.00 588.00 52.90 Rs: 1034.00 402.00 57.30 Rs: 268.00 195.00 79.30 Rs: 9.00 2.00 --Rs: 38.00 52.00 55.10 Rs: 77.00 105.00 55.10 Rs: 55.00 418.00 33.00 Rs: 86.00 627.00 33.00 Rs: 202.00 470.00 52.70 Rs: 13.00 4.00 81.80 Rs: 249.00 12.00 105.80 Rs: 7.00 15.00 38.90 Rs: 6.00 52.00 26.20 Rs: 1057.00 575.00 57.30 Rs: 639.00 314.00 57.30 Rs: 240.00 198.00 41.70 Rs: 552.00 575.00 66.70 Rs: 1012.00 679.00 66.50 Rs: 191.00 6.00 65.50 Rs: 237.00 198.00 41.70

CANAL AND ALLIED WORKS

WAGES OF WORKERS 1 Bar bender 2 Blaster ( Licensed ) 3 Carpentor Class II 4 Cartman with double bullock cart 5 Crowbarman 6 Electrician 7 Helper blasting 8 Maistry 9 Mason Class I 10 Mason Class II 11 Mazdoor heavy 12 Mazdoor light 13 Mechanic / Fitter / Welder 14 Pipe fitter 15 Rollerman with bullock roller 16 Stone breaker 17 Stone chiseller Cl- I 18 Stone chiseller Cl- II

Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs: Rs:

Per day 120.20 108.35 109.55 139.80 102.90 104.35 102.90 102.90 120.20 109.55 93.35 91.35 118.75 113.55 139.80 106.95 109.55 106.95

OTHER DATA : 1 Contractor's Overheads on Materials / Machinery / Labour 2 Contractor's Profit on Materials / Fuel & Energy charges / Labour 3 Cost of Other enabling works 4 Hidden cost on Labour 5 Rate of interest per annum 6 Small Tools & Plant on Materials / Machinery / Labour 7 Structural steel fabrication per kg 8 Sundries ( lumpsum rate for unquantified inputs )

% % % % % % Rs: Rs:

5.00 10.00 1.10 15.00 11.00 1.00 8.00 26.00

CANAL AND ALLIED WORKS

NOTES ON SCHEDULE OF RATES

CANAL AND ALLIED WORKS FOR THE YEAR : 2007-08 1. All notes under ' General Notes on Schedule of Rates ' and Notes on Lead, Lift, Loading and un-loading Charges are applicable to Canal and Allied Works also to the extent they are relevant. 2. The basic rates are inclusive of finishing, wastage of materials in handling, incidental works, profit, overheads, small tools / plants, hidden cost on labour etc. 3. The basic rates are inclusive of royalty charges payable on materials. 4. The recovery of royalty charges on materials, wherever applicable, shall be as per the guide lines listed under ' General notes on schedule of rates ' and the amount of royalty charges shall be as per the statement of royalty charges included in this section. 5. Unless otherwise specified the basic rates are inclusive of all lifts. 6. For earth / rockfill embankment works 1 km initial lead is considered in the basic rates. As no storing / stacking and re-handling of materials is involved for these works lead charges for additional lead shall be worked out for total lead including initial lead of 1 km and then the cost of first km lead shall be deducted. No loading and un-loading charges shall be added as the additional lead does not involve re-handling of materials. Example : Total lead for soil from approved borrow area : 2 km Initial lead included in the basic rate in the SR : 1 km Additional lead charges : Lead charges for 2 km Rs: 36.50 Less Lead charges for 1 km Rs: -29.30 Additional lead charges Rs: 7.20 No loading and un-loading charges shall be added. 7. Cement content specified for cement concrete works in the item description is based on theoritical design mix computations. The basic rate shall be adjusted upword or downword including lead, loading and un-loading charges for any varions in cement content based on trial mix studies furnished by Q.C unit. 8. The quantities of materials including wastage, requirements for incidentals etc., for working out additional lead charges shall be as per the statement of requirement of materials under this section. 9. The basic rates are exclusive of cost of dewatering and desilting. For the perticular reach of canal where dewatering and desilting are contemplated 2 percent of basic rate shall be added to all items in the estimate for that reach towards dewatering and desilting during execution of work.

CANAL AND ALLIED WORKS

CANAL AND ALLIED WORKS - DATA RATES

SECTION: CANAL AND ALLIED WORKS. YEAR : 2007-08 ITEM No: 1

ITEM: Excavation in all kinds of soil including boulders upto 0.6 m diameter ( 0.113 cum) for canal, seating of embankment, filter drains/ catch water drains etc., including dressing bed and sides to required level and profile, cost of all materials, machinery, labour, placing the excavated soil neatly in dump area or for the formation of service road / embankment as directed etc., complete with initial lead upto 1 km and all lifts. DATA: Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum Lead for disposal of excavated soil : Upto 1 km Speed for loaded tipper under canal excavation condition : 15 km / hr Speed for empty tipper under canal excavation condition : 15 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 20 sec 1. Quantity of excavation : In-situ quantity / bucket for 20 % bulkage on unloading ( 1 /1.20 ) : 0.83 cum In-situ quantity per load for 20 % bulkage of soil ( 5 /1.2 ) : 4.16 cum Number of buckets per load ( 4.16 / 0.83 ) say : 5 buckets Corrected Quantity of in-situ soil per load ( 5 x 0.83 ) say : 4.16 cum Ideal cycle time for loading 5 buckets ( 5 x 20 / 60 ) : 1.67 min The ideal cycle time for shovel requires spotting of a tipper within 1.67 minutes near the shovel. However, in practice for canal excavation the space available may not permit positioning of the tippers on either side of the shovel. Generally, one tipper has to move after loading to position the next tipper for loading. Assuming one cycle time extra the corrected cycle time for the shovel will be : ( 6 x 20 / 60 ) : 2.00 min Round trip cycle time for tipper: Corrected cycle time of shovel for digging & loading : 2.00 min Time for ( av ) 0.75 km haulage under load ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and un-loading : 2.00 min Time for ( av ) 0.75 km return trip ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and spotting : 0.50 min Total : 10.50 min No.of tippers to match corrected cycle time of shovel ( 10.50/ 2.00 ) : 5.25 Nos Output of tipper / hr with 50 min working / hr ( 50 x 4.16 / 10.50 ) : 19.80 cum Output for 5 tippers per day ( 5 x 19.80 x 8 ) : 792 cum Further, assuming about 90 percent of excavation by deploying shovel and about 10 percent excavation mainly for trimming the canal to final profile by manual labour the daily progress of excavation will be : ( 792 / 0.9 ) say : 880 cum Consider 880 cum for rate analysis. 2. Requirement of materials: No materials involved in the work. 3. Requirement of machinery : Deploy 0.85 cum capacity shovel for 8 hours for digging and loading 792 cum insitu soil. Deploy 5 tippers of 5 cum capacity for 8 hours for disposal of 792 cum insitu soil. 4. Requirement of workforce ( other than machinery crew ) : Average output of 1 heavy & 1 light mazdoor assumed at 5 cum / day for trimming and disposal. Deploy 18 heavy and 18 light mazdoors for trimming and disposal of 88 cum soil. Deploy 1 maistry.

CANAL AND ALLIED WORKS

RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars NIL Unit Quantity

UNIT :

880.00 cum Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 0.00

0.00 0.00 1% 10% 5% Total cost of Materials :

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour

Quantity 8.00 8.00 40.00 40.00

1 Shovel 0.85 cum capacity Fuel / Energy charges 2 Tippers 5 cum capacity ( 5 ) Nos Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5

Rate in Rs. 1057.00 575.00 240.00 198.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 8456.00 4600.00 9600.00 7920.00 30576.00 305.76 1252.00 1528.80 33662.56

Description

Unit Hour Hour Day Day Day

Quantity 8.00 40.00 1.00 18.00 18.00

Crew for Shovel Crew for Tipper Maistry Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 57.30 41.70 102.90 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 458.40 1668.00 102.90 1680.30 1644.30 5553.90 55.54 555.39 833.09 277.70 7275.61

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 880.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs:

0.00 33662.56 7275.61 40938.17 450.32 41388.49 47.00 45.00 ITEM No: 2

SECTION: CANAL AND ALLIED WORKS.

ITEM: Excavation in all kinds of soil including boulders upto 0.60 m diameter ( 0.113 cum ) for field channels, seating of embankment for field channels etc., including dressing of bed and sides to required profile, cost of all materials, machinery, labour, placing the excavated stuff for formation of service road / embankment as directed etc., complete with lead upto 10 m and lift upto 2 m.

