Professional Documents

Culture Documents

CLNG 5803-074

CLNG 5803-074

Uploaded by

DeepakOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CLNG 5803-074

CLNG 5803-074

Uploaded by

DeepakCopyright:

Available Formats

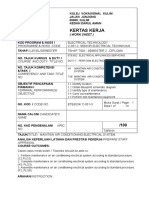

INSTRUMENT INSTALLATION LOOP CHECK SHEET Project No.: H0403600 Prepared By: Pipe I.D.: Instrument Tag No.

:

MEASURING ELEMENT: VERIFY LOCATION AND TAG NUMBER ISOLATING/DRAIN VALVES CORRECT CHECK DIRECTION AND METER RUN LOCATION AND TAG NUMBER CORRECT MATERIALS CORRECT INSTRUMENT FIELD: CONNECTION TO ELEMENT HI/LO IN D/P VERIFY LOCATION AND TAG NUMBER CHECK 3-WAY MAINIFOLD CHECK TERMINATION POLARITY CHECK SHIELD WIRE ISOLATION CHECK TUBES AND/OR CONDUIT SUPPORTS INSTALLED CORRECTLY POWER SUPPLY CORRECT WEATHER PROTECTED AIR SUPPLY CORRECT TRACING & INSULATION CORRECT TRANSMISSION: PNEUMATIC LINES VISUALLY INSPECTED BLOWN CLEAR & LEAK TESTED ELECTRONIC CONTINUITY CHECKED INSULATION CORE TO CORE CHECKED EARTH BONDING CHECKED LOOP IMPEDANCE CHECKED ZENER BARRIER DEVICES CORRECT GENERAL TRANSMITTER OUTPUT TO RELEVANT ITEMS LOOPS CHECKED-DCS CONTROLLED OUTPUT TO RELEVANT ITEMS OF LOOP CHECKED-DCS LOOP TEST LOOP TEST OUTPUT SENSOR INPUT LOCAL INST: DCS 0% 25% 75% 100% Sub-Contractor QA/QC Rep. By Date

Client: CLNG Location: Cameron Parish, LA Loop Number: Line or Equipment No:

Report No.: Date: Service:

IMPULSE CONNECTIONS: CONNECT TO HOOK-UP DRAWINGS PRESSURE TESTED TO PROCESS LINE TEST PRESSURE WEATHER PROTECTED TO REQUIREMENTS OF INSTRUMENT INDEX MATERIALS CORRECT FINAL CONTROL ELEMENT: VERIFY LOCATION OF TAG NUMBER STROKE TESTED POSITIONER CHECKED TYPE & SIZE CORRECT LIMIT SWITCH CORRECTLY SET I/P TRANSDUCER CHECKED INSTALLED TO CORRECT FLOW DIRECTION AIR SUPPLIES: VISUALLY INSPECTED BLOWN CLEAR & LEAK TESTED CORRECT TO INSTALLATION DETAIL T/C OR RTD INSTALLATION CHECKED CONTINUITY CHECKED SUPPORTS CHECKED LOOP IMPEDANCE CHECKED CABLE TO SPECIFICATION TAGGING CORRECT REMARKS:

AK/IHI QA/QC Rep. By Date

CLNG Rep. By Date

CP-5803.074

Rev 3

You might also like

- Pre-Commissioning Check ListDocument1 pagePre-Commissioning Check ListArturo100% (9)

- Grounding Installation Inspection and Test Plan (ITP)Document2 pagesGrounding Installation Inspection and Test Plan (ITP)benz100% (9)

- Instrument Hook-Up DrawingDocument15 pagesInstrument Hook-Up DrawingNikhil Kautilya92% (12)

- Air Cooled Chiller ChecklistDocument3 pagesAir Cooled Chiller ChecklistDevendra DhumalNo ratings yet

- Mechanical Inspection Form For Handing Over Completed Room or AreaDocument12 pagesMechanical Inspection Form For Handing Over Completed Room or Areacyno21No ratings yet

- Check List Junction BoxDocument9 pagesCheck List Junction BoxAldeline SungahidNo ratings yet

- ITP For Lighting & Small PowerDocument5 pagesITP For Lighting & Small PowerGanga Daran100% (1)

- Plate Heat Exchanger: Pre-Commissioning ChecklistDocument1 pagePlate Heat Exchanger: Pre-Commissioning ChecklistHoang Nam100% (1)

- Air Handling Unit Construction ChecklistDocument7 pagesAir Handling Unit Construction Checklistameeri143No ratings yet

- Installation Check ListDocument4 pagesInstallation Check ListAbdul Hakkim0% (1)

- Ip Control Valve Calibration FormDocument1 pageIp Control Valve Calibration FormKester Ndabai50% (2)

- AC System Check SheetDocument1 pageAC System Check SheetQOBITNo ratings yet

- PAT Repaired Equipment RegisterDocument3 pagesPAT Repaired Equipment RegisterDaniel William HillNo ratings yet

