Professional Documents

Culture Documents

Pt-Ru Nanoparticles Supported PAMAM Dendrimer Functionalized Carbon Nanofiber Composite Catalysts and Their Application To Methanol Oxid

Pt-Ru Nanoparticles Supported PAMAM Dendrimer Functionalized Carbon Nanofiber Composite Catalysts and Their Application To Methanol Oxid

Uploaded by

Kutty NilaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pt-Ru Nanoparticles Supported PAMAM Dendrimer Functionalized Carbon Nanofiber Composite Catalysts and Their Application To Methanol Oxid

Pt-Ru Nanoparticles Supported PAMAM Dendrimer Functionalized Carbon Nanofiber Composite Catalysts and Their Application To Methanol Oxid

Uploaded by

Kutty NilaCopyright:

Available Formats

J Solid State Electrochem (2009) 13:15611566 DOI 10.

1007/s10008-008-0730-0

ORIGINAL PAPER

PtRu nanoparticles supported PAMAM dendrimer functionalized carbon nanofiber composite catalysts and their application to methanol oxidation

T. Maiyalagan

Received: 22 August 2008 / Revised: 6 October 2008 / Accepted: 4 November 2008 / Published online: 20 November 2008 # Springer-Verlag 2008

Abstract Polyamidoamine (PAMAM) dendrimers has been anchored on functionalized carbon nanofibers (CNF) and supported PtRu nanoparticles have been prepared with NaBH4 as a reducing agent. The samples were characterized by X-ray diffraction, scanning electron microscopy, and transmission electron microscopy (TEM) analysis. It was shown that PtRu particles with small average size (2.6 nm) were uniformly dispersed on PAMAM/CNF composite support and displayed the characteristic diffraction peaks of Pt face-centered cubic structure. The electrocatalytic activities of the prepared-composites (20% PtRu/PAMAMCNF) were examined by using cyclic voltammetry for oxidation of methanol. The electrocatalytic activity of the CNF-based composite (20% PtRu/PAMAM-CNF) electrode for methanol oxidation showed better performance than that of commercially available Johnson Mathey 20% PtRu/C catalyst. The results imply that CNF-based PAMAM composite electrodes are excellent potential candidates for application in direct methanol fuel cells. Keywords Methanol oxidation . DMFC . Dendrimers . Nanostructured materials . Electro-catalyst

Introduction Fuel cells operate with the electrochemical oxidation of hydrogen or methanol, as fuels at the anode and the reduction of oxygen at the cathode are attractive power

T. Maiyalagan (*) Department of Chemistry, School of Science and Humanities, VIT University, Vellore 632014, India e-mail: maiyalagan@gmail.com

sources due to their high conversion efficiencies, low pollution, light weight, and high power density. Methanol offers the advantage of easy storage and transportation when compared to hydrogen oxygen fuel cell, its energy density (~2,000 Wh/kg) and operating cell voltage (0.4 V) are lower than the theoretical energy density (~6,000 Wh/kg) and the thermodynamic potential (~1.2 V) [1, 2]. However, the fuel cells could not reach the stage of commercialization due to the high cost, which is mainly associated with the noble metal-loaded electrodes and the membrane. In order to reduce the amount of Pt loading on the electrodes, there have been considerable efforts to increase the dispersion of the metal on the support. The catalyst is very often found to disperse on a conventional carbon support, and the support material influences the catalytic activity through metal support interaction [35]. New novel carbon support materials such as graphite nanofibers (GNFs) [6, 7], carbon nanotubes (CNT) [812], carbon nanohorns [13], and carbon nanocoils [14] provide alternate candidates of carbon support for fuel cell applications. Bessel et al. [6] and Steigerwalt et al. [7] used GNFs as supports for Pt and PtRu alloy electrocatalysts. They have observed better activity for methanol oxidation. The high electronic conductivity of GNF and the specific crystallographic orientation of the metal particles resulting from well-ordered GNF support are believed to be the factors for the observed enhanced electro-catalytic activity. In heterogeneous catalysis, one of the important tasks is the determination of the number of active sites in the catalyst. For a given catalyst, the number of active sites present is responsible for the observed catalytic activity. A considerable amount of research has been devoted toward understanding the number of active sites and the role played by the carrier of the supported catalysts. The most efficient utilization of any supported catalyst depends on