CANAL AND ALLIED WORKS

DATA: Capacity of shovel bucket : 0.50 cum Capacity of shovel bucket under heaped condition : 0.57 cum Lead for disposal of excavated soil : Upto 10 m In view of shallow depth of digging for field channels the cycle time for digging and disposal by shovel is assumed at 1.5 times the cycle time considered for canal. Shovel digging and loading cycle per bucket ( 1.5 x 20 ) : 30 sec 1. Quantity of excavation : In-situ qty / bucket for 15 % bulkage of soil ( 0.57 / 1.15 ) : 0.50 cum Output of shovel with 50 min./ hr working ( 50 x 60 x 0.5 / 30 ) : 50 cum / hr Daily output of excavation ( 8 x 50 ) : 400 cum As the excavated soil is dumped by the side of field channel within the reach of shovel boom no tippers are considered in the rate analysis for disposal of excavated soil. Further, assuming about 90 percent of excavation by deploying shovel and about 10 percent excavation mainly for trimming bed and sides of channels / trenches to final profile by manual labour, the daily output will be : ( 400 / 0.90 ) say : 445 cum Consider 445 cum for rate analysis. 2. Requirement of materials: No materials involved in the work. 3. Requirement of machinery : Deploy 0.85 cum capacity shovel for 8 hours for digging and loading 400 cum. 4. Requirement of workforce ( other than machinery crew ) : Average output of 1 heavy & 1 light mazdoor assumed at 5 cum / day for trimming and disposal. Deploy 9 heavy and 9 light mazdoors for trimming and disposing 45 cum soil. Deploy 1 maistry. RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars NIL Unit Quantity 0.00 0.00 1% 10% 5% Total cost of Materials : UNIT : 445.00 cum Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

B. MACHINERY: Sl No

Description

Unit Hour Hour

Quantity 8.00 8.00

1 Shovel 0.50 cum capacity Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4

Rate in Rs. 639.00 314.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 5112.00 2512.00 7624.00 76.24 251.20 381.20 8332.64

Description

Unit Hour Day Day Day

Quantity 8.00 1.00 9.00 9.00

Crew for Shovel Maistry Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 57.30 102.90 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 458.40 102.90 840.15 822.15 2223.60 22.24 222.36 333.54 111.18 2912.92

CANAL AND ALLIED WORKS

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 445.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs:

0.00 8332.64 2912.92 11245.56 123.70 11369.26 26.00 26.00 ITEM No: 3

SECTION: CANAL AND ALLIED WORKS.

ITEM: Excavation in soft rock without blasting including boulders upto 0.6 m diameter ( 0.113 cum ) for canals, seating of embankment, filter drain / catch water drains etc., including dressing of bed and sides to required level and profile, cost of all materials, machinery, labour, placing the excavated soft rock neatly in dump area or for formation of service road as directed etc., complete with lead upto 1 km and all lifts. DATA: Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum Lead for disposal of excavated soft rock : Upto 1 km Speed for loaded tipper under canal excavation condition : 15 km / hr Speed for empty tipper under canal excavation condition : 15 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 30 sec 1. Quantity of excavation : In-situ qty / bucket for 30 % bulkage on unloading : 0.77 cum In-situ quantity / load for 5 cum of soft rock ( 5 / 1.30 ) : 3.85 cum Number of buckets per load ( 3.85 / 0.77 ) say : 5 buckets Ideal cycle time for loading 5 buckets ( 5 x 30 / 60 ) : 2.50 min The ideal cycle time for shovel requires spotting of a tipper within 2.50 minutes near the shovel. However, in practice for dam or canal excavation the space available may not permit positioning of tippers on either side of the shovel. Generally one tipper has to move after loading to position the next tipper for loading. Assuming one cycle time extra the corrected cycle time for digging and loading one tipper by shovel will be : ( 6 x 30 / 60 ) 3.00 min Round trip cycle time for tipper: Corrected cycle time of shovel for digging & loading : 3.00 min Time for ( av ) 0.75km haulage under load ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and un-loading : 2.00 min Time for average 0.75 km return trip ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and spotting : 0.50 min Total : 11.50 min No.of tippers to match corrected cycle time of shovel ( 11.50/ 3.00 ) say : 3.83 Nos

CANAL AND ALLIED WORKS

Output of tipper / hr with 50 min working / hr ( 50 x 3.85 / 11.50 ) : 16.74 cum Output for 4 tippers per day ( 3.83 x 16.74 x 8 ) say : 513 cum Further, assuming about 90 percent of excavation by deploying shovel and about 10 percent excavation mainly for trimming of bed / sides to final profile by manual labour the daily output will be : ( 513 / 0.9 ) say : 570 cum Consider 570 cum for rate analysis. 2. Requirement of materials: No materials involved in the work. 3. Requirement of machinery : Deploy 0.85 cum capacity shovel for 8 hours for digging and loading 513 cum. Deploy 4 tippers of 5 cum capacity for disposal of 513 cum. 4. Requirement of workforce ( other than machinery crew ) : Output of 1crowbarman, 1 heavy and 1 light mazdoor assumed at 5 cum per day for trimming. Deploy 11 heavy and 11 light mazdoors for trimming and disposal of 57 cum soft rock. Deploy 11 crowbarman for trimming. Deploy 1 maistry. RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars NIL Unit Quantity 0.00 0.00 1% 10% 5% Total cost of Materials : UNIT : 570.00 cum Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour

Quantity 8.00 8.00 32.00 32.00

1 Shovel 0.85 cum capacity Fuel / Energy charges 2 Tippers 5 cum capacity ( 4 ) Nos Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6

Rate in Rs. 1057.00 575.00 240.00 198.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 8456.00 4600.00 7680.00 6336.00 27072.00 270.72 1093.60 1353.60 29789.92

Description

Unit Hour Hour Day Day Day Day

Quantity 8.00 32.00 1.00 11.00 11.00 11.00

Crew for Shovel Crew for Tipper Maistry Crowbarman Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 57.30 41.70 102.90 102.90 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 458.40 1334.40 102.90 1131.90 1026.85 1004.85 5059.30 50.59 505.93 758.90 252.97 6627.68

10

CANAL AND ALLIED WORKS

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 570.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs:

0.00 29789.92 6627.68 36417.60 400.59 36818.20 65.00 65.00 ITEM No: 4

SECTION: CANAL AND ALLIED WORKS.

ITEM: Excavation in soft rock without blasting including boulders upto 0.60 m diameter (0.113 cum) for field channels, seating of embankment for field channels etc., including dressing of bed and sides to required profile, cost of all materials, machinery, labour, placing excavated stuff for formation of service road as directed etc.,complete with lead upto 10 m and lift upto 2 m. DATA: Capacity of shovel bucket : 0.50 cum Capacity of shovel bucket under heaped condition : 0.57 cum Lead for disposal of excavated soil : Upto 10 m In view of shallow depth of digging for field channels the cycle time for digging and disposal by shovel is assumed at 1.5 times the cycle time considered for canal. Shovel digging and loading cycle per bucket ( 1.5 x 30 ) : 45 sec 1. Quantity of excavation : In-situ qty per bucket for 25 % bulkage of soil ( 0.57 / 1.25 ) : 0.45 cum Output of shovel with 50 min./ hr working ( 50 x 60 x 0.45 / 45 ) : 30 cum / hr Daily output of excavation ( 8 x 30 ) say : 240 cum Further, assuming about 90 percent of excavation by deploying shovel and about 10 percent excavation mainly for trimming the canal to final profile by manual labour, the daily progress of excavation in soft rock will be : ( 240 / 0.9 ) say : 265 cum Consider 265 cum for rate analysis. 2. Requirement of materials: No materials involved in the work. 3. Requirement of machinery : Deploy 0.85 cum capacity shovel for 8 hours for digging and loading 240 cum. 4. Requirement of workforce ( other than machinery crew ) : Output of 1 crowbarman, 1 heavy & 1 light mazdoor assumed at 5 cum per day. Deploy 5 crowbarman, 5 heavy and 5 light mazdoors for trimming and disposal of 25 cum. RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars NIL Unit Quantity 0.00 0.00 1% 10% 5% Total cost of Materials : UNIT : 265.00 cum Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 0.00

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

11

B. MACHINERY: Sl No

Description

Unit Hour Hour

Quantity 8.00 8.00

1 Shovel 0.50 cum capacity Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5

Rate CANAL Amount AND ALLIED WORKS in Rs. in Rs. 639.00 5112.00 314.00 2512.00 Total Rs: 7624.00 Rs: 76.24 Rs: 251.20 Rs: 381.20 Rs: 8332.64

Description

Unit Hour Day Day Day Day

Quantity 8.00 1.00 5.00 5.00 5.00

Crew for Shovel Maistry Crowbarman Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 57.30 102.90 102.90 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 458.40 102.90 514.50 466.75 456.75 1999.30 19.99 199.93 299.90 99.97 2619.08

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 265.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs:

0.00 8332.64 2619.08 10951.72 120.47 11072.19 42.00 42.00 ITEM No: 5

SECTION: CANAL AND ALLIED WORKS.

ITEM: Excavation in soft rock requiring blasting including boulders upto 0.6 m diameter( 0.113 cum) for canals, seating of embankment, filter drain / catch water drains etc., including dressing bed and sides to required level and profile, cost of all materials, machinery, labour, placing the excavated rock in dump area or for formation of service road as directed etc., complete with lead upto 1 km and depth of cut upto 18 m below ground level. Note: For depth of cut more than 18 m below ground level increase the basic rate by 5 %. DATA: Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum Lead for disposal of excavated soft rock : Upto 1 km Speed for loaded tipper under canal excavation condition : 15 km / hr Speed for empty tipper under canal excavation condition : 15 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 40 sec 1. Quantity of excavation : In-situ qty / bucket for 35 % bulkage on unloading ( 1 / 1.35 ) : 0.74 cum In-situ quantity / load for 5 cum of soft rock ( 5 / 1.35 ) : 3.70 cum Number of buckets per load ( 3.70 / 0.74 ) say : 5 buckets Ideal cycle time for loading 5 buckets ( 5 x 40 / 60 ) : 3.33 min The ideal cycle time for shovel requires spotting of a tipper within 3.33 minutes near the shovel. However, in practice for dam or canal excavation the space available may not permit positioning of tippers on either side of the shovel. Generally one tipper has to move after loading to position the next tipper for loading. Assuming one cycle time extra the corrected cycle time for digging and loading one tipper by shovel will be : ( 6 x 40 / 60 ) : 4.00 min Round trip cycle time for tipper: Corrected cycle time of shovel for digging & loading : 4.00 min Time for ( av ) 0.75 km haulage under load ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and un-loading : 2.00 min Time for average 0.75 km return trip ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and spotting : 0.50 min 12

CANAL AND ALLIED WORKS

2.

