Professional Documents

Culture Documents

Mitsubishi S-N Contactors

Uploaded by

David JuyarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mitsubishi S-N Contactors

Uploaded by

David JuyarCopyright:

Available Formats

Issued November 2009

12483

DATA SHEET

SN

CONTACTORS

Based on Mitsubishi MS-N Series Datasheet

12483

The Overview (Type designation breakdown)

N10 N11 N12 N18 N20 N21 N25 N35 N50 N65 N80 N95 N125 N150 N180 N220 N300 N400 N600 N800

Frame Size

Rated capacity

220-240V

2.5

3.5

3.5

4.5

5.5

5.5

7.5

Category AC-3(kW)

380-440V

5.5

5.5

7.5

11

11

15 18.5 22

11

15 18.5 22

30

37

45

55

75

30

55

60

75

90

132 160 220 330 440

45

90

125 190 220

Number of

aux. contacts

Spec

2NO2NC

Standard

1NO 1NO 1NO1NC 1NO1NC

Special

1NC 1NC 2NO 2NO

ACCESSORIES

Additional aux.

contact blocks

Front-on1

Side-on

CONTACTORS

Open

1NO1NC2(max.)

Surge absorber3

2NO2NC1

(max.)

1NO1NC2(max.)

Provided as a standard

Attachable

Attachable

Attachable

AC operated

S-

DC operated

SD-

S- CX

Mechanical interlock unit

Finger protected

SD- CX

Mechanically latched

SL(D)-

AC operated

MSO-

DC operated

MSOD-

With phase failure protection

MSO- KP

MSO- SR

with 2 heater elements

MSO- FS

with phase failure protection

MSO- KF

Standard type

MS-

With push button

MS- PM

With phase failure protection

MS- KP

Slow trip type

with saturable reactor

Quick-trip type

Enclosed

Class IP20

STARTERS

Open

2P or 4P

Mounting on 35mm rail

Available

Notes: 1. Additional head-on type aux. contact blocks cannot be attached to the enclosed type, mechanically latched type of size N50 & N65.

2. Surge absorber is provided as a standard on ac operated contactors and starters of sizes N50 to N800.

Based on Mitsubishi MS-N Series Datasheet

Page 1 of 7

12483

12483

Technical Data of Series S-N Contactors

V

A

S-N10

690

20

S/SDN11, N12

690

20

S-N18

690

25

S-N20

690

32

S/SDN21

690

32

S-N25

690

50

S/SDN35

690

60

S/SDN50

690

80

S/SDN65

690

100

kW(A)

kW(A)

kW(A)

kW(A)

7.5(20)

7(11)

7(8)

7(6)

7.5(20)

8.5(13)

9.5(11)

8(8)

9.5(25)

13(20)

13(16)

11(10)

12(32)

20(32)

25(32)

30(32)

12(32)

20(32)

25(32)

30(32)

18(50)

30(50)

40(50)

50(50)

20(60)

35(60)

50(60)

60(60)

30(80)

50(80)

65(80)

80(80)

35(100)

65(100)

85(100)

100(100)

11

9

7

5

13

12

9

7

18

16

13

9

22

22

17

9

22

22

17

9

30

30

24

12

40

40

32

17

55

50

38

26

65

65

60

38

85

85

75

52

105

105

85

65

125

120

90

70

150

150

140

100

180

180

180

120

0.75

1.1

1.1

1.1

6

1.1

1.5

1.5

1.5

9

1.5

2.2

2.2

2.2

9

2.2

3.7

3.7

3.7

13

2.2

3.7

3.7

3.7

13

3

5.5

5.5

5.5

17

3.7

5.5

5.5

5.5

24

5.5

7.5

7.5

7.5

32

7.5

11

11

11

47

7.5

15

15

15

62

11

18.5

18.5

18.5

75

15

22

22

22

90

18.5

30

37

30

110

10

8

8

12

12

12

12

12

12

20

20

20

20

20

20

25

25

22

35

35

30

50

50

40

65

65

50

80

80

60

93

93

70

120

100

80

150

150

150

Type

Contactor

Rated insulation voltage

Conventional free air thermal current

Ith

Rated capacity for resistive loads

3-ph, Category AC-1

220-240V

380-440V

500V

690V

Rated operational current

3-ph, Category AC-3

220-240V

380-440V

500V

690V

Rated capacity for jogging of AC motors

3-ph, category AC-4

220-240V

Electrical life is ca.

380-440V

200,000 operations

500V

690V

Max. current for AC-4 duty at 440V

Rated current for DC non-inductive loads

Category DC-1

48V

100 operations/hour max.

