Professional Documents

Culture Documents

B90 Bus Differential Relay and Breaker Failure Protection

B90 Bus Differential Relay and Breaker Failure Protection

Uploaded by

●●●●●●●1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B90 Bus Differential Relay and Breaker Failure Protection

B90 Bus Differential Relay and Breaker Failure Protection

Uploaded by

●●●●●●●1Copyright:

Available Formats

Industrial Systems

1

B90 Bus Differential Relay and Breaker Failure Protection

Cost-efficient

Good performance

Modern communications capability

Member of the Universal Relay (UR) family

Easy integration with other URs

Common configuration tool for all B90 IEDs

Proven algorithms (B30) and hardware (UR)

Expandable

Two levels of scalability (modules and IEDs)

Industrial Systems

2

NEW!

Busbar Protection Schemes

High-impedance / linear couplers

non-configurable busbars

cheap relay, expensive primary equipment

Blocking schemes for simple busbars

Analog low / medium - impedance schemes

Digital relays for small busbars

Digital relays for large busbars

Phase-segregated cost-efficient digital relays

for large busbars

B90

B30

BUS

PVD

Any

SPD

GE offer Approach

Industrial Systems

3

Why Digital Bus Relay?

Re-configurable busbars require dynamic assignment

of currents to multiple zones

expensive and dangerous when done externally on

secondary currents (analog way)

natural and safe when done in software

Breaker Fail for re-configurable busbars is naturally

integrated with the bus protection

No need for special CTs (cost)

Relaxed requirements for the CTs (cost)

Advantages of digital technology

Industrial Systems

4

Design Challenges for Digital Busbar Relays

Reliability

Security:

Immunity to CT saturation

Immunity to wrong input information

Large number of inputs and outputs required:

AC inputs (tens or hundreds)

Trip rated output contacts (tens or hundreds)

Other output contacts (tens)

Digital Inputs (hundreds)

Large processing power required to handle al the data

Industrial Systems

5

Traditionally Two Distinctive Architectures are Offered

Fits better new installations

Perceived less reliable

Slower

52

DAU

52

DAU

52

DAU

CU

copper

fiber

Distributed Bus Protection

52 52 52

CU

copper

Centralized Bus Protection

Fits better retrofit installations

Perceived more reliable

Potentially faster

Industrial Systems

6

i

A

, v

A

New Architecture Digital Phase-Segregated Busbar Scheme

Foundation:

Single-phase IEDs for primary

differential protection

Separate IEDs for Breaker

Failure and extra I/Os

Inter-IED communications for

sharing digital states

Scalability and flexibility

Phase A

Protection

TRIP

A

i

B

, v

B

Phase B

Protection

TRIP

B

i

C

, v

C

Phase C

Protection

TRIP

C

Breaker

Failure

Industrial Systems

7

B90 Capacity

Up to 24 circuits in a single zone without voltage

supervision

Multi-IED architecture with each IED built on modular

hardware

Up to 24 AC inputs per B90 IED freely selectable

between currents and voltages (24+0, 23+1, 22+2, ..)

Up to 96 digital inputs per B90 IED

Up to 48 output contacts per B90 IED

Flexible allocation of AC inputs, digital inputs and

output contacts between the B90 IEDs

Industrial Systems

8

B90 Features and Benefits

Maximum number of circuits in one zone: 24

Number of zones : 4

Busbar configuration: No limits

Sub-cycle tripping time

Security (only 2msec of clean waveforms required for stability)

Differential algorithm supervised by CT saturation detection and

directional principle

Dynamic bus replica, logic and signal processing

No need for interposing CTs (ratio matching up to 32:1)

CT trouble per each zone of protection

Breaker failure per circuit

End fault protection (EFP) per circuit

Undervoltage supervision per each voltage input

Overcurrent protection (IOC and TOC) per circuit

Communication, metering and recording

Industrial Systems

9

B90 Applications

Busbars:

Single

Breaker-and-a-half

Double

Triple

With and without transfer bus

Networks:

Solidly grounded

Lightly grounded (via resistor)

Ungrounded

Industrial Systems

10

B90 Architecture Overview

Phase-segregated multi-IED system built on Universal

Relay (UR) platform

Each IED can be configured to include up to six

modules:

AC inputs (up to 3 x 24 single phase inputs)

Contact outputs (up to 6 x 8)

Digital Inputs (up to 6 X 16)

Variety of combinations of digital inputs and output

contacts

Fast digital communications between the IEDs for

sharing digital states

Industrial Systems

11

B90 Architecture

B90

Phase A Protection

P

S

UR #1

C

P

U

C

O

M

M

S

D

S

P

I

/

O

D

S

P

I

/

O

D

S

P

I

/

O

phase A currents & voltages

f

i

b

e

r

,

r

i

n

g

c

o

n

f

i

g

u

r

a

t

i

o

n

phase A trip contacts

P

S

C

P

U

UR #2 Phase B Protection

D

S

P

I

/

O

D

S

P

I

/

O

D

S

P

I

/

O

C

O

M

M

S

phase B currents & voltages

phase B trip contacts

P

S

C

P

U

UR #3 Phase C Protection

D

S

P

I

/

O

D

S

P

I

/

O

D

S

P

I

/

O

C

O

M

M

S

phase C currents & voltages

phase C trip contacts

P

S

C

P

U

UR #4 Bus Replica & Breaker Fail

I

/

O

I

/

O

I

/

O

I

/

O

I

/

O

I

/

O

C

O

M

M

S

No A/C data traffic

No need for sampling

synchronization,

straightforward relay

configuration - all A/C signals

local to a chassis

Data traffic reduced to I/Os

Direct I/Os (similar to existing

UR Remote I/Os) used for

exchange of binary data

Oscillography capabilities

multiplied (available in each

IED separately)

Programmable logic

(FlexLogic) capabilities

multiplied

SOE capabilities multiplied

Extra URs in a loop for more

I/Os

Industrial Systems

12

B90 Components: Protection IEDs

Modular architecture (from 2 to 9 modules)

