Professional Documents

Culture Documents

Ductility: Almgsi Alloy

Uploaded by

zidaaanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ductility: Almgsi Alloy

Uploaded by

zidaaanCopyright:

Available Formats

Ductility

Tensile test of an AlMgSi alloy. The local necking and the cup and cone fracture surfaces are typical for ductile metals.

This tensile test of a nodular cast iron demonstrates low ductility. In materials science, ductility is a solid material's ability to deform under tensile stress; this is often characterized by the material's ability to be stretched into a wire. Malleability, a similar property, is a material's ability to deform under compressive stress; this is often characterized by the material's ability to form a thin sheet by hammering or rolling. Both of these mechanical properties are aspects of plasticity, the extent to which a solid material can be plastically deformed without fracture. Also, these material properties are dependent on temperature and

pressure (investigated by Percy Williams Bridgman as part of his Nobel Prize winning work on high pressures). Ductility and malleability are not always coextensive for instance, while gold is both ductile and malleable, lead is only malleable.[1] The word ductility is sometimes used to embrace both types of plasticity.[2]

You might also like

- Ductility Is When A Solid Material Stretches Under: Tensile Wire Malleability CompressiveDocument1 pageDuctility Is When A Solid Material Stretches Under: Tensile Wire Malleability Compressiveaditya singhNo ratings yet

- DuctilityDocument4 pagesDuctilitycelsolcruzNo ratings yet

- Duct IlityDocument14 pagesDuct IlityMehman NasibovNo ratings yet

- Materials Science TensileDocument3 pagesMaterials Science Tensileaditya2053No ratings yet

- Ductility and Malleability - The Difference Between Malleability andDocument2 pagesDuctility and Malleability - The Difference Between Malleability andRavi TarunNo ratings yet

- Ductility and Malleability - The Difference Between Malleability andDocument2 pagesDuctility and Malleability - The Difference Between Malleability andRavi TarunNo ratings yet

- Ductile - Brittle Transition TemperatureDocument2 pagesDuctile - Brittle Transition TemperatureRemya R. KumarNo ratings yet

- Ductility and MalleabilityDocument2 pagesDuctility and MalleabilityRavi TarunNo ratings yet

- Toughness: Types of Stresses On Loads Imposed On WeldmentsDocument7 pagesToughness: Types of Stresses On Loads Imposed On WeldmentsWilly UioNo ratings yet

- Production and Properties of Metal: Building Material Science-Iv AP-226Document9 pagesProduction and Properties of Metal: Building Material Science-Iv AP-226ADITI ADITINo ratings yet

- Mechanical Properties of A Metal: DuctilityDocument6 pagesMechanical Properties of A Metal: DuctilityNinfa LansangNo ratings yet

- Study Materials For Mechanical EngineersDocument63 pagesStudy Materials For Mechanical EngineersOmprakash ManharNo ratings yet

- Mechanical Properties of MaterialsDocument10 pagesMechanical Properties of Materialsosama raufNo ratings yet

- Mechanical Properties of Materials 1.elasticity:: Elastic Means ReversibleDocument5 pagesMechanical Properties of Materials 1.elasticity:: Elastic Means ReversibleWajahat RasoolNo ratings yet

- The Mechanical Properties of Metal: Group 1 Members: Reymark M.laureanoDocument6 pagesThe Mechanical Properties of Metal: Group 1 Members: Reymark M.laureanoNinfa LansangNo ratings yet

- 4 Mechanical PropertiesDocument4 pages4 Mechanical PropertiesVikash PalNo ratings yet

- AyushDocument4 pagesAyushsatabdi palNo ratings yet

- PR2 Malleability-Of-Metals 12eDocument20 pagesPR2 Malleability-Of-Metals 12eJAY NACIONNo ratings yet

- Properties of MetalsDocument3 pagesProperties of MetalsChris Michelle Japin100% (1)

- Materials of EngineeringDocument10 pagesMaterials of EngineeringVer MeoNo ratings yet

- DuctilityDocument3 pagesDuctilityCarlo CastorNo ratings yet

- EmmDocument18 pagesEmmrajasamygopalNo ratings yet

- Final PresentationDocument24 pagesFinal PresentationJoy DumlaoNo ratings yet

- Welding Course 1Document79 pagesWelding Course 1Orueta ClaudioNo ratings yet

- Behavior of MetalsDocument28 pagesBehavior of Metalssaurabh joshiNo ratings yet