110V

500,000 operations

220V

A

A

A

A

kW

kW

kW

kW

A

A

A

A

S/SDN80

690

135

S/SDN95

690

150

S/SDN125

690

150

S/SDN150

690

200

SN180

1000

260

S/SDN220

1000

260

S/SDN300

1000

350

S/SDN400

1000

450

S/SDN600

1000

8001

S/SDN800

1000

10002

130(350)

230(350)

300(350)

350(350)

170(450)

290(450)

380(450)

450(450)

250(660)

430(660)

570(660)

660(660)

300(800)

530(800)

700(800)

900(800)

250

250

200

150

300

300

250

220

400

400

350

300

630

630

500

420

800

800

720

630

22

37

45

50

150

22

45

55

55

180

37

60

60

75

220

45

75

90

90

300

65

110

130

130

400

75

130

150

150

630

180

180

180

220

220

220

300

300

300

400

400

300

630

630

630

800

800

800

50(135) 55(150) 55(150) 75(200) 95(260) 95(260)

85(135) 90(150) 90(150) 130(200) 170(260) 170(260)

110(135) 120(150) 120(150) 170(200) 220(260) 220(260)

135(135) 150(150) 150(150) 200(200) 260(260) 260(260)

Rated operating current of

auxiliary contacts

Conventional free air

thermal current

Rated operating current

16

Category

120VAC

AC-15

240VAC

500VAC

660VAC

1.5

24VDC

48VDC

110VDC

1.2

0.81

0.2

Category

DC-13

220VDC

Note: 1 UN-AX2(CX), UN-AX4(CX),

UN-AX11(CX).

Rated Current for DC motors

Category DC-3 & DC-5

100 operations/hour max.

500,000operations

Rated capacity for 3-ph, capacitors4

120 operations/hour max.

Electrical durability at maximum load:

100,000 operations

(ambient temperature 40C)

Rated insulation voltage

Making & breaking

3-ph, cos=0.35

240V/440V

Switching frequency

6

4

2

10

8

4

10

8

4

20

15

8

20

15

8

25

20

10

30

20

10

35

30

12

40

35

15

60

50

20

90

80

50

90

80

50

130

120

80

180

150

100

220

150

100

280

200

150

280

200

150

630

630

630

630

630

630

2.2

3.3

4

3.3

690

3

4

5

4.5

690

4

6

6

5.5

690

5.5

10

10

10

690

5.5

10

10

10

690

8.5

14

14

14

690

12

20

20

20

690

20

40

30

30

690

20

40

35

40

690

35

60

48

50

690

35

60

60

60

690

38

65

65

65

690

50

80

80

80

690

60

120

150

150

1,000

60

120

150

150

1,000

95

150

200

200

1,000

115

200

250

200

1,000

190

350

350

400

1,000

190

350

350

400

1,000

110/110

100/72

1,800

1,800

660

130/120

120/100

1,800

1,800

660

180/180

180/130

1,800

1,800

600

220/220

220/220

1,800

1,800

600

220/220

220/220

1,800

1,800

600

300/300

300/240

1,800

1,800

600

400/400

400/320

1,800

1,800

600

550/460

550/460

1,200

1,200

600

650/620

650/620

1,200

1,200

600

ms

ms

ms

ms

15

10

15

10

45

10

15

10

15

10

15

10

33

12

15

10

15

10

50

13

25

53

57

15

25

53

57

15

27

75

75

18

27

75

75

18

25

85

125

22

27

85

135

37

35

120

175

55

35

120

175

55

65

75

105

80

65

75

105

80

VA

VA

W

VA

VA

60

10

3.5

60

10

3.5

7

7

60

10

3.5

110

13

5.3

18

18

132

17

2.8

24

24

132

17

2.8

24

24

225

22

3.3

27

27

225

22

3.3

27

27

320

26

3.5

31

31

480

54

7.3

55

55

800

100

15

600

75

800

100

15

600

75

million

C

m/s2

m/s2

mm2

10

10

10

10

1-2.5

1-2.5

1-6

2-16

2-25

2-25

2-50

mm2

mm2

mm

1-2.5

1-2.5

1-2.5

1-2.5

1-6

1-2.5

2-16

1-2.5

2-25

1-2.5

2-25

1-2.5

2-50

1-2.5

15

2-50

(2-60)3

2-50

1-2.5

15

320

480

480

480

26

44

44

54

3.5

5

5

7.3

31

41

55

31

41

55

0.85 to 1.1 times rated coil voltage

5

5

5

5

25 to +55

19.6

49

(6-70)3

(6-70)3

1-2.5

15

48V

110V

220V

A

A

A

220-240V

380-440V

550V

690V

kvar

kvar

kvar

kvar

V

Making current

Breaking current

Category AC-1

Category AC2 & AC-3

Category AC-4

A

A

operations/hour

operations/hour

operations/hour

Operating time (at rated coil voltage)

