Professional Documents

Culture Documents

Asme PQR Demo

Asme PQR Demo

Uploaded by

Prabhu KalpakkamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme PQR Demo

Asme PQR Demo

Uploaded by

Prabhu KalpakkamCopyright:

Available Formats

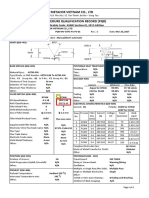

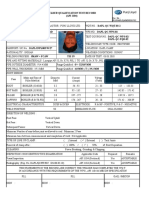

PROCEDURE QUALIFICATION RECORD (PQR)

ASME Boiler and Pressure Vessel Code , Section IX Company Name: www.WPSAmerica.com Company Address: info@WPSAmerica.com, 1 (877) WPS-WELD

PQR No.: DEMO-PQR Welding Procedure Specification WPS No.: DEMO-WPS Date: 11,12, 2005 Revision No.: (0)

Sheet 1 of 4

BASE METALS (QW-403)

Material Specification: SA-515 Welded to Material Specification: SA-515 Thickness of Test Coupon mm (in): 90 mm (3.54 in.) Type or Grade: 60 P-No.: 1 Group No.: 1 Type or Grade: 60 P-No.: 1 Group No.: 1

Diameter of Test Coupon mm (in): N/A

Other Information: This is a DEMO PQR prepared by online welding software of www.WPSAmerica.com

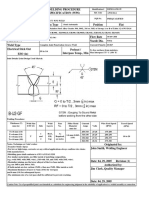

JOINTS (QW-402)

Joint Design: Double-Vee groove weld Backing: No Backing Backing Material (Refer to both backing and retainers.): N/A Groove Details (or per production drawing): Root Opening G: 0 to 1/8 in. Root Face RF: 1/8 in. Groove Angle: 60 (both sides) Radius (J-U): N/A

Joint Details/ Sketch:

Table for recorded welding parameters; Refer to QW-409

Pass No. (s) 1 to 3 4 to n Side 2 1 to n SMAW E7018 4.8 mm (3/16) 220-250 24-26 N/A 5-10 (in/min) Process Filler Metal Classification E7018 E7018 Filler Size Diameter mm (in) 4.0 mm (5/32) 4.8 mm (3/16) Current Amps 160-200 220-250 Volts Wire Feed Speed mm/min (in/min) N/A N/A Travel Speed mm/min (in/min) 5-10 (in/min) 5-10 (in/min) Max. Heat Input kJ/mm (kJ/in) Or Remarks Root Pass Fill and Cap Passes Backgouged Fill and Cap Passes

SMAW SMAW

24-26 24-26

PQR No.: DEMO-PQR FIRST PROCESS

Welding Process (es): Type (s): Shielded Metal Arc Welding (SMAW) Manual

Date: 11,12, 2005

Sheet 2 of 4

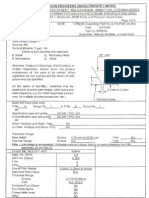

SECOND PROCESS

FILLER METALS (QW-404)

AWS Classification Electrode-Flux Class (SAW) SFA Specification Filler Metal F-No. Weld Metal Analysis A-No. Size of Filler Metals mm (in) Filler Metal Product Form Max. Weld Pass Thickness mm (in) Deposited Weld Metal Thickness mm (in) Weld Deposit Chemistry Flux Trade Name and Flux Type (SAW) Other information: This is a DEMO PQR from www.WPSAmerica.com E7018 SFA 5.1 4 1 5/32 to 3/16 in. Iron powder low hydrogen 3/16 in. 90 mm (3.54 in.) N/A N/A

POSITION (QW-405)

Position of Groove Welding Progression 1G

PREHEAT (QW-406)

Preheat Temperature C (F) Interpass Temperature C (F) 150 C 150 C

GAS (QW-408)

Shielding Gas Type (Mixture) Flow Rate Flow Rate Flow Rate lt/min. (CFH) lt/min. (CFH) lt/min. (CFH) Trailing Gas Type (Mixture) Gas Backing (Mixture) N/A _ N/A _ N/A _

ELECTRICAL CHARACTERISTICS (QW-409)

Following data may also shown on Table in Sheet 1 of 4 Current/ Polarity Amps (Range) Volts (Range) Wire Feed Speed (Range) mm/min (in/min) Travel Speed (Range) mm/min (in/min) Mode of Metal Transfer for GMAW (FCAW) Tungsten Electrode Size mm (in) Tungsten Type DCEP 160 to 250 24 to 26 N/A 5 to 10 (in./min) N/A _ N/A

TECHNIQUE (QW-410)

