Professional Documents

Culture Documents

Staircase

Staircase

Uploaded by

akhlaq_hssainkotaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Staircase

Staircase

Uploaded by

akhlaq_hssainkotaCopyright:

Available Formats

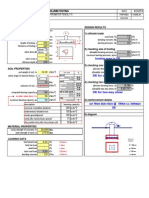

DESIGN OF STAIR CASE

(DESIGN OF LANDING SLAB A AND STAIR

( EX 11.12 LIMIT STATE DESIGN ASHOK K JAIN)

1

INPUT INPUT INPUT INPUT

INPUT

INPUT DATAS Min Head room above steps Ht of Floor Raise of the Stair Tread of the Stair Going of the Stair No of Goings on Ht of Floor and Raise No of Goings to be given The slope or Pitch of Stairway Check for Raise and Going Length of Landing A (2x) Total Length of Going G Length of Landing B (2y) Width of waist Slab Effective Span of Stair Flight Effective Span of Landing Slab A/B Width of Landing Slab A/B Grade of Concrete M Grade of Steel Fe Type of Support of Beam = =1 = = = Span / Eff depth Ratio Min Effective Depth of Stair Slab = Adopt Overall Depth of Stair Slab D Effective Length of Waist Slab Width of Waist Slab B

2.00 3.20 0.15 0.25 0.29 21 11 27.3 OK 1.5 3.19 1.50 1.50 4.69 3.30 1.50 25 500 CON 26 1 1.1 1 1 28.6 120 200 4.81 1.50

Mtr Mtr Mtr Mtr Mtr Nos Nos Degree Mtr Mtr Mtr Mtr Mtr Mtr Mtr

LANDING SLAB B WAIST SLAB

Per flight = No of Going/ ( 2 or 3)

INPUT INPUT INPUT

LANDING A

INPUT INPUT INPUT INPUT

CAN/SS/CON '7/20/26 for CAN/SS/CON '7/20/26 =1 up to 10 m, L>10, L/10 =Factor % Tension Rft =1 for 1 %, Fig 10.1

=Factor of Compression Rft 1 for 0 % Fig 10.

= Factor of Flanged Beam 1 for web L=B Fig 1 mm mm Mtr Mtr 200

CALCULATION OF LOAD, BM & SF Flight Load Dead Load of step section Dead Load of inclined Flight Super Imposed Dead Load Dead Load per Sqm on Plan Live Load on plan 550 1640 330 8690 5000 N/m N/m N/m N/Sqm N/Sqm

DL of Step Section= 1/2 * Going * Raise * 25000 Finishing Load = (R+G)*Finish thick * 25000

DL of Inclined Slab = Sqrt( G^2+R^2) *t * 25000

INPUT

Total Load Load Factor Factored Load on Flight w Total Factored Load on Flight Landing A Dead Load of Landing Super Imposed / Finish Load Total Dead Load Live Load on plan Total Load Load Factor Factored Load on Landing A Total Factored Load on Landing A Landing B Dead Load of Landing Super Imposed / Finish Load Total Dead Load Live Load on plan Total Load Load Factor Factored Load on Landing B Total Factored Load on Landing B Dist 150mm from the wall and 75 mm inside the wall only DL is considered Total Factored Load on Above length Reaction at Support B Reaction at Support A Point of Zero Shear from Support A Max BM on Waist Slab Effective Length of Waist Slab Max SF on Waist Slab Total Factor Load on Landing Slab A Reaction at A from Two Flight Total Factor Load on Landing Slab A

13690 1.5 20535 30.80

N/Sqm N/Sqm KN/m

5000 750 5750 5000 10750 1.5 16125 24.20

N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm KN/m

5000 750 5750 5000 10750 1.5 16125 24.20

N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm KN/m

12.94 71.64 76.71 2.65 106.41 4.69 76.71 119.73 153.43 273.16

KN/m KN KN Mtr KNm Mtr KN KN KN KN

Max BM in Landing slab A Max SF in Landing slab A

112.68 136.58

KNm KN

3 a

DESIGN OF MEMBER TO RESIST BENDING MOMENT Design of waist/ Flight Slab Grade of Concrete Grade of Steel Width of Slab Max BM Mx BM = (Const*fck) bd^2 Fe M 25 500 1.5 106.41 3.318 157 160 16 30 200 1500 25 500 8700 -435 2.77 At 1799 408.00 12000 1799 201.14 9 170 Mtr KN-M bd^2 mm mm mm mm mm mm 157 Max Depth of Nutral Axis fy 250 415 500 550 Limiting Moment of resistance MR

Calculated Eff Depth of Slab RESULT Adopt Effective Depth d INPUT Use Dia of Main rft Adopt Cover for Slab RESULT Over all Depth of Slab D Width of Beam Grade of Concrete Grade of Steel a= b= c=

m= Mu/(bd^2)

M Fe

Concrete M 15 20 25 30 35

0.87 *(fy^2/fck) -0.87 fy m= Mu/(bd^2)

p %= (-b- sqrt(b^2-4ac))/2a

2.77

0.749

Sqmm Sqmm Sqmm Sqmm Sqmm Nos mm 16 16 16 mm Dia mm Dia mm Dia

Min area of Tension Steel Ao=0.85*bd/fy

Max area of Tensile Steel = 0.04 bD Provide Area of Tension Steel Area of One Bar RESULT No of Bars RESULT Spacing of Distribution Bars

INPUT

Temp rft 0.15 % of gross area will be provided in the longitudinal direction 300 Sqmm Use 8 mm Dia bars Area of One Bar 50.29 Sqmm 8 170 mm 8

mm Dia mm Dia

RESULT Spacing of Distribution Bars

Landing Slab A

Grade of Concrete Grade of Steel Width of Slab Max BM Mx Fe

25 500 1.5 112.68 3.318 150 150 16 30 190 1500 25 500 8700 -435 m= Mu/(bd^2) At 2120 451.38 11400 2120 201.14 11 140 Mtr KN-M bd^2 mm mm mm mm mm mm Concrete M 15 20 25 30 35 Max Depth of Nutral Axis fy 250 415 500 550 Limiting Moment of resistance MR

BM = (Const*fck) bd^2 Calculated Eff Depth of Slab INPUT Adopt Effective Depth d Use Dia of Main rft Adopt Cover for Slab Over all Depth of Slab D Width of Slab Grade of Concrete Grade of Steel a= b= c=

m= Mu/(bd^2)

M Fe

0.87 *(fy^2/fck) -0.87 fy m= Mu/(bd^2)

p %= (-b- sqrt(b^2-4ac))/2a

3.32

0.939

Sqmm Sqmm Sqmm Sqmm Sqmm Nos mm 16 16 16 mm Dia mm Dia mm Dia

Min area of Tension Steel Ao=bd/fy Max area of Tensile Steel = 0.04 bD Provide Area of Tension Steel Area of One Bar RESULT No of Bars RESULT Spacing of Distribution Bars

INPUT

Temp rft 0.15 % of gross area will be provided in the longitudinal direction 285 Sqmm Use 8 mm Dia bars Area of One Bar 50.29 Sqmm 8 180 mm 8

mm Dia mm Dia

RESULT Spacing of Distribution Bars

4 a

DESIGN/ CHECK FOR MEMBER TO RESIST SHEAR Check for Shear in Waist Slab Grade of Concrete Eff Depth of Slab Over all Depth of Slab Width of Slab M 25 160 200 1500 mm mm mm

Grade of Concrete M

Max SS N/Sqmm

Dia of Main rft Area of One Bar No of Bars Max Shear Force wl/2

16 201.14 9 76.71

mm Sqmm Nos KN

Percentage of Tensile Steel 100At/2bd = Design Shear Strength

0.75 0.575

% Grade of Concrete M N/ Sqmm Max SS N/Sqmm 1.15 1.15

INPUT

For Permissible Max Shear Stress Nominal Shear stress Vu/bd Maximum Shear stress Tcm Shear Check Design of Stirrups Grade of Concrete Grade of Steel Fe Effective Depth of Slab Over all Depth of Beam Width of Beam Max Shear Force wl/2 Vu Strength of Shear rft Vus=Vu-Tc bd Dia of Shear rft Area of One Bar No of legged vertical stirrups Area of Vertical Stirrup Rft Asv Spacing of Shear rft x=0.87 fy Asv d/ Vus Check for Spacing Min Area of Shear rft 0.4 b x /fy Check for min Shear rft Area M