3.

4.

5.

Total : 12.50 min No.of tippers to match corrected cycle time of shovel ( 12.50 / 4.00 ) : 3.12 Nos Output of tipper / hr with 50 min working / hr ( 50 x 3.70 / 12.50 ) : 14.80 cum Output for 3 tippers per day ( 3 x 14.80 x 8 ) say : 355 cum Further, assuming about 90 percent of excavation by deploying shovel and about 10 percent excavation mainly for trimming of bed and sides to final profile by manual the daily output will be : ( 355 / 0.9 ) say : 395 cum Consider 395 cum excavation in soft rock requiring blasting for rate analysis. Drilling and Blasting : Depth of drilling per hole : 1.40 m Effective depth of pull : 1.25 m Grid spacing of holes for soft rock requiring blasting depends on the nature of soft rock at any perticular location. For the purpose of rate analysis holes at average spacing of 1.5 times the spacing considered for hard rock is assumed. Grid spacing of holes : 1.50 x 2.00 m Area of excavation for 395 cum ( 395 / 1.25 ) : 316 sqm Nos. of holes for 316 sqm area 316 / ( 1.5 x 2.0 ) : 105 Nos. Depth of drilling for 105 holes ( 105 x 1.4 ) say : 147.00 m Add for secondary blasting LS : 3.00 m Total depth of drilling : 150 m Rate of drilling in soft rock per hour : 12 m With 50 min / hour working rate of drilling ( 12 x 50 / 60 ) : 10 m Time required for drilling with 2 jack hammers ( 150 / 2 / 10 ) : 7.50 hours Requirement of materials : Jack hammer drill rod : 150 m drilling Quantity of Explosive ( Kelvex-220 ) at 0.2 kg / cum ( 395 x 0.2 ) : 79 kg Explosive for secondary blasting LS : 1 kg Ordinary detonators for secondary blasting 5 holes : 5 Nos. Electric detonators at 1 per hole for main blast : 105 Nos. Fuse coil : 175 Rm Requirement of machinery : Deploy 0.85 cum capacity shovel for 8 hours for digging and loading 240 cum. Deploy 3 tippers 5 cum capacity for 8 hours for disposal of 240 cum. Deploy 1 air compressor 8.5 cmm capacity for 7.5 hours. Deploy 2 jack hammers for 7.5 hours for drilling. Requirement of workforce ( other than machinery crew ) : Output of 1 heavy & 1 light mazdoor assumed at 5 cum per day for trimming and disposal. Deploy 2 crowbarman, 2 stone breaker, 8 heavy and 8 light mazdoors for 40 cum. Deploy 1 blaster and 1 blasting helper for loading and blasting. Deploy 1 maistry.

13

CANAL AND ALLIED WORKS 6. Use rate of materials : Cost of drill rod 1.5 m long @ Rs: 3000.00 / Each Life of drill rod for drilling in soft rock with reconditioning Use rate of drill rod per Rm drilling ( cost / life ) Length of air hose for drilling for each jack hammer Cost of 25 mm dia air hose 50 m @ Rs: 130.00 / Rm Life of air hose Use rate of 25 mm dia air hose per hr ( cost / life ) RATE ANALYSIS A. MATERIALS: Sl No Perticulars Unit Rm Hour kg Nos Nos Rm LS Quantity 150.00 15.00 80.00 5.00 105.00 175.00 3.00 UNIT : Rs: 3000.00 : 200 m Rs: 15.00 : 50 m Rs: 6500.00 : 800 hours Rs: 8.13 395.00 cum Rate in Rs. 15.00 8.13 44.00 4.50 8.00 5.00 26.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 2250.00 225.00 121.88 3520.00 22.50 840.00 875.00 78.00 7932.38 79.32 793.24 396.62 9201.56

1 Use rate of Jack hammer drill rod 1.5 m Reconditioning charges @ 10 % 2 Use rate of 50 m air hose 2 Nos 3 Explosive small dia ( Kelvex-220 ) 4 Ordinary detonators 5 Electric detonators 6 Fuse coil 7 Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour

Quantity 8.00 8.00 24.00 24.00 7.50 7.50 15.00 15.00

1 Shovel 0.85 cum capacity Fuel / Energy charges 2 Tippers 5 cum capacity 3 Nos. Fuel / Energy charges 3 Air compressor 8.5 cmm ( diesel ) Fuel / Energy charges 4 Jack hammers 2 Nos. Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9 10 11

Rate in Rs. 1057.00 575.00 240.00 198.00 185.00 588.00 13.00 4.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 8456.00 4600.00 5760.00 4752.00 1387.50 4410.00 195.00 60.00 29620.50 296.21 1382.20 1481.03 32779.93

Description

Unit Hour Hour Hour Hour Day Day Day Day Day Day Day

Quantity 8.00 24.00 7.50 15.00 1.00 1.00 1.00 2.00 2.00 8.00 8.00

Crew for Shovel Crew for Tipper Crew for Air compressor Crew for Jack hammer Maistry Blaster Helper blaster Crowbarman Stone breaker Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 57.30 41.70 52.90 81.80 102.90 108.35 102.90 102.90 106.95 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 458.40 1000.80 396.75 1227.00 102.90 108.35 102.90 205.80 213.90 746.80 730.80 5294.40 52.94 529.44 794.16 264.72 6935.66

14

CANAL AND ALLIED WORKS

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 395.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs:

9201.56 32779.93 6935.66 48917.15 538.09 49455.24 125.00 114.00 ITEM No: 6.a

SECTION: CANAL AND ALLIED WORKS.

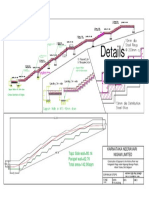

ITEM: Excavation in hard rock of all toughness including boulders above 0.6 m diameter (0.113 cum) by blasting for canals, cut-off trench of embankment, filter / catch water drains etc., adopting a combination of wagon drill holes of not more than 100 mm dia. and jack hammer holes including levelling the bed and minimising damage to side slopes in water prism by adopting any one or a combination of line drilling /pre-splitting /smooth blasting techniques and stacking the excavated rock neatly in approved dump area as directed etc., with initial lead upto 1 km and depth of cuts upto 18 m below ground level. Note: For depth of cut more than 18 m below ground level increase the basic rate by 5 %. DATA: Excavation for canal in hard rock can be by using jack hammers or by using waggon drills or by combination of both depending on the depth of cut, width of canal and side slope. In case of waggon drill the rate of drilling will be faster and yeild per hole will be more due to wider spacing of holes. For jack hammer drill the yeild per hole will be less due to closer spacing of holes. As both the systems have advantages as well as disadvantages it is proposed to work out rates using both the systems and include average rate in the Schedule of Rates. I. By using Jack hammers for drilling : Assume 10.80 m width of canal at the bench level and 1.25 m average depth of cutting. Assume side slopes of 0.25 horizontal to 1 vertical. Generally, the length of canal bench to be excavated per blast shall not be more than 7 m to avoid tight muck pile requiring higher digging time for shovel. Sectional area of excavation ( 10.80 + 10.175 ) x 0.5 x 1.25 : 13.11 sqm Consider 7 burden distance for excavation per blast. Number of rows considered : 7 No. Length of canal for 7 rows ( 7 x 1.00 ) : 7.00 m Quantity of excavation for 7 m length ( 13.11 x 7.00 ) say : 92.00 cum 10.80 m 8.4 m