- Mechanical Properties of MaterialsDocument4 pagesMechanical Properties of MaterialsBoykeNo ratings yet

- Mechanical Material PropertiesDocument10 pagesMechanical Material PropertiesDong HungNo ratings yet

- Mechanical Properties of MaterialsDocument4 pagesMechanical Properties of MaterialsMuhangi ChristopherNo ratings yet

- Mechanical Properties of MaterialsDocument5 pagesMechanical Properties of MaterialsSasaleleNo ratings yet

- Fundamentals of Professional WeldingDocument213 pagesFundamentals of Professional Weldingapi-3856939No ratings yet

- Pointers - EngineDocument3 pagesPointers - EngineIvan QuidlatNo ratings yet

- S Announcement 17688 PDFDocument36 pagesS Announcement 17688 PDFPatricia Reign BagaoisanNo ratings yet

- Examples of Malleable Metals Are Gold, Iron, Aluminum, Copper, and LeadDocument1 pageExamples of Malleable Metals Are Gold, Iron, Aluminum, Copper, and LeadUmer Iftikhar AhmedNo ratings yet

- Outcome 2t1Document16 pagesOutcome 2t1JosePeterPintoNo ratings yet

- Mechanical PropertiesDocument9 pagesMechanical PropertiessamstiraNo ratings yet

- Mod 6.1 B1.1-1Document38 pagesMod 6.1 B1.1-1gulphan.No ratings yet

- Drilling Operations l3 NotesDocument21 pagesDrilling Operations l3 Notesishimwe kwizera willyNo ratings yet

- MaterialsDocument41 pagesMaterialsBalaNo ratings yet

- MaterialsDocument18 pagesMaterialssonawanepmsNo ratings yet

- Precipitation HardeningDocument6 pagesPrecipitation Hardeningjyoti swaroop repaka100% (9)

- Draft Strain HardeningDocument9 pagesDraft Strain HardeningRho AsaNo ratings yet

- 22 Mechanical PropertiesDocument18 pages22 Mechanical PropertiesJASONNo ratings yet

- Assign 2Document7 pagesAssign 2world vibesNo ratings yet

- Welding FundametalsDocument55 pagesWelding Fundametalsyadavmihir63No ratings yet

- Aircraft Structural MaterialsDocument72 pagesAircraft Structural MaterialsLION KINGNo ratings yet

- Strength of MaterialsDocument5 pagesStrength of MaterialsKumar SubramanianNo ratings yet

- Aircraft Materials and Processes PDFDocument129 pagesAircraft Materials and Processes PDFgibea erllyn ramos100% (1)

- Brazing TC To SteelDocument12 pagesBrazing TC To SteelSrinath GurunathNo ratings yet

- 3 Mechanical Properties of MetalsDocument23 pages3 Mechanical Properties of MetalsJeffersonTalanNo ratings yet

- Engineering MaterialsDocument43 pagesEngineering MaterialsSyed Waqar AhmedNo ratings yet

- MT & HT Lecture 1Document16 pagesMT & HT Lecture 1Abban SiddiquiNo ratings yet

- Introduction To Material Science and MetallurgyDocument28 pagesIntroduction To Material Science and Metallurgytani nNo ratings yet

- Precipitation Hardening: The Commonwealth and International Library: Selected Readings in MetallurgyFrom EverandPrecipitation Hardening: The Commonwealth and International Library: Selected Readings in MetallurgyNo ratings yet

- Effect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steel PDFDocument5 pagesEffect of Welding On Microstructure and Mechanical Properties of An Industrial Low Carbon Steel PDFzidaaanNo ratings yet

- Lecture1 PDFDocument7 pagesLecture1 PDFarunNo ratings yet

- Butterfly: Butterflies Butterflies Are Part of The Class of Insects in The Order Lepidoptera, Along With The Moths. AdultDocument2 pagesButterfly: Butterflies Butterflies Are Part of The Class of Insects in The Order Lepidoptera, Along With The Moths. AdultzidaaanNo ratings yet