- Air Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationDocument6 pagesAir Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationGopinath GopiNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Ultrasonic Examination Report: Wayland EngineeringDocument1 pageUltrasonic Examination Report: Wayland EngineeringDeepak100% (1)

- API 580 Questions ModDocument18 pagesAPI 580 Questions ModDeepak100% (1)

- QR-TR FQP-106024-00 Electrical PDFDocument12 pagesQR-TR FQP-106024-00 Electrical PDFYahya SamaraNo ratings yet

- Visual and Technical Checking of Instrumentation and Control SystemDocument13 pagesVisual and Technical Checking of Instrumentation and Control SystemzhangyiliNo ratings yet

- MEP FP Inspection ChecklistDocument6 pagesMEP FP Inspection ChecklistMohanad SulimanNo ratings yet

- MEP FP Inspection ChecklistDocument6 pagesMEP FP Inspection ChecklistRichard RajkumarNo ratings yet

- MEP FP Inspection Checklist PDFDocument6 pagesMEP FP Inspection Checklist PDFRichard RajkumarNo ratings yet

- ChecksheetDocument423 pagesChecksheetAbdul Hakam Mohamed Yusof100% (2)

- Above Ground PipingDocument2 pagesAbove Ground PipingChristopher RothNo ratings yet

- Fahu - AhuDocument6 pagesFahu - AhuHadi AbdulkaderNo ratings yet

- Checklist GSR612 (E)Document12 pagesChecklist GSR612 (E)sumant.c.singh1694No ratings yet

- Piping ReportDocument2 pagesPiping ReportcomyahoothanhNo ratings yet

- Pipeline Engineering SheetDocument1 pagePipeline Engineering Sheetdesing789No ratings yet

- Electrical No 1 2 3 4 5 6 InstrumentDocument4 pagesElectrical No 1 2 3 4 5 6 Instrumentcherif yahyaouiNo ratings yet

- Pre-Functinal Checks FormatDocument15 pagesPre-Functinal Checks Formatchakravarthi kanugulaNo ratings yet

- Commisionign HVAC ChecklistDocument10 pagesCommisionign HVAC ChecklistCarolina HernándezNo ratings yet

- Forced Convection ApparatusDocument5 pagesForced Convection ApparatusPon ShanmugakumarNo ratings yet

- SVSW-004110-G16-0003-Rev.a-datasheet For Magnectic Level Gauge & TransmitterDocument4 pagesSVSW-004110-G16-0003-Rev.a-datasheet For Magnectic Level Gauge & Transmitternguyenquoc1988No ratings yet

- Air Handling Unit QC Checklist: AHU InformationDocument5 pagesAir Handling Unit QC Checklist: AHU InformationRaheel AhmedNo ratings yet

- What An Instrument Engineer Should Know - Instrumentation and Process Control PDFDocument10 pagesWhat An Instrument Engineer Should Know - Instrumentation and Process Control PDFricardolca100% (2)

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDocument81 pagesC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (2)

- ElectroMechanical Completion-INSTRUMENT INSTALLATIONDocument1 pageElectroMechanical Completion-INSTRUMENT INSTALLATIONhuseyinyuksel1903No ratings yet

- A.9.02 - CPCL Itp For Utility Boiler PackageDocument3 pagesA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarNo ratings yet

- Piping ISO Check SheetDocument3 pagesPiping ISO Check Sheetkulasera100% (2)

- LayoutDocument32 pagesLayoutDilip Yadav100% (1)

- 380 GIS - Site TestDocument21 pages380 GIS - Site TestSameer SyedNo ratings yet

- Check List Ladder & TrayDocument5 pagesCheck List Ladder & TrayAldeline SungahidNo ratings yet

- Appendix D: Engineering Standards Manual ISD 341-2Document17 pagesAppendix D: Engineering Standards Manual ISD 341-2tadagidsNo ratings yet

- Engineering ChecklistDocument4 pagesEngineering ChecklistShyBokxNo ratings yet

- Site Acceptance Test For 132Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentDocument2 pagesSite Acceptance Test For 132Kv Gis: Make Name / Type of Equipment Serial Number Rating Power Voltage CurrentBalamurugan SelvarajNo ratings yet

- Technical Problem Checklist: QRL No. DateDocument1 pageTechnical Problem Checklist: QRL No. DateMuhammad FerialNo ratings yet

- Air Conditioning Installation CertificationDocument13 pagesAir Conditioning Installation Certificationeng_amin1239449No ratings yet

- Pub Insp Wtic (Sep 09) RevisedDocument2 pagesPub Insp Wtic (Sep 09) RevisedagitentNo ratings yet

- Basic Instrumentation: Instrument UnitDocument53 pagesBasic Instrumentation: Instrument UnitBaqirMuhammad100% (1)

