Professional Documents

Culture Documents

Marine Brochure 2006 03 PDF

Uploaded by

platasturOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Brochure 2006 03 PDF

Uploaded by

platasturCopyright:

Available Formats

Plate Heat Exchangers

MARINE

Cool on all the 7 seas of the world

Shipbuilding: A tradition with a future

The tonnage to be realised in shipbuilding will notably grow over the next few decades. Outlooks prove the growth in worldwide trading over the seas. Cruise ships and high speed ferries will expect more and more passengers. Another trend are special-purpose ships as well as special constructions for raw material exploration and offshore technology (excavators, drilling platforms etc.). At the same time, the regulations governing the safety of ships and maritime environmental protection are becoming more stringent. As such, profitability for the ship owners becomes a crucial factor, and shipyards demand increasingly efficient solutions maximising safety and minimising operating costs with integrated control systems.

LT-HT fresh water/lube oil cooler incl. thermometers, pressure gauges and drain/venting pipes for Daedong Shipbuilding (STX), Korea

The maxim in sailing is: Safety first

Where ships manoeuvre in narrow waters or have to keep on course in a storm in the open sea, many things may happen, except the failure of the ships engine. This can be lethal, cost millions and do irreversible damage to the environment. For this reason, reliable propulsion and auxiliary systems are a must in modern operation on the seas. It is, therefore, only logical that many engine rooms are equipped with plate heat exchangers from GEA Ecoflex from the container ship to the luxurious cruise ship, from the polar circle to the tropics. As one of the pioneers in the development of plate heat exchangers (PHE), GEA Ecoflex not only offers you units proven at sea, but also in-depth special knowledge. The propulsion systems of the different manufacturers determine the design and dimensions of the cooling systems. In addition to cooling the propulsion systems, plate heat exchangers assume a large number of other tasks. Whatever the case may be: Safety, function and low lifetime costs are always on board also.

Lube oil cooler Varitherm VT 1306 installed on container ship Maersk Vancouver. Shipyard: J.J. Sietas, Hamburg

Efficient cooling for main and auxiliary engines

The cooling of ships engines requires a large number of different components, such as the plate heat exchangers of GEA Ecoflex. This illustration shows an exemplary function sequence. Solutions deviating from this are feasible without problems, thanks to the variety of sizes of the plate heat exchangers and their flexibility. We would be pleased to give advice or to show you other individual solutions.

Centralised cooling system with separate low temperature (LT) and high temperature (HT) circuits.

Preheater for sea water desalination

HT fresh water pumps Auxiliaries Charge air cooler M.E.

Lube oil cooler M.E.

Main engine

Aux. engine

LT fresh water pumps

Two principles having the same effect

There are two optional principles available for cooling high-power engines with plate heat exchangers: 1. The PHE are placed separately next to the engine 2. The PHE are directly built-on to the engine block to save space GEA Ecoflex closely co-operates with leading engine manufacturers and is involved in the development of new engine generations. This results in complete high-performance and economic drive systems.

Marine approvals

Plate heat exchangers manufactured by GEA Ecoflex are readily approved by the leading international ship classification bodies.

HT central coolers

LT central coolers

LT-central fresh water cooler Varitherm VT 80 installed on ferry Nils Holgersson (TT-Line)

Sea water pumps

Designing the suitable cooling system

At the time of the installation of the ships engine, the GEA Ecoflex plate heat exchangers are also installed. Depending on the design, the system can assume many tasks regarding the cooling and/or heating of all types of fluids. Typical applications include: Central cooling of the main or auxiliary engines or turbines Lubrication oil cooling Recooling of circulated water which cools cylinders, pistons, injection nozzles, valves and generators Cooling of gearing oil, compressor oil and other lubricants Pre-heating of lubrication oil and heavy fuel oil Pre-heating of sea water for fresh water generation Heat recovery Heat exchange to air-condition the passengers cabins and freight spaces

Queen Mary 2 sails with GEA Ecoflex

Even the machinery room of Queen Mary 2, the most prestigious cruise liner of the world, built at ALSTOM Marine, Saint Nazaire, France, is equipped with GEA Ecoflex plate heat exchangers, particularly with our NT 150 units.