200

Calculated k Value mm thick slab, k= 0.661 0.32 3.10 Safe N/ Sqmm N/ Sqmm N/ Sqmm

25 500 160 200 1500 76.71 0 8 50.29 2 100.57 0 NOT OK 0 NOT OK Sqmm mm mm mm KN N mm Sqmm Nos mm mm Stirrup Rft NOT REQUIRED

INPUT

Min Spacing is 100 mm for placing of Concrete,

Check for Shear in Landing Slab A Grade of Concrete M 25 150 190 mm mm

Grade of Concrete M

Effective Depth of Beam Over all Depth of Beam

Width of Beam Dia of Main rft Area of One Bar No of Bars Max Shear Force wl/2

1500 16 201.14 11 136.58

mm mm Sqmm Nos KN

Max SS N/Sqmm

Percentage of Tensile Steel 100At/2bd = Design Shear Strength

0.13 0.269

% Grade of Concrete M N/ Sqmm Max SS N/Sqmm 1.15 1.15

INPUT

For Permissible Max Shear Stress Nominal Shear stress Vu/bd Maximum Shear stress Tcm Shear Check Design of Stirrups Grade of Concrete Grade of Steel Fe Effective Depth of Slab Over all Depth of Beam Width of Beam Max Shear Force wl/2 Vu M

190

Calculated k Value mm thick slab, k= 0.310 0.61 3.10 Un safe N/ Sqmm N/ Sqmm N/ Sqmm

25 500 150 190 1500 76.71 6845 12 113.14 2 226.29 2160 180 OK 216 OK mm mm mm KN N mm Sqmm Nos mm mm 180 Sqmm

Strength of Shear rft Vus=Vu-Tc bd INPUT Dia of Shear rft Area of One Bar INPUT No of legged vertical stirrups Area of Vertical Stirrup Rft Asv RESULT Spacing of Shear rft x=0.87 fy Asv d/ Vus INPUT Provide Spacing of Shear Rft Check for Spacing Min Area of Shear rft 0.4 b x /fy Check for Min Shear rft Area

420

12

Min Spacing is 100 mm for placing of Concrete,

If NOT OK then Increase the size of Rft or mo

5 a

CKECK FOR DEVELOPMENT LENGTH At Long Edge Max Shear Force wl/2 136.58 KN Design Bond Stress

Grade of Concrete Grade of Steel Dia of Slab rft Area of Tension rft Area of One Bar Spacing of Bars INPUT Fe

25 500 160 16 1799 201.14 110 200 1.6 mm mm Sqmm Sqmm mm mm N/Sqmm

Greade

Tbd N/Sqmm

15 1.0

Adopt Effective Depth d

Assumed Development Length Bond Stress Tbd

Development Length based on Anchorage Bond Ld= 0'0.87 fy / 4Tbd Ld in Anchorage Bond 1088 mm

Development Length based on Flexural Bond INPUT Ld= 1.3 M1/V + Lo Assumed Development Length Moment of Resistance offered by M1 = V= Ld in Flexural Bond Factor of Develop Length Develop length of Single Bar Max Development Length Max Bar Size in Develop Length Check for Development Length CKECK FOR DEVELOPMENT LENGTH 136578.90 N 724 56 896 1088 16 OK mm mm mm 250 415 500 mm fy N/Sqmm M15 55 56 69 188 mm 16 mm dia bar @

56,361,000 Nmm Tension Bars

Development Length for Single B

At Short Edge Max Shear Force wl/2 Grade of Concrete Grade of Steel Width of Beam b Dia of Main rft Area of Tension rft Area of One Bar No of Bars Fe M 136.58 25 500 160.00 1500 16 1799 201.14 9 mm mm mm Sqmm Sqmm mm KN Greade

Tbd N/Sqmm

Design Bond Stress 15 1.0

Adopt Effective Depth d

INPUT

Assumed Development Length Bond Stress Tbd

200 2.2

mm N/Sqmm

Development Length based on Anchorage Bond Ld= 0'0.87 fy / 4Tbd Ld in Anchorage Bond 777 mm

Development Length based on Flexural Bond INPUT Ld= 1.3 M1/V + Lo Assumed Development Length Moment of Resistance offered by M1 = V= Ld in Flexural Bond Factor of Develop Length Develop length of Single Bar Max Development Length Max Bar Size in Develop Length Check for Development Length 136578.90 N 1201 56 896 1201 25 OK mm mm mm If NOT OK Then Reduce the Spacing of Bars 250 415 500 mm fy N/Sqmm 188 mm 16 mm dia bar @

106,439,000 Nmm Tension Bars M15 55 56 69

Development Length for Single B

CHECK FOR DEFLECTION Short Span of Slab Effective Depth d Width of Beam b Dia of Slab rft Area of Tension rft Area of One Bar Spacing of Bars Percentage of tension steel at Mid Span = = 4.7 160 1500 16 1799 201 110 Mtr mm mm mm Sqmm Sqmm mm 0.75 26 1 1.1 1 1 28.6 29.31 % for CAN/SS/CON '7/20/26

INPUT

Cal =

1.02

=1 = = =

=1 up to 10 m, L>10, L/10 =Factor % Tension Rft =1 for 1 %, Fig 10.1 =Factor of Compression Rft 1 for 0 % Fig 10.

= Factor of Flanged Beam 1 for web L=B Fig 1

Allowable L/d Actual L/d

Deflection Check is

NOT OK

N OF LANDING SLAB A AND STAIR FLIGHT)

ASHOK K JAIN)

190 200

mm Th with RFT mm Th with RFT

16 16

mm dia @ mm dia @

140 C/C 170 C/C

11 9

Nos Nos

No of Going/ ( 2 or 3) 1.5 3.19 BEAM

STAIR FLIGHT LANDING A STAIR FLIGHT LANDING B

1.50

BEAM

3.30 B E A M

2X

GOING( G)

2Y

SS/CON '7/20/26

10 m, L>10, L/10

% Tension Rft =1 for 1 %, Fig 10.1

of Compression Rft 1 for 0 % Fig 10.2

of Flanged Beam 1 for web L=B Fig 10.3

8 200 190 Section= 1/2 * Going * Raise * 25000

th with rft

dia @ dia @ dia @ dia @

170 170 140 180

C/C C/C C/C C/C

16 16 8

th with rft

ned Slab = Sqrt( G^2+R^2) *t * 25000

oad = (R+G)*Finish thick * 25000

Max Depth of Nutral Axis Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm 0.53 d 0.48 d 0.46 d 0.44 d Limiting Moment of resistance MR = Const * b*d^2 N mm Const= 0.36*fck*Xm(1-0.42*Xm) Steel Fe 250 2.229 2.972 3.715 4.458 5.201 Fe 415 2.067 2.755 3.444 4.133 4.822 Fe 500 1.991 2.655 3.318 3.982 4.645 Fe 550 1.949 2.598 3.248 3.897 4.547

Max Depth of Nutral Axis Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm 0.53 d 0.48 d 0.46 d 0.44 d Limiting Moment of resistance MR = Const * b*d^2 N mm Const= 0.36*fck*Xm(1-0.42*Xm) Steel Fe 250 2.229 2.972 3.715 4.458 5.201 Fe 415 2.067 2.755 3.444 4.133 4.822 Fe 500 1.991 2.655 3.318 3.982 4.645 Fe 550 1.949 2.598 3.248 3.897 4.547

Max Shear Stress

Grade of Concrete M

25 3.1

Max SS N/Sqmm

fck 100 As bd 0.75

25

Design Shear Strength

3.87

SS N/Sqmm

0.575

Max Shear Stress Grade of Concrete M Max SS N/Sqmm 15 2.5 Value of K >300 275 1.00 1.05 20 2.8 25 3.1 30 3.5 35 3.7