- Notes of Field Mounted Transmitter PT PDT FT LT Installation With Impulse Tubing Connection InspectionDocument2 pagesNotes of Field Mounted Transmitter PT PDT FT LT Installation With Impulse Tubing Connection Inspectionnoorakhtar007100% (1)

- ETE602 K4firstintake-Maintain AircondDocument14 pagesETE602 K4firstintake-Maintain AircondZunnur ZamzamNo ratings yet

- Measuring THE Flow: Coefficients OFDocument100 pagesMeasuring THE Flow: Coefficients OFdanndiamondNo ratings yet

- Schwenk-Air Flow Measurement AccuracyDocument27 pagesSchwenk-Air Flow Measurement AccuracydcgaoatNo ratings yet

- P&ID ChecklistDocument4 pagesP&ID ChecklistShyBokxNo ratings yet

- HVAC T and C StandardsDocument67 pagesHVAC T and C StandardsArun kumarNo ratings yet

- EG 15-14-1.1 Inspection and Testing of InstrumentsDocument3 pagesEG 15-14-1.1 Inspection and Testing of Instrumentsamin100% (1)

- Itp Mandrel CCTVDocument1 pageItp Mandrel CCTVbcdavidNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964From EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryNo ratings yet

- BS English 17-04-2020Document10 pagesBS English 17-04-2020DeepakNo ratings yet

- Syllabus Barc Rtl2 160714Document7 pagesSyllabus Barc Rtl2 160714DeepakNo ratings yet

- Icml Mla IiDocument3 pagesIcml Mla IiDeepak100% (2)

- 29 7 16Cl4EETestPortionDocument1 page29 7 16Cl4EETestPortionDeepakNo ratings yet

- Icml Mla IDocument3 pagesIcml Mla IDeepak100% (1)

- CL 4 PPT Animal World For Flipped LearningDocument7 pagesCL 4 PPT Animal World For Flipped LearningDeepakNo ratings yet

- FortiGate 30DDocument4 pagesFortiGate 30DIulianNo ratings yet

- Subject - Hindi Class IV Date of Test: 08-07-16 TopicDocument1 pageSubject - Hindi Class IV Date of Test: 08-07-16 TopicDeepakNo ratings yet

- 5 8 16Cl4MathsTestportionDocument1 page5 8 16Cl4MathsTestportionDeepakNo ratings yet

- Welding Procedure Specification: Technip KT India LimitedDocument5 pagesWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- The School Is The Temple of LearningDocument2 pagesThe School Is The Temple of LearningDeepakNo ratings yet

- Q.1) Pick Out Three Adjectives and Write Them in The Place Given BelowDocument2 pagesQ.1) Pick Out Three Adjectives and Write Them in The Place Given BelowDeepakNo ratings yet

- Tripride 1 Equivalent PDFDocument4 pagesTripride 1 Equivalent PDFDeepakNo ratings yet

- Here Is The MoonDocument2 pagesHere Is The MoonDeepakNo ratings yet

- NDT Methods AvailableDocument1 pageNDT Methods AvailableDeepakNo ratings yet

- Survey Form: Delhi Public School, Bopal, Ahmedabad Topic: Water, Water Everywhere Conservation of WaterDocument2 pagesSurvey Form: Delhi Public School, Bopal, Ahmedabad Topic: Water, Water Everywhere Conservation of WaterDeepakNo ratings yet

- Life Without LimitsDocument31 pagesLife Without LimitsDeepakNo ratings yet

- Nozzle Location Plate Identification Thickness Location E W N SDocument9 pagesNozzle Location Plate Identification Thickness Location E W N SDeepakNo ratings yet

- Vibration Pen TV200/220/260: Technical SpecificationsDocument1 pageVibration Pen TV200/220/260: Technical SpecificationsDeepakNo ratings yet

- XL Go Data SheetDocument4 pagesXL Go Data SheetDeepakNo ratings yet

- TR200Document3 pagesTR200DeepakNo ratings yet

- Vibration Tester TV110: Technical SpecificationsDocument1 pageVibration Tester TV110: Technical SpecificationsDeepakNo ratings yet

- TR210Document2 pagesTR210DeepakNo ratings yet

- Surface Roughness Tester TR110: Technical Specifications Standard DeliveryDocument1 pageSurface Roughness Tester TR110: Technical Specifications Standard DeliveryDeepakNo ratings yet

- PPEA-WI-016 Management of ChangeDocument3 pagesPPEA-WI-016 Management of ChangeDeepakNo ratings yet

- PPEA-WI-012 - B Consultation and Communication at SiteDocument6 pagesPPEA-WI-012 - B Consultation and Communication at SiteDeepakNo ratings yet

- Surface Roughness Tester TR100: Technical SpecificationsDocument1 pageSurface Roughness Tester TR100: Technical SpecificationsDeepakNo ratings yet

- PPEA-WI-016 Management of ChangeDocument3 pagesPPEA-WI-016 Management of ChangeDeepakNo ratings yet