1 0.25 10.175 m -1.0 m 1.2 m

1.25 m

7.00 m

Free face SKETCH SHOWING DRILLING & BLASTING PATTERN

15

CANAL AND ALLIED WORKS 1. Drilling and Blasting: Consider drilling by Jack hammers and mucking by combination of Shovel and Tippers. The burden ( distance of hole from free face of excavation ) is considered at 25 to 30 times dia of hole and spacing of holes is considered at 1.20 to 1.25 times burden. Burden distance for 32 mm dia jack hammer holes ( 0.032 x 30 ) say : 1.00 m Spacing of holes ( 0.032 x 30 x 1.25 ) : 1.20 m Grid spacing of holes for 32 mm dia jack hammer holes : 1.00 x 1.20 m Depth of drilling per hole : 1.40 m Effective depth of pull considering 10 % sub-drilling : 1.25 m Rate of drilling by jack hammer in hard rock per hour : 8.00 m Rate of drilling per hour with 50 min / hour working ( 8 x 50 / 60 ) say : 6.5 m No.of holes in 7 rows @1.2 m interval staggered ( 4x8 + 3x9 + 16 ) : 75 Nos Length of drilling for 75 holes @ 1.4 m per hole ( 75 x 1.4 ) : 105 m Add drilling for secondary blasting for 5% quantity @ 0.6 m / cum say : 3 m Total : 108.00 m Time for drilling 108 m for 2 jack hammers ( 108 / 2 / 6.5 ) : 8.30 hours Drilling and Blasting pattern : Pattern of holes : Staggered Hole initiation : Bottom Initiation system : Ele detonators Initiation pattern : All rows 2. Disposal of excavated rock : Quantity of excavation ( in-situ ) : 92.00 cum Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum Lead for disposal of excavated rock : Upto 1 km Speed for loaded tipper under canal excavation condition : 15 km / hr Speed for empty tipper under canal excavation condition : 15 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 45 sec In-situ qty / bucket for 40 % bulkage of hard rock ( 1 /1.40 ) : 0.71 cum In-situ qty per load for 40 % bulkage of hard rock ( 5 /1.40 ) : 3.57 cum Number of buckets per load ( 3.57 / 0.71 ) say : 5 buckets Ideal cycle time for loading 5 buckets ( 5 x 45 / 60 ) : 3.75 min The ideal cycle time for shovel requires spotting of a tipper within 3.75 minutes near the shovel. However, in practice for dam or canal excavation the space available may not permit positioning of tippers on either side of the shovel. Generally one tipper has to move after loading to position next tipper for loading. Assuming one loading cycle extra, the corrected cycle time for shavel will be ( 6 x 45 / 60 ) 4.50 min Round trip cycle time for tipper: Cycle time of shovel for digging & loading : 4.50 min Time for (av ) 0.75 km haulage under load ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and un-loading : 2.00 min Time for average 0.75 km return trip ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and spotting : 0.50 min Total : 13.00 min No.of tippers to match corrected cycle time of shovel ( 13.00 / 4.50) : 2.9 Nos Output of tipper / hr with 50 min working / hr ( 50 x 3.57 / 13.00 ) : 13.73 cum Deploy 0.9 cum shovel and 3 tippers for disposal of excavated rock. Output of 1 shovel & 3 tippers per hour ( in-situ qty ) ( 13.73 x 2.9 ) : 39.80 cum Out of the total blasted rock some residual muck at the bed needs to be removed by deploying manual labour. Assume residual muck at bed at 0.10 cum / sqm of bed area. Quantity of muck to be disposed by shovel ( 92 - 0.1 x 70 ) 85 cum Time for disposal of 85 cum by shovel ( 85 / 39.80 ) : 2.2 hours For levelling 85 cum muck in dump yard deploy 1 dozer for : 0.25 hour Quantity of muck to be disposed by manual labour ( 92 - 85 ) 7 cum 3. Requirement of materials : Jack hammer drill rod : 108 m drilling Quantity of Explosive ( Kelvex-220 ) at 0.3 kg / cum ( 92 x 0.3 ) : 27.60 kg Add for secondary blasting @ 0.2 kg / cum ( 92 x 0.05 x 0.2 ) : 0.90 kg Total : 28.50 kg Ordinary detonators for secondary blasting 8 holes of 0.6 m each : 8 Nos. Electric detonators @ 1 per hole for main blast : 75 Nos Detonating fuse coil : 120 Rm 16

CANAL AND ALLIED WORKS

4. Requirement of machinery : Deploy 0.85 cum capacity shovel for 2.2 hours for digging and loading 85 cum. Deploy 3 tippers 5 cum capacity for 2.2 hours for disposal of 85 cum. Deploy 1 air compressor 8.5 cmm capacity for 8.5 hours. Deploy 2 jack hammers for 8.5 hours for drilling. Deploy 1 angle dozer for 0.25 hour for levelling muck in dump area. 5. Requirement of workforce ( other than machinery crew ) : Deploy 1 Crowbarman, 1 Stone breaker for 1 day for levelling bed. Deploy 2 heavy and 2 light mazdoors for disposal of 9 cum residual muck at bed level and for other miscellaneous works. Deploy 1 blaster and 1 blasting helper for loading and blasting. Deploy 1 maistry. 6. Use rate of materials : Cost of drill rod 1.5 m long @ Rs: 3000.00 / Each Rs: 3000.00 Life of drill rod for drilling in hard rock with reconditioning : 150 m Use rate of drill rod per Rm drilling ( cost / life ) Rs: 20.00 Length of air hose for drilling for each jack hammer : 50 m Cost of 25 mm dia 50 m air hose @ Rs: 130.00 / Rm Rs: 6500.00 Life of air hose : 800 hours Use rate of 25 mm dia air hose per hour ( cost / life ) Rs: 8.13 RATE ANALYSIS A. MATERIALS: Sl No Perticulars Unit Rm Hour kg Nos Nos Rm LS Quantity 108.00 17.00 28.50 8.00 75.00 120.00 2.00 UNIT : 92.00 cum Rate in Rs. 20.00 8.13 44.00 4.50 8.00 5.00 26.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 2160.00 216.00 138.13 1254.00 36.00 600.00 600.00 52.00 5056.13 50.56 505.61 252.81 5865.11

1 Use rate of Jack hammer drill rod 1.5 m Reconditioning charges @ 10 % 2 Use rate of 50 m air hose 2 Nos. 3 Explosive small dia. (Kelvex-220 ) 4 Ordinary detonators 5 Electric detonators 6 Fuse coil 7 Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour

Quantity 2.20 2.20 0.25 0.25 6.60 6.60 8.50 8.50 17.00 17.00

1 Shovel 0.85 cum capacity Fuel / energy charges 2 Angle dozer 90 hp Fuel / Energy charges 3 Tippers 5 cum capacity 3 Nos. Fuel / Energy charges 4 Air compressor 8.5 cmm ( diesel ) 1 Nos Fuel / Energy charges 5 Jack hammers 2 Nos. Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery :

Rate in Rs. 1057.00 575.00 1034.00 402.00 240.00 198.00 185.00 588.00 13.00 4.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 2325.40 1265.00 258.50 100.50 1584.00 1306.80 1572.50 4998.00 221.00 68.00 13699.70 137.00 773.83 684.99 15295.51

17

C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9 10 11 12

Description

Unit Hour Hour Hour Hour Hour Day Day Day Day Day Day Day

Quantity 2.20 0.25 6.60 8.50 17.00 1.00 1.00 1.00 1.00 1.00 2.00 2.00

Crew for Shovel Crew for Dozer Crew for Tipper Crew for Air compressor Crew for Jack hammer Maistry Blaster Helper blaster Crowbarman Stone breaker Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

AND ALLIED WORKS Rate CANAL Amount in Rs. in Rs. 57.30 126.06 57.30 14.33 41.70 275.22 52.90 449.65 81.80 1390.60 102.90 102.90 108.35 108.35 102.90 102.90 102.90 102.90 106.95 106.95 93.35 186.70 91.35 182.70 Total Rs: 3149.26 Rs: 31.49 Rs: 314.93 Rs: 472.39 Rs: 157.46 Rs: 4125.52

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 92.00 cum Rate per cum

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs:

5865.11 15295.51 4125.52 25286.14 278.15 25564.29 278.00

II. By using waggon drills for drilling : Assume 12.70 m width of excavation at bench level and 5.40 m depth of cutting in hard rock. Assume side slopes of 0.25 horizontal to 1 vertical. 1. Drilling and Blasting: Consider drilling by Waggon drill and mucking by combination of Shovel and Tippers. For good fragmentation to facilitate easy loading by 0.85 cum capacity shovel the bench height to burden ratio shall be more than 3. The burden ( distance of hole from free face of excavation ) is considered at 20 times diameter of hole and spacing of holes is considered at 1.25 times burden. Burden distance for 100 mm dia holes ( 0.10 x 20 ) : 2.00 m Spacing of holes at 1.25 times burden ( 0.10 x 20 x 1.25 ) : 2.50 m Grid spacing of holes for 100 mm dia Waggon drill holes : 2.00 x 2.50 m Consider 3 burden distance for excavation per blast. Depth of drilling per hole : 6.00 m Effective depth of pull considering 10 % sub-drilling say : 5.40 m Rate of drilling in hard rock per hour by Waggon drill : 12.00 m Rate of drilling per hour with 50 min per hour working ( 12 x 50 / 60 ) : 10 m 12.70 m