Ds k

250 1.10

225 1.15

200 1.20

175 1.25

<151 1.30

* Shear rft be provided in a slab deeper than 200 mm

t NOT REQUIRED

ng is 100 mm for placing of Concrete, Max 450 mm

Max Shear Stress

Grade of Concrete M

25

Max SS N/Sqmm fck 100 As bd 0.13

3.1 25

Design Shear Strength

22.99

SS N/Sqmm

0.269

Max Shear Stress Grade of Concrete M Max SS N/Sqmm 15 2.5 Value of K >300 275 1.00 1.05 20 2.8 25 3.1 30 3.5 35 3.7

Ds k

250 1.10

225 1.15

200 1.20

175 1.25

<151 1.30

* Shear rft be provided in a slab deeper than 200 mm

mm Dia

Legs

ng is 100 mm for placing of Concrete, Max 450 mm then Increase the size of Rft or more No of Legs or reduce spacing of rft

Design Bond Stress

20 1.2

25 1.4

30 1.5

35 1.7

40 1.9

220

mm C/C

Development Length for Single Bars Tension Bars M20 46 47 58 40 49 38 46 30 36 M25 M30 M40 M15 44 45 54 Compression Bars M20 37 38 46 32 39 31 36 24 29 M25 M30 M40

Design Bond Stress 20 1.2 25 1.4 30 1.5 35 1.7 40 1.9

18

mm C/C

Development Length for Single Bars Tension Bars M20 46 47 58 Compression Bars M15 44 45 54 M20 37 38 46

Then Reduce the Spacing of Bars

SS/CON '7/20/26

10 m, L>10, L/10 % Tension Rft =1 for 1 %, Fig 10.1 of Compression Rft 1 for 0 % Fig 10.2

of Flanged Beam 1 for web L=B Fig 10.3

(Distribution Bars)

(Distribution Bars)

40 4.0

40 4.0

DESIGN OF STAIR CASE W/O EDGE BEAM (DESIGN OF LANDING S ( EX 11.12 LIMIT STATE DESIGN ASHOK K JAIN)

1

INPUT INPUT INPUT INPUT

INPUT

INPUT DATAS Min Head room above steps Ht of Floor Raise of the Stair Tread of the Stair Going of the Stair No of Goings on Ht of Floor and Raise No of Goings to be given The slope or Pitch of Stairway Check for Raise and Going Length of Landing A (2x) Total Length of Going G Length of Landing B (2y) Width of waist Slab Effective Span of Stair Flight Effective Span of Landing Slab A Width of Landing Slab A Grade of Concrete M Grade of Steel Fe Type of Support of Beam = =1 = = = Span / Eff depth Ratio Min Effective Depth of Beam = Adopt Overall Depth of Beam D Effective Length of Waist Beam Width of Waist Slab B

2.00 3.20 0.15 0.25 0.29 21 11 27.3 OK 1.5 3.19 1.50 1.50 4.69 3.30 1.50 25 500 CON 26 1 1.1 1 1 28.6 120 200 4.81 1.50

Mtr Mtr Mtr Mtr Mtr Nos Nos Degree Mtr Mtr Mtr Mtr Mtr Mtr Mtr

LANDING SLAB B WAIST SLAB

Per flight = No of Going/ ( 2 or 3)

INPUT INPUT INPUT

LANDING A

INPUT INPUT INPUT INPUT

CAN/SS/CON '7/20/26 for CAN/SS/CON '7/20/26 =1 up to 10 m, L>10, L/10 =Factor % Tension Rft =1 for 1 %, Fig 10.1

=Factor of Compression Rft 1 for 0 % Fig 10.

= Factor of Flanged Beam 1 for web L=B Fig 1 mm mm Mtr Mtr 200

CALCULATION OF LOAD, BM & SF Flight Load Dead Load of step section Dead Load of inclined Flight Super Imposed Dead Load Dead Load per Sqm on Plan Live Load on plan 550 1640 330 8690 5000 N/m N/m N/m N/Sqm N/Sqm

DL of Step Section= 1/2 * Going * Raise * 25000 Finishing Load = (R+G)*Finish thick * 25000

DL of Inclined Slab = Sqrt( G^2+R^2) *t * 25000

INPUT

Total Load Load Factor Factored Load on Flight w Total Factored Load on Flight Landing A Dead Load of Landing Super Imposed / Finish Load Total Dead Load Live Load on plan Total Load Load Factor Factored Load on Landing A Total Factored Load on Landing A Landing B Dead Load of Landing Super Imposed / Finish Load Total Dead Load Live Load on plan Total Load Load Factor Factored Load on Landing B Total Factored Load on Landing B Dist 150mm from the wall and 75 mm inside the wall only DL is considered Total Factored Load on Above length Reaction at Support B Reaction at Support A Point of Zero Shear from Support A Max BM on Waist Slab Effective Length of Waist Slab Max SF on Waist Slab Total Factor Load on Landing Slab A Reaction at A from Two Flight Total Factor Load on Landing Slab A

13690 1.5 20535 30.80

N/Sqm N/Sqm KN/m

5000 750 5750 5000 10750 1.5 16125 24.20

N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm KN/m

5000 750 5750 5000 10750 1.5 16125 24.20

N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm N/Sqm KN/m

12.94 71.64 76.71 2.65 106.41 4.69 76.71 119.73 153.43 273.16

KN/m KN KN Mtr KNm Mtr KN KN KN KN 73.77 119.79 162.30 282.09 110.09

FACTORED LOAD * WAIST LENG

FACTORED LOAD * WAIST LENG

APROX METHOD OF CALCULAT REACTION FROM WAIST SLAB *

FACTORED LOAD * LENGTH * WI

Max BM in Landing slab A Max SF in Landing slab A

116.36 141.05

KNm KN

TOTAL FACTORED LOAD * LENG TOTAL FACTORED LOAD/2

3 a

DESIGN OF MEMBER TO RESIST BENDING MOMENT Design of waist/ Flight Slab Grade of Concrete Grade of Steel Width of Slab Max BM Mx BM = (Const*fck) bd^2 Fe M 25 500 1.5 110.09 3.318 149 160 16 30 200 1500 25 500 8700 -435 2.87 At 1875 408.00 12000 1875 201.14 10 160 Mtr KN-M bd^2 mm mm mm mm mm mm 157 Max Depth of Nutral Axis fy 250 415 500 550 Limiting Moment of resistance MR

Calculated Eff Depth of Slab RESULT Adopt Effective Depth d INPUT Use Dia of Main rft Adopt Cover for Slab RESULT Over all Depth of Slab D Width of Beam Grade of Concrete Grade of Steel a= b= c=

m= Mu/(bd^2)

M Fe

Concrete M 15 20 25 30 35

0.87 *(fy^2/fck) -0.87 fy m= Mu/(bd^2)

p %= (-b- sqrt(b^2-4ac))/2a

2.87

0.781

Sqmm Sqmm Sqmm Sqmm Sqmm Nos mm 16 16 16 mm Dia mm Dia mm Dia

Min area of Tension Steel Ao=0.85*bd/fy

Max area of Tensile Steel = 0.04 bD Provide Area of Tension Steel Area of One Bar RESULT No of Bars RESULT Spacing of Distribution Bars

INPUT

Temp rft 0.15 % of gross area will be provided in the longitudinal direction 300 Sqmm Use 8 mm Dia bars Area of One Bar 50.29 Sqmm 8 170 mm 8

mm Dia mm Dia

RESULT Spacing of Distribution Bars

Landing Slab A

Grade of Concrete Grade of Steel Width of Slab Max BM Mx Fe

25 500 1.5 116.36 3.318 153 153 16 30 190 1500 25 500 8700 -435 m= Mu/(bd^2) At 2155 458.71 11400 2155 201.14 11 140 Mtr KN-M bd^2 mm mm mm mm mm mm Concrete M 15 20 25 30 35 Max Depth of Nutral Axis fy 250 415 500 550 Limiting Moment of resistance MR