AC operated

Closing

Opening

DC operated

Closing

Opening

Coil consumption (at rated coil voltage)

AC operated

Inrush

Sealed

Watts

DC operated

Inrush

Sealed

Coil voltage tolerance

Mechanical endurance (make/break operations)

Permissible ambient temperature

Vibration (10-55 Hertz)

Shock (10 ms half sine wave)

Conductor size

Main terminal (contactor)

Main terminal (overload relay)

Control terminal

Busbar width

110

90

90

13

15

15

5.3

5.3

5.3

16

16

0.85 to 1.1 times rated coil voltage

10

10

10

25 to +55

19.6

49

2-16

1-6

1-6

1-6

1-2.5

1-6

1-2.5

2-16

1-2.5

850/850 1050/1050 1250/1250 1500/1500 1800/1800 2500/2500 3000/3000 4000/4000 6500/6500 8000/8000

800/750 930/930 1000/1000 1200/1200 1450/1450 2000/2000 2400/2400 3200/3200 5040/5040 6400/6400

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

1,200

600

300

300

300

300

300

300

300

300

300

(6-95)3

(6-95)3

1-2.5

20

30

100

30

100

145

40

(10-120)3 (10-150)3 (25-240)3 (25-240)3 (70-325)3 (70-325)3

(10-120)3 (10-150)3 (25-240)3 (25-240)3

1-4

1-4

1-2.5

1-2.5

1-2.5

1-2.5

35

35

25

25

30

30

Notes: 1. 660A at ambient temperature 40-55C. 2. 800A at ambient temperature 40-55C.

3. Conductor size in parentheses indicate compression terminal style not for bare clamping.

4. The peak value of inrush current should be less than 2000% of the effective value for rated current of capacitors.

The selection is invalid for the circuit of parallel capacitors which are controlled individually.

Based on Mitsubishi MS-N Series Datasheet

Page 2 of 7

Based on Mitsubishi MS-N Series Datasheet

Page 3 of 7

12483

Performance of Series S-N Contactors

Electrical Life

N = Nr/1 +

where

(Nr/NI -1) ...................................... Eq.1.1

100

N : Life in the case of % jogging duty

Nr : Life in the case of normal duty

Nl : Life in the case of 100% jogging duty

: Percentage of jogging duty

3

2

Electrical life (million of operations, average)

The electrical life of the main contacts of a contactor is

determined mainly by the circuit-opening duty it will perform.

The relationship between electrical life and rated current of

Mitsubishi contactors under normal and jogging duties of

squirrel-cage motors is shown in Fig. 1.4.2(1) and 1.4.2(2).

In the case of a mixture of normal and jogging duties, the

expected contactor life can be determined as follows:

220~240VAC

1.5

1

0.7

0.5

S-N18

0.3

0.2

0.15

0.1

0.07

0.05

S-N220

0.03

S-N25

0.02

0.01

Electrical life versus rated operating current

S-N10

S-N125

S-N20,21

S-N180

S-N65 S-N95 S-N300

S-N800

S-N400

S-N11,12

S-N35

S-N600

S-N50 S-N80 S-N150

3

5 7 10 15 20 30 50 70 100 150 200 300 500 800

Rated operating current (A)

380~440VAC

Fig.1.4.2 (2)

Normal duty, 6le on, le off, on-load factor 40%,

1200 operations/hour (AC3)

Jogging duty, 6le on, 6le off, on-load factor 7%,

600 operations/hour (AC4)-S-N10~S-N300

300 operations/hour (AC4)-S-N400~S-N600

150 operations/hour (AC4)-S-N800

Electrical life (million of operations, average)

2

1.5

1

0.7

0.5

0.3

0.2

0.15

0.1

0.07

0.05

S-N125 S-N180

0.03

S-N95

S-N25

S-N300

S-N50

S-N18

S-N150

S-N65

S-N400

S-N11,N12 S-N20,21 S-N35 S-N80 S-N220 S-N600

0.02

0.01

S-N10

7 10 15 20 30 50 70 100 150 200 300 500 800

Rated operating current (A)

1.4.3 Mounting Attitude of Starters and Contactors

To assure proper performance, Mitsubishi magnetic motor

starters and contactors should be mounted on a vertical

supporting surface with the line terminals upwards and the

load terminals downwards. The supporting surface may have

a maximum inclination of 30 from the vertical in any direction.

S-N800

Top

30 30

30 30

Bottom

Regular installation

Based on Mitsubishi MS-N Series Datasheet

Inclined installation

Page 4 of 7

12483

Selection Table of Contactors

Type S-N , SD-N

Ordering Designation

Model name ................................................................................................. S-N10

Coil designation (See page 13) ............................................................................... AC400V

If required special aux. contact (never specify for standard). ................................................. 1B

Complete type designation

S-N10AC400V1B

Rated

Rated motor capacity

operational

3-phase AC-2 & AC-3

Model name

Standard

aux.