1 5.40 m 0.25 10.00 m 12.70 m

1 5.40 m 0.25

18

2.0 m 2.5 m 6.00 m

CANAL AND ALLIED WORKS

Free face SKETCH SHOWING DRILLING & BLASTING PATTERN Sectional area of excavation ( 12.70+10.00 ) x 0.5 x 5.40 : 61.29 sqm Length of canal for excavation ( 3 x 2.00 ) : 6.00 m Quantity of excavation for 6.0 m length ( 61.29 x 6.00 ) : 368 cum No. of blast holes in 3 rows (2x5+1x6+2x4) : 24 holes Length of drilling for 24 holes ( 11 x 6 + 13 x 6.2 ) say : 147 m Drilling for secondary blasting for 5% qty @ 0.6 m / cum : 11.00 m No.of blast holes for secondary blasting @ 0.6 m / hole ( 11 / 0.6 ) : 18 holes Consider 2 waggon drills for drilling holes. Time for drilling 147 m for 2 Waggon drill @ 10 m / hour : 7.33 hours Consider 368 cum hard rock excavation for rate analysis. 2. Disposal of excavated rock : Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum Lead for disposal of excavated rock rock : Upto 1 km Speed for loaded tipper under canal excavation condition : 15 km / hr Speed for empty tipper under canal excavation condition : 15 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 45 sec In-situ qty / bucket for 40 % bulkage of hard rock ( 1 / 1.40 ) : 0.71 cum In-situ qty per load for 40 % bulkage of hard rock ( 5 / 1.40 ) : 3.57 cum Number of buckets per load ( 3.57 / 0.71 ) say : 5 buckets Ideal cycle time for loading 5 buckets ( 5 x 45 / 60 ) : 3.75 min The ideal cycle time for shovel requires spotting of a tipper within 3.75 minutes near the shovel. However, in practice for dam or canal excavation the space available may not permit positioning of tippers on either side of the shovel. Generally one tipper has to move after loading to position next tipper for loading. Assuming one loading cycle extra, the corrected cycle time for shovel will be ( 6 x 45 / 60 ) 4.50 min Round trip cycle time for tipper: Cycle time of shovel for digging & loading : 4.50 min Time for (av ) 0.75 km haulage under load ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and un-loading : 2.00 min Time for average 0.75 km return trip ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and spotting : 0.50 min Total : 13.00 min No.of tippers to match corrected cycle time of shovel (13.00 / 4.50) say : 2.9 Nos Output of tipper / hr with 50 min working / hr ( 50 x 3.57 / 13.00 ) : 13.73 cum Output of 2.7 tippers per hour ( 13.73 x 2.9 ) : 39.80 cum Out of the total blasted rock some residual muck at the bed needs to be removed by deploying manual labour. Assume residual muck at bed at 0.10 cum / sqm of bed area. Quantity of muck to be disposed by shovel ( 368 - 0.1 x 60 ) : 362 cum Time required for disposal of 362 cum ( 362 / 39.80 ) say : 9 hours For levelling 362 cum muck in dump yard deploy 1 dozer for : 1.00 hour Quantity of muck to be disposed by manual labour ( 368 - 362 ) : 6 cum 3. Requirement of materials : 100 mm dia TC bit : 147 m drilling Extension rods with sleeve : 147 m drilling Jack hammer drill rod : 11 m drilling Quantity of Explosive @ 0.5 kg / cum for 368 cum : 184.00 kg Consider 20 % high strength ANFO booster for priming ANFO. : 37.00 kg Consider 80 % ANFO mixed with diesel oil for colunm. : 147.00 kg Diesel oil @ 180 ml per kg of ANFO : 27.00 ltrs Quantity of Explosive @ 0.2 kg / cum for secondary blast : 4 kg Ordinary detonators for secondary blasting : 18 Nos. Detonating cord for 24 holes in 3 rows : 210 Rm. Detonating fuse coil for secondary blasting : 20 Rm 19

4. Requirement of machinery : CANAL AND ALLIED WORKS Deploy 0.85 cum capacity shovel for 9 hours for digging and loading 362 cum. Deploy 3 tippers 5 cum capacity for 9 hours for disposal of 362 cum. Deploy 2 air compressors 8.5 cmm capacity for 7.5 hours. Deploy 2 waggon drills for 7.5 hours for drilling main blast holes. Deploy 1 air compressor 8.5 cmm capacity for 1 hour. Deploy 2 jack hammers for 1 hour for drilling secondary blast holes. Deploy 1 angle dozer for 1 hour for levelling muck in dump area. 5. Requirement of workforce ( other than machinery crew ) : Deploy 1 Crowbarman, 1 Stone breaker for 1 day for levelling bed. Deploy 2 heavy and 2 light mazdoors for disposal of 9 cum residual muck at bed level. Deploy 1 blaster and 1 blasting helper for loading and blasting. Deploy 1 maistry. 6. Use rate of materials : Cost of T.C bit 100 mm dia @ Rs: 8500.00 / Each Rs: 8500.00 Life of drill bit for drilling in hard rock : 80 m Use rate of T.C bit per Rm drilling ( Cost / Life ) Rs: 106.25 Cost of extn rod with sleeve 4.5 m @ Rs: 3000.00 / Rm Rs: 13500.00 Life of extension rod : 1500 m Use rate of extension rod per Rm drilling ( Cost / Life ) Rs: 9.00 Cost of 1.5 m drill rod @ Rs: 3000.00 / Each Rs: 3000.00 Life of drill rod for drilling in hard rock with reconditioning : 150 m Use rate of drill rod per Rm drilling ( Cost / Life ) Rs: 20.00 Length of air hose for drilling for each jack hammer : 50 m Cost of 50 m air hose 25 mm @ Rs: 130.00 / Rm Rs: 6500.00 Life of air hose : 800 hours Use rate of air hose per hr ( Cost / Life ) Rs: 8.13 Cost of 50 m air hose 50 mm dia @ Rs: 170.00 / Rm Rs: 8500.00 Life of air hose : 800 hours Use rate of air hose per hr ( Cost / Life ) Rs: 10.63 RATE ANALYSIS A. MATERIALS: Sl No Perticulars Unit Rm Rm Rm Hour Hour kg kg ltr kg Nos Rm Rm LS Quantity 147.00 147.00 11.00 15.00 2.00 37.00 147.00 27.00 4.00 18.00 210.00 20.00 5.00 UNIT : 368.00 cum Rate in Rs. 106.25 9.00 20.00 10.63 8.13 50.00 21.00 38.00 44.00 4.50 7.00 5.00 26.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 15618.75 1323.00 220.00 22.00 159.38 16.25 1850.00 3087.00 1026.00 176.00 81.00 1470.00 100.00 130.00 25279.38 252.79 2527.94 1263.97 29324.08

1 Use rate of T.C bit 100 mm dia 2 Use rate of Extension rod with sleeve 3 Use rate of Jack hammer drill rod 1.5 m Reconditioning charges @ 10 % 4 Use rate of 50 m air hose for waggon drill Use rate of 25 m air hose for JH 2 Nos 5 High strength ANFO booster 6 ANFO 7 Diesel oil 8 Explosive small dia ( Kelvex-220 ) 9 Ordinary detonators 10 D-cord 11 Detonating fuse coil 12 Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour 20

Quantity 27.00 27.00 9.00 9.00 1.00 1.00 16.00 16.00 15.00 15.00

1 Tippers 5 cum capacity Fuel / Energy charges 2 Shovel 0.85 cum capacity Fuel / Energy charges 3 Angle dozer Fuel / Energy charges 4 Air compressor 8.5 cmm ( diesel ) Fuel / Energy charges 5 Waggon drill Fuel / Energy charges

Rate in Rs. 240.00 198.00 1057.00 575.00 1034.00 402.00 185.00 588.00 191.00 6.00

Amount in Rs. 6480.00 5346.00 9513.00 5175.00 1034.00 402.00 2960.00 9408.00 2865.00 90.00

6 Jack hammer Fuel / Energy charges

Hour Hour

2.00 2.00

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9 10 11 12 13

13.00 26.00 CANAL AND ALLIED 4.00 8.00 WORKS Total Rs: 43307.00 Rs: 433.07 Rs: 2042.90 Rs: 2165.35 Rs: 47948.32

Description

Unit Hour Hour Hour Hour Hour Hour Day Day Day Day Day Day Day

Quantity 27.00 9.00 1.00 16.00 15.00 2.00 1.00 1.00 1.00 1.00 1.00 2.00 2.00

Crew for Tipper Crew for Shovel Crew for Dozer Crew for Air compressor Crew for Waggon drill Crew for Jack hammer Maistry Blaster Helper blaster Crowbarman Stone breaker Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 41.70 57.30 57.30 52.90 65.50 81.80 102.90 108.35 102.90 102.90 106.95 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 1125.90 515.70 57.30 846.40 982.50 163.60 102.90 108.35 102.90 102.90 106.95 186.70 182.70 4584.80 45.85 458.48 687.72 229.24 6006.09

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 368.00 cum Rate per cum Assuming use of Jack hammers & Waggon drills in 50 : 50 ratio Rate per cum Rate approved per cum SECTION: CANAL AND ALLIED WORKS. YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs: Rs:

29324.08 47948.32 6006.09 83278.48 916.06 84194.55 229.00 254.00 210.00 ITEM No: 6.b

ITEM: Excavation in hard rock of all toughness including boulders above 0.6 m diameter(0.113 cum) by approved controlled blasting methods by using delay detonators and controlling flying of rock fragments by suitable muffling arrangements for canals, cut-off trench of embankments, filter / catch water drains, other appurtenent structures etc., adopting only jack hammer holes and minimising damage to side slopes in water prism by adopting any one or combination of line drilling / pre-splitting / smooth blasting techniques, cost of all materials, machinery, labour, placing excavated rock neatly in approved dump area as directed etc., complete with initial lead upto 1 km and depth of cut upto 18 m below ground level. Note: For depth of cut more than 18 m below ground level increase the basic rate by 5 %. DATA: Work requires: - use of delay detonators to reduce ground vibrations. - covering blasting area with chain link mesh or waste conveyor belts or waste tyres and sand bags to prevent flying of rock fragments during blasting. 10.80 m 8.4 m

