Professional Documents

Culture Documents

Purchasing Managemen1

Purchasing Managemen1

Uploaded by

Shikha MehtaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Purchasing Managemen1

Purchasing Managemen1

Uploaded by

Shikha MehtaCopyright:

Available Formats

PURCHASING MANAGEMENT Purchasing is the acquisition of needed goods and services at optimum cost from competent, reliable sources.

o Needs: examine need, timing, quantity, source, specifications o Goods and services: Make or buy or lease o Optimum cost: Best total cost, not only lowest acquisition cost, consider also quality and service o Competent sources: select carefully o Reliable sources: monitor performance. Components of purchasing o Needs assessment o Source identification o Contract negotiation o Supplier selection o PO issuance o Expediting / follow-up o Performance evaluation Purchasing objectives: o Right quality o Right quantity o Right time o Right source o Right price Purchasing management cycle o Analysis o Planning make or buy, domestic vs. overseas, national vs. local, distributor vs. manufacturer, purchasing timing o Implementation o Control o Organisation Purchasing role in corporate planning o Quantity o Time o Money Purchasing organisation 2 types o Type : Structural, Process o Elements: People, activities o Content : reporting relationships, work sequences o Nature: static, dynamic

o Diagram format: Organisation chart, flow diagram o Example: product specialization, PERT network chart Principles of Purchasing organisation o Specialisation o Control o Co-ordination o Communication o Line and Staff Setting up a Purchasing Dept: o Task delegation o Work classification Management, buying, clerical work, expediting, special project or studies o Centralisation vs. decentralization o Material management Procurement Process: o Recognition of need o Requisition issue o Requisition review o Specification dept. o Supplier search o Supplier selection o PO issue o Contract formation o Expediting o Receiving and inspection o Contract completion Basic options in materials sourcing o Number of suppliers o Supplier size o Supplier location o Distribution channel o Co-operative purchasing Evaluation and selection of vendors 1. Published sources o General industrial registers or directories o Industry sources Publication of trade / professional asso. Trade periodicals Industry buyers guide o Yellow pages o Manufacturers; catalogues and sales literature

2. Internal sources o Supplier files o Technical personnel 3. Personal contacts o Sales personnel o Professional colleagues o Trade exhibits 4. International sources o Foreign embassies, consulates o Intl. chamber of commerce o Plant conditions financial status o Quality and service o Price o Selection and follow-up o The categorical plan o The weighted point plan o The cost ratio plan Source Management and Development The purchasing must: o Evaluate supplier performance continuously o Reward satisfactory suppliers with additional orders o Inform unsatisfactory / deficiencies are identified, suggest remedies and offer assistance o Remove consitently unsatisfactory suppliers from approved list and eliminate from further contract awards o Limit the size of supplier base, kept it fresh and dynamic and identify new sources o Proactively cultivate and manger supplier relations to produce CIP in quality, service and price. Economic consideration in price making: o Cost approach govt. controlled prices o Market approach o Discounts o Trade discounts o Quantity discounts Price cost analysis: The analysis of all the factors that enter into a price, and the attempt to ensure that the final price is a reasonable one in terms of the use to which the material is to be put and the competitive situation faced by the buying and selling firms. Learning curve: Is a formalization of the common sense realization that the per unit cost of production of a new item decreased as additional units of that product are manufactured. The cost should decline with each succeeding unit producted, as the supplier becomes more skilled, or learns how to make the product. CIP. Factors kept in mind while doing price-cost analysis: o Price

o Costs o Learning Curve o Direct material costs o Direct labour costs o Overhead costs o General and administrative costs o Profits Purchasing procedure: o Parameters of PR o Format of PR o Approval of PR o Checking PR o Method of purchase o Who calls Quotations / tenders o Opens the Tenders o How should be tenders open and handled o Negotiations o Competent authority to approve Purchase o PO o Follow-up with the supplier o Negotiate purchase documents, customs clearance etc. o Receive materials and inspection o Carry out inspection o Discrepancy report in case of damages o Rejected materials handling