All modules but CPU and PS optional

Up to 24 AC inputs total (24 currents and no

voltages, through 12 currents and 12

voltages)

Three I/O modules for trip contacts or extra

digital inputs

Features oriented towards AC signal

processing (differential, IOC, TOC, UV, BF

current supervision)

P

o

w

e

r

S

u

p

p

l

y

C

P

U

D

S

P

1

I

/

O

D

S

P

2

I

/

O

D

S

P

3

I

/

O

C

o

m

m

s

8

A

C

s

i

n

g

l

e

-

p

h

a

s

e

i

n

p

u

t

s

8

A

C

s

i

n

g

l

e

-

p

h

a

s

e

i

n

p

u

t

s

8

A

C

s

i

n

g

l

e

-

p

h

a

s

e

i

n

p

u

t

s

O

t

h

e

r

U

R

-

b

a

s

e

d

I

E

D

s

B90 is built on UR hardware (4 years of field experience)

Industrial Systems

13

B90 Components: Logic IEDs

Modular architecture (from 2 to 9 modules)

All modules but CPU and PS optional

Up to 96 digital inputs or

48 output contacts or

Virtually any mix of the above

Features oriented towards logic functions (BF

logic and timers, isolator monitoring and

alarming)

P

o

w

e

r

S

u

p

p

l

y

C

P

U

O

t

h

e

r

U

R

-

b

a

s

e

d

I

E

D

s

I

/

O

I

/

O

I

/

O

I

/

O

I

/

O

I

/

O

C

o

m

m

s

B90 is built on UR hardware (4 years of field experience)

Industrial Systems

14

B90 Scheme for Large Busbars

Dual (redundant) fiber with

3msec delivery time between

neighbouring IEDs. Up to 8

B90s/URs in the ring

Phase A AC signals and

trip contacts

Phase B AC signals and

trip contacts

Phase C AC signals and

trip contacts

Digital Inputs for isolator

monitoring and BF

Industrial Systems

15

Security of the B90 Communications

Dual (redundant) ring each message send

simultaneously in both directions

No switching equipment (direct TX-RX connection)

Self-monitoring incorporated

Information re-sent (repeated) automatically

32-bit CRC

Default states of exchanged flags upon loss of

communications (allows developing secure

applications)

Industrial Systems

16

B90 Communications

The communications feature (Direct I/Os) requires

digital communications card (dual-port 820nmm LED)

Up to 96 inputs / outputs could be sent / received

Up to 8 UR IEDs could be interfaced

When interfacing with other URs, 32 inputs / outputs

are available

The Direct I/O feature is modeled on UCA GOOSE but

is sent over dedicated fiber (not LAN) and is optimized

for speed

User-friendly configuration mechanism is available

Simple applications do not require communications

Industrial Systems

17

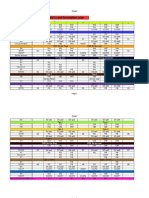

Typical B90 Applications for Large Busbars

7 to 24 feeders

Basic: 87 & BF

for less than 16

feeders

Extended: BF for more

than 16 feeders

Full version: 24 Feeders

with BF.

1 2 3 23 24

ZONE 1

1 2 3 21 22

ZONE 1

ZONE 2

23 24

Industrial Systems

18

Typical B90 Applications for Large Busbars

7 to 24 feeders

7 to 24 feeders

1

2

3

4

21

22

23

24

ZONE 1

ZONE 2

1 2 11

ZONE 1

12 13 22

23 24

ZONE 2

Industrial Systems

19

B90 and Small Single Busbars 8-circuit busbar

Two levels of scalability allow flexible applications

P

o

w

e

r

S

u

p

p

l

y

C

P

U

D

S

P

1

I

/

O

D

S

P

2

I

/

O

D

S

P

3

I

/

O

S

p

a

r

e

8

p

h

a

s

e

-

A

c

u

r

r

e

n

t

s

8

p

h

a

s

e

-

B

c

u

r

r

e

n

t

s

8

p

h

a

s

e

-

C

c

u

r

r

e

n

t

s

D

i

f

f

Z

o

n

e

1

D

i

f

f

Z

o

n

e

2

D

i

f

f

Z

o

n

e

3

One B90 IED with 3 zones

could protect a single

8-circuit busbar!

Industrial Systems

20

B90 and Small Single Busbars 12-circuit busbar

P

o

w

e

r

S

u

p

p

l

y

C

P

U

D

S

P

1

I

/

O

D

S

P

2

I

/

O

D

S

P

3

I

/

O

S

p

a

r

e

8

p

h

a

s

e

-

A

c

u

r

r

e

n

t

s

4

p

h

a

s

e

-

A

c

u

r

r

e

n

t

s

8

p

h

a

s

e

-

B

c

u

r

r

e

n

t

s

Two B90 IEDs with 2 zones

could protect a single

12-circuit busbar!

4

p

h

a

s

e

-

B

c

u

r

r

e

n

t

s

P

o

w

e

r

S

u

p

p

l

y

C

P

U

D

S

P

1

I

/

O

D

S

P

2

I

/

O

S

p

a

r

e

S

p

a

r

e

S

p

a

r

e

8

p

h

a

s

e

-

C

c

u

r

r

e

n

t

s

4

p

h

a

s

e

-

C

c

u

r

r

e

n

t

s

Two levels of scalability allow flexible applications

Industrial Systems

21

B90 and Small Single Busbars 16-circuit busbar

P

o

w

e

r

S

u

p

p

l

y

C

P

U

D

S

P

1

I

/

O

D

S

P

2

I

/

O

S

p

a

r

e

S

p

a

r

e

S

p

a

r

e

8

p

h

a

s

e

-

A

c

u

r

r

e

n

t

s

8

p

h

a

s

e

-

A

c

u

r

r

e

n

t

s

P

o

w

e

r

S

u

p

p

l

y

C

P

U

D

S

P

1

I

/

O

D

S

P

2

I

/

O

S

p

a

r

e

S

p

a

r

e

S

p

a

r

e

8

p

h

a

s

e

-

B

c

u

r

r

e

n

t

s

8

p

h

a

s

e

-

B

c

u

r

r

e

n

t

s

P

o

w

e

r

S

u

p

p

l

y

C

P

U

D

S

P

1

I

/

O

D

S

P

2

I

/

O

S

p

a

r

e

S

p

a

r

e

S

p

a

r

e

8

p

h

a

s

e

-

C

c

u

r

r

e

n

t

s

8

p

h

a

s

e

-

C

c

u

r

r

e

n

t

s

Three B90 single-zone IEDs

could protect a single

16..24-circuit busbar!