380

220

Finger

Additional auxiliary contact block

protection

contacts

current AC-3

220

Note: Markindicates

a blank space.

terminal cover

380

240V 440V 240V 440V 500V

690V

(A)

(A)

(kW)

(kW)

(kW)

(kW)

11

2.5

13

12

3.5

5.5

5.5

5.5

13

12

3.5

5.5

5.5

5.5

18

16

4.5

7.5

7.5

7.5

AC operated DC operated

NO

NC

22

22

5.5

11

11

7.5

22

22

5.5

11

11

7.5

30

30

7.5

15

15

11

40

40

11

18.5

18.5

15

55

50

15

22

22

22

65

62

18.5

30

37

30

S-N10

S-N10CX1

S-N10(1B)

S-N10CX1(1B)

S-N11

S-N11CX1

S-N11(1B)

S-N11CX1(1B)

S-N12

S-N12CX1

S-N12(2A)

S-N12CX1(2A)

S-N18

S-N18CX1

S-N20

S-N20CX1

S-N20(2A)

S-N20CX1(2A)

S-N21

S-N21CX1

S-N25

S-N25CX1

S-N35

S-N35CX1

S-N50

S-N50CX1

S-N65

S-N65CX1

85

85

22

45

45

45

S-N80

SD-N80

105

105

30

55

55

55

S-N95

SD-N95

125

120

37

60

60

60

S-N125

SD-N125

150

150

45

75

90

90

S-N150

SD-N150

180

180

55

90

110

110

S-N180

250

250

75

132

132

132

S-N220

SD-N220

300

300

90

160

160

200

S-N300

SD-N300

400

400

125

220

225

250

S-N400

SD-N400

630

630

190

330

330

330

S-N600

SD-N600

800

800

220

440

500

500

S-N800

SD-N800

SD-N11

SD-N11CX1

SD-N11(1B)

SD-N11CX1(1B)

SD-N12

SD-N12CX1

SD-N12(2A)

SD-N12CX1(2A)

SD-N35

SD-N35CX1

SD-N50

SD-N65

SD-N21

SD-N21CX1

Provided

Provided

Provided

Provided

Provided

Provided

Provided

Provided

Provided

Provided

Provided

Provided

Provided

Provided

UN-

UN-

AX2(CX)

AX4(CX)

UN-

UN-

AX11(CX) AX80

UN-

UN-

AX150 AX600

Max.

Max.

Note:1 CX denotes with finger protection terminal covers.

S-N10CX

S-N21

SD-N65

Based on Mitsubishi MS-N Series Datasheet

S-N220

SD-N400

S-N800

Page 5 of 7

12483

Connections and Contact Arrangement

A2 A1

A2 A1

1/L1 3/L2 5/L3 13

2/T1 4/T2 6/T3 14

A2 A1 13 1/L1 3/L2 5/L3 23

A2 A1

14 2/T1 4/T2 6/T3 24

S-N12(2NO)

S-N20(2NO)

2/T1 4/T2 6/T3 22

14 2/T1 4/T2 6/T3 22

A1 A2

43 31

/ / 13 21

a b (13) (31) 1/L1 3/L2 5/L3 (23) (41)

A1

/

a

14 22 2/T1 4/T2 6/T3 44 32

(24) (42)

(14) (32)

A2

/

b

S-N12, N20

SD-N12

1/L1 3/L2 5/L3

A2 A1 13 21 1/L1 3/L2 5/L3 43 31

2/T1 4/T2 6/T3

14 22 2/T1 4/T2 6/T3 44 32

S-N18

S-N21, N25, N35

SD-N21, N35

13 21 43 31

(13) (31) (23) (41) 1/L1 3/L2 5/L3

14 22 44 32 2/T1 4/T2 6/T3

(14) (32) (24) (42)

S-N50~N400

SD-N50~N400

A1/a

13 21 43 31

(13) (31) (23) (41) 1/L1 3/L2 5/L3

A2/b

14 22 44 32 2/T1 4/T2 6/T3

(14) (32) (24) (42)

A2 A1 13 1/L1 3/L2 5/L3 21

S-N10, N11(INC)

SD-N11(INC)

S-N10, N11(1NO)

SD-N11(1NO)

1/L1 3/L2 5/L3 21

S-N600, N800

SD-N600, N800

Based on Mitsubishi MS-N Series Datasheet

Page 6 of 7

12483

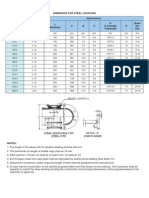

Outline Dimensions

Dimensions

2 mtg. holes for M4 screws

78

78

AA AB AC BB BA CC CA D Mass(kg) T

35 4.5 70

50

19

10 106 4

S-N12(CX)

53

78

78

40 4.5

50

19

10 106 4 0.32 5

S-N18(CX)

43

79

81

30

60

13

10 109 4 0.33 5

SD-N11(CX)

43

78 110 35 4.5 70

50

19

10 138 4 0.62 5

SD-N12(CX)

53

78 110 40 4.5

50

19

10 138 4 0.64 5

0.3

BA

Type

BB

S-N10(CX),-N11(CX) 43

Mounting rail

(35mm

)

Note: Front clip-on and side clip-on aux. contact blocks should not

be mounted both.