Q: Discuss the various steps of purchasing Ans: Steps in purchasing Need for purchasing procedure o Standardising o Provide guidance to handle issues on past experience o Purchasing procedure is good training tool o Procurement of quality products quality assurance and maintenance o Personal likes and dislikes are eliminated on timely procurement o Insurance claims are settled Designing of purchasing strategies o Sourcing o Cost o People o Logistic o Outsourcing Performance measures:

o Purchase price performance o Purchase price change analysis o Inventory level (weeks of stock) o Delivery performance o Quality performance o Number of vendors in use o Lead-time analysis Price and cost Negotiations: The P.manager shall take into account: Terms of payment and delivery Trade-in, rebate and other allowance Tooling costs Setup charges Potential penalties for quantity variances Special packaging or service requirement Quality specifications Primary steps of the preparation of negotiation process: o Setting objectives must have, want, tradables o Getting the facts Pre-requisites for Competitive bidding: o Clear specifications o Significant expenditure o Adequate competition o Sufficient time The competitive bidding process: o Preparation of specifications o Selection of prospective bidders o Issuance of invitations to bid o Bid preparation by vendors o Receipt and review of bid o Award of contract Tasks for computerization in purchasing: o Preparation of PI o RFQ o Typing PO o Amendments to PO o Review of status of PR and PO management reports o Searching of data thro; manual files for Management info o Consolidation of data o Checking the finished work for mathematical accuracy and typo errors o Maintaining purchase history data o Storing records of old POs Benefits of computerization:

o Reduced direct purchased material costs lower material costs, savings in manual time. Economic purchase quantities Calculating order release time Calculating least-cost suppliers Identifying buying opportunities Make / buy decisions o Reduced departmental running costs Clerical costs Additional personnel Eliminating duplicate information Data errors duplicate files, reduction in key punching, entering new data, using a database. Lower expediting costs Lower shipping charges Reduced cost of forms o Imporved personnel productivity o Simplyfying the buying process researching new sources, prepare price nego., remaining on top of market, know when to make or buy, building assurance o Improving inter departmental communication o Better planning o Job satisfaction o Increased purchasing productivity o Reduction in inventory o Other benefits more accurate info for nego., timely info for purchase decisions, faster response time. Appropriate software for purchasing: A software package A general purchase program Database managers, spreadsheets, communications, word processing, integrated software Custom made programs Internal and External communications: Linking to other departments Networking Inter-departmental data exchange Production planning and purchasing Reverse flow of info. From purchasing to production planning Stores and purchasing Finance and purchasing Quality control and purchasing Communicating with suppliers Developing an external system Closer communication Electronic mail Communication of purchasing with other modules:

Controlling Financial accounting Sales and Distribution Integration of purchasing with MM Determination of requirements Source determination Vendor selection PO processing PO follow-up Goods receiving and inventory management Invoice verifications Blocking of invoices Vendor evaluation

You might also like

- Purchasing ProcessDocument54 pagesPurchasing Processraks_mechnadNo ratings yet

- Stock VerificationDocument26 pagesStock VerificationRishi MaliNo ratings yet

- Competency Mapping ModelsDocument23 pagesCompetency Mapping ModelsMalathi Meenakshi Sundaram100% (1)

- Stores ManagementDocument7 pagesStores ManagementVinay SinghNo ratings yet

- ProcurementDocument18 pagesProcurementfeteneNo ratings yet

- Procurement Audit Notes PDFDocument4 pagesProcurement Audit Notes PDFJohn Sulaiman Koroma50% (2)

- Purchasing ManagementDocument21 pagesPurchasing ManagementJiju Justin100% (3)

- Strategic Procurement Management Lecture Notes by Bagaya Ramathan PDFDocument11 pagesStrategic Procurement Management Lecture Notes by Bagaya Ramathan PDFFatmata Sheriff KamaraNo ratings yet

- Purchase ManagementDocument46 pagesPurchase Managementgau776686% (7)