1 0.25 10.175 m 21

1.25 m

CANAL AND ALLIED WORKS

1.2 m -1.0 m All detonators in this row are 150 ms delay type All detonators in this row are 125 ms delay type All detonators in this row are 100 ms delay type All detonators in this row are 75 ms delay type All detonators in this row are 50 ms delay type All detonators in this row are 25 ms delay type All detonators in this row are 0 ms delay type Free face SKETCH SHOWING DRILLING & BLASTING PATTERN Assume 10.80 m width of canal at the bench level and 1.25 m average depth of cutting. Assume side slopes of 0.25 horizontal to 1 vertical. Generally, the length of canal bench to be excavated per blast shall not be more than 7 m to avoid tight muck pile requiring higher digging time for shovel. Sectional area of excavation ( 10.80 + 10.175 ) x 0.5 x 1.25 : 13.11 sqm Consider 7 burden distance for excavation per blast. Number of rows considered : 7 No. Length of canal for 7 rows ( 7 x 1.00 ) : 7.00 m Quantity of excavation for 7 m length ( 13.11 x 7.00 ) say : 92.00 cum 1. Drilling and Blasting: Consider drilling by Jack hammers and mucking by combination of Shovel and Tippers. The burden ( distance of hole from free face of excavation ) is considered at 25 to 30 times dia of hole and spacing of holes is considered at 1.20 to 1.25 times burden. Burden distance for 32 mm dia jack hammer holes ( 0.032 x 30 ) say : 1.00 m Spacing of holes ( 0.032 x 30 x 1.25 ) : 1.20 m Grid spacing of holes for 32 mm dia jack hammer holes : 1.00 x 1.20 m Depth of drilling per hole : 1.40 m Effective depth of pull considering 10 % sub-drilling : 1.25 m Rate of drilling by jack hammer in hard rock per hour : 6.00 m Rate of drilling per hour with 50 min / hour working ( 6 x 50 / 60 ) say : 5 m No.of holes in 7 rows @ 1.2 m interval ( 4 x 8 + 3 x 9 + 16 ) : 75 Nos Length of drilling for 75 holes @ 1.4 m per hole ( 75 x 1.4 ) : 105 m Add drilling for secondary blasting for 5% quantity @ 0.6 m / cum say : 3 m Total : 108.00 m

22

CANAL AND ALLIED WORKS

Time for drilling 108 m for 2 jack hammers ( 108 / 2 / 5 ) : 10.80 hours Drilling and Blasting pattern : Pattern of holes : Staggered Hole initiation : Bottom Initiation system : Short delay detonators Delay system : 25 ms interval Initiation pattern : Straight line row by row 2. Muffling arrangements: For controlling flying of rock fragments during blasting consider covering the blasting area with 20 guage 50 x 50 mm chain link mesh and sand bags. 10 % extra area of wire mesh is considered for overlaps. Area of chain link mesh for controlled blast area ( 12 x 8 x 1.1) say : 106 sqm No.of 30 to 40 kg sand bags at 1 per hole ( 75 x 1 ) : 75 Nos Add 20 % extra for edges : 15 Nos Total : 90 Nos 3. Disposal of excavated rock : Quantity of excavation ( in-situ ) : 92.00 cum Capacity of shovel bucket : 0.85 cum Capacity of shovel bucket under heaped condition : 1.00 cum Capacity of tipper : 5.00 cum Lead for disposal of excavated rock rock : Upto 1 km Speed for loaded tipper under canal excavation condition : 15 km / hr Speed for empty tipper under canal excavation condition : 15 km / hr Turning and unloading time : 2.00 min Shovel digging and loading cycle per bucket : 45 sec In-situ qty / bucket for 40 % bulkage of hard rock ( 1 /1.40 ) : 0.71 cum In-situ qty per load for 40 % bulkage of hard rock ( 5 /1.40 ) : 3.57 cum Number of buckets per load ( 3.57 / 0.71 ) say : 5 buckets Ideal cycle time for loading 5 buckets ( 5 x 45 / 60 ) : 3.75 min The ideal cycle time for shovel requires spotting of a tipper within 3.75 minutes near the shovel. However, in practice for dam or canal excavation the space available may not permit positioning of tippers on either side of the shovel. Generally one tipper has to move after loading to position next tipper for loading. Assuming one loading cycle extra, the corrected cycle time for shavel will be ( 6 x 45 / 60 ) 4.50 min Round trip cycle time for tipper: Cycle time of shovel for digging & loading : 4.50 min Time for (av ) 0.75 km haulage under load ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and un-loading : 2.00 min Time for average 0.75 km return trip ( 0.75 x 60 / 15 ) : 3.00 min Time for turning and spotting : 0.50 min Total : 13.00 min

23

CANAL AND ALLIED WORKS

4.

5.

6.

7.

No.of tippers to match corrected cycle time of shovel ( 13.00 / 4.50) : 2.9 Nos Output of tipper / hr with 50 min working / hr ( 50 x 3.57 / 13.00 ) : 13.73 cum Deploy 0.9 cum shovel and 3 tippers for disposal of excavated rock. Output of 1 shovel & 3 tippers per hour ( in-situ qty ) ( 13.73 x 2.9 ) : 39.80 cum Out of the total blasted rock some residual muck at the bed needs to be removed by deploying manual labour. Assume residual muck at bed at 0.10 cum / sqm of bed area. Quantity of muck to be disposed by shovel ( 92 - 0.1 x 70 ) 85 cum Time for disposal of 85 cum by shovel ( 85 / 39.80 ) : 2.2 hours For levelling 85 cum muck in dump yard deploy 1 dozer for : 0.25 hour Quantity of muck to be disposed by manual labour ( 92 - 85 ) 7 cum Requirement of materials : Jack hammer drill rod : 108 m drilling Quantity of Explosive ( Kelvex-220 ) at 0.3 kg / cum ( 92 x 0.3 ) : 27.60 kg Add for secondary blasting @ 0.2 kg / cum ( 92 x 0.05 x 0.2 ) : 0.90 kg Total : 28.50 kg Ordinary detonators for secondary blasting 8 holes of 0.6 m each : 8 Nos. Electric short delay detonators @ 1 per hole for main blast : 75 Nos Detonating fuse coil : 120 Rm 50 x 50 mm chain link wire mesh 119 sqm Sand bags 0.025 cum 90 Nos Requirement of machinery : Deploy 0.85 cum capacity shovel for 2.2 hours for digging and loading 85 cum. Deploy 3 tippers 5 cum capacity for 2.2 hours for disposal of 85 cum. Deploy 1 air compressor 8.5 cmm capacity for 11 hours. Deploy 2 jack hammers for 11 hours for drilling. Deploy 1 angle dozer for 0.25 hour for levelling muck in dump area. Requirement of workforce ( other than machinery crew ) : Deploy 1 Crowbarman, 1 Stone breaker for 1 day for levelling bed. Deploy 2 heavy and 2 light mazdoors for disposal of 9 cum residual muck at bed level and for other miscellaneous works. Deploy 1 blaster and 1 blasting helper for loading and blasting. Deploy 1 maistry. Use rate of materials : Cost of drill rod 1.5 m long @ Rs: Rs: 3000.00 / Each Rs: 3000.00 Life of drill rod for drilling in hard rock with reconditioning : 150 m Use rate of drill rod per Rm drilling ( cost / life ) Rs: 20.00 Length of air hose for drilling for each jack hammer : 50 m Cost of 25 mm dia 50 m air hose @ Rs: 130.00 / Rm Rs: 6500.00 Life of air hose : 800 hours Use rate of air hose per hr ( cost / life ) Rs: 8.13 Cost of wire mesh @ Rs: 120.00 / sqm Rs: 120.00 less salvage value at 10 % Rs: -12.00 Total Rs: 108.00 Add for replacement of damaged mesh @ 10 % Rs: 10.80 Total Rs: 118.80 Life of wire mesh with 25 % replacement each use : 3 uses Use rate of wire mesh / use / sqm ( cost / life ) Rs: 39.60 Cost of empty cement bag per No. @ Rs: 1.00 / Each Rs: 1.00 Cost of sand / bag for 0.025 cum @ Rs: 115.00 / cum Rs: 2.88 Add for 1 km lead/loading/unloading charges for 0.015 cum Rs: 1.63 Filling charges @ 2 heavy mazdoors per 100 bags / day Rs: 1.87 Total cost per bag Rs: 7.37

24

Life of sand bag Use rate of sand bag / use / bag RATE ANALYSIS A. MATERIALS: Sl No Perticulars Unit Rm Hour sqm Nos kg Nos Nos Rm LS

( cost / life ) UNIT : Quantity 108.00 22.00 106.00 90.00 28.50 8.00 75.00 120.00 2.00

: 1 use CANAL AND ALLIED Rs: 7.37 WORKS 92.00 cum Rate in Rs. 20.00 8.13 39.60 7.37 44.00 4.50 15.00 5.00 26.00 Total Rs: Rs: Rs: Rs: Rs: Amount in Rs. 2160.00 216.00 178.75 4197.60 663.71 1254.00 36.00 1125.00 600.00 52.00 10483.06 104.83 1048.31 524.15 12160.34

1 Use rate of Jack hammer drill rod 1.5 m Reconditioning charges @ 10 % 2 Use rate of 50 m air hose 2 Nos. 3 Use rate of wire mesh 4 Use rate of sand bag 5 Explosive small dia. (Kelvex-220 ) 6 Ordinary detonators 7 Electric short delay detonators 8 Fuse coil 9 Sundries Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @

1% 10% 5% Total cost of Materials :

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour

Quantity 2.20 2.20 0.25 0.25 6.60 6.60 11.00 11.00 22.00 22.00

1 Shovel 0.85 cum capacity Fuel / Energy charges 2 Angle dozer 90 hp Fuel / Energy charges 3 Tippers 5 cum capacity 3 Nos. Fuel / Energy charges 4 Air compressor 8.5 cmm ( diesel ) 1 No Fuel / Energy charges 5 Jack hammers 2 Nos. Fuel / Energy charges

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9 10 11 12

Rate in Rs. 1057.00 575.00 1034.00 402.00 240.00 198.00 185.00 588.00 13.00 4.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 2325.40 1265.00 258.50 100.50 1584.00 1306.80 2035.00 6468.00 286.00 88.00 15717.20 157.17 922.83 785.86 17583.06

Description

Unit Hour Hour Hour Hour Hour Day Day Day Day Day Day Day

Quantity 2.20 0.25 6.60 11.00 22.00 1.00 1.00 1.00 1.00 1.00 2.00 2.00

Crew for Shovel Crew for Angle dozer Crew for Tipper Crew for Air compressor Crew for Jack hammer Maistry Blaster Helper blaster Crowbarman Stone breaker Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 57.30 57.30 41.70 52.90 81.80 102.90 108.35 102.90 102.90 106.95 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 126.06 14.33 275.22 581.90 1799.60 102.90 108.35 102.90 102.90 106.95 186.70 182.70 3690.51 36.91 369.05 553.58 184.53 4834.56

ABSTRACT: A. Cost of Materials B. Hire charges of Machinery C. Cost of Labour 25

Rs: Rs: Rs:

12160.34 17583.06 4834.56

CANAL AND ALLIED WORKS

Add for other enabling works @ Total cost for

1.10% 92.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

TOTAL Rs: Rs: Rs: Rs: Rs:

34577.97 380.36 34958.32 380.00 340.00 ITEM No: 7

SECTION: CANAL AND ALLIED WORKS.

