Professional Documents

Culture Documents

Calculations For Shrink Fitting

Calculations For Shrink Fitting

Uploaded by

Branimir KrsticOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculations For Shrink Fitting

Calculations For Shrink Fitting

Uploaded by

Branimir KrsticCopyright:

Available Formats

Calculations For Shrink Fitting

The amount that a particular metal will expand can be calculated using the coefficient of thermal expansion:

= L(t)

= Total deformation desired (in or mm) = Coefficient of thermal expansion (in/in F or mm/mm C) L = Nominal length of the part being heated (the diameter for a cylinder) (in or mm) t = Temperature difference (F or C) The coefficient of thermal expansion () for a particular metal can be found in Table 1. The amount of holding stress developed once contraction of the outer hole has occurred can be calculated:

St =

E D a 2 1 + 2 4a b

Sr =

E D a 2 1 2 4 a b

St and Sr = Tangential and radial stresses developed between the collar and the shaft. 'a' and 'b' = Internal and external radii of the collar E = Elastic modulus D = Change of inner diameter of hole.

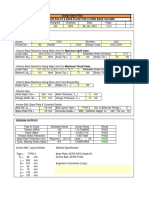

Table 1: Coefficient of Thermal Expansion and Elastic Modulus Coefficient of thermal exp ansion,

Material In/in F mm/mm C Elastic Modulus (E) psi (at 70F) 30x106 29x106

Steel: AISI 1020 AISI 1050 AISI 4140 Stainless Steel: AISI 301 AISI 430 Aluminum: 2014 6061

6.5x10-6 6.1x10-6 6.2x10-6 9.4x10-6 5.8x10-6 12.8x10-6 13.0x10-6

11.7x10-6 11.0x10-6 11.2x10-6 16.9x10-6 10.4x10-6 23.0x10-6 23.4x10-6

28.0x106 29.0x106 10.5x106

Bronze: 10.0x10-6 18.0x10-6 17x106 * The elastic of modulus will decrease as temperature increases. At 1000F, E, will be 22x106 for steel.

39 Main Street Scottsville NY USA 14546 TEL: (716) 889-9000 FAX: (716) 889-8030 http://www.ameritherm.com

ISO 9001

You might also like

- Chapter05 Probs44 61Document39 pagesChapter05 Probs44 61fang123100% (1)

- Calculations For Shrink Fitting: B A A D E S B A A D E SDocument1 pageCalculations For Shrink Fitting: B A A D E S B A A D E SSezgin BayrakNo ratings yet

- 1 T 3Document14 pages1 T 3Kristi GjokaNo ratings yet

- Us - 12e - pr1271 Screw Plug StrengthDocument1 pageUs - 12e - pr1271 Screw Plug StrengthrenebbNo ratings yet

- Heating and Cooling of Circular Saws: K KT KTTDocument8 pagesHeating and Cooling of Circular Saws: K KT KTTte2makanza5279No ratings yet

- Calculations - First EditionDocument6 pagesCalculations - First Editionmohamed.hassan031No ratings yet

- Zheng2012 PDFDocument5 pagesZheng2012 PDFanon_47684961No ratings yet

- HW2 Mat e 202 W18Document5 pagesHW2 Mat e 202 W18TahirNo ratings yet

- Design A Bell Crank'95Document27 pagesDesign A Bell Crank'95Al DrinNo ratings yet

- Potash CrystallizationDocument14 pagesPotash CrystallizationUditha Lakshan100% (1)

- Mse SW2BDocument25 pagesMse SW2BmarkkkkkNo ratings yet

- Lecture # 16 (Thermal StressDocument11 pagesLecture # 16 (Thermal StressOs ,No ratings yet

- Prepared by Jishnu V Engineer Bhel-IsgDocument38 pagesPrepared by Jishnu V Engineer Bhel-IsgmSNDjvnsnNo ratings yet

- Thermal Expansion of Solid BodiesDocument4 pagesThermal Expansion of Solid BodiesdarshanNo ratings yet

- Chapter 4. Estimation of Temperature Load Effects: E T C FDocument7 pagesChapter 4. Estimation of Temperature Load Effects: E T C FspattiwarNo ratings yet

- 07 Thermal StressDocument13 pages07 Thermal StressSundaravathanan ChellappanNo ratings yet

- Assignment 2 MechanicsDocument8 pagesAssignment 2 Mechanicstuansyafiq100% (1)

- CE 6306 / Strength of Materials Mechanical Engineering 2016-17Document6 pagesCE 6306 / Strength of Materials Mechanical Engineering 2016-17amdevaNo ratings yet