- Documents Used in Purchase and Stores ProcedureDocument2 pagesDocuments Used in Purchase and Stores Procedurelayyah201388% (8)

- Types of PurchasingDocument5 pagesTypes of PurchasingKARISHMAAT100% (2)

- Itil 4 Co-Create Value and Drive Business Success in The Digital EraDocument16 pagesItil 4 Co-Create Value and Drive Business Success in The Digital EraĐoàn Đức ĐềNo ratings yet

- Tata Kelola Teknologi Informasi Pada PT Gits IndonesiaDocument9 pagesTata Kelola Teknologi Informasi Pada PT Gits IndonesiaDessy MitaNo ratings yet

- Five Steps To Effective ProcurementDocument7 pagesFive Steps To Effective ProcurementtkurasaNo ratings yet

- Sourcing Materials and ServicesDocument30 pagesSourcing Materials and ServicesMikkay WongNo ratings yet

- Inventory-SOP-Policy & FormsDocument25 pagesInventory-SOP-Policy & FormsSaad Khan100% (2)

- Stock TakingDocument3 pagesStock TakingWong Miaw Ning0% (1)

- Company Purchase:: Business Organization Goods ServicesDocument14 pagesCompany Purchase:: Business Organization Goods ServicesNoman KhanNo ratings yet

- Employee Sop For Pms (2018-19)Document6 pagesEmployee Sop For Pms (2018-19)Parixit DasNo ratings yet

- Inventory ControlDocument25 pagesInventory ControlSuja Pillai100% (1)

- 11 Essential Procurement KPIs You CanDocument6 pages11 Essential Procurement KPIs You Canahmed morsi100% (1)

- l4 03 Measuring Purchasing PerformanceDocument150 pagesl4 03 Measuring Purchasing PerformanceMahendra Kumar Soni100% (3)

- Purchase ManagementDocument34 pagesPurchase Managementshweta_4666475% (8)

- Laduree PowerPoint Report - Final - UpdateDocument61 pagesLaduree PowerPoint Report - Final - Updatewinki0312No ratings yet

- Purchasing: Meaning Aand Definition of PurchasingDocument6 pagesPurchasing: Meaning Aand Definition of PurchasingShahl kvNo ratings yet

- Purchasing and Materials ManagementDocument73 pagesPurchasing and Materials ManagementShivamitra ChiruthaniNo ratings yet

- CH12-Inventory Management PoliciesDocument32 pagesCH12-Inventory Management PoliciesChristian John Linalcoso AranteNo ratings yet

- Purchase Management.Document41 pagesPurchase Management.ajitthomas98100% (1)

- Supply Chain Strategy Study For Marks and SpencerDocument9 pagesSupply Chain Strategy Study For Marks and SpencerSiva Kumar ArumughamNo ratings yet

- Purchase ManagementDocument55 pagesPurchase ManagementRaj KumarNo ratings yet

- Material ManagementDocument37 pagesMaterial ManagementThea GonzalesNo ratings yet

- L4 04 Managing Purchasing and Supply Relationships 1Document95 pagesL4 04 Managing Purchasing and Supply Relationships 1ukal100% (2)

- Order Fulfilment PDFDocument21 pagesOrder Fulfilment PDFSaikumar SelaNo ratings yet

- Purchasing and Material Management PDFDocument60 pagesPurchasing and Material Management PDFAlfred Allotey PappoeNo ratings yet

- Stock Verifications Part 2Document26 pagesStock Verifications Part 2Anand DubeyNo ratings yet

- Leadership in Procurement and SupplyDocument16 pagesLeadership in Procurement and SupplyNyeko Francis100% (3)

- The 10 Steps of The Procurement CycleDocument3 pagesThe 10 Steps of The Procurement Cycleleekwal_momand100% (1)

- What Is Procurement ManagementDocument7 pagesWhat Is Procurement ManagementNaveed Chaudary100% (1)