AA

AB

13.5

M3.5 screw

AC

CC

CA

(with side clip-on aux.

contact block)

(with front clip-on aux.

contact block)

Dimensions

2 mtg. holes for M4 screws

M4 screw

BB

BA

M3.5 screw

D

CC

AA

AB

13.5

CA

(with front clip-on aux.

contact block)

(with side clip-on aux.

contact block)

BB

BA

AA

D

T

A

M4 screw

AC

C

81

AA AB AC BB BA CC CA D Mass(kg) T

54 4.5 90

S-N25(CX),-N35(CX) 75

89

91

65

60

14 6.5 109 4

102 70

0.4

13 6.5 119 4 0.52 5

SD-N21(CX)

63

81 113 54 4.5 90

SD-N35(CX)

75

89 123 65

102 70

60

14 6.5 141 4 0.72 5

13 6.5 151 4 0.85 5

SLD-N21

63

81 137 54

45

90

60

14 6.5

4 0.55 5

SLD-N35

75

89 147 65

102 70

13 6.5

4 0.67 5

Type

S-N50,-N65

S-N50CX, -N65CX

S-N80,-N95

A

B

C AA AB AC

88 106 106 70 9

88 108 106 70 9

100 124 127 80 10 128

BB BA

75 15.5

75 15.5

110 7

CC CA D

M

P Mass(kg) T

10 135 4.5 M4 M6 0.75 10

10 135 4.5 M4 M6 0.77 10

12 M5 M6 1.8 10

SD-N50,-N65

SD-N80,-N95

88 107.5 133 70

100 134 157 80

9

75 15.5 10

10 128 110 7 12

M4 M6 2.1

M5 M6 3.3

10

10

SL-N50,-N65

SL-N80,-N95

88 106 135.5 70

100 172 127 80

9

75 15.5 10

10 128 110 7 12

M4 M6 1.3

M5 M6 2.1

10

10

C

CA

(with head clip-on aux.

contact block)

(with side mounted aux.

contact block)

B

81

Dimensions

CC

2 mtg. holes for M screws

P screw

A

63

Note: Front clip-on and side clip-on aux. contact blocks should not

be mounted both.

AC

AB

Mounting rail

(35mm

)

Type

S-N20(CX),-21(CX)

Mounting rail

(35mm

)

(N50/N65 only)

Dimensions

4 mtg. holes for M screws

BA

BB

B

P screw

AA

A

AB

M4 screw

CC

T

Type

S-N125

S-N150

S-N180,-N220

S-N300,-N400

S-N600,-N800

A

100

120

138

163

290

B

150

160

204

243

310

C

137

145

175

195

235

SD-N125

SD-N150

SD-N220

SD-N300,-N400

SD-N600,-N800

102

120

138

163

375

150

160

204

243

310

SL(D)-N125

SL(D)-N150

SL(D)-N220

SL(D)-N300,-N400

SL(D)-N600,-N800

100

120

138

163

290

191

201

224

259

390

Based on Mitsubishi MS-N Series Datasheet

AA AB BB BA CC

90

5 125 12.5 1.6

100 10 125 17.5 1.6

120 9 190 7 1.6

145 9 225 9 2.3

250 20 250 30 10.5

CA

D

M

M4

M5

M6

M8

M10

P Mass(kg) T

M8 2.5 10

M8 3.2 10

M10 5.5 10

M12 9.5 10

M16 27 10

162

169.5

200.5

221

235

90

100

120

145

250

5

10

9

9

20

125 12.5 1.6

125 17.5 1.6

190 7 2.0

225 9 2.3

250 30 10.5

M4

M5

M6

M8

M10

M8

M8

M10

M12

M16

4.3

4.3

7.5

13.5

28

30

30

30

50

10

137

145

175

195

235

90

100

120

145

250

5

10

9

9

20

125 12.5 1.6

125 17.5 1.6

190 7 1.6

225 9 2.3

250 30 10.5

M4

M5

M6

M8

M10

M8

M8

M10

M12

M16

3.0

3.6

6.0

10

27

30

30

30

50

10

Page 7 of 7

You might also like

- Proportional Amplifier PVRDocument8 pagesProportional Amplifier PVRgaliardiNo ratings yet