ITEM: Providing impervious hearting embankment with selected soil from approved borrow areas in layers of 250 to 300 mm before compaction including cost of all materials, machinery, labour, all operations such as excavation, sorting out, transporting, spreading in layer of specified thickness, breaking clods, sectioning, watering, compacting each layer to density control of not less than 95 percent or as stipulated by power roller etc., complete with initial lead upto 1 km and all lifts. DATA: Capacity of shovel bucket Capacity of shovel bucket under heaped condition Capacity of tipper Lead for conveyance of soil Speed for loaded tipper under haul road condition Speed for empty tipper under haul road condition Turning and unloading time Shovel digging and loading cycle per bucket 1. Quantity of embankment : In-situ qty / bucket for 15 % bulkage of soil In-situ quantity per load for 20 % bulkage of soil Number of buckets per load Cycle time for loading 8 buckets Round trip cycle time for tipper: Ideal cycle time of shovel for digging & loading Time for 1km haulage under load Time for turning and un-loading Time for 1 km return trip Time for turning and spotting : : : : : : : : ( 0.58 / 1.15 ) ( 5.0 / 1.2 ) ( 4.00 / 0.50 ) ( 8 x 20 / 60 ) : : say : say : 0.50 cum 0.58 cum 5.00 cum Upto 1 km 20 km / hr 25 km / hr 2.00 min 20 sec 0.50 cum 4.00 cum 8 buckets 2.67 min

: 2.67 min : 3.00 min : 2.00 min ( 60 / 25 ) : 2.40 min : 0.50 min : 10.57 min No.of tippers to match corrected cycle time of shovel (10.57 / 2.67) : 4 Nos Output of tipper / hr with 50 min working / hr ( 50 x 4.00 / 10.57 ) : 18.92 cum Output for 4 tippers per day ( 4 x 18.92 x 8 ) say : 605 cum The in-situ dry density of soil in borrow area will be generally less than dry density of compacted embankment. Therefore, the rolled embankment quantity will be slightly less than the borrow area in-situ quantity. The extent of shrinkage in quantity depends on the degree of compaction. For 95 % density control of embankment a shrinkage factor of 5 % may be assumed. Quantity of embankment considering 5 %shrinkage ( 605 x 0.95 ) : 575 cum Qty of soil for computing royalty charges @ 1.6 t / cum ( 575x1.6 ) : 920 tonnes ( 60 / 20 )

26

CANAL AND ALLIED WORKS

2. Stripping of borrow area : Generally borrow area is stripped once in a week for 6 days requirement of soil. Area to be stripped assuming 2.0 m depth of cut ( 605 x 6 / 2.0 ) : 1815 sqm Depth of stripping : 0.25 m Qty of stripping with 5 % extra area ( 1815 x 1.05 x 0.25 ) : 476 cum Output of dozer per hr with 50 min / hr working for stripping : 100 cum Time required for stripping 476 cum ( 476 / 100 ) : 4.76 hours Consider 6 hours including time for levelling stripped siol / dozer shifting time. Time required for stripping for one day embankment work 575 cum : 1.00 hour 3. Collection of soil for embankment : Deploy one 0.50 cum capacity shovel for 8 hours for digging and loading soil. Deploy 4 tippers of 5.00 cum capacity for 8 hours to convey soil to embankment area. 4. Spreading soil in 250 to 300 mm layer : Quantity of loose soil to be spread ( 605 x 1.20 ) : 726 cum Output of dozer for levelling per hour : 250 cum Time required for levelling 726 cum ( 726 / 250 ) say : 3.00 hours 5. Watering : Generally soil in the borrow area will be in moist condition. In the beginning of the season no watering may be necessary and in summer months about 8 to 10 percent watering may be needed to maintain the soil moisture within OMC plus or minus 3 percent limit. Assuming seasonal average of 4 to 5 percent watering by weight, daily requirement of water for 575 cum of embankment will be about 5 tanker loads of 8000 ltrs each. Deploy 8000 ltr capacity water tanker for 5 hours daily for watering before rolling. Deploy 5 hp pump for 2.5 hours. 6. Compaction : Soil collected for embankment layer gets compacted to some extent during levelling. Generally 8 to 10 passes of vibratory pad foot roller is adequate for achieving specified density control of 95 percent. Effective length of roller drum : 1.90 m Speed of roller per hour : 4.0 km Thickness of layer : 0.3 m Number of roller passes to achieve specified density control : 9 Nos Output of roller / hr with 50 min / hr working and 75 % effenciancy ( 1.9 x 4000 x 0.3 x 0.75 / 9 ) x 50 / 60 say : 160 cum Time for rolling 726 cum loose soil in embankment layer ( 726/160) say : 4.5 hours 7. Sorting out / sectioning / labour for testing etc : Assume 2 heavy and 2 light mazdoors. RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars NIL Unit Quantity 0.00 0.00 1% 10% 5% Rs: 5.00 / tonne Total cost of Materials : UNIT : 575.00 cum Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs: Rs: Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 4600.00 4600.00

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @ Add Royalty charges on 920 t soil @

27

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour LS

Quantity 4.00 4.00 8.00 8.00 32.00 32.00 2.50 2.50 5.00 5.00 4.50 4.50 2.00

1 Angle dozer Fuel / Energy charges 2 Shovel 0.50 cum capacity Fuel / Energy charges 3 Tippers 5.00 cum capacity 4 Nos. Fuel / Energy charges 4 Pump 5 hp ( diesel ) Fuel / Energy charges 5 Water tanker 8000 ltr Fuel / Energy charges 6 Vibratory pad foot roller 8 tonne Fuel / Energy charges 7 Sundries

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery : C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9

AND ALLIED WORKS Rate CANAL Amount in Rs. in Rs. 1034.00 4136.00 402.00 1608.00 639.00 5112.00 314.00 2512.00 240.00 7680.00 198.00 6336.00 6.00 15.00 52.00 130.00 237.00 1185.00 198.00 990.00 1012.00 4554.00 679.00 3055.50 26.00 52.00 Total Rs: 37365.50 Rs: 373.66 Rs: 1468.35 Rs: 1868.28 Rs: 41075.78

Description

Unit Hour Hour Hour Hour Hour Hour Day Day Day

Quantity 4.00 8.00 32.00 2.50 5.00 4.50 2.00 2.00 2.00

Crew for Dozer Crew for Shovel Crew for Tipper Crew for Pump Crew for Water tanker Crew for Roller Maistry Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Rate in Rs. 57.30 57.30 41.70 26.20 41.70 66.50 102.90 93.35 91.35 Total Rs: Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 229.20 458.40 1334.40 65.50 208.50 299.25 205.80 186.70 182.70 3170.45 31.70 317.05 475.57 158.52 4153.29

ABSTRACT: A. Cost of Materials including royalty charges B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 575.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs:

4600.00 41075.78 4153.29 49829.07 548.12 50377.19 88.00 88.00 ITEM No: 8

SECTION: CANAL AND ALLIED WORKS.

ITEM: Providing semi-pervious / pervious casing embankment using soil from approved borrow area in layers of 250 to 300 mm before compaction including cost of all materials, machinery, labour, all operations such as excavation, sortingout, transporting, spreading in layer of specified thickness, breaking clods, sectioning, watering, compacting to density control of not less than 95 percent or as stipulated by power roller etc., complete with initial lead upto 1 km and all lifts. DATA: Capacity of shovel bucket Capacity of shovel bucket under heaped condition Capacity of tipper Lead for conveyance of soil Speed for loaded tipper under haul road condition Speed for empty tipper under haul road condition Turning and unloading time Shovel digging and loading cycle per bucket 28 : : : : : : : : 0.50 cum 0.58 cum 5.00 cum Upto 1 km 20 km / hr 25 km / hr 2.00 min 30 sec

CANAL AND ALLIED WORKS

1. Quantity of embankment : In-situ qty per bucket for 15 % bulkage of soil In-situ quantity per load for 20 % bulkage of soil Number of buckets per load Cycle time for loading 8 buckets Round trip cycle time for tipper: Ideal cycle time of shovel for digging & loading Time for 1km haulage under load Time for turning and un-loading Time for 1 km return trip Time for turning and spotting

( 0.58 / 1.15 ) ( 5.0 / 1.2 ) ( 4.00 / 0.50 ) ( 8 x 30 / 60 )

: 0.50 cum say : 4.00 cum say : 8 buckets say : 4.00 min

2.