Two levels of scalability allow flexible applications

Industrial Systems

22

Applicability to Ungrounded and Lightly Grounded Systems

Three phase protection units for phase-to-phase faults and

saturation detection

Fourth unit with AC inputs for zero-sequence differential

protection (fed from split-core or regular CTs)

B90 can be applied to solidly and lightly grounded

as well as ungrounded systems

I

A

I

B

I

C

3I

0

Phase A

Phase B

Phase C

Ground

Industrial Systems

23

B90 Configuration Program

(1) B90 Protection system is

a site

(2) That includes the

required IEDs

(3) Functions available for

dealing with all IEDs

simultaneously

URPC program used for configuration

Common setting file for all B90 IEDs

All B90 can be accessed

simultaneously

Off-line setting files can easily be

produced

Industrial Systems

24

B90 Algorithms

Bus differential protection

Dynamic bus replica

Isolator monitoring and alarming

End Fault Protection

Breaker Failure

Industrial Systems

25

d

i

f

f

e

r

e

n

t

i

a

l

restraining

CT Saturation Problem

External

fault: ideal

CTs

t

0

fault inception

t

2

fault conditions

t

0

t

2

Industrial Systems

26

d

i

f

f

e

r

e

n

t

i

a

l

restraining

CT Saturation Problem

External fault:

CT ratio

mismatch

t

0

fault inception

t

2

fault conditions

t

0

t

2

Industrial Systems

27

d

i

f

f

e

r

e

n

t

i

a

l

restraining

CT Saturation Problem

External

fault: CT

saturation

t

0

fault inception

t

1

CT saturation time

t

2

CT saturated

t

0

t

1

t

2

Industrial Systems

28

Differential Protection

B90 algorithms aimed at:

Improving the main differential function by providing

better filtering, faster response, better restraining

technique, robust switch-off transient blocking, etc.

Incorporating a saturation detection mechanism that

would recognize CT saturation on external faults in

a fast and reliable manner

Applying a second protection principle namely

phase directional (phase comparison) for better

security

Industrial Systems

29

Bus Differential Function Block Diagram

Industrial Systems

30

B90 Differential Function Theory of Operation

Definition of the Restraining Current

Operating Characteristic

CT Saturation Detector

Default Tripping Logic

Customizing the Tripping Logic

Industrial Systems

31

maximum of

geometrical average

scaled sum of

sum of

n R

i i i i i + + + + = ...

3 2 1

( )

n R

i i i i

n

i + + + + = ...

1

3 2 1

( )

n R

i i i i Max i ,..., , ,

3 2 1

=

n

n R

i i i i i = ...

3 2 1

Various Definitions of the Restraining Signal

Industrial Systems

32

Restraining Current

The amount of restraint provided by various definitions

is different; sometimes significantly different particularly

for multi-circuit differential elements such as busbar

protection

When selecting the slope (slopes) one must take into

account the applied definition of the restraining signal

The B90 uses the maximum of definition of the

restraining current

Industrial Systems

33

Sum of vs. Max of definitions of restraint

Sum of approach:

more restraint on external faults; less sensitivity on internal

faults

scaled sum of may take into account the actual number of

connected circuits increasing sensitivity

characteristic breakpoints difficult to set

Max of approach (B30, B90 and UR in general):

less restraint on external faults

more sensitivity on internal faults

breakpoints easier to set

better handles situations when one CT may saturate

completely (99% slope settings possible)

Industrial Systems

34

Differential Function Characteristic

d

i

f

f

e

r

e

n

t

i

a

l

restraining

LOW

SLOPE

OPERATE

BLOCK

I

R

|I

D

|

HIGH

SLOPE

L

O

W

B

P

N

T

H

I

G

H

B

P

N

T

PICKUP

Industrial Systems

35

Differential Function Adaptive Approach

d

i

f

f

e

r

e

n

t

i

a

l

restraining

Region 1

(low differential

currents)

Region 2

(high differential

currents)

low currents

saturation possible due to dc offset

saturation very difficult to detect

more security required

large currents

quick saturation possible due to

large magnitude

saturation easier to detect

security required only if saturation

detected

Industrial Systems

36

Adaptive Logic

DIF

1

DIR

SAT

DIF

2

O

R

A

N

D

O

R

TRIP

A

N

D

Industrial Systems

37

Adaptive Approach

d

i

f

f

e

r

e

n

t

i

a

l

restraining

Region 1

(low differential

currents)

Region 2

(high differential

currents)

Dynamic 2-out-of-2,

1-out-of-2 operating

mode

2-out-of-2

operating

mode

Industrial Systems

38

Directional Principle

DIF

1

DIR

SAT

DIF

2

O

R

A

N

D

O

R

TRIP

A

N

D

Industrial Systems

39

Directional Principle

Voltage signal is not required

Internal faults:

all fault (large) currents approximately in phase

External faults:

one current approximately out of phase

Secondary current of

the faulted circuit

(deep CT saturation)