Photo provided with courtesy of Alstom / France

In use for long and short voyages

For marine applications, GEA Ecoflex offers a range of plate heat exchangers that has proven itself over many years. The NT series launched on the market in 2000 rounds off the Varitherm range which has been established for a long time. Due to the high quality materials and their special gap geometry, all our units feature a long operating life and a high-performance.

NT plate heat exchanger

Optimum design due to variable lengths and profiles Low investment due to maximum heat transfer High-corrosion resistance due to a suitable material selection: titanium for sea water, stainless steel for oil and closed-circuit water systems Self-positioning plate package (anti-waving)

VARITHERM

Extremely variable in its capacity, profile and material selection Heat exchanger surfaces from 0.1 to 2,000 m2 per unit Flow quantities up to 3,600 m3/h per unit Space and weight saving due to a particularly compact design

Complete solution

Upon customer request, GEA Ecoflex fully equip the cooling units with control components (thermometer, pressure gauges etc.).

Clean plate heat exchangers

The inline filters protect the system from contamination contained in the sea water, such as sea tang, sludge and mussel shells they can be easily cleaned and quickly re-installed.

Economic seals

Here GEA Ecoflex offers the non-adhesive systems EcoLoc or LocIn which permit short down times while reducing your maintenance costs. On request, these seals are, of course, also available in the glue-in version. For technical details on all product groups, please refer to our separate leaflets.

GEA Ecoflex GmbH For more than 75 years, GEA Ecoflex has been developing customer-oriented and cost-optimised plate heat exchanger solutions for the following fields of application:

HVAC refrigeration sugar chemical paper

food life science marine power ethanol

France, Paris GEA Ecoflex, France Phone: + 33-130-146-521 Fax: + 33-130-146-529 E-mail: info.france@gea-ecoflex.com Great Britain, Sheffield GEA Ecoflex UK Ltd. Phone: + 44 -190-955 -1107 Fax: + 44 -190-955 -0885 E-mail: info.uk@gea-ecoflex.com Sweden, Landskrona GEA Ecobraze AB Phone: + 46 - 418 -446 -160 Fax: + 46 - 418 -446 -177 E-mail: info@gea-ecobraze.com

Italy, Parma GEA Ecoflex, Italy Phone: + 39 -0521-965 -453 Fax: + 39 -0521-965 -507 E-mail: info.italy@gea-ecoflex.com Denmark, Skanderborg GEA Ecoflex, Scandinavia Phone: + 45 - 7015 -2200 Fax: + 45 - 7015 -2244 E-mail: info.scandinavia@gea-ecoflex.com USA, Louisville GEA Ecoflex North America Inc. Phone: + 1-502-962 -3535 Fax: + 1-502-962 -5497 E-mail: info.northamerica@gea-ecoflex.com Poland, Warsaw GEA Ecoflex, Poland Phone: + 48 -22-608 14 15 Fax: + 48 -22-608 14 25 E-mail: info.poland@gea-ecoflex.com

China, Shanghai GEA Ecoflex, China Phone: + 86-21 63 90 00 01 Fax: + 86-21 63 90 05 56 E-mail: info.china@gea-ecoflex.com Singapore GEA Ecoflex, Asia Pacific Phone: + 65 -6336 -7278 Fax: + 65 -6336 -3363 E-mail: info.asia@gea-ecoflex.com Malaysia, Puchong GEA Ecoflex (Asia) Sdn. Bhd. Phone: + 60 -3-8060-9592 Fax: + 60 -3-8060-9594 E-mail: info.asia@gea-ecoflex.com India, Navi Mumbai GEA Ecoflex, India Phone: + 91-22 -2764 -2025 Fax: + 91-22 -2769 -3821 E-mail: info.india@gea-ecoflex.com