- BCG IndonesiaDocument20 pagesBCG IndonesiaHamdiIrzaNo ratings yet

- SourcingDocument9 pagesSourcingKailas Sree Chandran100% (1)

- Accounting GeniusDocument9 pagesAccounting Geniusryan angelica allanicNo ratings yet

- Outline FIVE Differences Between Purchasing Goods and Purchasing ServicesDocument34 pagesOutline FIVE Differences Between Purchasing Goods and Purchasing ServicesAlaeldin Amir100% (1)

- Types of Purchases in A Purchasing ProcessDocument3 pagesTypes of Purchases in A Purchasing ProcessJonnah Fernandez Dalogdog100% (1)

- ACI Infotech Solutions SynposisDocument14 pagesACI Infotech Solutions SynposisSid KandukuriNo ratings yet

- Procurement and NGOsDocument6 pagesProcurement and NGOsMAGOMU DAN DAVID100% (1)

- P. Procurement MCQs 2014Document6 pagesP. Procurement MCQs 2014Mehar Azhar AbbasNo ratings yet

- Knowledge Area Quiz Project Procurement Management Practice Questions-Answer Key and ExplanationsDocument3 pagesKnowledge Area Quiz Project Procurement Management Practice Questions-Answer Key and ExplanationsDanish Habib100% (1)

- P. J. H. Baily B.sc. (Econ.), A.C.I.S., F. Inst. P.S. (Auth.) - Purchasing and Supply Management-Springer US (1978)Document310 pagesP. J. H. Baily B.sc. (Econ.), A.C.I.S., F. Inst. P.S. (Auth.) - Purchasing and Supply Management-Springer US (1978)Alina EnacheNo ratings yet

- D1 - Contexts - Questions and AnswersDocument9 pagesD1 - Contexts - Questions and AnswersAlan Dwi SetiawanNo ratings yet

- Organization For Materials ManagementDocument60 pagesOrganization For Materials ManagementNaushad PulikkandyNo ratings yet

- Bsc. Procurement and Supply Chain ManagementDocument5 pagesBsc. Procurement and Supply Chain ManagementVictor BoatengNo ratings yet

- Inventory Management FAQDocument5 pagesInventory Management FAQsurenNo ratings yet

- Stores ManagementDocument43 pagesStores Managementatul_gaikwad_967% (3)

- Physical Distribution ManagementDocument8 pagesPhysical Distribution ManagementGANESWAR BARIK100% (2)

- Topic 1A Legal Aspects of ProcurementDocument112 pagesTopic 1A Legal Aspects of ProcurementMichael Zuniga100% (1)

- Purchasing Management MCQsDocument4 pagesPurchasing Management MCQsNaeem HussainNo ratings yet

- Purchasing ObjectivesDocument8 pagesPurchasing ObjectivesghaziaNo ratings yet

- LogisticsSupplyChainManagement MB064 QuestionDocument14 pagesLogisticsSupplyChainManagement MB064 QuestionAiDLo100% (1)

- Study Review Procurement 5Document3 pagesStudy Review Procurement 5Alyssa Mae Castro0% (1)

- VP Procurement Supply Chain Management in United States Resume Larry DingerDocument2 pagesVP Procurement Supply Chain Management in United States Resume Larry DingerLarryDingerNo ratings yet

- CIPS Global Standard Segment 3.1 Understanding Systems For Procurement and SupplyDocument3 pagesCIPS Global Standard Segment 3.1 Understanding Systems For Procurement and SupplytmtsukataNo ratings yet

- Warehouse Problems and SolutionsDocument5 pagesWarehouse Problems and SolutionsAshutosh SinhaNo ratings yet

- Legal Framework Course OutlineDocument2 pagesLegal Framework Course OutlineAUGUSTINE ANANE100% (1)

- Weele.5th Ed - Chapter 02.2010Document24 pagesWeele.5th Ed - Chapter 02.2010Imran SohailNo ratings yet

- Organisational BuyingDocument10 pagesOrganisational Buyinglulughosh100% (1)