Industrial Systems

40

Directional Principle

Implementation:

step 1: select fault contributors

A contributoris a circuit carrying significant amount of current

A circuit is a contributor if its current is above higher break

point

A circuit is a contributor if its current is above a certain portion

of the restraining current

step 2: check angle between each contributor and the sum of all

the other currents

Sum of all the other currents is the inverted contributor if the

fault is external; on external faults one obtains an angle of 180

degrees

step 3: compare the maximum angle to the threshold

A threshold is a factory constant of 90 degrees

An angle shift of more than 90 degrees due to CT saturation is

physically impossible

Industrial Systems

41

External Fault

BLOCK

OPERATE

BLOCK

|

|

.

|

\

|

p D

p

I I

I

real

|

|

.

|

\

|

p D

p

I I

I

imag

I

p

I

D

- I

p

External Fault Conditions

OPERATE

Industrial Systems

42

Internal Fault

BLOCK

BLOCK

|

|

.

|

\

|

p D

p

I I

I

real

|

|

.

|

\

|

p D

p

I I

I

imag

I

p

I

D

- I

p

Internal Fault Conditions

OPERATE

OPERATE

Industrial Systems

43

Saturation Detector

DIF

1

DIR

SAT

DIF

2

O

R

A

N

D

O

R

TRIP

A

N

D

Industrial Systems

44

d

i

f

f

e

r

e

n

t

i

a

l

restraining

Saturation Detector

t

0

t

1

t

2

t

0

fault inception

t

1

CT starts to saturate

t

2

external fault under

heavy CT saturation

conditions

Industrial Systems

45

Saturation Detector The State Machine

NORMAL

SAT := 0

EXTERNAL

FAULT

SAT := 1

EXTERNAL

FAULT & CT

SATURATION

SAT := 1

The differential

characteristic

entered

The differential-

restraining trajectory

out of the differential

characteristic for

certain period of time

saturation

condition

The differential

current below the

first slope for

certain period of

time

Industrial Systems

46

Saturation Detector

Operation:

The SAT flag WILL NOT be set during internal faults

whether or not any CTs saturate

The SAT flag WILL be SET during external faults

whether or not any CTs saturate

By design the SAT flag is NOT used to block the

relay but to switch to 2-out-of-2 operating principle

Industrial Systems

47

Examples External Fault

0.06 0.07 0.08 0.09 0.1 0.11 0.12

-200

-150

-100

-50

0

50

100

150

200

time, sec

c

u

r

r

e

n

t

,

A

~1 ms

The bus differential

protection element

picks up due to heavy

CT saturation

The CT saturation f lag

is set safely bef ore the

pickup f lag

Despite heavy CT

saturation the

external fault current

is seen in the

opposite direction

The

directional flag

is not set

The element

does not

maloperate

Industrial Systems

48

Examples Internal Fault

The bus diff erential

protection element

picks up

The saturation

flag is not set - no

directional

decision required

The element

operates in

10ms

All the fault currents

are seen in one

direction

The

directional

flag is set

Industrial Systems

49

User-Modified Tripping Logic

All the key logic flags (DIFferential, SATuration, DIRectional) are

available as FlexLogic

TM

operands with the following meanings:

BUS BIASED PKP - differential characteristic entered

BUS SAT - saturation (external fault) detected

BUS DIR - directionality confirmed (internal

fault)

FlexLogic

TM

can be used to override the default 87B logic

Example: 2-out-of-2 operating principle with extra security applied

to the differential principle:

Industrial Systems

50

Dynamic Bus Replica

Dynamic bus replica mechanism is provided by associating a

status signal with each current of a given differential zone

Each current can be inverted prior to configuring into a zone (tie-

breaker with a single CT)

The status signal is a FlexLogic

TM

operand (totally user

programmable)

The status signals are formed in FlexLogic

TM

including any

filtering or extra security checks from the positions of switches

and/or breakers as required

Bus replica applications:

Isolators

Tie-Breakers

Breakers

Industrial Systems

51

Dynamic Bus Replica - Isolators

Reliable Isolator Closed signal is composed

The Isolator Position signal:

Decides whether the associated current is to be included into

differential calculations

Decides whether the associated breaker is to be tripped

For maximum safety:

Both normally open and normally closed contacts are used

Isolator alarm is established under discrepancy conditions

Isolator position to be sorted out under non-valid combinations

of the auxiliary contacts (open-open, closed-closed)

Switching operations in the substation shall be inhibited until

the bus image is recognized with 100% accuracy

Optionally the 87B may be inhibited from the isolator alarm

Industrial Systems

52

Dynamic Bus Replica - Isolators

Isolator Open

Auxiliary

Contact

Isolator Closed

Auxiliary

Contact

Isolator

Position

Alarm

Block Switching

Off

On

CLOSED

No

No

Off

Off

LAST VALID

After time delay

until

acknowledged

Until Isolator

Position is valid

On

On

CLOSED

On

Off

OPEN

No

No

ISOLATOR 1 OPEN

ISOLATOR 1 CLOSED

ISOLATOR 1 BLOCK

ISOLATOR 1 ALARM

ISOLATOR 1 RESET

ISOLATOR 1 POSITION

Isolator position valid

(isolator opened)

Isolator position valid

(isolator opened)

Isolator position invalid

alarm time

delay

blocking signal resets when

isolator position valid

alarm

acknowledged

alarm acknowledging

signal

Industrial Systems

53

Dynamic Bus Replica Isolator Positions and Differential Protection

Phase A AC signals wired

here, bus replica configured

here

Phase B AC signals wired

here, bus replica configured

here

Phase C AC signals wired

here, bus replica configured

here

Up to 96 auxuliary switches

wired here; Isolator Monitoring

function configured here

Industrial Systems

54

Dynamic Bus Replica Tie-Breakers: Two-CT Configuration

Overlapping zones no blind spots

Both zones trip the Tie-Breaker

No special treatment of the TB required in terms of its

status for Dynamic Bus Replica (treat as regular

breaker see next section)