BM = (Const*fck) bd^2 Calculated Eff Depth of Slab INPUT Adopt Effective Depth d Use Dia of Main rft Adopt Cover for Slab Over all Depth of Slab D Width of Slab Grade of Concrete Grade of Steel a= b= c=

m= Mu/(bd^2)

M Fe

0.87 *(fy^2/fck) -0.87 fy m= Mu/(bd^2)

p %= (-b- sqrt(b^2-4ac))/2a

3.32

0.939

Sqmm Sqmm Sqmm Sqmm Sqmm Nos mm 16 16 16 mm Dia mm Dia mm Dia

Min area of Tension Steel Ao=bd/fy Max area of Tensile Steel = 0.04 bD Provide Area of Tension Steel Area of One Bar RESULT No of Bars RESULT Spacing of Distribution Bars

INPUT

Temp rft 0.15 % of gross area will be provided in the longitudinal direction 285 Sqmm Use 8 mm Dia bars Area of One Bar 50.29 Sqmm 8 180 mm 8

mm Dia mm Dia

RESULT Spacing of Distribution Bars

4 a

DESIGN/ CHECK FOR MEMBER TO RESIST SHEAR Check for Shear in Waist Slab Grade of Concrete Eff Depth of Slab Over all Depth of Slab Width of Slab M 25 160 200 1500 mm mm mm

Grade of Concrete M

Max SS N/Sqmm

Dia of Main rft Area of One Bar No of Bars Max Shear Force wl/2

16 201.14 10 73.77

mm Sqmm Nos KN

Percentage of Tensile Steel 100At/2bd = Design Shear Strength

0.78 0.584

% Grade of Concrete M N/ Sqmm Max SS N/Sqmm 1.15 1.15

INPUT

For Permissible Max Shear Stress Nominal Shear stress Vu/bd Maximum Shear stress Tcm Shear Check Design of Stirrups Grade of Concrete Grade of Steel Fe Effective Depth of Slab Over all Depth of Beam Width of Beam Max Shear Force wl/2 Vu Strength of Shear rft Vus=Vu-Tc bd Dia of Shear rft Area of One Bar No of legged vertical stirrups Area of Vertical Stirrup Rft Asv Spacing of Shear rft x=0.87 fy Asv d/ Vus Check for Spacing Min Area of Shear rft 0.4 b x /fy Check for min Shear rft Area M

200

Calculated k Value mm thick slab, k= 0.672 0.31 3.10 Safe N/ Sqmm N/ Sqmm N/ Sqmm

25 500 160 200 1500 73.77 0 8 50.29 2 100.57 0 NOT OK 0 NOT OK Sqmm mm mm mm KN N mm Sqmm Nos mm mm Stirrup Rft NOT REQUIRED

INPUT

Min Spacing is 100 mm for placing of Concrete,

Check for Shear in Landing Slab A Grade of Concrete M 25 153 190 mm mm

Grade of Concrete M

Effective Depth of Beam Over all Depth of Beam

Width of Beam Dia of Main rft Area of One Bar No of Bars Max Shear Force wl/2

1500 16 201.14 11 141.05

mm mm Sqmm Nos KN

Max SS N/Sqmm

Percentage of Tensile Steel 100At/2bd = Design Shear Strength

0.12 0.267

% Grade of Concrete M N/ Sqmm Max SS N/Sqmm 1.15 1.15

INPUT

For Permissible Max Shear Stress Nominal Shear stress Vu/bd Maximum Shear stress Tcm Shear Check Design of Stirrups Grade of Concrete Grade of Steel Fe Effective Depth of Slab Over all Depth of Beam Width of Beam Max Shear Force wl/2 Vu M

190

Calculated k Value mm thick slab, k= 0.307 0.61 3.10 Un safe N/ Sqmm N/ Sqmm N/ Sqmm

25 500 153 190 1500 73.77 3287 12 113.14 2 226.29 4580 180 OK 216 OK mm mm mm KN N mm Sqmm Nos mm mm 180 Sqmm

Strength of Shear rft Vus=Vu-Tc bd INPUT Dia of Shear rft Area of One Bar INPUT No of legged vertical stirrups Area of Vertical Stirrup Rft Asv RESULT Spacing of Shear rft x=0.87 fy Asv d/ Vus INPUT Provide Spacing of Shear Rft Check for Spacing Min Area of Shear rft 0.4 b x /fy Check for Min Shear rft Area

420

12

Min Spacing is 100 mm for placing of Concrete,

If NOT OK then Increase the size of Rft or mo

5 a

CKECK FOR DEVELOPMENT LENGTH At Long Edge Max Shear Force wl/2 141.05 KN Design Bond Stress

Grade of Concrete Grade of Steel Dia of Slab rft Area of Tension rft Area of One Bar Spacing of Bars INPUT Fe

25 500 160 16 1875 201.14 110 200 1.6 mm mm Sqmm Sqmm mm mm N/Sqmm

Greade

Tbd N/Sqmm

15 1.0

Adopt Effective Depth d

Assumed Development Length Bond Stress Tbd

Development Length based on Anchorage Bond Ld= 0'0.87 fy / 4Tbd Ld in Anchorage Bond 1088 mm

Development Length based on Flexural Bond INPUT Ld= 1.3 M1/V + Lo Assumed Development Length Moment of Resistance offered by M1 = V= Ld in Flexural Bond Factor of Develop Length Develop length of Single Bar Max Development Length Max Bar Size in Develop Length Check for Development Length CKECK FOR DEVELOPMENT LENGTH 141046.07 N 707 56 896 1088 16 OK mm mm mm 250 415 500 mm fy N/Sqmm M15 55 56 69 188 mm 16 mm dia bar @

56,361,000 Nmm Tension Bars

Development Length for Single B

At Short Edge Max Shear Force wl/2 Grade of Concrete Grade of Steel Width of Beam b Dia of Main rft Area of Tension rft Area of One Bar No of Bars Fe M 141.05 25 500 160.00 1500 16 1875 201.14 10 mm mm mm Sqmm Sqmm mm KN Greade

Tbd N/Sqmm

Design Bond Stress 15 1.0

Adopt Effective Depth d

INPUT

Assumed Development Length Bond Stress Tbd

200 2.2

mm N/Sqmm

Development Length based on Anchorage Bond Ld= 0'0.87 fy / 4Tbd Ld in Anchorage Bond 777 mm

Development Length based on Flexural Bond INPUT Ld= 1.3 M1/V + Lo Assumed Development Length Moment of Resistance offered by M1 = V= Ld in Flexural Bond Factor of Develop Length Develop length of Single Bar Max Development Length Max Bar Size in Develop Length Check for Development Length 141046.07 N 1203 56 896 1203 25 OK mm mm mm If NOT OK Then Reduce the Spacing of Bars 250 415 500 mm fy N/Sqmm M15 55 56 69 188 mm 16 mm dia bar @

110,109,000 Nmm Tension Bars

Development Length for Single B

CHECK FOR DEFLECTION Short Span of Slab Effective Depth d Width of Beam b Dia of Slab rft Area of Tension rft Area of One Bar Spacing of Bars Percentage of tension steel at Mid Span = = 4.7 160 1500 16 1875 201 110 Mtr mm mm mm Sqmm Sqmm mm 0.78 26 1 1.1 1 1 28.6 29.31 % for CAN/SS/CON '7/20/26

INPUT

Cal =

1.02

=1 = = =

=1 up to 10 m, L>10, L/10 =Factor % Tension Rft =1 for 1 %, Fig 10.1 =Factor of Compression Rft 1 for 0 % Fig 10.