- Synchronous Generator J.Majumder MIE Senior FacultyDocument18 pagesSynchronous Generator J.Majumder MIE Senior FacultyQuang Tiên100% (1)

- 661 Didb LV To32-33 Lxcos V1.0Document3 pages661 Didb LV To32-33 Lxcos V1.0hariana100% (1)

- Humber Battery Charger - CDHD-60-24III4-J0说明书 (中英文)Document13 pagesHumber Battery Charger - CDHD-60-24III4-J0说明书 (中英文)Clarence ClarNo ratings yet

- Ed-15 Electric Propeller Shaft Revolutions and Electric Revolution Counter (Incl Inst and Test Report)Document58 pagesEd-15 Electric Propeller Shaft Revolutions and Electric Revolution Counter (Incl Inst and Test Report)BorysNo ratings yet

- MPPT Solar Charger 3Kw: User ManualDocument29 pagesMPPT Solar Charger 3Kw: User ManualBassamAlAghbari100% (1)

- Spectrum 375 MillerDocument36 pagesSpectrum 375 Millerluiz-simoesNo ratings yet

- Ultrasonic Cleaner S 700 HM PDFDocument109 pagesUltrasonic Cleaner S 700 HM PDFJulian Andrés FajardoNo ratings yet

- Crane Electrical Part 3Document33 pagesCrane Electrical Part 3ruslan100% (1)

- QSK19 CM850 MCRS Wiring DiagramDocument11 pagesQSK19 CM850 MCRS Wiring DiagramMussardNo ratings yet

- Troubleshooting and Service Information For Voltmaster GeneratorsDocument15 pagesTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- 841 VCB HVF&HVG Catalogue 2012.1Document56 pages841 VCB HVF&HVG Catalogue 2012.1Sergio Ignacio Zurita VargasNo ratings yet

- 201-0853 Apollo User Manual KODEN KAT-330 EN v2Document104 pages201-0853 Apollo User Manual KODEN KAT-330 EN v2thỏa100% (1)

- Stamford PI734FDocument8 pagesStamford PI734FTaz UddinNo ratings yet

- Alternators PDFDocument76 pagesAlternators PDFVikash Khaliyav YadavNo ratings yet

- NDB Spares Kit Se125Document1 pageNDB Spares Kit Se125chienNo ratings yet

- Manual FMS3000-Eng Software 1.7Document43 pagesManual FMS3000-Eng Software 1.7Rahat AliNo ratings yet

- Shema Esab Origo Mag C171 C201 C251Document20 pagesShema Esab Origo Mag C171 C201 C251cornelutsNo ratings yet

- Manual - WAS100 (R1) AnemometerDocument33 pagesManual - WAS100 (R1) Anemometerrohithunni.pNo ratings yet

- 11 SnorkelDocument44 pages11 SnorkelLuis Roberto Perez DominguezNo ratings yet

- Sulzer 51031Document2 pagesSulzer 51031bryan_bello_14No ratings yet

- Finder Temperizadores 87 PDFDocument8 pagesFinder Temperizadores 87 PDFflywheel2006No ratings yet

- TSI-SC-007 Diagnostics and Logbook Request FormDocument14 pagesTSI-SC-007 Diagnostics and Logbook Request Formg arvNo ratings yet

- Date: Model: 10/07/2019 Rev.00Document3 pagesDate: Model: 10/07/2019 Rev.00Mim MD Rahmatullah100% (1)

- Engine Starting SystemsDocument19 pagesEngine Starting SystemsSal St0% (1)

- Synchronizing and Synchronizing EquipmentDocument10 pagesSynchronizing and Synchronizing EquipmentLog in 2007No ratings yet

- Mexichem Cartagena Tuma 1 Undervoltage Shutdown Due To Generator Remanent Voltage LossDocument19 pagesMexichem Cartagena Tuma 1 Undervoltage Shutdown Due To Generator Remanent Voltage LossMiguelCamachoNo ratings yet

- Lenze 8200 Vector-25Document25 pagesLenze 8200 Vector-25poaguiNo ratings yet

- Powertron Motor Starter Manual ENAD Ver5Document24 pagesPowertron Motor Starter Manual ENAD Ver5Aruljyothy PCNo ratings yet

- 801AP MX Service ToolDocument10 pages801AP MX Service ToolDiones CristianNo ratings yet

- Markon Generator ManualDocument52 pagesMarkon Generator ManualjuanlukaNo ratings yet

- PhasesDocument74 pagesPhasesRuth Velasquez QuirozNo ratings yet

- Celect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmDocument3 pagesCelect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmEduardo TorresNo ratings yet