TB Z1 Z2

Industrial Systems

55

Dynamic Bus Replica Tie-Breakers Tie-Breakers: Single-CT Configuration

Both zones trip the Tie-Breaker

Blind spot between the TB and the CT

Fault between TB and CT is external to Z2

Z1: no special treatment of the TB required (treat as

regular CB)

Z2: special treatment of the TB status required:

The CT must be excluded from calculations after the

TB is opened

Z2 gets extended (opened entirely) onto the TB

TB Z1 Z2

Industrial Systems

56

Tie-Breakers: Single-CT Configuration

Sequence of events:

Z1 trips and the TB gets opened

After a time delay the current from the CT shall be

removed from Z2 calculations

As a result Z2 gets extended up to the opened TB

The Fault becomes internal for Z2

Z2 trips finally clearing the fault

expand

Industrial Systems

57

Dynamic Bus Replica Breakers: Bus-side CTs

Blind spot exists between the CB and CT

CB is going to be tripped by line protection

After the CB gets opened, the current shall be removed from

differential calculations (expanding the differential zone up to the

opened CB)

Relay configuration required: identical as for the Single-CT Tie-

Breaker

CT

CB

Blind spot for

bus protection

Industrial Systems

58

Dynamic Bus Replica Breakers: Line-side CTs

Over-trip spot between the CB and CT when the CB is opened

When the CB gets opened, the current shall be removed from

differential calculations (contracting the differential zone up to the

opened CB)

Relay configuration required: identical as for a Single-CT Tie-Breaker,

but.

CB

CT

Over-trip spot for

bus protection

Industrial Systems

59

Dynamic Bus Replica Breakers: Line-side CTs

but.

A blind spot created by contracting the bus differential zone

End Fault Protection required B90 provides one EFP element per

current input

CB

CT

Blind spot for

bus protection

c

o

n

t

r

a

c

t

Industrial Systems

60

End Fault Protection

SETTING

EFP 1 FUNCTION:

Disabled = 0

Enabled = 1

SETTING

EFP 1 CT:

Current Magnitude, |I|

FLEXLOGIC OPERANDS

EFP 1 OP

SETTING

B90 FUNCTION:

Logic = 0

Protection = 1

A

N

D

SETTING

EFP 1 BLOCK:

Off = 0

EFP 1 DPO

EFP PKP

SETTINGS

EFP 1 BRK DELAY:

t

PKP

0

SETTING

| I | > PICKUP

RUN

EFP 1 PICKUP:

SETTING

EFP 1 MANUAL CLOSE:

Off = 0

SETTING

EFP 1 BREAKER OPEN:

Off = 0

A

N

D

SETTING

EFP 1 PICKUP DELAY:

t

PKP

0

(1) The EFP gets armed

after the breaker is open

(2) Excessive current .

(3) Causes the EFP

to operate

Industrial Systems

61

Breaker Failure Protection

BF Architecture:

Current supervision residing on protection IEDs

BFI signal can be generated internally (from protection IEDs)

or externally via communications or a digital input from any

IED

BF logic and timers residing on the logic IED

Trip contacts distributed freely between various IEDs

BF Performance:

Reset time of current sensors below 0.7 power system cycle

Communications delays around 0.2 power system cycle

between any two neighboring IEDs

Industrial Systems

62

Breaker Failure Protection Current Supervision

Phase A AC signals wired

here, current status

monitored here

Phase B AC signals wired

here, current status

monitored here

Phase C AC signals wired

here, current status

monitored here

Up to 24 BF elements

configured here

Industrial Systems

63

Breaker Failure Protection Initiate

Phase A AC signals wired

here, current status

monitored here

Phase B AC signals wired

here, current status

monitored here

Phase C AC signals wired

here, current status

monitored here

Up to 24 BF elements

configured here

BFI

BFI

Industrial Systems

64

Breaker Failure Protection Trip Action

Phase A AC signals wired

here, current status

monitored here

Phase B AC signals wired

here, current status

monitored here

Phase C AC signals wired

here, current status

monitored here

Trip command generated here

and send to trip appropraite

breakers

Trip

Trip

Trip

Trip

Industrial Systems

65

Programmable Logic (FlexLogic

TM

)

All B90 IEDs provide for programmable logic

Distributed logic over fiber-optic communications

(Direct I/Os)

Functions available:

Gates

Edge detectors

Latches and non-volatile latches

Timers

Industrial Systems

66

Disturbance Recording

All AC inputs automatically recorded

Programmable sampling rate: 8, 16, 32, 64 s/c

Programmable content (phasor magnitudes and angles,

differential, restraint currents, frequency, any digital flag)

Programmable number of records vs. record length

Flexible treatment of old records (overwrite, preserve)

Programmable trigger

Programmable pre-/post-trigger windows

Individual (independent) oscillography configuration of each B90

IED

Industrial Systems

67

Sequence of Events Recording

Up to 1040 events per each B90 IED

Events stamped with 1microsecond resolution

0.5 msec scanning rate for digital inputs

All B90 IEDs synchronized via IRIG-B or SNTP

All events (except hardware-related alarms) user programmable

Events can be enabled independently for:

All protection elements

All digital inputs and contact outputs

Communications driven signals

Individual (independent) SOE configuration of each B90 IED

Industrial Systems

68

Substation one-line and

wiring diagrams

F4-Z2-IN

VO 23

F3-Z2-IN

VO 22

F2-Z2-IN

VO 21

F4-Z1-IN

VO 7

SWITCHING ON Z1 & Z2, Z1 & Z3 OR Z2 & Z3 BUSBARS

B

F3-Z1-IN

VO 6

F2-Z1-IN

VO 5

F1-Z1-IN&

Z2-OUT

VO 4

ISO 1

TRIP

PERM

Z1/Z2

VO 63

60

0

ISO 3

LATCH

ISO 6

ISO 9

0

100

CLOSING ORDER

52b

F2-Z1-OUT

VO 53

F2-Z2-OUT

VO 54

B

A

A

ISO 3

A

ISO 1

ISO 2

ISO 4

ISO 7

ISO 2

ISO 5

ISO 8

F2-Z3-IN

VO 37

F3-Z3-IN

VO 38

F4-Z3-IN

VO 39

OPTION: ZONE 3 AS

TRANSFER BUS

LOGIC FOR COUPLER

ISO 2

ISO 3

ISO 1

ISO 3

ISO 2

ISO 6

ISO 5

ISO 9

ISO 8

ISO 6

ISO 4

ISO 9

ISO 7

ISO 5

ISO 4

ISO 8

ISO 7

Logic design FlexLogic

TM

Implementation

Engineering the B90

Industrial Systems

69

B90 Summary

Cost-efficient

Good performance

Modern communications capability

Member of the Universal Relay (UR) family

Easy integration with other URs

Common configuration tool for all B90 IEDs

Proven algorithms (B30) and hardware (UR)

