Professional Documents

Culture Documents

Wet Seat and Back Leak Test Machine: Brief Description

Wet Seat and Back Leak Test Machine: Brief Description

Uploaded by

Arvin BabuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wet Seat and Back Leak Test Machine: Brief Description

Wet Seat and Back Leak Test Machine: Brief Description

Uploaded by

Arvin BabuCopyright:

Available Formats

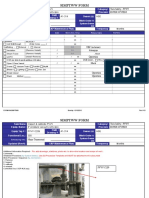

Wet seat and back leak test machine

Brief description

The machine is used to determine the following characteristics of nozzles: Reading of the Data Matrix Code Optical measurement of the wet seat (volumetric and/or pixel) Measurement of the back leak (volumetric and/or pressure drop) Disassembly of nozzle and needle

Loading / unloading is done automatically by a 3-axis scara robot that takes the parts from a tray and put them into the rotary table. Passed parts will be set back into the tray, scrap parts are sorted into error chutes.

General view

Highlights

Low cycle time (13,5 seconds) Back leak measurement (volumetric and/or pressure drop) Wet seat measurement with a camera Descriptive visualization of expiring processes and results Operation panel with touch screen and comfortable user interface

Technical data

Test pressure Cycle time Test temperature Test media: 50 bar 500 bar 13,5s 25 C - 40 C V-Oil 1404

Wet seat station and DMC reading station

Sonplas GmbH Sachsenring 57 94315 Straubing Tel:+49-9421-9275-0 Email: info@sonplas.com www.sonplas.com

You might also like

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Engine Control JazzDocument170 pagesEngine Control Jazzhumam50% (2)

- Durag D-R 300-40Document55 pagesDurag D-R 300-40michael75% (4)

- V and VDocument11 pagesV and Vdakshina656087No ratings yet

- ApplicationGuide PDFDocument17 pagesApplicationGuide PDFsteam100deg1658No ratings yet

- Simatic: First StepsDocument24 pagesSimatic: First StepsIgor TusjakNo ratings yet

- SIMPTWW PSV C12aDocument4 pagesSIMPTWW PSV C12aVijay RajaindranNo ratings yet

- TPMDocument32 pagesTPMvignesh_sundaresan_1No ratings yet

- TPMDocument32 pagesTPMmanolo6490No ratings yet

- SIMATIC S7 Graph For S7-300 400 - Getting StartedDocument24 pagesSIMATIC S7 Graph For S7-300 400 - Getting StartedErica BeasleyNo ratings yet

- Service Training: Mcube Technology Co., LTDDocument54 pagesService Training: Mcube Technology Co., LTDJeosafá PereiraNo ratings yet

- Simptww PVVV C209Document4 pagesSimptww PVVV C209Vijay RajaindranNo ratings yet

- Project Presentation (CS499) - Albert MairaDocument30 pagesProject Presentation (CS499) - Albert Mairakingunge100% (1)

- Field Measurement: On-The Job-TrainingDocument18 pagesField Measurement: On-The Job-Training趙富煌No ratings yet

- SAP PP Work CentreDocument15 pagesSAP PP Work CentrebethojiNo ratings yet

- Indicador Fairbanks IND HR2500 QF1Document57 pagesIndicador Fairbanks IND HR2500 QF1Raul PadillaNo ratings yet

- Hygk307 ManualDocument16 pagesHygk307 Manualkenlavie1No ratings yet

- Problem Solving Basic 7 QC ToolsDocument53 pagesProblem Solving Basic 7 QC Toolsshukumar_24100% (4)

- Computer Numerically Controlled (CNC) MachiningDocument8 pagesComputer Numerically Controlled (CNC) MachiningGurvinder SinghNo ratings yet

- Defecte Presiune PneuriDocument37 pagesDefecte Presiune PneuriGoranka Bulatovic IlicNo ratings yet

- Chapter 3 - Plant Location, Layout Line Balancing (Part 2)Document17 pagesChapter 3 - Plant Location, Layout Line Balancing (Part 2)shirleyna saraNo ratings yet

- A PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)Document61 pagesA PLC System: CPU Module (Left) and An I/O Rack (Right) (Allen Bradley PLC-5)Muhammad Zaka100% (2)

- Basis ArticlesDocument11 pagesBasis ArticlesKrishna PrasadNo ratings yet

- Motion and Time Study (Practical)Document18 pagesMotion and Time Study (Practical)Francois de VilliersNo ratings yet

- FALCON Technical Datasheet GBDocument18 pagesFALCON Technical Datasheet GBegr00No ratings yet

- CTS EnglishDocument4 pagesCTS EnglishAdolfo AnguloNo ratings yet

- Capacity VerificationDocument5 pagesCapacity VerificationHarsha MP100% (2)

- OEE ExplainedDocument3 pagesOEE Explainedvvv5452100% (2)

- DCS TrainingDocument29 pagesDCS TrainingShahzaibUsman100% (2)

- SATR-J-6501 - Rev 0 PDFDocument5 pagesSATR-J-6501 - Rev 0 PDFAdel KlkNo ratings yet

- FMEA FDocument58 pagesFMEA Fstd_88886871No ratings yet

- SabicTahir - Leading KPI Zenica March'10Document3 pagesSabicTahir - Leading KPI Zenica March'10mac1677No ratings yet