- Machine Design Jindall (Part Of)Document187 pagesMachine Design Jindall (Part Of)zidaaanNo ratings yet

- Lecture1 PDFDocument7 pagesLecture1 PDFarunNo ratings yet

- Self Help Handbook 2015 PDFDocument30 pagesSelf Help Handbook 2015 PDFHomitchi SorinaNo ratings yet

- Experimental Analysis of TIG Welding and Comparison Between Activated-TIG and TIG On Duplex Stainless Steel (2205)Document8 pagesExperimental Analysis of TIG Welding and Comparison Between Activated-TIG and TIG On Duplex Stainless Steel (2205)zidaaanNo ratings yet

- Friction Stir Welding A Brief DiscrptionDocument7 pagesFriction Stir Welding A Brief DiscrptionzidaaanNo ratings yet

- Fatigue Life Estimates Using Goodman DiagramsDocument11 pagesFatigue Life Estimates Using Goodman Diagramsloveleshvarma100% (1)

- Cobalt MetalDocument6 pagesCobalt MetalzidaaanNo ratings yet

- Eagle PDFDocument6 pagesEagle PDFzidaaanNo ratings yet

- Electrical Discharge MachiningDocument6 pagesElectrical Discharge MachiningzidaaanNo ratings yet

- Eagle PDFDocument6 pagesEagle PDFzidaaanNo ratings yet

- Antenna: Science and EngineeringDocument1 pageAntenna: Science and EngineeringzidaaanNo ratings yet

- Aluminium OxideDocument3 pagesAluminium OxidezidaaanNo ratings yet

- PlasterDocument3 pagesPlasterzidaaanNo ratings yet

- Very Important On Bead GeometryDocument10 pagesVery Important On Bead GeometryzidaaanNo ratings yet

- Eddy-Current Testing - Wikipedia, The Free Encyclopedia PDFDocument3 pagesEddy-Current Testing - Wikipedia, The Free Encyclopedia PDFzidaaanNo ratings yet

- CarbonDocument19 pagesCarbonzidaaanNo ratings yet

- BainiteDocument3 pagesBainitezidaaanNo ratings yet

- Tungsten CarbideDocument3 pagesTungsten CarbidezidaaanNo ratings yet

- Eddy-Current Testing - Wikipedia, The Free Encyclopedia PDFDocument3 pagesEddy-Current Testing - Wikipedia, The Free Encyclopedia PDFzidaaanNo ratings yet

- SnakeDocument12 pagesSnakezidaaanNo ratings yet

- SulfurDocument20 pagesSulfurzidaaanNo ratings yet

- TitaniumDocument17 pagesTitaniumzidaaanNo ratings yet

- ZincDocument29 pagesZinczidaaanNo ratings yet

- PoisonDocument7 pagesPoisonzidaaanNo ratings yet

- CNC G-Code Programming Tutorial, Course, Examples, and ProgramsDocument5 pagesCNC G-Code Programming Tutorial, Course, Examples, and Programszidaaan0% (1)

- Polarity (Mutual InductanceDocument3 pagesPolarity (Mutual InductancezidaaanNo ratings yet

- TinDocument16 pagesTinzidaaanNo ratings yet

- Hints ABAQUS PDFDocument14 pagesHints ABAQUS PDFAndres CarphioNo ratings yet

- 33 - India - Connecting Rod AnalisysDocument7 pages33 - India - Connecting Rod AnalisysBima SorayaNo ratings yet

- Civil Engineering TRB Study Materials (Mechanics)Document99 pagesCivil Engineering TRB Study Materials (Mechanics)Anitha Muthukumaran63% (8)

- New Distortional Buckling Design Rules For Slotted Perforated Cold-Formed Steel BeamsDocument21 pagesNew Distortional Buckling Design Rules For Slotted Perforated Cold-Formed Steel Beamsdinesh lakshmananNo ratings yet

- A Novel and Simple Technique For Development of Dual Phase Steels WithDocument6 pagesA Novel and Simple Technique For Development of Dual Phase Steels WithDaniel Carlos AndradeNo ratings yet

- (Paper) Design of Tunnel Under Seismic ConditionDocument23 pages(Paper) Design of Tunnel Under Seismic ConditionRAJENDRA PRASADNo ratings yet