- Strength of Materials-II 2-2 Set-2 (A)Document13 pagesStrength of Materials-II 2-2 Set-2 (A)Sri DNo ratings yet

- Thermal StrainDocument14 pagesThermal StrainMavrix AgustinNo ratings yet

- Vessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure VesselDocument19 pagesVessel, BS5500 Cat-3, Is Followed. The Chamber Is Designed As A Pressure Vesselbhalchandrak1867No ratings yet

- Properties of Materials PDFDocument42 pagesProperties of Materials PDFpika pikaNo ratings yet

- Homework Seatwork No.1F Thermal Stresses Torsion - ArchDocument2 pagesHomework Seatwork No.1F Thermal Stresses Torsion - ArchReyn Ma G.No ratings yet

- Calorimetry & Heat Transfer (QB)Document16 pagesCalorimetry & Heat Transfer (QB)Raju SinghNo ratings yet

- ISF Aachen Welding Technology Part II PDFDocument140 pagesISF Aachen Welding Technology Part II PDFscott2355No ratings yet

- Solutions For Practice Questions # 1 MECH 321 Winter 2014Document5 pagesSolutions For Practice Questions # 1 MECH 321 Winter 2014Metehan AtagürNo ratings yet

- Thermal StressesDocument17 pagesThermal StressesLacasaNo ratings yet

- Quiz 2Document3 pagesQuiz 2desibling613No ratings yet

- 02 03ChapGereDocument16 pages02 03ChapGereXavier Pacheco PaulinoNo ratings yet

- Bài Tập Nhóm Môn Kỹ Thuật Chế TạoDocument8 pagesBài Tập Nhóm Môn Kỹ Thuật Chế TạotranngNo ratings yet

- Strength of Materials-II 2-2 Set-3 (A)Document18 pagesStrength of Materials-II 2-2 Set-3 (A)Sri DNo ratings yet

- 06 Practical Application Bolted Cylindrical VesselDocument12 pages06 Practical Application Bolted Cylindrical Vesselenrico.michelatoNo ratings yet

- Calculate Thermal ExpansionDocument5 pagesCalculate Thermal ExpansionMELVIN MAGBANUANo ratings yet

- Engg Final ExamDocument9 pagesEngg Final ExamTanner LeakosNo ratings yet

- Transient Temperature Distribution in A Steel Rod Subjected To Friction WeldingDocument11 pagesTransient Temperature Distribution in A Steel Rod Subjected To Friction WeldingMuhammad Fatka FirmansyahNo ratings yet

- Thermal StressesDocument6 pagesThermal Stressesaraz_1985100% (1)

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 pagesDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNo ratings yet

- Met 02023 Material Science IDocument13 pagesMet 02023 Material Science IlallyprabhNo ratings yet

- 2 Calormetry and Heat TrasferDocument15 pages2 Calormetry and Heat TrasferKedar AdkineNo ratings yet

- MOM Assignment IDocument3 pagesMOM Assignment IAll_regNo ratings yet

- Tugas Metalurgi Las - Heat Flow in WeldingDocument4 pagesTugas Metalurgi Las - Heat Flow in WeldingRhidiyan Waroko100% (4)

- Mero Connector (Steel Ball) DesignDocument3 pagesMero Connector (Steel Ball) DesignParvez KhanNo ratings yet

- Lecture Three - Welded ConnectionsDocument30 pagesLecture Three - Welded ConnectionsAhmedNo ratings yet

- 1 MatlpropDocument24 pages1 MatlpropShaddab AliNo ratings yet

- Lista 3Document7 pagesLista 3Rodolfo Souza MartinsNo ratings yet

- Temperature Field Calculation and Analysis Within Steel Tube Reinforced ColumnsDocument6 pagesTemperature Field Calculation and Analysis Within Steel Tube Reinforced ColumnsBatepola BacNo ratings yet

- Unit2B SSDocument8 pagesUnit2B SSRahul YadavNo ratings yet

- IE 337: Materials & Manufacturing Processes: Metal Forming Operations 2Document31 pagesIE 337: Materials & Manufacturing Processes: Metal Forming Operations 2silverknights007No ratings yet

- SpringDocument1 pageSpringvirtualpop3No ratings yet

- Tutorial3-Shear and TorsionDocument3 pagesTutorial3-Shear and TorsionKunal ShroteNo ratings yet

- Nominal Moment Capacity of Box Reinforced Concrete Beams Exposed To FireDocument14 pagesNominal Moment Capacity of Box Reinforced Concrete Beams Exposed To FireReivax50No ratings yet

- Design 7 ENDocument6 pagesDesign 7 ENAlejandra BenavidesNo ratings yet