- 5000-6000 LeroyDocument24 pages5000-6000 LeroyKhaleel Khan100% (1)

- PowerLink Operational Manualopen-SetDocument114 pagesPowerLink Operational Manualopen-SetJorge JaramilloNo ratings yet

- TD - As480 Avr - 04.08 - 02 - GBDocument6 pagesTD - As480 Avr - 04.08 - 02 - GBmo7amedengNo ratings yet

- ESD-5100 Series Speed Control Unit ManualDocument14 pagesESD-5100 Series Speed Control Unit ManualreckyNo ratings yet

- GAC 154217 docTR PDFDocument3 pagesGAC 154217 docTR PDFaupNo ratings yet

- Part Winding Motor PDFDocument4 pagesPart Winding Motor PDFBj Valdez100% (2)

- ICOMDocument47 pagesICOMal nakheel electronicsNo ratings yet

- FLC Pi Tachometer enDocument4 pagesFLC Pi Tachometer enJohn GarnetNo ratings yet

- DSEL401 MKII Operators ManualDocument92 pagesDSEL401 MKII Operators ManualGenset Genset100% (1)

- Testing and Inspection EGR ValveDocument4 pagesTesting and Inspection EGR ValveAmna Fayyaz100% (1)

- MITSUBISHI - FX3U Users Manual - Hardware Edition PDFDocument520 pagesMITSUBISHI - FX3U Users Manual - Hardware Edition PDFindra putraNo ratings yet

- C6 Wiper Diagnostics and SchematicsDocument8 pagesC6 Wiper Diagnostics and Schematicsel_frNo ratings yet

- TLG 12esx PDFDocument9 pagesTLG 12esx PDFGeiler Benitez PiñaNo ratings yet

- A.C.Synchronous Transmitter Manual PDFDocument15 pagesA.C.Synchronous Transmitter Manual PDFAbhishek RajNo ratings yet

- Controller HT Jumo Dicon Touch EN.Document9 pagesController HT Jumo Dicon Touch EN.Jevgenij ChupinNo ratings yet

- MotorEffic&PF CM5Document28 pagesMotorEffic&PF CM5Alaa RamadanNo ratings yet

- Engine Indicator Type 50 z1Document2 pagesEngine Indicator Type 50 z1CalandrasReyCalandrasreyNo ratings yet

- Anchor & Chains Dimensions GuideDocument3 pagesAnchor & Chains Dimensions GuideJohn Angelo TuliaoNo ratings yet

- Data Sheet Epn-110dn,-2Document5 pagesData Sheet Epn-110dn,-2roy fadliNo ratings yet

- Mitsubishi U100 ManuaDocument90 pagesMitsubishi U100 Manuapepe1bmNo ratings yet

- Eltorque User ManualDocument29 pagesEltorque User Manualdhlinva3205No ratings yet

- Technical Description: Type: 810.001.210Document6 pagesTechnical Description: Type: 810.001.210Radu VasilacheNo ratings yet

- MCCBDocument72 pagesMCCBmadhan_22No ratings yet

- Lvped208013en (Web)Document76 pagesLvped208013en (Web)GigieseNo ratings yet

- Air Circuit Breaker-ChintDocument66 pagesAir Circuit Breaker-Chintdmugalloy100% (1)

- Minas A DriverDocument14 pagesMinas A DriverPham Long100% (1)

- Retrofit Masterpact M PlugnplayDocument21 pagesRetrofit Masterpact M Plugnplaynot bookNo ratings yet

- The Use of Two Nuts To Prevent Self Loosening of FastenersDocument2 pagesThe Use of Two Nuts To Prevent Self Loosening of FastenersmanbkkNo ratings yet

- Gantry CranesDocument15 pagesGantry CranesmanbkkNo ratings yet

- Epicon Finish (Polyamide Finish Coat)Document1 pageEpicon Finish (Polyamide Finish Coat)manbkkNo ratings yet

- Epicon Finish (Polyamide Finish Coat)Document1 pageEpicon Finish (Polyamide Finish Coat)manbkkNo ratings yet

- Dimension For Steel Coupling Pipe Dimensions Dimensions Tolerance On O.D. L Minimum A B C D X Average Thickness E Bolts No. DiaDocument1 pageDimension For Steel Coupling Pipe Dimensions Dimensions Tolerance On O.D. L Minimum A B C D X Average Thickness E Bolts No. DiamanbkkNo ratings yet

- CS Colours2011-1 PDFDocument3 pagesCS Colours2011-1 PDFmanbkk100% (1)