= Factor of Flanged Beam 1 for web L=B Fig 1

Allowable L/d Actual L/d

Deflection Check is

NOT OK

GE BEAM (DESIGN OF LANDING SLAB A AND STAIR FLIGHT)

ASHOK K JAIN)

190 200

mm Th with RFT mm Th with RFT

16 16

mm dia @ mm dia @

140 C/C 160 C/C

11 10

Nos Nos

No of Going/ ( 2 or 3) 1.5 3.19 BEAM

STAIR FLIGHT LANDING A STAIR FLIGHT LANDING B

1.50

3.30 B E A M

BEAM

2X

GOING( G)

2Y

SS/CON '7/20/26

10 m, L>10, L/10

% Tension Rft =1 for 1 %, Fig 10.1

of Compression Rft 1 for 0 % Fig 10.2

of Flanged Beam 1 for web L=B Fig 10.3

8 200 190 Section= 1/2 * Going * Raise * 25000

th with rft

dia @ dia @ dia @ dia @

170 160 140 180

C/C C/C C/C C/C

16 16 8

th with rft

ned Slab = Sqrt( G^2+R^2) *t * 25000

oad = (R+G)*Finish thick * 25000

FACTORED LOAD * WAIST LENGTH / 8 * FACTOR 1.3 FACTORED LOAD * WAIST LENGTH /2 * FACTOR 1.3 APROX METHOD OF CALCULATION FACTORED LOAD * LENGTH * WIDTH OF LAANDING SLAB A REACTION FROM WAIST SLAB * 2 NOS * FACTOR 1.1

TOTAL FACTORED LOAD * LENGTH/ 8 TOTAL FACTORED LOAD/2

Max Depth of Nutral Axis Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm 0.53 d 0.48 d 0.46 d 0.44 d Limiting Moment of resistance MR = Const * b*d^2 N mm Const= 0.36*fck*Xm(1-0.42*Xm) Steel Fe 250 2.229 2.972 3.715 4.458 5.201 Fe 415 2.067 2.755 3.444 4.133 4.822 Fe 500 1.991 2.655 3.318 3.982 4.645 Fe 550 1.949 2.598 3.248 3.897 4.547

Max Depth of Nutral Axis Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm 0.53 d 0.48 d 0.46 d 0.44 d Limiting Moment of resistance MR = Const * b*d^2 N mm Const= 0.36*fck*Xm(1-0.42*Xm) Steel Fe 250 2.229 2.972 3.715 4.458 5.201 Fe 415 2.067 2.755 3.444 4.133 4.822 Fe 500 1.991 2.655 3.318 3.982 4.645 Fe 550 1.949 2.598 3.248 3.897 4.547

Max Shear Stress

Grade of Concrete M

25 3.1

Max SS N/Sqmm

fck 100 As bd 0.78

25

Design Shear Strength

3.72

SS N/Sqmm

0.584

Max Shear Stress Grade of Concrete M Max SS N/Sqmm 15 2.5 Value of K >300 275 1.00 1.05 20 2.8 25 3.1 30 3.5 35 3.7

Ds k

250 1.10

225 1.15

200 1.20

175 1.25

<151 1.30

* Shear rft be provided in a slab deeper than 200 mm

t NOT REQUIRED

ng is 100 mm for placing of Concrete, Max 450 mm

Max Shear Stress

Grade of Concrete M

25

Max SS N/Sqmm fck 100 As bd 0.12

3.1 25

Design Shear Strength

23.36

SS N/Sqmm

0.267

Max Shear Stress Grade of Concrete M Max SS N/Sqmm 15 2.5 Value of K >300 275 1.00 1.05 20 2.8 25 3.1 30 3.5 35 3.7

Ds k

250 1.10

225 1.15

200 1.20

175 1.25

<151 1.30

* Shear rft be provided in a slab deeper than 200 mm

mm Dia

Legs

ng is 100 mm for placing of Concrete, Max 450 mm then Increase the size of Rft or more No of Legs or reduce spacing of rft

Design Bond Stress

20 1.2

25 1.4

30 1.5

35 1.7

40 1.9

220

mm C/C

Development Length for Single Bars Tension Bars M20 46 47 58 40 49 38 46 30 36 M25 M30 M40 M15 44 45 54 Compression Bars M20 37 38 46 32 39 31 36 24 29 M25 M30 M40

Design Bond Stress 20 1.2 25 1.4 30 1.5 35 1.7 40 1.9

20

mm C/C

Development Length for Single Bars Tension Bars M20 46 47 58 40 49 38 46 30 36 M25 M30 M40 M15 44 45 54 Compression Bars M20 37 38 46 32 39 31 36 24 29 M25 M30 M40

Then Reduce the Spacing of Bars

SS/CON '7/20/26

10 m, L>10, L/10 % Tension Rft =1 for 1 %, Fig 10.1 of Compression Rft 1 for 0 % Fig 10.2

of Flanged Beam 1 for web L=B Fig 10.3

(Distribution Bars)

(Distribution Bars)

40 4.0

40 4.0

DESIGN OF STAIR CASE WITH CENTRE BEAM ( EX 7.5 RCC PUNMIA)

1

INPUT INPUT INPUT INPUT

INPUT

INPUT DATAS Min Head room above steps Ht of Floor Raise of the Stair Tread of the Stair Going of the Stair No of Goings on Ht of Floor and Raise No of Goings to be given The slope or Pitch of Stairway Check for Raise and Going Length of Landing A (2x) Total Length of Going G Length of Landing B (2y) Width of Stair Case Effective Span for Stair Effective Span of Landing Slab Width of Landing Slab Provided Thickness of Beam Grade of Concrete M Grade of Steel Fe Type of Support of Beam = =1 = = = Span / Eff depth Ratio Min Effective Depth of Beam = Adopt Overall Depth of Beam D Effective Length of Waist Beam Width of Beam

2.00 2.10 0.15 0.25 0.29 14 14 27.3 OK 1.5 4.06 1.50 1.50 7.06 3.15 1.50 0.25 25 415 CON 26 1 1.1 1 1 28.6 110 450 7.17 0.25

Mtr Mtr Mtr Mtr Mtr Nos Nos Degree Mtr Mtr Mtr Mtr Mtr Mtr Mtr Mtr

INPUT INPUT INPUT

INPUT INPUT INPUT INPUT INPUT

CAN/SS/CON '7/20/26 for CAN/SS/CON '7/20/26 =1 up to 10 m, L>10, L/10

CAL VALUE FROM =Factor CELL% E335 Tension

Rft =1 for 1 %, Fig 10.1

=Factor of Compression Rft 1 for 0 % Fig 10.2

= Factor of Flanged Beam 1 for web L=B Fig 10 mm mm Mtr Mtr 450

CALCULATION OF LOAD, BM & SF Dead Load of step section Dead Load of inclined Flight Super Imposed Dead Load Dead Load on Plan Live Load on plan Total Load 550 3680 330 5140 5000 10140 N/m N/m N/m N/Sqm N/Sqm N/Sqm

INPUT

Load Factor Factored Load on Flight w Total Factored Load on Flight Cantilever Span of Step Cantilever Moment = W*L

1.5 15210 22.80 0.63 4.45 N/Sqm KN/m Mtr KNm

3 a

DESIGN OF MEMBER TO RESIST BENDING MOMENT Design of Cantilever Slab Pr to Centre Beam Grade of Concrete Grade of Steel Width of Slab Max BM Mx BM = (Const*fck) bd^2 Fe M 25 415 1.0 4.45 3.444 36 80 8 30 110 1000 25 415 5993.43 -361.05 0.70 At 160 163.86 4400 164 50.29 4 310 Mtr KN-M bd^2 mm mm mm mm mm mm 80 Max Depth of Nutral Axis fy 250

Calculated Eff Depth of Slab RESULT Adopt Effective Depth d INPUT Use Dia of Main rft Adopt Cover for Slab RESULT Over all Depth of Slab D Width of Beam Grade of Concrete Grade of Steel a= b= c=

m= Mu/(bd^2)

415 500 550 Limiting Moment of resistance MR =

M Fe

Concrete M 15 20 25 30 35

0.87 *(fy^2/fck) -0.87 fy m= Mu/(bd^2)

p %= (-b- sqrt(b^2-4ac))/2a

0.70

0.199

Sqmm Sqmm Sqmm Sqmm Sqmm Nos mm 8 8 8 mm Dia mm Dia mm Dia

Min area of Tension Steel Ao=0.85*bd/fy

Max area of Tensile Steel = 0.04 bD Provide Area of Tension Steel Area of One Bar RESULT No of Bars RESULT Spacing of Distribution Bars