Expandable

Two levels of scalability (modules and IEDs)

Industrial Systems

70

Ordering the B90

The B90 can be ordered as an engineered product

The following order code applies to the engineered B90

B90 * * * * ** * * **

B90 Base system

S Single busbar

D Double busbar

T Double busbar with transfer

X Special arrangement

C Cabinet supply

F Frame supply

A RS485 + RS485 (ModBus RTU, DNP)

C RS485 + 10BaseF (MMS/UCA2, ModBus TCP/IP, DNP)

D RS485 + redundant 10BaseF (MMS/UCA2, ModBus, TCP/IP, DNP)

H 125/250, AC/DC

L 24-48V (DC only)

** Specify the number of lines + bus couplers (two digits)

0 Without Breaker Fail

B With Breaker Fail

0 Without End Fault Protection

E With End Fault Protection

00 Sequential number

Industrial Systems

71

How to Order

International: +1 905 294 6222

Europe: +34 94 485 88 00

Email: info.pm@indsys.ge.com

Web: http://www.GEindustrial.com/pm

You might also like

- Chrysler Specific Diagnostic Trouble CodesDocument8 pagesChrysler Specific Diagnostic Trouble CodesVadim UrupaNo ratings yet

- SCD5200 Dual Communications ModulesDocument8 pagesSCD5200 Dual Communications ModulesWisnu HartonoNo ratings yet

- GE B90 PresentationDocument71 pagesGE B90 PresentationIsuru WijewardeneNo ratings yet

- Micom C264-Rtu PDFDocument4 pagesMicom C264-Rtu PDFCepi SukmayaraNo ratings yet

- I/A Series Remote Terminal Unit (RTU) RTU 20 For Oil, Gas, and Water SCADA ApplicationsDocument8 pagesI/A Series Remote Terminal Unit (RTU) RTU 20 For Oil, Gas, and Water SCADA ApplicationsFatah MedAmineNo ratings yet

- SICAM A8000 Series - DescriptionDocument2 pagesSICAM A8000 Series - Descriptionquoc dat NguyenNo ratings yet

- Magic System 3200 ET Shortform Catalog - r3Document4 pagesMagic System 3200 ET Shortform Catalog - r3Saikat BanerjeeNo ratings yet

- BL20Document80 pagesBL20buturcasNo ratings yet

- Scadapack 100 DatasheetDocument4 pagesScadapack 100 DatasheetAqua Technology GroupNo ratings yet

- TI - Texas Instruments - Slyy041c - Programmable Logic Control (PLC) Solutions GuideDocument20 pagesTI - Texas Instruments - Slyy041c - Programmable Logic Control (PLC) Solutions GuideAnonymous R0s4q9X8No ratings yet

- C8000system Manual en 130905Document14 pagesC8000system Manual en 130905RobertNo ratings yet

- Ec 5Document2 pagesEc 5DRESPLNo ratings yet

- GS33P06B10 31eDocument1 pageGS33P06B10 31eAhmet UyanıkNo ratings yet

- Automation Component AK 1703 ACP: Answers For EnergyDocument6 pagesAutomation Component AK 1703 ACP: Answers For EnergybepperigaNo ratings yet

- SCADAPack100 DataSheeetDocument4 pagesSCADAPack100 DataSheeetAqua Technology Group100% (1)

- R501 Multi Channel Rugged Fiber Optic Temperature Monitor RMDocument4 pagesR501 Multi Channel Rugged Fiber Optic Temperature Monitor RMRugged MonitoringNo ratings yet

- 17 Ied 670 Rel670 Red670Document48 pages17 Ied 670 Rel670 Red670moon111222No ratings yet

- 1769 td006 - en PDocument132 pages1769 td006 - en PpaplusNo ratings yet

- Micom C964C / C964 Modular Remote Terminal Unit - Rtu: Ieds GatewayDocument2 pagesMicom C964C / C964 Modular Remote Terminal Unit - Rtu: Ieds GatewayTomuta StefanNo ratings yet

- Numatics Series g3 Fieldbus Electronics CatalogDocument64 pagesNumatics Series g3 Fieldbus Electronics CatalogIsraelNo ratings yet

- CompactCom EDocument4 pagesCompactCom Enabeel hassan aliNo ratings yet

- Micom C264C / C264 Modular Bay Controller - MBC: Ieds GatewayDocument2 pagesMicom C264C / C264 Modular Bay Controller - MBC: Ieds GatewayTomuta StefanNo ratings yet

- AC500 - The Scalable PLC For Customized Automation: Technical InformationDocument43 pagesAC500 - The Scalable PLC For Customized Automation: Technical InformationIAmTheShankNo ratings yet

- Scadapack 314 DatasheetDocument4 pagesScadapack 314 DatasheetAqua Technology GroupNo ratings yet

- A6V12027144 - Automation Stations PXC4.E16 - enDocument20 pagesA6V12027144 - Automation Stations PXC4.E16 - enahmad jouriehNo ratings yet