- Epicon F-HBDocument1 pageEpicon F-HBmanbkkNo ratings yet

- Tokyo Keiso Co., LTDDocument3 pagesTokyo Keiso Co., LTDmanbkkNo ratings yet

- 1.supplemental SpecDocument1 page1.supplemental SpecmanbkkNo ratings yet

- JIS Standards Conv2 Iso.Document1 pageJIS Standards Conv2 Iso.manbkkNo ratings yet

- Boq Bolt and Nut 8rrDocument1 pageBoq Bolt and Nut 8rrmanbkkNo ratings yet

- XXCCFDocument1 pageXXCCFAnkush SehgalNo ratings yet

- Usman Public School System: 1 Monthly Test Mid-Term 2018 - 2019Document3 pagesUsman Public School System: 1 Monthly Test Mid-Term 2018 - 2019Huzaifa KhanNo ratings yet

- Manitoba 1 FinalDocument14 pagesManitoba 1 FinalChin Sheng JiNo ratings yet

- 347 Worksheet 8.1 PDFDocument2 pages347 Worksheet 8.1 PDFSandra Ruiz HerediaNo ratings yet

- Gas Well Deliverability II 2018Document55 pagesGas Well Deliverability II 2018Johny ImitazNo ratings yet

- Syllabus Che CBCSDocument111 pagesSyllabus Che CBCSShasanka Sekhar BorkotokyNo ratings yet

- BP504T PGPC Unit IiDocument28 pagesBP504T PGPC Unit IiFarhadullah KhanNo ratings yet

- Star Health and Allied Insurance Company Limited Tariff Statement - Mini SOC (FINALISED)Document1 pageStar Health and Allied Insurance Company Limited Tariff Statement - Mini SOC (FINALISED)Sanket Sahare100% (1)

- Preparing Laboratory Solutions and ReagentsDocument61 pagesPreparing Laboratory Solutions and ReagentsAlmira Kaye CuadraNo ratings yet

- ProbabilityDocument40 pagesProbabilitykingjanuariusNo ratings yet

- Contador de Partículas RexrothDocument44 pagesContador de Partículas RexrothJohnny Eddy DantasNo ratings yet

- APPENDIX Quick Quiz AnswersDocument13 pagesAPPENDIX Quick Quiz AnswersJustDeyシNo ratings yet

- The Last Flight of S/Sgt. Linwood W. WhiteDocument6 pagesThe Last Flight of S/Sgt. Linwood W. Whiteandtodo2No ratings yet

- Trigonometry Identities & Equations: Vidyamandir ClassesDocument7 pagesTrigonometry Identities & Equations: Vidyamandir Classesसंघर्ष - सहयोग EducationNo ratings yet

- #006.03 Concrete Accessories (Anchoring Resin)Document5 pages#006.03 Concrete Accessories (Anchoring Resin)M. Murat ErginNo ratings yet

- DND BbegDocument13 pagesDND BbegRicky JohnsonNo ratings yet

- ICON Case Book 2017 - Volume 7 (B) PDFDocument152 pagesICON Case Book 2017 - Volume 7 (B) PDFOmkarNo ratings yet

- Modern RiddlesDocument1 pageModern RiddlesHannah BautistaNo ratings yet

- Kane Mele PaperDocument4 pagesKane Mele PaperVardha RajanNo ratings yet

- Be Comp Engg Sem-Viii r2019Document56 pagesBe Comp Engg Sem-Viii r2019Sahil KNo ratings yet

- The Gross Motor Function Classification System For Cerebral PalsyDocument5 pagesThe Gross Motor Function Classification System For Cerebral PalsyMarco Tulio FigueroaNo ratings yet

- Template Version 20181231: Equipment Detail ( ) - Input Details: Low Impedance Differential ProtectionDocument6 pagesTemplate Version 20181231: Equipment Detail ( ) - Input Details: Low Impedance Differential ProtectionGirija Sankar PatiNo ratings yet

- The Story of Hour - Q N AnsDocument21 pagesThe Story of Hour - Q N Ansnaeviscalling.ytNo ratings yet

- Certificate IEC 61701 Salt-Mist Poly-And-MonoDocument5 pagesCertificate IEC 61701 Salt-Mist Poly-And-Monosunny0% (1)

- Validation Report Gul AhmedDocument86 pagesValidation Report Gul AhmedjavariaashrafNo ratings yet

- HPC 420 P0Document15 pagesHPC 420 P0Christian TéllezNo ratings yet

- Uct SretsrptDocument4 pagesUct SretsrptjohnNo ratings yet

- Amigurumi Adventure Time JakeDocument6 pagesAmigurumi Adventure Time JakeKatherine Hernandez Espinoza100% (3)

- Nicolas Saunier - LectureDocument27 pagesNicolas Saunier - LectureUsamaNo ratings yet

- Answers Word Search Mechanics 1Document3 pagesAnswers Word Search Mechanics 1Glenn DiazNo ratings yet