Technical modification reserved. MARINE E 12 / 05 inform advertising

Your contact:

GEA Ecoflex GmbH Karl-Schiller-Str. 1 3 D-31157 Sarstedt Phone: + 49 (0) 50 66 / 6 01- 0 Fax: + 49 (0) 50 66 / 6 01-1 04 www.gea-ecoflex.com E-mail: info@gea-ecoflex.de

A company of GEA Group

The specifications contained in this printing unit are intended only to serve the nonbinding description of our products and services and are not subject to guarantee. Binding specifications, especially pertaining to performance data and suitability for specific operating purposes, are dependent upon the individual circumstances at the operation location and can, therefore, only be made in terms of precise requests.

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- GEA PHE Marine enDocument8 pagesGEA PHE Marine enTimmyJuriNo ratings yet

- Ensuring Efficient Reliability For Marine Thermal Systems: Industry OverviewDocument24 pagesEnsuring Efficient Reliability For Marine Thermal Systems: Industry Overviewpetar petar100% (1)

- HE TransterDocument16 pagesHE Transteribnuhary100% (1)

- DMA BrochureDocument20 pagesDMA BrochurelongttNo ratings yet

- NEM Power-Systems BrochureDocument16 pagesNEM Power-Systems Brochurehung100% (1)

- 2010 en Marine Catalog WebastoDocument138 pages2010 en Marine Catalog WebastoPablo PosadaNo ratings yet

- Cooling & Heating: ShellmaxDocument3 pagesCooling & Heating: Shellmaxvijaysirsat2007No ratings yet

- Differences in Marine and Land Based Power Generation ApplicationDocument7 pagesDifferences in Marine and Land Based Power Generation ApplicationChaitra Pm0% (1)

- Brochure Air Cooled CondenserDocument8 pagesBrochure Air Cooled CondenserFathur Rahman Handoko100% (1)

- Brochure ACCDocument8 pagesBrochure ACCbabis1980No ratings yet

- Bartlett Snow Rotary CoolersDocument2 pagesBartlett Snow Rotary CoolersDea AvrildaNo ratings yet

- Inert Gas System (IGG)Document3 pagesInert Gas System (IGG)Fadzil NorNo ratings yet

- GEA KME Brochure Evaporadores SearleDocument12 pagesGEA KME Brochure Evaporadores SearleCarlos Labra FierroNo ratings yet

- Climate Master All Products CatalogDocument602 pagesClimate Master All Products CatalogShannon WilliamsNo ratings yet

- Hypochlorite GenerationDocument2 pagesHypochlorite GenerationsidatsenaNo ratings yet

- DVI143 Neatpump EN 1209 PDFDocument4 pagesDVI143 Neatpump EN 1209 PDFHamza BaraketNo ratings yet

- SSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Document12 pagesSSCDW-1112 R134a Water Cooled Screw Chiller SSCX (55-300RT) (Rev2 230413)Naing Oo KyawNo ratings yet

- Thermal Energy Storage SystemDocument55 pagesThermal Energy Storage SystemTrain13100% (1)

- Active Heated Pipe Technologies For Field Development Optimisation (OTC 26578-MS)Document21 pagesActive Heated Pipe Technologies For Field Development Optimisation (OTC 26578-MS)ArsénioNo ratings yet

- AFC Compact Systems: GEA Searle KEC Air Cooler: Top-Level Engineering SolutionsDocument12 pagesAFC Compact Systems: GEA Searle KEC Air Cooler: Top-Level Engineering SolutionsJt LoutfiNo ratings yet

- GEA Shell and Tube Heat Exchangers For The Oil and Gas IndustryDocument10 pagesGEA Shell and Tube Heat Exchangers For The Oil and Gas IndustryMauricio Huerta JaraNo ratings yet

