Professional Documents

Culture Documents

Fluorescent Penetration Inspection: 1. Pre Cleaning The Surface 2. Apply Water Washable Penetrant

Uploaded by

rukmavaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluorescent Penetration Inspection: 1. Pre Cleaning The Surface 2. Apply Water Washable Penetrant

Uploaded by

rukmavaCopyright:

Available Formats

FLUORESCENT PENETRATION INSPECTION

Fluorescent penetration inspection is basically a Non Destructive Test (NDT) which is done to detect any types of discontinuity up to 6 mm depth of the surface of any part or components of the Auxiliary Power Unit (APU). The inspection is carried out in the following steps -

1. Pre cleaning the surface 2. Apply water washable penetrant by spray, dip, or wipe (Part surface

temperature between 4-52*C) FP-900, FP-901, FP-902

3. DWELL for minimum 10 minutes or 20 min if temperature is less than 50*F 4. RINSE with water at a temperature of 10-30*C 5. DRY at maximum temperature of 71*C 6. APPLY NONAQUEOUS or DRY DEVELOPER D-70 D-72A 7. DWELL for minimum of 10 minutes 8. INSPECTION- Use UV-A illumination of 1000 microwatts/cm2 not more than 2

ftcandles visible light, 20 lux Inspection from 10 minutes to 2 hours after developer application

CRACK

SCRATCH

You might also like

- RNS - NDT - PT - 001 Rev.0Document8 pagesRNS - NDT - PT - 001 Rev.0Goutam Kumar Deb100% (1)

- 9286-2-Detroit Integrated Powertrain BrochureDocument8 pages9286-2-Detroit Integrated Powertrain BrochureCapacitaciones RutasNo ratings yet

- Pump DecokingDocument8 pagesPump Decokingrohl55No ratings yet

- MX Spark Test Detector FUX 3001 FUX 3001ex FTX 3001 Ex PDFDocument2 pagesMX Spark Test Detector FUX 3001 FUX 3001ex FTX 3001 Ex PDFNarendra Reddy BhumaNo ratings yet

- Pavement Analysis & DesignDocument11 pagesPavement Analysis & DesignLo0oVve100% (1)

- Liquid Penetrant ProcedureDocument5 pagesLiquid Penetrant Procedurenur hudaNo ratings yet

- Dye Penetrant ProcedureDocument8 pagesDye Penetrant ProcedureTouil HoussemNo ratings yet

- Penetrant Testing NotesDocument26 pagesPenetrant Testing NotesGauthamSarangNo ratings yet

- Insulation Resistance Testing: A Complete Solution - For Every ApplicationDocument8 pagesInsulation Resistance Testing: A Complete Solution - For Every Applicationkumar1123100% (1)

- PLC IntroductionDocument50 pagesPLC IntroductionAhmadYousefAhmad100% (1)

- Procedure For Magnetic Particle TestingDocument19 pagesProcedure For Magnetic Particle TestingKarrar TalibNo ratings yet

- Automated Cleveland Open Cup Flash Point Tester Model Aco-8/aco-8 As Instruction ManualDocument59 pagesAutomated Cleveland Open Cup Flash Point Tester Model Aco-8/aco-8 As Instruction ManualAbdellah BenadlaNo ratings yet

- Measurement Values: Absolute Color Scales (Available When Display Type Is Absolute)Document26 pagesMeasurement Values: Absolute Color Scales (Available When Display Type Is Absolute)rafael_dvgNo ratings yet

- DSS Lecture Note 2 - Gravity LoadsDocument92 pagesDSS Lecture Note 2 - Gravity LoadsMrSamspartNo ratings yet

- Written Instruction (WELD) PT Rev 2Document4 pagesWritten Instruction (WELD) PT Rev 2Anna PariniNo ratings yet

- DP Test ProcedureDocument8 pagesDP Test ProcedureAjith KumarNo ratings yet

- 221EDocument19 pages221EAnonymous RTGzZGtINo ratings yet

- Dye Penetrant TestDocument4 pagesDye Penetrant Testarunkumarnoola100% (2)

- Iron Ore Processing 2009 PDFDocument41 pagesIron Ore Processing 2009 PDFglz1100% (2)

- Emergency Shower and EyewashDocument7 pagesEmergency Shower and EyewashYusmadi J MohamadNo ratings yet

- NDT PT (NSH Procedure)Document9 pagesNDT PT (NSH Procedure)Midhun K ChandraboseNo ratings yet

