Professional Documents

Culture Documents

Lean Manufac

Uploaded by

Ashley KaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lean Manufac

Uploaded by

Ashley KaCopyright:

Available Formats

Module Title Module Code

1.

Module Information Lean Operations and Management of Lean Organisations EMM2515

MODULE SUMMARY

Aims and Summary The aim of this module is to enable the students to identify and eliminate waste / non-value adding activities at all levels to improve business competitiveness. Students will be taught lean tools and techniques and value stream mapping. Assessment of transformation to lean and management of lean organisation will be discussed. Effect of implementation of lean concepts in fortune five hundred companies will be discussed through case studies. Module Size and Credits Module size CATS points ECTS credits Open / restricted Availability on/off campus Total student study hours Number of weeks Department responsible Academic Year Single 10 N/A Restricted On Campus 100 5 weeks Full-Time or 8 weeks Part-Time Department of Mechanical and Manufacturing Engineering 2012

Entry Requirements (pre-requisites and co-requisites) Normally to be qualified for entry to the Postgraduate Engineering Programme Excluded Combinations None Composition of Module Mark (including weighting of components) Full-time / Part-time : 50% Written Examination and 50 % Assignment Pass Requirements A minimum of 40 % marks in the written examination and a minimum of 40% marks in the assignment and overall 40% marks are required for a pass Special Features 80% attendance in theory and 80% attendance in laboratory are required. It is likely that considerable time will be spent in School facilities outside of normal timetabled class time. Courses for which this module is mandatory M.Sc. [Engg] in Engineering and Manufacturing Management

Courses for which this module is a core option M.Sc. [Engg] in Technology and Engineering Management

Ver: 4

November 2011

MI EMM2515

Page 1 of 5

2.

TEACHING, LEARNING AND ASSESSMENT On completion of this module the student should be able to: 1. Evaluate the current operational practices in industries 2. Apply analytical techniques to identify and eliminate the seven types of wastes 3. Analyse value stream mapping to appraise the current state and to develop a vision for the future 4. Implement Lean techniques and manage transformation 5. Demonstrate the ability to manage and sustain a Lean organisation

Intended Module Learning Outcomes

Indicative Content Class Room Lectures 1. History of Lean manufacturing and the Need for Change :Evolution of lean, Contributions of Taylor, Gilbert, Ford, Solan and Toyoda family 2. Current Industrial Requirements, Practitioner Thinking, People Issues: New economics of lean, House of lean, Different kind of wastes 3. Total Quality Management.: Introduction and Definition of TQM, Customers and Producers perspective on Quality, Framework and Steps in Implementing of TQM and Employee Involvement 4. Visual Management: 5S, Poka yoke, Jidoka, Andon, Yamazumi board, Kanban, Performance measures, TPM and OEE 5. Waste Identification and Elimination Techniques: Wastes, Pareto, Product flow analysis, String diagrams, Cluster analysis, Non value added analysis, Single Minute Exchange of Die (SMED) 6. Pull Production: Kanban, Rules of kanban system Standard operations, Capacity charts, Walk diagrams 7. Manufacturing Cell Design: Flow lines, Nagare cells, Standard cells, Work allocation, Cell layout 8. Value Stream Mapping: Current state mapping, Lean Metrics, Line balancing, Load levelling, Lot sizing, LFL, Dependent demand, Independent demand, POQ, EOQ, EMQ, Future state mapping and Implementation plans 9. Change Management: Demand patterns, Competitive forces, and Organisational change in engineering businesses 10. Financial Control: Existing financial control systems, Activity Based Costing, Target pricing, Costing and Fixed cost reduction. Laboratory Practice/ Industrial Visit 1. Students shall visit industries practicing lean manufacturing to prepare case studies and discuss the same in class presentations

Ver: 4

November 2011

MI EMM2515

Page 2 of 5

Teaching and Learning Methods 1. Theoretical Knowledge a. Face to face lectures 30 hours 2. 3. Laboratory Practice (Skills) 30 hours Application Orientation and Problem Solving a. Reading b. Research c. Written Examination d. Assignment Solving and Documentation 40 hours

Method of Assessment Part-A Examination [50% Weightage] 1. 2. 3. Part B Assignment [50% Weightage] Students are required to submit a word processed assignment report. Viva/Presentation on a specified topic............................................... (10%) Field work / Laboratory test............................................... (10%) Written examination...........................................................................(30%)

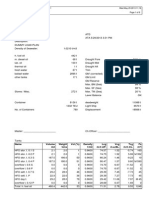

Assessment Learning Outcomes Part A Part B 1 X 2 X X 3 X X X X 4 5

Both written examination scripts and assignment reports will be double marked. Re-assessment A minimum of 40 % marks in the written examination and a minimum of 40% marks in the assignment are required for a pass in the module. A student failing in any one of the components or both is considered as FAIL in the module. A failed student is required to retake the module at the next opportunity. A maximum of 3 attempts including the original are allowed. Date of Last Amendment November -2011

Ver: 4

November 2011

MI EMM2515

Page 3 of 5

3.