String or Weave Bead Multiple or Single Electrodes Multiple or Single Pass (per side) Orifice or Gas Cup Size Contact Tube to Work Distance mm (in) Initial and Interpass Cleaning Method of Back Gouging Oscillation Peening Other information: Clean each layer before start welding new passes/layers String and Weave Bead Single Multiple N/A N/A Brushing and Grinding Grinding Not Required Not Required

POSTWELD HEAT TREATMENT (QW-407)

Holding Temperature Range C (F): 600 to 620 C Heating Rate C/hr (F/hr): 120 C/hr Cooling Rate C/hr (F/hr): 120 C/hr Holding Time Range: 1 Hour per in. Method: Furnace Method: Open Air

PQR No.: DEMO-PQR

Date: 11,12, 2005

Sheet 3 of 4

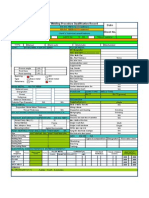

Heat Treatment (ASME Codes Guideline):

PREHEAT TABLE: ASME Section VIII-Division 1: Preheating from Appendix R (a) 175 F (80 C) for material which has both a specified maximum carbon content in excess of 0.30% and a thickness at the joint in excess of 1 in. (25 mm): (b) 50 F (10 C) for all other materials of P-No. 1 group.

POSTWELD HEAT TREATMENT TABLE: ASME Section VIII-Division 1: Requirements for PWHT of Table UCS-56 Min. Holding Temperature: 1,100 F (595 C) Min. Holding Time for Weld Thickness (Nominal): Up to 2 in. (50 mm): 1 hr/in. (2 min/mm), 15 min Min. Over 2 in. (50 mm): 2 hr plus 15 min for each additional inch over 2 in. (50 mm) Heating and Cooling rate: Max. 400 F (220 C) per hr divided by the maximum thickness of material in inches at the weld, but no more than 400 F (220 C)/hr: Min. 100 F (55 C)/hr For Mandatory & Non-Mandatory thickness conditions of PWHT, See Note (2) of Table UCS-56 For PWHT at lower temperatures for longer periods of time, See Note (1) of Table UCS-56

PQR Qualified Range (ASME IX Guideline):

Qualified Positions (Groove, Fillet): All Positions for Plate or Pipe. Unless specifically required otherwise by the welding variables (QW-250), a qualification in any position qualifies the procedure for all positions. The welding process and electrodes must be suitable for all positions permitted by the WPS (ASME Section IX, QW-203). (For impact test application, there are some restrictions for welding in vertical-uphill progression position; See ASME Section IX, QW-405.2) Qualified Thicknesses (Groove, Fillet): 3/16 in. (5 mm) Min., 8 in. (200 mm) Max. (Plate or Pipe) [When testing longitudinal-bend tests only: 2T Max.] [For impact test application, except ESW process: Min. Qualified Thickness is 5/8 in. (16 mm); This variable does not apply when a WPS is qualified with a PWHT above the upper transformation temperature or when an austenitic material is solution annealed after welding. ASME IX, QW-403.6] [For ferrous base metals other than P-No. 7, 8 and 45 (when test coupon receives a PWHT above the upper transformation temperature): 1.1T Max. ASME IX, QW-407.4] [For any weld pass greater than 1/2 in. (13 mm) thick: 1.1T Max. (Except GTAW process). ASME IX, QW-403.9] T: Thickness of Test Plate or Pipe Wall in PQR (ASME Section IX, Table QW-451.1) Qualified Diameters (Groove, Fillet): All Nominal Pipe (Tube) Sizes, within Qualified Thicknesses in PQR WPS Base Metal P-Number Allowed by PQR: Any metals of the same P-No. 1 tested in PQR (ASME Section IX, QW-424) Qualified WPS Filler Metal Allowed by PQR: Only Filler Metal categories with the same F-number and same A-number tested in PQR. Any electrode diameter sizes can be used in WPS, as it is not an essential variable for the most process and conditions. For Non-impacted test applications only, filler metal classification within an SFA specification, with the same F-number and the same A-number and the same minimum tensile strength and the same nominal chemical composition can be used in WPS. (ASME Section IX, QW-250) Qualified Weld Metal Deposit (Groove, Fillet): 2t Max. when t is less than 3/4 in. (19 mm) (Plate or Pipe) Qualified Weld Metal Deposit (Groove, Fillet): 8 in. (200 mm) Max. when t is equal or larger than 3/4 in. (19 mm) [For GMAW-Short Circuit Arc, when t is less than 1/2 in. (13 mm): 1.1t Max.] [When testing longitudinal-bend tests only: 2t Max.] t: Thickness of Weld Metal Deposit in PQR, Plate or Pipe Wall (ASME Section IX, Table QW-451.1)

PROCEDURE QUALIFICATION RECORDS Test Results

PQR No.: DEMO-PQR

Date: 11,12, 2005

Sheet 4 of 4

TENSILE TEST (QW-150)