- SCD6000 - IO Specification - PSS 31H-8K1Document20 pagesSCD6000 - IO Specification - PSS 31H-8K1Mahmoud ChihebNo ratings yet

- Datasheet F2M03GLADocument46 pagesDatasheet F2M03GLALucosidENo ratings yet

- DM130 Flyer EDocument2 pagesDM130 Flyer Eahmad7160No ratings yet

- Master-Controller RCO 700D-M/W: Data SheetDocument4 pagesMaster-Controller RCO 700D-M/W: Data SheetAnonymous NcB95G6XwNo ratings yet

- ACOS 710 - 720 Product AnnouncementDocument5 pagesACOS 710 - 720 Product AnnouncementEhsan RohaniNo ratings yet

- Field CommunicationsDocument7 pagesField CommunicationsSameer NaeemNo ratings yet

- SICAM AK - Hardware Based SASDocument6 pagesSICAM AK - Hardware Based SASsavijolaNo ratings yet

- DMA-22-01 - 02 Data Sheet E R21 20180209Document18 pagesDMA-22-01 - 02 Data Sheet E R21 20180209scrappy traderNo ratings yet

- Centum CS 3000 DCS Training ModuleDocument45 pagesCentum CS 3000 DCS Training Modulepuneet kumarNo ratings yet

- Micro Controller Interfacing TechniquesDocument16 pagesMicro Controller Interfacing TechniquesAhmad Mustafa AtharNo ratings yet

- Power Logic BCMDocument4 pagesPower Logic BCMOky LimNo ratings yet

- Modulo de Bahia BM-9100Document2 pagesModulo de Bahia BM-9100Jose M. VasquezNo ratings yet

- Building Management SystemDocument32 pagesBuilding Management SystemNiranjan DalviNo ratings yet

- Interfacing MCDocument57 pagesInterfacing MCMaha DevanNo ratings yet

- Scadapack 350 Scadapack 357 DatasheetDocument6 pagesScadapack 350 Scadapack 357 DatasheetAqua Technology GroupNo ratings yet

- K 76 800 - ARIES - NetLink - 10 8 14Document14 pagesK 76 800 - ARIES - NetLink - 10 8 14DioNo ratings yet

- IVRS Architecture & Features: Centre For Development of TelematicsDocument20 pagesIVRS Architecture & Features: Centre For Development of TelematicsShankarananda SherNo ratings yet

- PQS PFC Components PBDocument12 pagesPQS PFC Components PBChristina BoydNo ratings yet

- Yokogawa DCS and SIS System ArchitectureDocument11 pagesYokogawa DCS and SIS System ArchitectureShumraiz MNo ratings yet

- 1086616Document48 pages1086616Anonymous MBapZd8No ratings yet

- High Speed 2k BoardDocument8 pagesHigh Speed 2k BoardPhi MacNo ratings yet

- DIRIS ADocument6 pagesDIRIS ARelief_EngineerNo ratings yet

- Reason MU320E Brochure EN 2021 02 33130BDocument8 pagesReason MU320E Brochure EN 2021 02 33130BCarlos FersilNo ratings yet

- BK Oprema PDFDocument24 pagesBK Oprema PDFDragan LazicNo ratings yet

- 32 DataSheetDocument6 pages32 DataSheetAqua Technology GroupNo ratings yet

- 444 Buses PDFDocument16 pages444 Buses PDFhl5udvNo ratings yet

- PXC SERIES IP DDC - enDocument18 pagesPXC SERIES IP DDC - ensiraj sNo ratings yet

- SCADAPack 350 DatasheetDocument6 pagesSCADAPack 350 DatasheetWiedNo ratings yet

- Ateis PAVA2013 Online PDFDocument60 pagesAteis PAVA2013 Online PDFArman Ul NasarNo ratings yet

- Janitza Umg 806 en PDFDocument6 pagesJanitza Umg 806 en PDFjobbrettNo ratings yet

- MiCOM C264RTU PDFDocument4 pagesMiCOM C264RTU PDFYasser RagabNo ratings yet

- C264-SER Application: Modular Sequence of Event RecorderDocument4 pagesC264-SER Application: Modular Sequence of Event RecorderAleksandar BognarNo ratings yet

- Aislador Digital Input 8DIDocument1 pageAislador Digital Input 8DIEduardo_77No ratings yet

- Fioa0402u 16Document4 pagesFioa0402u 16mcsecNo ratings yet

- Altitude or HeightDocument1 pageAltitude or HeightHamayoun MurtazaNo ratings yet

- Bushing DesignDocument1 pageBushing DesignHamayoun MurtazaNo ratings yet

- Instrument Transformers 11010Document48 pagesInstrument Transformers 11010Hamayoun MurtazaNo ratings yet

- Quality of Vacuum: Quality Torr Pa Milli BarDocument1 pageQuality of Vacuum: Quality Torr Pa Milli BarHamayoun MurtazaNo ratings yet

- Campus MapDocument1 pageCampus MapHamayoun MurtazaNo ratings yet

- 500KV Switch Yard DrawingDocument2 pages500KV Switch Yard DrawingHamayoun MurtazaNo ratings yet

- Imperial Units Length: Edmund GunterDocument2 pagesImperial Units Length: Edmund GunterHamayoun MurtazaNo ratings yet

- What Is Trip Circuit Supervision Relay How Does It Work in SwitchgearDocument7 pagesWhat Is Trip Circuit Supervision Relay How Does It Work in SwitchgearHamayoun MurtazaNo ratings yet

- Power Transformers: Your Partner in Energy SolutionsDocument24 pagesPower Transformers: Your Partner in Energy SolutionsHamayoun MurtazaNo ratings yet

- Project Management Procedures4266Document27 pagesProject Management Procedures4266Hamayoun MurtazaNo ratings yet

- Symmetrical ComponentsDocument2 pagesSymmetrical ComponentsHamayoun Murtaza100% (1)

- Tan DeltaDocument1 pageTan DeltaHamayoun MurtazaNo ratings yet

- Creepage DistanceDocument2 pagesCreepage DistanceHamayoun MurtazaNo ratings yet