INPUT

Temp rft 0.15 % of gross area will be provided in the longitudinal direction 165 Sqmm Use 8 mm Dia bars Area of One Bar 50.29 Sqmm 8

mm Dia

RESULT Spacing of Distribution Bars Effective Span L Max BM in Center Beam W*L^2/8 Max SF in Centre Beam W*L/2

300 7.17 146.52 81.74

mm

mm Dia

KNm KN

Design of Beam at Centre Grade of Concrete Grade of Steel Width of Beam Max BM Mx BM = (Const*fck) bd^2 Calculated Eff Depth of Beam Adopt Effective Depth d Use Dia of Main rft Adopt Cover for Beam Over all Depth of Beam D Width of Beam Grade of Concrete Grade of Steel a= b= c=

m= Mu/(bd^2)

25 415 0.25 146.52 3.444 412 412 16 30 450 250 25 415 5993.43 -361.05 m= Mu/(bd^2) At 1226 248.49 4500 1226 201.14 7 Mtr KN-M bd^2 mm mm mm mm mm mm Concrete M 15 20 25 30 35 200 Max Depth of Nutral Axis fy 250 415

Fe

INPUT

500 550 Limiting Moment of resistance MR =

M Fe

0.87 *(fy^2/fck) -0.87 fy m= Mu/(bd^2)

p %= (-b- sqrt(b^2-4ac))/2a

3.44

1.188

Sqmm Sqmm Sqmm Sqmm Sqmm Nos 16 16 mm Dia mm Dia

Min area of Tension Steel Ao=bd/fy Max area of Tensile Steel = 0.04 bD Provide Area of Tension Steel Area of One Bar RESULT No of Bars

4 a

DESIGN/ CHECK FOR MEMBER TO RESIST SHEAR Check for Shear in Centre Beam Grade of Concrete Eff Depth of Beam Over all Depth of Beam Width of Beam M 25 412 450 250 mm mm mm

Grade of Concrete M

Max SS N/Sqmm

Dia of Main rft Area of One Bar No of Bars Max Shear Force wl/2

16 201.14 7 81.74

mm Sqmm Nos KN

Percentage of Tensile Steel 100At/2bd = Design Shear Strength

0.16 0.299

% Grade of Concrete M N/ Sqmm Max SS N/Sqmm 1.15 1.15

INPUT

For Permissible Max Shear Stress Nominal Shear stress Vu/bd Maximum Shear stress Tcm Shear Check Design of Stirrups Grade of Concrete Grade of Steel Fe Effective Depth of Beam Over all Depth of Beam Width of Beam Max Shear Force wl/2 Vu Strength of Shear rft Vus=Vu-Tc bd Dia of Shear rft Area of One Bar No of legged vertical stirrups Area of Vertical Stirrup Rft Asv Spacing of Shear rft x=0.87 fy Asv d/ Vus Check for Spacing Min Area of Shear rft 0.4 b x /fy Check for min Shear rft Area M

450

Calculated k Value mm thick slab, k= 0.343 0.79 3.10 Un safe N/ Sqmm N/ Sqmm N/ Sqmm

25 415 412 450 250 81.74 46329 8 50.29 2 101 320 OK 77.11 OK Sqmm mm mm mm KN N mm Sqmm Nos mm mm 96

INPUT

Min Spacing is 100 mm for placing of Concrete, M

5 a

CKECK FOR DEVELOPMENT LENGTH At Long Edge Max Shear Force wl/2 Grade of Concrete M 81.74 25 KN Greade Design Bond Stress 15

Grade of Steel Dia of Slab rft

Fe

415 412 8 160 50.29 310 200 1.6 mm mm Sqmm Sqmm mm mm N/Sqmm

Tbd N/Sqmm

1.0

Adopt Effective Depth d Area of Tension rft Area of One Bar Spacing of Bars INPUT Assumed Development Length Bond Stress Tbd

Development Length based on Anchorage Bond Ld= 0'0.87 fy / 4Tbd Ld in Anchorage Bond 451 mm

Development Length based on Flexural Bond INPUT Ld= 1.3 M1/V + Lo Assumed Development Length 124 mm 8 mm dia bar @

Moment of Resistance offered by M1 = V= Ld in Flexural Bond Factor of Develop Length Develop length of Single Bar Max Development Length Max Bar Size in Develop Length Check for Development Length CKECK FOR DEVELOPMENT LENGTH 81738.00 N 316 56 448 451 8 OK mm mm mm mm

12,041,000 Nmm fy N/Sqmm M15 250 415 500 55 56 69 Tension Bars

Development Length for Single B

At Short Edge Max Shear Force wl/2 Grade of Concrete Grade of Steel Width of Beam b Dia of Main rft Area of Tension rft Area of One Bar No of Bars Assumed Development Length Bond Stress Tbd Fe M 81.74 25 415 412 1000 8 164 50.29 4 200 2.2 mm mm mm Sqmm Sqmm mm mm N/Sqmm KN Greade

Tbd N/Sqmm

Design Bond Stress 15 1.0

Adopt Effective Depth d

INPUT

Development Length based on Anchorage Bond Ld= 0'0.87 fy / 4Tbd Ld in Anchorage Bond 322 mm

Development Length based on Flexural Bond INPUT Ld= 1.3 M1/V + Lo Assumed Development Length 124 mm 8 mm dia bar @

Moment of Resistance offered by M1 = V= Ld in Flexural Bond Factor of Develop Length Develop length of Single Bar Max Development Length Max Bar Size in Develop Length Check for Development Length 81738.00 N 510 56 448 510 13 OK mm mm mm mm

24,242,000 Nmm fy N/Sqmm 250 415 500 Tension Bars M15 55 56 69

Development Length for Single B

If NOT OK Then Reduce the Spacing of Bars

CHECK FOR DEFLECTION Span of Beam Effective Depth d Width of Beam b Dia of Slab rft Area of Tension rft Area of One Bar Spacing of Bars Percentage of tension steel at Mid Span = = 7.1 412 250 8 160 50 310 Mtr mm mm mm Sqmm Sqmm mm 0.16 26 1 1.1 1 1 28.6 17.12 OK % for CAN/SS/CON '7/20/26

INPUT

Cal =

1.18

=1 = = =

=1 up to 10 m, L>10, L/10 =Factor % Tension Rft =1 for 1 %, Fig 10.1 =Factor of Compression Rft 1 for 0 % Fig 10.2

= Factor of Flanged Beam 1 for web L=B Fig 10

Allowable L/d Actual L/d Deflection Check is

ENTRE BEAM

SS/CON '7/20/26

10 m, L>10, L/10

% Tension Rft =1 for 1 %, Fig 10.1

of Compression Rft 1 for 0 % Fig 10.2

of Flanged Beam 1 for web L=B Fig 10.3

Max Depth of Nutral Axis Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm 0.53 d 0.48 d 0.46 d 0.44 d Limiting Moment of resistance MR = Const * b*d^2 N mm Const= 0.36*fck*Xm(1-0.42*Xm) Steel Fe 250 2.229 2.972 3.715 4.458 5.201 Fe 415 2.067 2.755 3.444 4.133 4.822 Fe 500 1.991 2.655 3.318 3.982 4.645 Fe 550 1.949 2.598 3.248 3.897 4.547

Max Depth of Nutral Axis Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm 0.53 d 0.48 d 0.46 d 0.44 d Limiting Moment of resistance MR = Const * b*d^2 N mm Const= 0.36*fck*Xm(1-0.42*Xm) Steel Fe 250 2.229 2.972 3.715 4.458 5.201 Fe 415 2.067 2.755 3.444 4.133 4.822 Fe 500 1.991 2.655 3.318 3.982 4.645 Fe 550 1.949 2.598 3.248 3.897 4.547