- KPI OEE Downtime AnalyticsDocument16 pagesKPI OEE Downtime Analyticsrasa55555No ratings yet

- Data Sheet - DCS Master P-5000 IO Test System PDFDocument12 pagesData Sheet - DCS Master P-5000 IO Test System PDFtriplbingaziNo ratings yet

- Introduction To Vibration Analysis Program - Bnetly NevadaDocument52 pagesIntroduction To Vibration Analysis Program - Bnetly NevadaSam100% (5)

- Eschmann SES2000 - Service ManualDocument46 pagesEschmann SES2000 - Service ManualAugusto Vieira50% (2)

- 20091113Document114 pages20091113emrouz100% (1)

- Next PresentationDocument22 pagesNext PresentationNurSarah Ainaa Abdul HalimNo ratings yet

- Final Qi ReportDocument11 pagesFinal Qi ReportDarshanRavalNo ratings yet

- TP04310 Interface & Applications ManualDocument162 pagesTP04310 Interface & Applications ManualAnoop JoshiNo ratings yet

- Attachment 4 Fuji CR Imaging EquipmentDocument8 pagesAttachment 4 Fuji CR Imaging EquipmentKimberly Pascual VicmudoNo ratings yet

- Chap 4 SPCDocument47 pagesChap 4 SPCماياأمال100% (1)

- Chapter 2 Problem Solving ToolsDocument67 pagesChapter 2 Problem Solving ToolsDebrina PuspitariniNo ratings yet

- FSAE Data Analysis Day 2 To PrintDocument55 pagesFSAE Data Analysis Day 2 To PrintJorge CorderoNo ratings yet

- How To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopDocument10 pagesHow To Proceed With Troubleshooting: 1 Vehicle Brought To WorkshopMohamed HarbNo ratings yet

- NC 5 Prezentare EngDocument39 pagesNC 5 Prezentare EngSolomon Bogdan-DanielNo ratings yet

- Bloomden Milling Machine X5 Operation ManualDocument21 pagesBloomden Milling Machine X5 Operation ManualAngel TrujilloNo ratings yet

- QH Talbros - PVT.LTD.: On Summer Training atDocument18 pagesQH Talbros - PVT.LTD.: On Summer Training atJashandeep Singh100% (1)

- Experiement 8 - IACDocument7 pagesExperiement 8 - IACPRAMOD MAHAJANNo ratings yet

- Software Metrics in Use: Don HarveyDocument29 pagesSoftware Metrics in Use: Don HarveysendtosayakNo ratings yet

- Tutorial PSCADDocument43 pagesTutorial PSCADJitendra TambeNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Coating PropertiesDocument1 pageCoating PropertiesArvin BabuNo ratings yet

- Quotation / Proforma: Commercial ProposalDocument1 pageQuotation / Proforma: Commercial ProposalArvin BabuNo ratings yet

- Valveseatvibration PDFDocument3 pagesValveseatvibration PDFArvin BabuNo ratings yet

- PFC 108supradicscDocument12 pagesPFC 108supradicscArvin BabuNo ratings yet

- Diesel Fuel Injector Application: "Above & Beyond Honing"Document4 pagesDiesel Fuel Injector Application: "Above & Beyond Honing"Arvin BabuNo ratings yet

- Choose User RegistrationDocument10 pagesChoose User RegistrationArvin BabuNo ratings yet

- Iamonds Are A Block S Best Friend For Honing: Pplication EportDocument5 pagesIamonds Are A Block S Best Friend For Honing: Pplication EportArvin BabuNo ratings yet

- Gun Dri L L I NG On Swi Ss Type CNC Machi NesDocument1 pageGun Dri L L I NG On Swi Ss Type CNC Machi NesArvin BabuNo ratings yet

- M CodesDocument8 pagesM CodesArvin BabuNo ratings yet

- U.S. Diamond Wheel: AbrasivesDocument1 pageU.S. Diamond Wheel: AbrasivesArvin BabuNo ratings yet

- Cause Map TemplateDocument18 pagesCause Map TemplateArvin BabuNo ratings yet

- Simpsons ParadoxDocument3 pagesSimpsons ParadoxArvin BabuNo ratings yet

- Countermeasures: To: Chuck O. From: Art S. Date: 12/10/2006Document1 pageCountermeasures: To: Chuck O. From: Art S. Date: 12/10/2006Arvin BabuNo ratings yet

- Die Casting Maintainance PDFDocument32 pagesDie Casting Maintainance PDFgksp100% (1)

- M CodesDocument8 pagesM CodesArvin BabuNo ratings yet

- Data Collection Plan: From Process Map From C&E Matrix or Fmea Input/output Signal/Control/Noise Continuous/ AttributeDocument7 pagesData Collection Plan: From Process Map From C&E Matrix or Fmea Input/output Signal/Control/Noise Continuous/ AttributeArvin BabuNo ratings yet

- Spray Visualization System: HighlightsDocument1 pageSpray Visualization System: HighlightsArvin BabuNo ratings yet

- A S O I V S A A T: Urvey N Ndustrial Ision Ystems, Pplications ND OolsDocument38 pagesA S O I V S A A T: Urvey N Ndustrial Ision Ystems, Pplications ND OolsArvin BabuNo ratings yet