- Tertiary Winding of TransformerDocument2 pagesTertiary Winding of TransformerHamayoun MurtazaNo ratings yet

- High Frequency VCO Design and SchematicsDocument18 pagesHigh Frequency VCO Design and SchematicsHamayoun MurtazaNo ratings yet

- Preventive Maintenance and Reliability of LV Overcurrent Protective DevicesDocument7 pagesPreventive Maintenance and Reliability of LV Overcurrent Protective DevicesHamayoun MurtazaNo ratings yet

- What Is Magnetizing Current in A TransformerDocument1 pageWhat Is Magnetizing Current in A TransformerHamayoun MurtazaNo ratings yet

- Causes of Over Fluxing in TransformerDocument3 pagesCauses of Over Fluxing in TransformerHamayoun Murtaza0% (1)

- Sab 'S 1.618 System: Test Physics (Full Book) Total Marks 50 Q1:Give Brief Answers of The Following QuestionsDocument2 pagesSab 'S 1.618 System: Test Physics (Full Book) Total Marks 50 Q1:Give Brief Answers of The Following QuestionsHamayoun MurtazaNo ratings yet

- Line BayDocument17 pagesLine Bayabhinav_baishwarNo ratings yet

- Capacitance Power FactorDocument1 pageCapacitance Power FactorHamayoun MurtazaNo ratings yet

- Excitation Current in TransformersDocument2 pagesExcitation Current in TransformersHamayoun Murtaza100% (1)

- SVR 204Document15 pagesSVR 204nikolayeyNo ratings yet

- CarbeneDocument7 pagesCarbeneHarman Preet Kaur100% (1)

- Sem 215 Smart Universal Temperature TransmitterDocument4 pagesSem 215 Smart Universal Temperature TransmitterKalpesh PatilNo ratings yet

- BSIT 1st Semester Paper 2Document5 pagesBSIT 1st Semester Paper 2Asif SyedNo ratings yet

- IP Ratings Explained Ingress Protection RatingDocument26 pagesIP Ratings Explained Ingress Protection RatingRanjeet SinghNo ratings yet

- Assignment On BTRC (Bangladesh Telecommunication Regulatory Commission) Tools and Techniques.Document26 pagesAssignment On BTRC (Bangladesh Telecommunication Regulatory Commission) Tools and Techniques.Mosabbir Ahmed0% (1)

- Dynamic Logic CircuitsDocument61 pagesDynamic Logic Circuitsbirla_sNo ratings yet

- OhmDocument5 pagesOhmRenee BaldwinNo ratings yet

- NSN BTSDocument5 pagesNSN BTSgadekaNo ratings yet

- Embraco CompressorDocument2 pagesEmbraco CompressorКръстю КръстевNo ratings yet

- PIC16/PIC18 ADC Technical Brief: 2018 Microchip Technology Inc. 90003194a-Page 1Document27 pagesPIC16/PIC18 ADC Technical Brief: 2018 Microchip Technology Inc. 90003194a-Page 1Java Papa DoqNo ratings yet

- B.Tech Syllabus 2017 Batch (From 2019 Onwards)Document244 pagesB.Tech Syllabus 2017 Batch (From 2019 Onwards)AKULA DINESHNo ratings yet

- SSAS DSAS Mk2 DiagnosticChecklistDocument3 pagesSSAS DSAS Mk2 DiagnosticChecklistkrupa kumarNo ratings yet

- Improvement of Power Quality Using Advanced Artificial Neural Network AlgorithmDocument6 pagesImprovement of Power Quality Using Advanced Artificial Neural Network AlgorithmtalktokammeshNo ratings yet

- ASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderDocument1 pageASR1201D ASR1201D-D: Slim Water-Proof RFID ReaderSTEPHANE LAIRNo ratings yet

- Test Bank Mid 2Document13 pagesTest Bank Mid 2mhd slmnNo ratings yet

- R Rec M.1797 0 200703 I!!pdf eDocument12 pagesR Rec M.1797 0 200703 I!!pdf eLuis GarciaNo ratings yet

- Chapter 2Document10 pagesChapter 2api-285133030No ratings yet

- Automotive Batteries 101: WMG, University of WarwickDocument24 pagesAutomotive Batteries 101: WMG, University of WarwickAliNo ratings yet

- Colibri 2Document64 pagesColibri 2Petar ZivanicNo ratings yet

- Volvo 1800eDocument6 pagesVolvo 1800emnbvqwertNo ratings yet

- ZMM r000 Material DetailsDocument3 pagesZMM r000 Material DetailsMrconfusionSapNo ratings yet

- An Introduction To Microwave Amplifiers Part 1 - Microwave Amplifier Applications - Marki Microwave RF & MicrowaveDocument7 pagesAn Introduction To Microwave Amplifiers Part 1 - Microwave Amplifier Applications - Marki Microwave RF & MicrowaveRAJKUMARSCRIBD_123No ratings yet

- Inv Datasheet Growatt-MAX-50-80KTL3-LV Datasheet ENDocument2 pagesInv Datasheet Growatt-MAX-50-80KTL3-LV Datasheet ENAlan Tiago FernandesNo ratings yet

- Exam2-Problem 1 Part (A)Document15 pagesExam2-Problem 1 Part (A)syedsalmanali91100% (1)

- DynaN v3Document2 pagesDynaN v3arlequintensorNo ratings yet

- Z - Wave ReportDocument25 pagesZ - Wave Reportqwerty123890No ratings yet

- Megapixel Series Vari-Focal Lenses: Ir Corrected Aspherical, DC Auto Iris/Manual IrisDocument2 pagesMegapixel Series Vari-Focal Lenses: Ir Corrected Aspherical, DC Auto Iris/Manual Irischandan211No ratings yet

- Landing GearDocument21 pagesLanding GearMr.Me Almulla100% (1)