- Weele 5th Ed - Chapter 03Document17 pagesWeele 5th Ed - Chapter 03Neha SharmaNo ratings yet

- Presentation Transcript: Industrial vs. Consumer MarketsDocument4 pagesPresentation Transcript: Industrial vs. Consumer MarketsvasanthpriyaNo ratings yet

- Introduction To Procurement and Inventory MGTDocument45 pagesIntroduction To Procurement and Inventory MGTEuroline NtombouNo ratings yet

- College of Engineering and TechnologyDocument3 pagesCollege of Engineering and TechnologyShroukAdelMohamedGaribNo ratings yet

- Types of Borrowers and Lending ServicesDocument52 pagesTypes of Borrowers and Lending Servicesgodfrey grizzlyNo ratings yet

- Solution Manual For Managerial Accounting Tools For Business Decision Making 3rd Canadian Edition by WeygandtDocument13 pagesSolution Manual For Managerial Accounting Tools For Business Decision Making 3rd Canadian Edition by Weygandta8899779880% (1)

- Credit Application FormDocument2 pagesCredit Application FormKELLY WONG ING SWAN MoeNo ratings yet

- Cost Concepts and ClassificationsDocument6 pagesCost Concepts and ClassificationsNailiah MacakilingNo ratings yet

- WSB - Itc Limited PresentationDocument22 pagesWSB - Itc Limited PresentationvamshiNo ratings yet

- Unit 1 PDFDocument15 pagesUnit 1 PDFvNo ratings yet

- BBA - JNU - 103 Principles of Management PDFDocument202 pagesBBA - JNU - 103 Principles of Management PDFJTSalesNo ratings yet

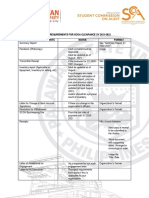

- General Requirements For Scoa Clearance Sy 2021-2022 Documents/Requirements Notes FormatDocument2 pagesGeneral Requirements For Scoa Clearance Sy 2021-2022 Documents/Requirements Notes FormatIan Jayson BaybayNo ratings yet

- Accounts 11Document120 pagesAccounts 11Thakur Manu PratapNo ratings yet

- Ghosh 2021Document14 pagesGhosh 2021Very BudiyantoNo ratings yet

- Topic 1 Example Task: Topic 1: Work and CareersDocument3 pagesTopic 1 Example Task: Topic 1: Work and CareerswigunaNo ratings yet

- My Investing Notebook - Jim Chanos - The Power of Negative Thinking (CFA Annual Conference 2010)Document3 pagesMy Investing Notebook - Jim Chanos - The Power of Negative Thinking (CFA Annual Conference 2010)mhaftelNo ratings yet

- Feasibility Analysis: Bruce R. Barringer R. Duane IrelandDocument33 pagesFeasibility Analysis: Bruce R. Barringer R. Duane IrelandShah Zeb YousafzaiNo ratings yet

- Time and Attendance Policy FinalDocument1 pageTime and Attendance Policy FinalAmy YiNo ratings yet

- Walton Products Hold A Posh Volume of Share in Local and International Market by Ensuring The Best Quality With World Class FeaturesDocument37 pagesWalton Products Hold A Posh Volume of Share in Local and International Market by Ensuring The Best Quality With World Class Featuresনিঃসঙ্গ পথিকNo ratings yet

- Balance Sheet (Standard) : PT - Cahaya Semesta SelularDocument1 pageBalance Sheet (Standard) : PT - Cahaya Semesta SelularTabryan TajrilNo ratings yet

- IAS 24 Related Party DisclosuresDocument3 pagesIAS 24 Related Party DisclosuresAKNo ratings yet

- BPSM Avi AssingmentDocument7 pagesBPSM Avi AssingmentAvi JainNo ratings yet

- SAE J1995 & J1349 BorchureDocument2 pagesSAE J1995 & J1349 BorchureSeyed Alireza SharifiNo ratings yet

- Syllabus Labor Review 2018Document6 pagesSyllabus Labor Review 2018denbar15No ratings yet