- Green Power Transformers Brochure GBDocument4 pagesGreen Power Transformers Brochure GBKali MuthuNo ratings yet

- Aosmith HeatersDocument48 pagesAosmith HeatersAli Kamel AkilNo ratings yet

- 10 Tips Refrigerant PipingDocument3 pages10 Tips Refrigerant PipingAndres CarrascoNo ratings yet

- Wärtsilä MSF Marine LowResDocument7 pagesWärtsilä MSF Marine LowResBarbara VasconcelosNo ratings yet

- Plate Heat Exchangers: Brian A. Flynn Limited. RefrigerationDocument8 pagesPlate Heat Exchangers: Brian A. Flynn Limited. Refrigerationarshadkhan77No ratings yet

- EN TankHeating DG H56887 - tcm432 26444 PDFDocument30 pagesEN TankHeating DG H56887 - tcm432 26444 PDFyassine633No ratings yet

- GEABtt GBJan 2011Document13 pagesGEABtt GBJan 2011sribd9128No ratings yet

- Umar Plate Heat Exchangers and EthanolDocument13 pagesUmar Plate Heat Exchangers and EthanolTara EdwardsNo ratings yet

- 2.hamon CatalogueDocument12 pages2.hamon CatalogueFREDIELABRADORNo ratings yet

- 4052 - Mcquay MNG 115.2 PDFDocument88 pages4052 - Mcquay MNG 115.2 PDFFarrukhAhmedKhanNo ratings yet

- Engine Driven RefrigerationDocument2 pagesEngine Driven RefrigerationValentin LupascuNo ratings yet

- ViFlow Funke GB PDFDocument8 pagesViFlow Funke GB PDFukalNo ratings yet

- Heat Exchanger Failure CourseworkDocument4 pagesHeat Exchanger Failure Courseworkswqoqnjbf100% (2)

- Installation and ServiceDocument19 pagesInstallation and ServiceJosé Emilio D' LeónNo ratings yet

- Heat Exchangers Deaerator Feedwater TankDocument2 pagesHeat Exchangers Deaerator Feedwater TankNury RinjaniNo ratings yet

- Safe ThermDocument6 pagesSafe ThermLoganBohannonNo ratings yet

- Marine System Solutions: Expertise For Maximum Performance, Profitability and Environmental ProtectionDocument22 pagesMarine System Solutions: Expertise For Maximum Performance, Profitability and Environmental Protectionalejandro_roldán_61No ratings yet

- Catálogo Thermax LTDocument14 pagesCatálogo Thermax LTLarissa BarbosaNo ratings yet

- Helium Leak Detection - Manufactering ColboxDocument9 pagesHelium Leak Detection - Manufactering ColboxhoseinNo ratings yet

- Leister Process Heat GunDocument40 pagesLeister Process Heat GunTorcuato GonzalezNo ratings yet

- Weco en - 03-08Document6 pagesWeco en - 03-08Mohd NaserNo ratings yet

- Vacuum Hardening HssDocument6 pagesVacuum Hardening Hssharanus2000No ratings yet

- Manual Secador KAESER TE91Document9 pagesManual Secador KAESER TE91Monica SholesNo ratings yet

- DepVAPOR290409 PDFDocument8 pagesDepVAPOR290409 PDFltrevino100No ratings yet

- SNAME InsulationDesignDocument15 pagesSNAME InsulationDesignAllAmericanMarineNo ratings yet

- PHD Thesis On Refrigeration and Air ConditioningDocument6 pagesPHD Thesis On Refrigeration and Air Conditioningafcmunxna100% (2)

- Chemical Engineering Magazine Abril 2009 PDFDocument108 pagesChemical Engineering Magazine Abril 2009 PDFFélix Vargas Santillán100% (1)

- Marine Diesel Engine ThesisDocument6 pagesMarine Diesel Engine Thesisfc5wsq30100% (1)