Max Shear Stress

Grade of Concrete M

25 3.1

Max SS N/Sqmm

fck 100 As bd 0.16

25

Design Shear Strength

18.27

SS N/Sqmm

0.299

Max Shear Stress Grade of Concrete M Max SS N/Sqmm 15 2.5 Value of K >300 275 1.00 1.05 20 2.8 25 3.1 30 3.5 35 3.7

Ds k

250 1.10

225 1.15

200 1.20

175 1.25

<151 1.30

* Shear rft be provided in a slab deeper than 200 mm

ng is 100 mm for placing of Concrete, Max 450 mm

Design Bond Stress 20 25 30 35 40

1.2

1.4

1.5

1.7

1.9

620

mm C/C

Development Length for Single Bars Tension Bars M20 46 47 58 40 49 38 46 30 36 M25 M30 M40 M15 44 45 54 Compression Bars M20 37 38 46 32 39 31 36 24 29 M25 M30 M40

Design Bond Stress 20 1.2 25 1.4 30 1.5 35 1.7 40 1.9

mm C/C

Development Length for Single Bars Tension Bars M20 46 47 58 Compression Bars M15 44 45 54 M20 37 38 46

Then Reduce the Spacing of Bars

SS/CON '7/20/26

10 m, L>10, L/10 % Tension Rft =1 for 1 %, Fig 10.1 of Compression Rft 1 for 0 % Fig 10.2

of Flanged Beam 1 for web L=B Fig 10.3

40 4.0

DESIGN OF CANTILEVER STAIR CASE ONE EDGE OF STEP IS FIXED

1

INPUT INPUT INPUT

INPUT DATAS Width of Cantilever Slab L Assume Thickness of Step L/8 Assume Tread b CALCULATION OF LOAD, BM & SF Self Wt of Step Finishes Live Load Total Load of one step Factor of Safety Design Load w Max BM=w*L/2 Max SF = w*L Grade of Concrete M Grade of Steel Fe

(EX 6.4 DHAYARATNAM) 1.20 0.15 0.35 1.6 0.4 1.5 3.5 1.00 3.50 2.1 4.2 25 415 Mtr Mtr Mtr KN/m KN/m KN/m KN/m KN/m KN/m KN/m KN

INPUT INPUT

3 a

DESIGN OF MEMBER TO RESIST BENDING MOMENT Design of waist/ Flight Slab Grade of Concrete Grade of Steel Width of Slab Max BM Mx BM = (Const*fck) bd^2 Fe M 25 415 0.35 2.10 3.444 42 80 10 30 120 350 25 415 5993.43 -361.05 0.94 At 77 144.00 1680 Mtr KN-M bd^2 mm mm mm mm mm mm 80 Max Depth of Nutral Axis fy 250

Calculated Eff Depth of Slab RESULT Adopt Effective Depth d INPUT Use Dia of Main rft Adopt Cover for Slab RESULT Over all Depth of Slab D Width of Beam Grade of Concrete Grade of Steel a= b= c=

m= Mu/(bd^2)

415 500 550 Limiting Moment of resistance MR =

M Fe

Concrete M 15 20 25 30 35

0.87 *(fy^2/fck) -0.87 fy m= Mu/(bd^2)

p %= (-b- sqrt(b^2-4ac))/2a

0.94

0.272

Sqmm Sqmm Sqmm

Min area of Tension Steel Ao=0.12*bd

Max area of Tensile Steel = 0.04 bD

Provide Area of Tension Steel Area of One Bar RESULT No of Bars RESULT Spacing of Distribution Bars

144 78.57 2 190

Sqmm Sqmm Nos mm 10 10 10 mm Dia mm Dia mm Dia

INPUT

Temp rft 0.15 % of gross area will be provided in the longitudinal direction 180 Sqmm Use 10 mm Dia bars Area of One Bar 78.57 Sqmm 10 150 mm 10

mm Dia mm Dia

RESULT Spacing of Distribution Bars

4 a

DESIGN/ CHECK FOR MEMBER TO RESIST SHEAR Check for Shear in Waist Slab Grade of Concrete Eff Depth of Slab Over all Depth of Slab Width of Slab Dia of Main rft Area of One Bar No of Bars Max Shear Force wl/2 M 25 80 120 350 10 78.57 2 4.20 mm mm mm mm Sqmm Nos KN

Grade of Concrete M

Max SS N/Sqmm

Percentage of Tensile Steel 100At/2bd = Design Shear Strength

0.51 0.495

% Grade of Concrete M N/ Sqmm Max SS N/Sqmm 1.30 1.30

INPUT

For Permissible Max Shear Stress Nominal Shear stress Vu/bd Maximum Shear stress Tcm Shear Check CKECK FOR DEVELOPMENT LENGTH

120

Calculated k Value mm thick slab, k= 0.643 0.15 3.10 Safe N/ Sqmm N/ Sqmm N/ Sqmm

At Short Edge Max Shear Force wl/2 4.20 KN Design Bond Stress

Grade of Concrete Grade of Steel Width of Beam b Dia of Main rft Area of Tension rft Area of One Bar No of Bars INPUT Fe

25 415 80.00 350 10 144 78.57 2 200 2.2 mm mm mm Sqmm Sqmm mm mm N/Sqmm

Greade

Tbd N/Sqmm

15 1.0

Adopt Effective Depth d

Assumed Development Length Bond Stress Tbd

Development Length based on Anchorage Bond Ld= 0'0.87 fy / 4Tbd Ld in Anchorage Bond 403 mm

Development Length based on Flexural Bond INPUT Ld= 1.3 M1/V + Lo Assumed Development Length 140 mm 10 mm dia bar @

Moment of Resistance offered by M1 = V= Ld in Flexural Bond Factor of Develop Length Develop length of Single Bar Max Development Length Max Bar Size in Develop Length Check for Development Length 4200.00 N 1317 56 560 1317 33 OK mm mm mm mm

3,804,000 Nmm fy N/Sqmm M15 250 415 500 55 56 69 Tension Bars

Development Length for Single B

If NOT OK Then Reduce the Spacing of Bars

CASE ONE EDGE OF STEP IS FIXED ON WALL

Max Depth of Nutral Axis Xm=0.0035/(.0055+0.87*fy/Es), Es= 200000 N/Sqmm 0.53 d 0.48 d 0.46 d 0.44 d Limiting Moment of resistance MR = Const * b*d^2 N mm Const= 0.36*fck*Xm(1-0.42*Xm) Steel Fe 250 2.229 2.972 3.715 4.458 5.201 Fe 415 2.067 2.755 3.444 4.133 4.822 Fe 500 1.991 2.655 3.318 3.982 4.645 Fe 550 1.949 2.598 3.248 3.897 4.547

Max Shear Stress

Grade of Concrete M

25 3.1 25

Max SS N/Sqmm fck 100 As bd 0.51

Design Shear Strength

5.64

SS N/Sqmm

0.495

Max Shear Stress Grade of Concrete M Max SS N/Sqmm 15 2.5 Value of K >300 275 1.00 1.05 20 2.8 25 3.1 30 3.5 35 3.7

Ds k

250 1.10

225 1.15

200 1.20

175 1.25

<151 1.30

* Shear rft be provided in a slab deeper than 200 mm

Design Bond Stress

20 1.2

25 1.4

30 1.5

35 1.7

40 1.9

mm C/C

Development Length for Single Bars Tension Bars M20 46 47 58 40 49 38 46 30 36 M25 M30 M40 M15 44 45 54 Compression Bars M20 37 38 46 32 39 31 36 24 29 M25 M30 M40

Then Reduce the Spacing of Bars

40 4.0

You might also like

- Foundation DesignDocument15 pagesFoundation Designlokesh.lucky.nit7228No ratings yet

- Retaining Wall DesignDocument168 pagesRetaining Wall DesignSuraj Muley0% (1)

- Foundation DesignsDocument137 pagesFoundation DesignssitehabNo ratings yet

- Slab DesignsDocument97 pagesSlab DesignssitehabNo ratings yet

- Isolated Footing DesignDocument24 pagesIsolated Footing DesignSANJEEV GANDOTRANo ratings yet