Specimen No. TA1 TA2 TM1 TM2 TB1 TB2 Width mm (in) 25.1 25.1 25 25.1 25 25 Thickness mm (in) 30 30 30 30 30 29.8 Area mm x mm (in x in) 753 753 750 753 750 745 Ultimate Total Load, Kg (lb) 36212 Kg 36712 Kg 35712 Kg 35612 Kg 36412 Kg 36312 Kg Ultimate Unit Stress, MPa (psi) 471 (MPa) 477 (Mpa) 466 (MPa) 463 (MPa) 475 (MPa) 478 (MPa) Type of Failure and Location Ductile out Weld Ductile out Weld Ductile out Weld Ductile out Weld Ductile out Weld Ductile out Weld

GUIDED-BEND TESTS (QW-160)

Type and Figure No. QW 462.2 PL1 QW 462.2 PL2 QW 462.2 PL3 QW 462.2 PL4 Results Satisfactory Satisfactory Satisfactory Satisfactory Remarks Ductile Ductile Ductile Ductile

TOUGHNESS TESTS (QW-170)

Specimen No. TVA1 TVA2 TVA3 TVB1 TVB2 TVB3 Specimen Size mm x mm (in x in) 10 X 10 10 X 10 10 X 10 10 X 10 10 X 10 10 X 10 Test Temperature C (F) 0 C 0 C 0 C 0 C 0 C 0 C Impact Values Joule J (ft-lb) 78 39 83 73 78 73 Lateral Exp. % Shear mm/mm Drop Weight Break: Yes/ No

Notch Location

in weld in weld in weld in weld in weld in weld

Comments (Notch type, etc.): Charpy V Notch, 2 mm

Other Tests (Notes): No further tests are required.

Radiographic-ultrasonic examination:

RT report no: 1230-RT UT report no: 2310-UT Result: O.K. Result: O.K.

FILLET-WELD TEST RESULTS (QW-180)

Result-Satisfactory: Penetration into Parent Metal: Macro-Results: N/A Welders name: Joe Smith Name of Laboratory: Quality Weld Lab, Inc. Tests conducted by: WPSAmerica.com Laboratory Tests Number: TN-46547 Clock No.: 123-12-1234 Stamp No.: JS-02

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME Code.

Additional Notes: This is a DEMO-PQR prepared with WPSAmerica.com online welding software. Manufacturer or Contractors Welding Engineer:

Name: Jim Clark Signature: J.C. Title: Welding Engineer Date: 12, 12, 2005

Authorized by:

Name: John Smith Signature: J.S. Title: QA Manager Date: 12,12, 2005

You might also like

- Mazda 3 Workshop Manual - TRANSMISSION + DTC + Wiring DiagramsDocument268 pagesMazda 3 Workshop Manual - TRANSMISSION + DTC + Wiring DiagramsMichael Cobarde67% (3)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- WPS PQRDocument23 pagesWPS PQRHashim Khan88% (8)

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (2)

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- Wps - PQR 401 TerbaruDocument12 pagesWps - PQR 401 TerbaruJeffri MalauNo ratings yet

- PQRDocument2 pagesPQRHoangNo ratings yet

- WPS PQR WPQ PeiplDocument16 pagesWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam75% (4)

- OSD Welding ProcedureDocument6 pagesOSD Welding ProcedureVijayakumar Chandran100% (1)

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocument1 pageIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- ElectrodosDocument14 pagesElectrodosanon-635614100% (6)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS - 020Document15 pagesWPS - 020MAT-LION100% (2)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Document5 pagesWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (2)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasNo ratings yet

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- Weld GaugesDocument15 pagesWeld Gaugesraobabar21100% (1)

- Welder Performance Qualification (WPQ)Document2 pagesWelder Performance Qualification (WPQ)alokbdasNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document1 pagePreliminary Welding Procedure Specification (PWPS)AzriNo ratings yet

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- TWI CSWIP 3.1 Wis 5 Welding Inspection Destructive Tests: World Centre For Materials Joining TechnologyDocument20 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Destructive Tests: World Centre For Materials Joining TechnologyOnur Altuntaş100% (1)

- WQT - 1 PDFDocument2 pagesWQT - 1 PDFLuttpi100% (1)

- APSM WPS 008R Rev. 0Document3 pagesAPSM WPS 008R Rev. 0Amir NorNo ratings yet

- WPQR SMAW EN-2 - 30mm (Under Modification)Document2 pagesWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinNo ratings yet

- WPS PQR Check List Table 2017Document5 pagesWPS PQR Check List Table 2017TuTuy An89% (19)

- Welder Qualification Tests WQT DL QC 001 2019Document24 pagesWelder Qualification Tests WQT DL QC 001 2019adelNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WQT - WPS 02Document33 pagesWQT - WPS 02Gururaj P KundapurNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Electrodes ConsumablesDocument2 pagesElectrodes Consumablesranjith_007100% (3)

- TWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyDocument53 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyOnur Altuntaş100% (1)

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocument3 pagesSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013No ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- Eqt RecordDocument41 pagesEqt RecordShaikh sohilNo ratings yet

- PQR Asme BlankDocument3 pagesPQR Asme Blankamirul8686No ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps Demoharis saleemNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Die Casting DesignDocument20 pagesDie Casting Designtiep_design100% (1)

- AbktDocument5 pagesAbktboergleNo ratings yet

- Building ServicesDocument49 pagesBuilding Servicesankitmehta131No ratings yet

- Malaysian Code of Practice On Energy Efficient Cooling TowersDocument21 pagesMalaysian Code of Practice On Energy Efficient Cooling TowersmitasyahuNo ratings yet

- FinFan Technical InfoDocument15 pagesFinFan Technical InfoRoozbeh PNo ratings yet

- (12-4-5) NPTEL - Gas Liquefaction and Refrigeration Systems PDFDocument52 pages(12-4-5) NPTEL - Gas Liquefaction and Refrigeration Systems PDFAbinash ANo ratings yet

- Amphenol: T9602 Humidity & Temperature Sensor For OEM InstallationDocument4 pagesAmphenol: T9602 Humidity & Temperature Sensor For OEM Installationamaza_prodeoNo ratings yet

- Plastic DomainDocument8 pagesPlastic DomainAshish S GhevadeNo ratings yet

- Micro Electronic and Mechanical SystemsDocument524 pagesMicro Electronic and Mechanical SystemsGilberto AlmeidaNo ratings yet

- DYWIDAG THREADBAR Metric UnitsDocument1 pageDYWIDAG THREADBAR Metric UnitsArve CruzNo ratings yet

- Cost-Data Book FY 2023-24Document107 pagesCost-Data Book FY 2023-24filesend681No ratings yet

- EagleBurgmann - Araflon 6426 - ENDocument2 pagesEagleBurgmann - Araflon 6426 - ENsf wNo ratings yet

- Ok Aristorod - Welders Love It and So Do RobotsDocument6 pagesOk Aristorod - Welders Love It and So Do RobotsMRC WeldingNo ratings yet

- Soil Stabilization Using Ground Granulated Blast Furnace Slag (GGBS)Document7 pagesSoil Stabilization Using Ground Granulated Blast Furnace Slag (GGBS)Civil EngineeringNo ratings yet

- Rilsamid® Aesno TL: Main CharacteristicsDocument2 pagesRilsamid® Aesno TL: Main Characteristicsjuliushasan2No ratings yet

- Process Discription PDFDocument41 pagesProcess Discription PDFAshish TiwariNo ratings yet

- 20.02 GEK103616d ProtUnassembledGenCompDocument36 pages20.02 GEK103616d ProtUnassembledGenCompLIUNo ratings yet

- Davao Asia Plastic Corporation: A Case Company For Operations and Supply Chain Management StudyDocument42 pagesDavao Asia Plastic Corporation: A Case Company For Operations and Supply Chain Management StudyRichie DonatoNo ratings yet

- Energy-Efficient RefurbishmentDocument36 pagesEnergy-Efficient RefurbishmentNeedleandMortarNo ratings yet

- CZ 2012 2013 DieselDocument14 pagesCZ 2012 2013 DieselSoeAyeNo ratings yet

- MORT&H Stone in Wire Crates SpecififcationDocument8 pagesMORT&H Stone in Wire Crates SpecififcationKunal MandalaywalaNo ratings yet

- IAEABuriedPiping NESeriesWebDocument389 pagesIAEABuriedPiping NESeriesWebAnonymous 1hOgJqwZuz100% (1)

- ASTM Grade 70-50-05 (ISO 500-7, En-JS 1050) Ductile Cast IronDocument8 pagesASTM Grade 70-50-05 (ISO 500-7, En-JS 1050) Ductile Cast IronNagarjun ReddyNo ratings yet

- Yes-O Action Plan 2020-2021Document3 pagesYes-O Action Plan 2020-2021Ruth Audrei Tuliao100% (1)

- AskelandPhuleNotes CH07PrintableDocument56 pagesAskelandPhuleNotes CH07PrintableManoj Janardan Jayashree TerekarNo ratings yet

- Drilling Hole Opener WebDocument2 pagesDrilling Hole Opener WebBehrangNo ratings yet

- p120-p121-p122-p123 RelaysDocument628 pagesp120-p121-p122-p123 Relayskjfens100% (1)

- Project Phase I - ReportDocument62 pagesProject Phase I - ReportAswini NRNo ratings yet

- 3L Filters CompleteDocument66 pages3L Filters CompleteHugo Ruiz100% (1)