- CondCooling-Tower-Fundamentalsenser Cooling SystemsDocument3 pagesCondCooling-Tower-Fundamentalsenser Cooling SystemsMohamed ZaghloulNo ratings yet

- Energy Solutions Heat RecoveryDocument4 pagesEnergy Solutions Heat RecoveryyaserbadrNo ratings yet

- EN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFDocument6 pagesEN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFermusatNo ratings yet

- Pathfinder HDS-1 MWD Gamma ToolDocument2 pagesPathfinder HDS-1 MWD Gamma Toolcheeeky_monkeyNo ratings yet

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Medical Icons For Windows 7Document17 pagesMedical Icons For Windows 7platasturNo ratings yet

- Anti HeelingDocument5 pagesAnti HeelingplatasturNo ratings yet

- Planta de TratamientoDocument8 pagesPlanta de TratamientoplatasturNo ratings yet

- Heatpac CBM: Brazed Plate Heat ExchangerDocument2 pagesHeatpac CBM: Brazed Plate Heat ExchangerplatasturNo ratings yet

- Aalborg Solutions: Keep Your Feedwater Steaming HotDocument2 pagesAalborg Solutions: Keep Your Feedwater Steaming HotRavikumar GangadharanNo ratings yet

- Perkins Marine Engine HandbookDocument49 pagesPerkins Marine Engine Handbookpgupta71100% (1)

- Intercambiadores de PlacasDocument36 pagesIntercambiadores de PlacasplatasturNo ratings yet

- Briggs& Stratton Spare Parts 31a600 SeriesDocument16 pagesBriggs& Stratton Spare Parts 31a600 SeriesplatasturNo ratings yet

- Intro PipingDocument64 pagesIntro PipingAjay Kumar92% (12)

- Marine OffshoreDocument12 pagesMarine OffshoreplatasturNo ratings yet

- Imo Pump Ace3 - 1122.03 - GBDocument16 pagesImo Pump Ace3 - 1122.03 - GBplatasturNo ratings yet

- Isometric Piping Symbols - Oil and GasDocument21 pagesIsometric Piping Symbols - Oil and GasAfiawan MaleekNo ratings yet

- Music Circuits, Practical ElectronicDocument9 pagesMusic Circuits, Practical Electronicplatastur100% (2)

- Glossary of Oil and Gas TermsDocument86 pagesGlossary of Oil and Gas TermsplatasturNo ratings yet

- (Ships) Plates & Diagrams For MarinersDocument171 pages(Ships) Plates & Diagrams For MarinersplatasturNo ratings yet

- Cable and Tension StructuresDocument17 pagesCable and Tension StructuresplatasturNo ratings yet

- Imm3 TS6Document209 pagesImm3 TS6platasturNo ratings yet

- S7-300 RHB eDocument702 pagesS7-300 RHB eSourabh Varun VermaNo ratings yet

- Ebook - Approved Code Practice For CraneDocument110 pagesEbook - Approved Code Practice For CraneplatasturNo ratings yet

- Ebook - Slings SafetyDocument35 pagesEbook - Slings SafetyplatasturNo ratings yet

- Water Treatment Handbook UNITORDocument46 pagesWater Treatment Handbook UNITORplatastur100% (26)

- ABB Circuit1343844018 OriginalDocument60 pagesABB Circuit1343844018 OriginalplatasturNo ratings yet

- Electromyostimulation StudyDocument22 pagesElectromyostimulation StudyAgnes Sophia PenuliarNo ratings yet

- How Do I Predict Event Timing Saturn Nakshatra PDFDocument5 pagesHow Do I Predict Event Timing Saturn Nakshatra PDFpiyushNo ratings yet

- INDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor PositioningDocument8 pagesINDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor Positioningzeeshan ahmedNo ratings yet

- Product 97 File1Document2 pagesProduct 97 File1Stefan StefanNo ratings yet

- Mythology GreekDocument8 pagesMythology GreekJeff RamosNo ratings yet

- Cultural AnthropologyDocument12 pagesCultural AnthropologyTRISH BOCANo ratings yet