- Apphysics Lec 12Document25 pagesApphysics Lec 12Vijay KumarNo ratings yet

- Test 4 - StressesDocument3 pagesTest 4 - StressesCouline Castillo Roldan - DinoyNo ratings yet

- Composite Stress MethodsDocument47 pagesComposite Stress Methodsluuvandong48xf396No ratings yet

- Ravi2020 Article ExperimentalAnalyticalAndNumerDocument17 pagesRavi2020 Article ExperimentalAnalyticalAndNumerRodyShineNo ratings yet

- Column Webs in Steel Beam-To-Column Connexions Part I-Formulation and VerificationDocument27 pagesColumn Webs in Steel Beam-To-Column Connexions Part I-Formulation and VerificationSabra SABRANo ratings yet

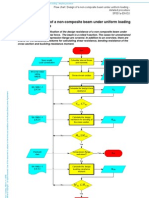

- EC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed ProcedureDocument5 pagesEC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed Procedurejskolmen100% (1)

- Strengthening Powerpoint PDFDocument109 pagesStrengthening Powerpoint PDFAndrew PetryszakNo ratings yet

- Introduction To Structural Steel DesignDocument25 pagesIntroduction To Structural Steel DesignMelchizedek Ell100% (1)

- Mechanical Properties of SolidsDocument4 pagesMechanical Properties of SolidsSteveMathewKuruvillaNo ratings yet

- Constitiutive Modelling ConcreteDocument37 pagesConstitiutive Modelling ConcreteGaby GarcíaNo ratings yet

- Midas Civil - Analysis ReferenceDocument400 pagesMidas Civil - Analysis ReferenceMohd FaizalNo ratings yet

- Evaluation of The Capacity of Steel Special Bolted Moment FrameDocument23 pagesEvaluation of The Capacity of Steel Special Bolted Moment Frameramtin hajirezaeiNo ratings yet

- Research On Thin Glass-Polycarbonate Composite Panels PDFDocument10 pagesResearch On Thin Glass-Polycarbonate Composite Panels PDFGino TironiNo ratings yet

- Journal of Constructional Steel Research Volume 103 Issue 2014 (Doi 10.1016 - j.jcsr.2014.08.006) Hu, Hong-Song Nie, Jian-Guo Eatherton, Matthew R. - Deformation Capacity of Concrete-Filled Steel PDocument11 pagesJournal of Constructional Steel Research Volume 103 Issue 2014 (Doi 10.1016 - j.jcsr.2014.08.006) Hu, Hong-Song Nie, Jian-Guo Eatherton, Matthew R. - Deformation Capacity of Concrete-Filled Steel PPrapa KaranNo ratings yet

- 4 - P. Moze, D. Beg - On The Bearing Resistance of Bolted ConnectionsDocument10 pages4 - P. Moze, D. Beg - On The Bearing Resistance of Bolted ConnectionsChandana KumaraNo ratings yet

- Advances in Material Forming and Joining-5th AIMTDR PDFDocument385 pagesAdvances in Material Forming and Joining-5th AIMTDR PDFAbhijeetNo ratings yet

- A Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Document1 pageA Textbook of Machine Design by R.S.KHURMI AND J.K.GUPTA - 216Vivek MishraNo ratings yet

- Die Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingDocument30 pagesDie Basics 101: Intro To Stamping: Stamping (Metalworking) Stamping PressingAmitNo ratings yet

- Strain Gauge TrainerDocument22 pagesStrain Gauge TrainerParveen DhullNo ratings yet

- Dynamic Analysis of Three-Roll Pyramidal Configuration Roll Bending Process and Experimental VerificationDocument7 pagesDynamic Analysis of Three-Roll Pyramidal Configuration Roll Bending Process and Experimental Verificationdesign mosNo ratings yet

- Behaviour and Analysis of Bamboo Reinforced Concrete Beams Under Flexural LoadingDocument11 pagesBehaviour and Analysis of Bamboo Reinforced Concrete Beams Under Flexural LoadingOyekunle VictorNo ratings yet

- Lab Report#4Document15 pagesLab Report#4brayanNo ratings yet

- Microcracking and Stress-Strain Curves For Concrete in TensionDocument4 pagesMicrocracking and Stress-Strain Curves For Concrete in TensionjayanthNo ratings yet