MODULE RESOURCES

Essential Reading 1. Module Notes

Recommended Reading Books 1. 2. 3. 4. Rother and Shock. (1999) Learning to See, Lean Enterprise List D. Tapping. (2002) Value Stream Management, Productivity Inc Womack and Jones. (2003) Lean Thinking, Free Press Dennis Hobbs. (2004) Lean manufacturing: complete execution manual for any seize manufacturing, J Ross 5. Santos. (2006) Improving production with lean thinking, John Wiley 6. Bill Carreira. (2007) Lean manufacturing that works: powerful tools for dramatically reducing waste, Prentice hall 7. AME. (2007) Lean administration case studies in leadership and improvement, Productivity press 8. James Huntzinger. (2007) Lean cost management for lean by establishing flows, J Ross 9. Chris Harris and Rick Harris. (2007) Developing a lean work force, Productivity Press 10. Greg Lane. (2007) Made To order lean: Excelling in a high mix- low volume environment, Productivity press Journals 1. 2. 3. International Journal of Operations and Production Management, Emerald Group Publishing Limited Journal of Manufacturing Technology Management, Emerald Group Publishing Limited International Journal of Productivity and Performance Management, Emerald Group Publishing Limited Industry 2.0

Magazines 1.

Videos 1. Quick Changeover for lean manufacturing 2. Customer focused manufacturing 3. Mapping your value stream 4. Visual control 5. Five S Factory makeover 6. Learning lean through simulation 7. Break through Kaizen Events 8. Mistake proofing, achieving zero defects 9. The human side of lean manufacturing 10. Kanban system Internet Sites 1. Laboratory Hardware: None Software: None Software Manual: None www.lean.org (accessed on 20th January 2012)

Ver: 4

November 2011

MI EMM2515

Page 4 of 5

4.

MODULE ORGANISATION

Module Leader Name Room Telephone number E-mail Date and Time of Examination As per time table Sandeep. N B-504 080-49065555-2403 sandeepn@msrsas.org

Subject Quality and Approval Information Subject Quality Group / Subject Board Subject Assessment Board Shortened title Date of approval by MARP Mechanical and Manufacturing Engineering Postgraduate Engineering and Management Programmes LO November 2011

Ver: 4

November 2011

MI EMM2515

Page 5 of 5

You might also like

- Yantian International Container Terminals Limited: O/B Figure ListDocument7 pagesYantian International Container Terminals Limited: O/B Figure ListAshley KaNo ratings yet

- Scan PlanDocument4 pagesScan PlanAshley KaNo ratings yet

- Anan Bhum Stowage InstructionsDocument2 pagesAnan Bhum Stowage InstructionsAshley KaNo ratings yet

- Mol Cosmos Scan PlanDocument1 pageMol Cosmos Scan PlanAshley KaNo ratings yet

- RecapDocument1 pageRecapAshley KaNo ratings yet

- Excel Made SimpleDocument62 pagesExcel Made SimpleAshley KaNo ratings yet

- OOG VoidDocument1 pageOOG VoidAshley KaNo ratings yet

- Tank Cond Dep N PortDocument5 pagesTank Cond Dep N PortAshley KaNo ratings yet

- Fins - Main Trader - 051e - 20150308005940Document1 pageFins - Main Trader - 051e - 20150308005940Ashley KaNo ratings yet

- Dummy Maa Load Tank CondDocument6 pagesDummy Maa Load Tank CondAshley KaNo ratings yet

- Fins - Main Trader - 051e - 20150308005940Document1 pageFins - Main Trader - 051e - 20150308005940Ashley KaNo ratings yet

- MJ DeMarco's 5 Fastlane Commandments for Building an Exponential BusinessDocument1 pageMJ DeMarco's 5 Fastlane Commandments for Building an Exponential BusinessAnonymous WnxskULNo ratings yet

- DG in Transit ListDocument2 pagesDG in Transit ListAshley KaNo ratings yet

- 45-Footer High-Cube 26-03-2015 15:13:38 Page 1 of 1: F 20' 45' YTNDocument1 page45-Footer High-Cube 26-03-2015 15:13:38 Page 1 of 1: F 20' 45' YTNAshley KaNo ratings yet

- The Gazette of India: Extraordinary Part Ii - Section IDocument53 pagesThe Gazette of India: Extraordinary Part Ii - Section I1976rkadvNo ratings yet

- CICAT Syllabus 2012Document13 pagesCICAT Syllabus 2012Ashley KaNo ratings yet

- Hatch Cover Arrangement of Wilhelm eDocument3 pagesHatch Cover Arrangement of Wilhelm eAshley KaNo ratings yet

- Flygbussarna E TicketDocument1 pageFlygbussarna E TicketAshley KaNo ratings yet

- FurnitureDocument1 pageFurnitureAshley KaNo ratings yet

- Maa Additional Scan PlanDocument1 pageMaa Additional Scan PlanAshley KaNo ratings yet

- Conectori PCDocument134 pagesConectori PCzavaidoc70100% (1)

- PDFDocument1 pagePDFAshley KaNo ratings yet

- Design EntrepreneurshipDocument5 pagesDesign EntrepreneurshipAshley KaNo ratings yet

- Module Information Module Title Electric Drives and Control Module Code MMD2511Document4 pagesModule Information Module Title Electric Drives and Control Module Code MMD2511Ashley KaNo ratings yet

- Lean ManufacDocument5 pagesLean ManufacAshley KaNo ratings yet

- The Great GamaDocument7 pagesThe Great GamaDivyanshDwivedi100100% (2)

- Book 21Document3 pagesBook 21Ashley KaNo ratings yet

- Certificates Onboard A VesselDocument19 pagesCertificates Onboard A VesselAshley KaNo ratings yet

- RestowDocument1 pageRestowAshley KaNo ratings yet

- Ah48 10807794 WPTDocument1 pageAh48 10807794 WPTAshley KaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)