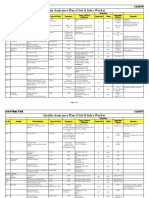

- Quality Assurance Plan - CivilDocument11 pagesQuality Assurance Plan - CivilDeviPrasadNathNo ratings yet

- Skills Check Extra 2ADocument1 pageSkills Check Extra 2AVishmi JayawardeneNo ratings yet

- Sel027 PDFDocument9 pagesSel027 PDFSmart BiomedicalNo ratings yet

- CMS156Document64 pagesCMS156Andres RaymondNo ratings yet

- Embedded System Lab ManualDocument67 pagesEmbedded System Lab Manualsaim100% (1)

- Brianna Pratt - l3stl1 - Dsu Lesson Plan TemplateDocument5 pagesBrianna Pratt - l3stl1 - Dsu Lesson Plan Templateapi-593886164No ratings yet

- Term Paper A and CDocument9 pagesTerm Paper A and CKishaloy NathNo ratings yet

- Vicente BSC2-4 WhoamiDocument3 pagesVicente BSC2-4 WhoamiVethinaVirayNo ratings yet

- Detailed Lesson Plan in Mathematics (Pythagorean Theorem)Document6 pagesDetailed Lesson Plan in Mathematics (Pythagorean Theorem)Carlo DascoNo ratings yet

- Higher Vapor Pressure Lower Vapor PressureDocument10 pagesHigher Vapor Pressure Lower Vapor PressureCatalina PerryNo ratings yet

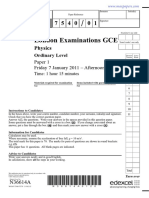

- 7540 Physics Question Paper 1 Jan 2011Document20 pages7540 Physics Question Paper 1 Jan 2011abdulhadii0% (1)

- A Meta Analysis of The Relative Contribution of Leadership Styles To Followers Mental HealthDocument18 pagesA Meta Analysis of The Relative Contribution of Leadership Styles To Followers Mental HealthOnii ChanNo ratings yet

- Cognitive Coaching AdelaideDocument3 pagesCognitive Coaching AdelaideBusiness-Edu100% (2)

- Malaybalay CityDocument28 pagesMalaybalay CityCalvin Wong, Jr.No ratings yet

- HSG Vs SonohysterographyDocument4 pagesHSG Vs Sonohysterography#15No ratings yet

- Annotated Bibliography 2Document3 pagesAnnotated Bibliography 2api-458997989No ratings yet

- Pinterest or Thinterest Social Comparison and Body Image On Social MediaDocument9 pagesPinterest or Thinterest Social Comparison and Body Image On Social MediaAgung IkhssaniNo ratings yet

- Matter Around Me: SC1 - Teaching Science in ElementaryDocument27 pagesMatter Around Me: SC1 - Teaching Science in ElementaryYanna Marie Porlucas Macaraeg50% (2)

- Opening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayDocument3 pagesOpening Checklist: Duties: Monday Tuesday Wednesday Thursday Friday Saturday SundayAlven BlancoNo ratings yet

- Growth Kinetic Models For Microalgae Cultivation A ReviewDocument16 pagesGrowth Kinetic Models For Microalgae Cultivation A ReviewJesús Eduardo De la CruzNo ratings yet

- Chapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatDocument123 pagesChapter 8 - Current Electricity - Selina Solutions Concise Physics Class 10 ICSE - KnowledgeBoatskjNo ratings yet

- Market Structure and TrendDocument10 pagesMarket Structure and TrendbillNo ratings yet

- T2 Group4 English+for+BusinessDocument8 pagesT2 Group4 English+for+Businessshamerli Cerna OlanoNo ratings yet

- Excel Lesson 5 QuizDocument5 pagesExcel Lesson 5 Quizdeep72No ratings yet