- Design of Isolated Rectangular FootingDocument3 pagesDesign of Isolated Rectangular FootingdsanandaNo ratings yet

- Design ProjectDocument36 pagesDesign Projectveenabalu20No ratings yet

- Loading (For 1m Wide Staire Case) : Beams Provided at The Ends of Landings & Span at Right AngleDocument3 pagesLoading (For 1m Wide Staire Case) : Beams Provided at The Ends of Landings & Span at Right AnglePita KymNo ratings yet

- Manual Beam DesignDocument14 pagesManual Beam DesignRonald Kaaku50% (2)

- Sample Calulation BeamDocument9 pagesSample Calulation Beamche azimNo ratings yet

- Asphalt Footing3Document37 pagesAsphalt Footing3Bert EngNo ratings yet

- Design of Slab: Ly/lx 2. So This Is Two Way SlabDocument6 pagesDesign of Slab: Ly/lx 2. So This Is Two Way SlabSudip ShresthaNo ratings yet

- Strap Footing Working 1Document3 pagesStrap Footing Working 1Mainali IshuNo ratings yet

- FinalDocument42 pagesFinalVishnu Kumar0% (1)

- Design of Purlin (Rectangular Sections Only)Document3 pagesDesign of Purlin (Rectangular Sections Only)Amit Parikh100% (1)

- Stair CaseDocument5 pagesStair CaseMahitha ReddyNo ratings yet

- RCC Beam Design Task-01Document29 pagesRCC Beam Design Task-01Mohamed SaheelNo ratings yet

- Slab DesignDocument25 pagesSlab DesignSabin Leroy HmgnNo ratings yet

- Wind Load CalculationDocument98 pagesWind Load CalculationAnonymous HJ7hmihhNo ratings yet

- Sao-Atan House - Fencing EstimateDocument89 pagesSao-Atan House - Fencing EstimateJun Michael Artates VelascoNo ratings yet

- 2 Design ផ្ទោងមុំ 35Document1 page2 Design ផ្ទោងមុំ 35lavyNo ratings yet

- Design of SyphonDocument7 pagesDesign of SyphonraghurmiNo ratings yet

- Structural Design Criteria: Load Type Type of OccupancyDocument8 pagesStructural Design Criteria: Load Type Type of OccupancyJoseph TuzonNo ratings yet

- Footing DesignDocument4 pagesFooting DesignpnbastolaNo ratings yet

- Case Study ppt11Document25 pagesCase Study ppt11WHATS APP STATUSNo ratings yet

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- CANTILEVER SLAB DESIGN Latest CorrectedDocument6 pagesCANTILEVER SLAB DESIGN Latest CorrectedBijendra PradhanNo ratings yet

- Design of Simply Supported One Way SlabDocument15 pagesDesign of Simply Supported One Way SlabNikhil100% (2)

- C.C Drain DesignDocument2 pagesC.C Drain DesignSeph RjyNo ratings yet

- Purlins & GirtsDocument10 pagesPurlins & GirtsRaviKiranNo ratings yet

- Presentation On Analysis and Design of Small Reinforced Concrete BuildingsDocument29 pagesPresentation On Analysis and Design of Small Reinforced Concrete BuildingsPuneeth H GowdaNo ratings yet

- Structure of RCC Beam Design Task 01Document29 pagesStructure of RCC Beam Design Task 01George GeorgianNo ratings yet

- Design of Two Way SlabDocument8 pagesDesign of Two Way SlabdhanarajNo ratings yet

- Types of Loads On ColumnDocument4 pagesTypes of Loads On ColumnSam TomNo ratings yet

- Main Tie BeamDocument3 pagesMain Tie BeamZaher Mhd SharafNo ratings yet

- Combined Footing DesignDocument4 pagesCombined Footing Designrukesh104No ratings yet

- 2 Way Slab Design-Roof SlabDocument120 pages2 Way Slab Design-Roof SlabSambhav PoddarNo ratings yet

- 5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputDocument27 pages5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputNH SyzlnNo ratings yet

- 2 Way Slab DesignDocument66 pages2 Way Slab DesignSambhav PoddarNo ratings yet

- Design of Slab Final 1Document24 pagesDesign of Slab Final 1Aashish MaharjanNo ratings yet

- Calculation On Sizing of SlabDocument20 pagesCalculation On Sizing of SlabazhimsyammelNo ratings yet

- Column Design of 300x400Document24 pagesColumn Design of 300x400karthik100% (1)

- Design of BeamsDocument19 pagesDesign of BeamssnsatyanarayanaNo ratings yet

- Circular Column CalculationDocument6 pagesCircular Column CalculationKwan Hau LeeNo ratings yet

- BS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MDocument7 pagesBS 8110:part 1: 1985, Section Three, Table 3.9: C S V 1/3 1/4 MnaconnetNo ratings yet

- Design of Pile CapDocument3 pagesDesign of Pile CapHaris Lee100% (2)

- Steel QuantityDocument21 pagesSteel QuantityAshish Jain100% (1)

- Splice Check - 07282020 PDFDocument3 pagesSplice Check - 07282020 PDFAngelo MoralNo ratings yet

- RC BeamDocument36 pagesRC BeamMuhamad Amirul Md. RazdiNo ratings yet

- Bar Bending Schedule RCC SlabDocument8 pagesBar Bending Schedule RCC SlabRajendra BadjatyaNo ratings yet

- Chequred PlateDocument2 pagesChequred PlateKumar Prasanna HNNo ratings yet

- PILE FOUNDATION DESIGN Manual Cal - CommentsDocument6 pagesPILE FOUNDATION DESIGN Manual Cal - CommentsDilip PatelNo ratings yet

- Wall Description: Calculation of Supporting Wall FootingDocument24 pagesWall Description: Calculation of Supporting Wall FootingPrakash Singh RawalNo ratings yet

- Continuous Slab Design ProgrammeDocument31 pagesContinuous Slab Design ProgrammeNikhilNo ratings yet

- Sample Circular Tank Ring Tension OnlyDocument4 pagesSample Circular Tank Ring Tension OnlyHiren DesaiNo ratings yet

- Design Data: Hostel Building Kaaf Uni Danniel Pascal StairDocument5 pagesDesign Data: Hostel Building Kaaf Uni Danniel Pascal StairDENCONo ratings yet

- Beam DesignsDocument123 pagesBeam DesignssitehabNo ratings yet

- Retaining Wall DesignDocument180 pagesRetaining Wall DesignVictor Rudio71% (7)

- Retaining Wall DesignDocument180 pagesRetaining Wall DesignMayco Velasco100% (1)

- ETABS Tutorial 2: The Design of Tall BuildingsDocument11 pagesETABS Tutorial 2: The Design of Tall Buildingsakhlaq_hssainkotaNo ratings yet

- 13 Nisa CivilDocument8 pages13 Nisa Civilakhlaq_hssainkotaNo ratings yet

- Elevation 220613Document1 pageElevation 220613akhlaq_hssainkotaNo ratings yet

- 5-TB - Ventilation Air For Indoor PoolsDocument4 pages5-TB - Ventilation Air For Indoor Poolsakhlaq_hssainkotaNo ratings yet

- 7EC2ED Aeration Tank Design Us UnitsDocument2 pages7EC2ED Aeration Tank Design Us Unitsakhlaq_hssainkotaNo ratings yet

- Staad FileDocument15 pagesStaad Fileakhlaq_hssainkotaNo ratings yet

- Steel Structure Subjected To Fire and FatigueDocument12 pagesSteel Structure Subjected To Fire and Fatigueakhlaq_hssainkotaNo ratings yet

- Ground Floor Plan-280513Document1 pageGround Floor Plan-280513akhlaq_hssainkotaNo ratings yet

- Ground Floor Plan THE Wall: Final PresentationDocument1 pageGround Floor Plan THE Wall: Final Presentationakhlaq_hssainkotaNo ratings yet