3.

4.

5.

6.

: 4.00 min : 3.00 min : 2.00 min ( 60 / 25 ) : 2.40 min : 0.50 min Total : 11.90 min No.of tippers to match corrected cycle time of shovel (11.90 / 4.00) : 3 Nos Output of tipper / hr with 50 min working / hr ( 50 x 4.00 / 11.90 ) : 16.80 cum Output for 3 tippers per day ( 3 x 16.80 x 8 ) say : 403 cum The in-situ dry density of soil in borrow area will be generally less than dry density of compacted embankment. Therefore, the rolled embankment quantity will be slightly less than the borrow area in-situ quantity. The extent of shrinkage in quantity depends on the degree of compaction. For 95 % density control of embankment a shrinkage factor of 5 % may be assumed. Quantity of embankment considering 5 % shrinkage ( 403 x 0.95 ) say : 385 cum Qty of soil for computing royalty charges @ 1.6 t / cum ( 385x1.6 ) : 616 tonnes Stripping of borrow area : Generally borrow area is stripped once in a week for 6 days requirement of soil. Area to be stripped assuming 2.0 m depth of cut ( 403 x 6 / 2.0 ) : 1209 sqm Depth of stripping : 0.20 m Quantity of stripping with 5 % extra area ( 1209 x 1.05 x 0.20 ) : 254 cum Output of dozer per hr with 50 min / hr working for stripping : 70 cum Time required for stripping 254 cum : 3.60 hours Consider 4.5 hours including time for levelling stripped siol / dozer shifting time. Requirement of dozer for one day work 403 cum say : 0.75 hours Collection of soil for embankment : Deploy one 0.50 cum capacity shovel for 8 hours for digging and loading soil. Deploy 3 tippers of 5.00 cum capacity for 8 hours to convey soil to embankment area. Spreading soil in 250 to 300 mm layer : Quantity of loose soil to be spread ( 403 x 1.20 ) : 484 cum Output of dozer for levelling per hour : 250 cum Time required for levelling 484 cum say : 2.00 hours Watering : Generally soil in the borrow area will be in moist condition. In the beginning of the season no watering be may necessary and in summer months about 8 to 10 percent watering may be needed to maintain the soil moisture within OMC plus or minus 3 percent limit. Assuming seasonal average of 4 to 5 percent watering by weight, daily requirement of water for 385 cum of embankment will be about 4 tanker loads of 8000 ltrs each. Deploy 8000 ltr capacity water tanker for 4 hours daily for watering before rolling. Deploy 5 hp pump for 2 hours. Compaction : Soil collected for embankment layer gets compacted to some extent during levelling. Generally 8 to 10 passes of vibratory pad foot roller is adequate for achieving specified density control of 95 percent. Effective length of roller drum : 1.90 m Speed of roller per hour : 4.0 km Thickness of layer : 0.3 m Number of roller passes to achieve specified density control : 9 Nos Output of roller / hr with 50 min / hr working and 75 % effenciancy ( 1.9 x 4000 x 0.3 x 0.75 / 9 ) x 50 / 60 say : 160 cum ( 60 / 20 )

29

CANAL AND ALLIED WORKS

Time for rolling 484 cum loose soil in embankment layer 7. Sorting out / sectioning / labour for testing etc : Assume 2 heavy and 2 light mazdoors. RATE ANALYSIS A. MATERIALS: Sl No 1 Perticulars NIL Unit Quantity 0.00 0.00 1% 10% 5% Rs: 5.00 / tonne Total cost of Materials : UNIT :

say : 3 hours

385.00 cum Rate in Rs. 0.00 0.00 Total Rs: Rs: Rs: Rs: Rs: Rs: Amount in Rs. 0.00 0.00 0.00 0.00 0.00 0.00 3080.00 3080.00

Add for small Tools and Plants @ Add for Contractor's Profit @ Add for Contractor's Overheads @ Add Royalty charges on 616 t soil @

B. MACHINERY: Sl No

Description

Unit Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour Hour LS

Quantity 2.75 2.75 8.00 8.00 24.00 24.00 2.00 2.00 4.00 4.00 3.00 3.00 2.00

1 Angle dozer 90 hp Fuel / Energy charges 2 Shovel 0.50 cum capacity Fuel / Energy charges 3 Tippers 5.00 cum capacity 3 Nos. Fuel / Energy charges 4 Pump 5 hp ( diesel ) Fuel / Energy charges 5 Water tanker 8000 ltr Fuel / Energy charges 6 Vibratory pad foot roller 8 tonne Fuel / Energy charges 7 Sundries

Add for small Tools and Plants @ 1% Add for Contractor's Profit on DPOL / Energy @ 10% Add for Contractor's Overheads @ 5% Total hire charges of Machinery :

Rate in Rs. 1034.00 402.00 639.00 314.00 240.00 198.00 6.00 52.00 237.00 198.00 1012.00 679.00 26.00 Total Rs: Rs: Rs: Rs: Rs:

Amount in Rs. 2843.50 1105.50 5112.00 2512.00 5760.00 4752.00 12.00 104.00 948.00 792.00 3036.00 2037.00 52.00 29066.00 290.66 1135.45 1453.30 31945.41

30

C. LABOUR: Sl No 1 2 3 4 5 6 7 8 9

Description

Unit Hour Hour Hour Hour Hour Hour Day Day Day

Quantity 2.75 8.00 24.00 2.00 4.00 3.00 2.00 2.00 2.00

Crew for Dozer Crew for Shovel Crew for Tipper Crew for Pump Crew for Water tanker Crew for Roller Maistry Heavy mazdoor Light mazdoor Add for small Tools and Plants @ Add for Contractor's Profit @ Add for hidden cost on Labour @ Add for Contractor's Overheads @

1% 10% 15% 5% Total cost of Labour :

Amount Rate CANAL AND ALLIED WORKS in Rs. in Rs. 57.30 157.58 57.30 458.40 41.70 1000.80 26.20 52.40 41.70 166.80 66.50 199.50 102.90 205.80 93.35 186.70 91.35 182.70 Total Rs: 2610.68 Rs: 26.11 Rs: 261.07 Rs: 391.60 Rs: 130.53 Rs: 3419.98

ABSTRACT: A. Cost of Materials including royalty charges B. Hire charges of Machinery C. Cost of Labour Add for other enabling works @ Total cost for 1.10% 385.00 cum Rate per cum Rate approved per cum YEAR : 2007-08

Rs: Rs: Rs: TOTAL Rs: Rs: Rs: Rs: Rs:

3080.00 31945.41 3419.98 38445.39 422.90 38868.29 101.00 101.00 ITEM No: 9

SECTION: CANAL AND ALLIED WORKS.

ITEM: Providing hearting / casing embankment with homogeneous soil from approved borrow areas in layers of 250 to 300 mm before compaction including cost of all materials, machinery, labour, all operations such as excavation, sorting out, transporting, spreading in layer of specified thickness, breaking clods, sectioning, watering, compacting each layer to density control of not less than 95 percent or as stipulated by power roller etc., complete with initial lead upto 1 km and all lifts. DATA: Capacity of shovel bucket Capacity of shovel bucket under heaped condition Capacity of tipper Lead for conveyance of soil Speed for loaded tipper under haul road condition Speed for empty tipper under haul road condition Turning and unloading time Shovel digging and loading cycle per bucket 1. Quantity of embankment : In-situ qty / bucket for 15 % bulkage of soil In-situ quantity per load for 20 % bulkage of soil Number of buckets per load Cycle time for loading 8 buckets Round trip cycle time for tipper: Ideal cycle time of shovel for digging & loading Time for 1km haulage under load Time for turning and un-loading Time for 1 km return trip Time for turning and spotting : : : : : : : : ( 0.58 / 1.15 ) ( 5.0 / 1.2 ) ( 4.00 / 0.50 ) ( 8 x 22 / 60 ) : : say : say : 0.50 cum 0.58 cum 5.00 cum Upto 1 km 20 km / hr 25 km / hr 2.00 min 22 sec 0.50 cum 4.00 cum 8 buckets 2.93 min

: 2.93 min : 3.00 min : 2.00 min ( 60 / 25 ) : 2.40 min : 0.50 min Total : 10.83 min No.of tippers to match corrected cycle time of shovel (10.83 / 2.93) : 3.7 Nos Output of tipper / hr with 50 min working / hr ( 50 x 4.00 / 10.83 ) : 18.47 cum Output for 3.7 tippers per day ( 3.7 x 18.47 x 8 ) say : 547 cum The in-situ dry density of soil in borrow area will be generally less than dry density of compacted embankment. Therefore, the rolled embankment quantity will be slightly less than the borrow area in-situ quantity. The extent of shrinkage in quantity depends on the degree of compaction. For 95 % density control of embankment a shrinkage factor of 5 % may be assumed. Quantity of embankment considering 5 % shrinkage ( 547 x 0.95 ) : 520 cum Qty of soil for computing royalty charges @ 1.6 t / cum ( 520x1.6 ) : 832 tonnes 2. Stripping of borrow area : Generally borrow area is stripped once in a week for 6 days requirement of soil. 31 ( 60 / 20 )

CANAL AND ALLIED WORKS

3.

4.

5.