- NVX80 Ei00 PDFDocument20 pagesNVX80 Ei00 PDFZoltan MarosanNo ratings yet

- VP 30 Product Data 11 15Document2 pagesVP 30 Product Data 11 15marcos crisosto100% (1)

- 8.0 Examination:: W43434343t4efrefrqDocument5 pages8.0 Examination:: W43434343t4efrefrqRakesh Kumar MundaNo ratings yet

- High Sensitivity Post Emulsifiable - FPI Procedure SheetDocument7 pagesHigh Sensitivity Post Emulsifiable - FPI Procedure SheetrenjithaeroNo ratings yet

- Codes FinalDocument7 pagesCodes Finalapi-290160257No ratings yet

- Endo Angl v2011Document58 pagesEndo Angl v2011Yousab CreatorNo ratings yet

- 700 UkDocument4 pages700 UkAhmed IbrahimNo ratings yet

- 45241c Reflex Ultra PTR 45 Brochure - August 2015Document8 pages45241c Reflex Ultra PTR 45 Brochure - August 2015AngelSanchezNo ratings yet

- Definition and Importance of NDT: Components and Assemblies For Flaws in Their Structure Without Damaging Their FutureDocument6 pagesDefinition and Importance of NDT: Components and Assemblies For Flaws in Their Structure Without Damaging Their FutureRakesh Kumar MundaNo ratings yet

- Detector Notifier PDFDocument2 pagesDetector Notifier PDFJoni EfwanNo ratings yet

- Instalation Manual AGB600Document4 pagesInstalation Manual AGB600ADNo ratings yet

- Eye Wash STN Testing 1649368425Document8 pagesEye Wash STN Testing 1649368425richardNo ratings yet

- Degree of ProtectionDocument3 pagesDegree of Protectionsharif1974No ratings yet

- Sicc PT 01 Asme Rev 01Document12 pagesSicc PT 01 Asme Rev 01Enrique Campos Cannavaro100% (1)

- IP Ratings InformationDocument3 pagesIP Ratings InformationAlex AntropovNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548chepurthiNo ratings yet

- Dye Penetrant Testing Procedure: Applicable Codes & StandardsDocument2 pagesDye Penetrant Testing Procedure: Applicable Codes & StandardsEkamjot SinghNo ratings yet

- 4012 WI58 DP Test Procedure - Rev.0Document4 pages4012 WI58 DP Test Procedure - Rev.0sachinpsawantNo ratings yet

- Radiography StandardsDocument15 pagesRadiography Standardsjena_anshumanNo ratings yet

- Product Specifications: 1.scopeDocument7 pagesProduct Specifications: 1.scopeSweqZNo ratings yet

- HeatShield EPX H20 APPLICATION GUIDEDocument4 pagesHeatShield EPX H20 APPLICATION GUIDEMazwan Che MansorNo ratings yet

- F F O P L: Insufine - VI 610Document2 pagesF F O P L: Insufine - VI 610Karishma PrabhuNo ratings yet

- Honeywell IS216T CUR Install GuideDocument2 pagesHoneywell IS216T CUR Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Honeywell Fg1625 Install GuideDocument2 pagesHoneywell Fg1625 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Leakage TesterDocument2 pagesLeakage TesterGurjeet SinghNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsDinesh ChouguleNo ratings yet

- Domnick Hunter Pneudri Dme040 Secador ArDocument23 pagesDomnick Hunter Pneudri Dme040 Secador ArRafael CardosoNo ratings yet

- aE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1260 - Eng - A4 - 20150205Document4 pagesaE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1260 - Eng - A4 - 20150205Annas QahharNo ratings yet

- TD TFK 110 SBDocument2 pagesTD TFK 110 SBtedjo sasongkoNo ratings yet

- 2-Wire Photoelectric Duct Smoke DetectorDocument4 pages2-Wire Photoelectric Duct Smoke DetectorAr JunNo ratings yet

- EPOXY FINISH PAINT - FiveDocument4 pagesEPOXY FINISH PAINT - FiveR K Heavy Engineering Private LimitedNo ratings yet

- Experiment No.13Document2 pagesExperiment No.13T.MNo ratings yet

- Alert Service Bulletin: ASB221EDocument20 pagesAlert Service Bulletin: ASB221ENathaniel LuraNo ratings yet

- TD Akc-50600 - R191001Document2 pagesTD Akc-50600 - R191001Handi HBNo ratings yet

- Technical Sheet Azud Luxon MFH (Pre Filter 1 & 2)Document2 pagesTechnical Sheet Azud Luxon MFH (Pre Filter 1 & 2)Hikmah ArulNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1120 - Eng - A4 - 20201117Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1120 - Eng - A4 - 20201117Ramesh RathinamNo ratings yet

- 4.1 - 6.3 - 1720E Turbidity SensorDocument4 pages4.1 - 6.3 - 1720E Turbidity Sensorcuongnv_19No ratings yet

- IP CodeDocument6 pagesIP CodeYousif AbdalhalimNo ratings yet

- System Sensor D4S Data SheetDocument4 pagesSystem Sensor D4S Data SheetJMAC SupplyNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548Syed FaridNo ratings yet

- LPT Procedure. Rev.01Document8 pagesLPT Procedure. Rev.01shivanshsovNo ratings yet

- Product Data Sheet SKL-WP: Spotcheck Red PenetrantDocument3 pagesProduct Data Sheet SKL-WP: Spotcheck Red PenetrantMai Anh TaiNo ratings yet

- Ev Uv AlmaksDocument8 pagesEv Uv Almakszoran_stevNo ratings yet

- AAB 071416 Cold Fluid Applied Waterproofing (To Wet Areas)Document3 pagesAAB 071416 Cold Fluid Applied Waterproofing (To Wet Areas)tewodrosNo ratings yet

- Properties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensDocument3 pagesProperties:: F9200 Is A Ready-To-Use Dryblend Mortar Based On Cement, Which HardensMuhsin KhanNo ratings yet

- Huawei V1R8 V3R5 Software Upgrade Guide v1 2Document58 pagesHuawei V1R8 V3R5 Software Upgrade Guide v1 2ivanjcm85No ratings yet

- Atm SynopsisDocument8 pagesAtm Synopsismarifs2002No ratings yet

- Profile of VHTP CompaniesDocument33 pagesProfile of VHTP CompaniesSerge BatovNo ratings yet

- Front Hub & Spindle PartsDocument14 pagesFront Hub & Spindle PartsAmit Chopra Amit100% (1)

- H-Beam Catalogue JindalDocument4 pagesH-Beam Catalogue JindalVikram DalalNo ratings yet

- Ibm Thinkpad r30Document36 pagesIbm Thinkpad r30dwayne_hibbertNo ratings yet

- Debugging Package For Motorola 68K Cisc Cpus User'S Manual (Part 1 of 2)Document280 pagesDebugging Package For Motorola 68K Cisc Cpus User'S Manual (Part 1 of 2)Raul BrunoNo ratings yet

- IoT LearningDocument6 pagesIoT LearningDeepak PareekNo ratings yet

- Tema-Htri by Bert BoxmaDocument5 pagesTema-Htri by Bert BoxmaKarthik AnandanNo ratings yet

- R R RoadDocument10 pagesR R RoadvenugopalchintaNo ratings yet

- Davis 1972Document16 pagesDavis 1972Akshat RastogiNo ratings yet

- Mass Balance FixDocument125 pagesMass Balance FixAbdullah AbdulNo ratings yet

- Finite Element Analysis of Hospital BEDDocument10 pagesFinite Element Analysis of Hospital BEDG SATHVIKNo ratings yet

- Bda 14303Document8 pagesBda 14303Mahfuzah MustaphaNo ratings yet

- Transfer CharacteristicsDocument17 pagesTransfer Characteristicsgirishkumardarisi254No ratings yet

- A Practical Method For The Assessment of Work-Related Musculoskeletal Risks - Quick Exposure Check (QEC)Document6 pagesA Practical Method For The Assessment of Work-Related Musculoskeletal Risks - Quick Exposure Check (QEC)hildaNo ratings yet

- ACO Sport Overview - ACOUK - 2008Document12 pagesACO Sport Overview - ACOUK - 2008Mihaela CimpeanuNo ratings yet

- Intuitive Control Algorithm Development of 4WIS/4WID Using A SpaceMouseDocument46 pagesIntuitive Control Algorithm Development of 4WIS/4WID Using A SpaceMouseTyler KimNo ratings yet

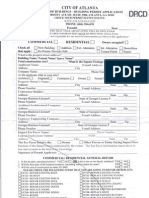

- City of Atlanta Demolition Permit and ProceduresDocument2 pagesCity of Atlanta Demolition Permit and ProceduresgragsdaleNo ratings yet

- Electricity (Licensing) Regulations 1991Document67 pagesElectricity (Licensing) Regulations 1991robert_hampson1No ratings yet

- NFPA 13-2019 Handbook 33Document1 pageNFPA 13-2019 Handbook 33sundarayya.giscoestimationNo ratings yet