1562

J Solid State Electrochem (2009) 13:15611566

the percentage of exposed or the dispersion of the active component on the surface of the carrier material. Among the various factors that influence the dispersion of an active component, the nature of the support and the extent of the active component loading are of considerable importance. Without surface modification, most of the carbon nanomaterials lack sufficient binding sites for anchoring precursor metal ions or metal nanoparticles, which usually lead to poor dispersion and the aggregation of metal nanoparticles, especially at high loading conditions. To introduce more binding sites and surface anchoring groups, an acid oxidation process was very frequently adopted to treat carbon nanomaterials in a mixed acid aqueous solution, which introduces surface bound polar hydroxyl and carboxylic acid groups for subsequent anchoring and reductive conversion of precursor metal ions to metal nanoparticles [15]. Generally, metal nano-particles have been synthesized for the purpose of increasing the catalytic surface area in comparison to bulk metal and have utilized strategies such as stabilization in a soluble polymer matrix or encapsulation in dendrimers to protect them from aggregation. Dendrimers are good candidates for preparing metal nanoparticles because they can act as structurally and well-defined templates and robust stabilizers. Polyamidoamine (PAMAM) dendrimers, in particular, have been used as nanoreactors with effective nanoparticle stabilization. In addition, encapsulated nanoparticles surfaces are accessible to substrates so that catalytic reactions can be carried out [1618]. PAMAM dendrimer encapsulated Pt nanoparticles and PtPd bimetallic nanoaparticles are electrocatalytically active for oxygen reduction [1921]. Also dendrimer-encapsulated platinum nanoparticles supported on carbon fiber and nitrogendoped CNT as electrodes for oxygen reduction [22, 23]. In addition, platinumruthenium alloys are the best catalysts for methanol oxidation direct methanol fuel cells [24, 25]. PAMAM dendrimers were modified with a Nicyclam as novel electrocatalytic material for the electrochemical oxidation of methanol [26]. Kim et al. [27] have reported the preparation of platinumdendrimer hybrid nanowires using alumina templates, which exhibited and enhanced electro-catalytic activity toward methanol oxidation. PAMAM dendrimer (PAMAM 4.5)-encapsulated Pt nanoparticles chemically linked to gold substrates through a cystamine monolayer exhibited electrocatalytic activity toward the oxidation of methanol [28].The terminal functional groups of the dendrimers stabilizes metal nanoparticles without aggregation. In this paper, we make use of the fourthgeneration amine-terminated PAMAM dendrimers (G4-NH2) to anchor on the functionalized carbon nanofiber (CNF) as a substrate and then encapsulate PtRu nanoparticles on dendrimers for the better dispersion of the electrode, which exhibited very good catalytic activity. These materials are characterized and studied, using X-ray diffraction (XRD),

scanning electron microscopy (SEM), transmission electron microscopy (TEM), and cyclic voltammetry. The electrochemical properties of the composite electrode (PtRu PAMAM/CNF) were compared to those of the commercial electrode (PtRu/C), using cyclic voltammetry. The 20% Pt RuPAMAM/CNF exhibited excellent catalytic activity and stability when compared to the 20 wt.% PtRu/C.

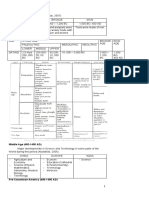

Experimental Materials All the chemicals used are of analytical grade. CNFs (grade PR 24 LHT) are commercially available from Pyrograf, USA. 1-(3-Dimethyl-aminopropyl)-3-ethyl-carbodiimidehydrochloride (EDC), N-hydroxysuccinimide (NHS), hexachloroplatinic acid, and ruthenium (III) chloride hydrate are procured from Sigma-Aldrich and used as received. Vulcan XC-72 carbon black is purchased from Cabot. Methanol and sulfuric acid are obtained from Fischer Chemicals. Nafion 5 wt.% solution is obtained from Dupont and is used as received. Fourth generation amine-terminated polyamidoamine PAMAM dendrimers (G4-NH2) with the highest available purity (10 wt.% in methanol) are obtained from Aldrich and used without further purification. Functionalization of CNF The CNF is treated with mixed acid aqueous solution of HNO3 and H2SO4 in 1:3 ratios under magnetic stirrer for 3 h. It is then washed with water and evaporated to dryness. Preparation of CNF-PAMAM Fifty milliliters of 0.1 mg/ml carboxylated CNF containing 100 mg of EDC and 100 mg of NHS is slowly added into a methanol solution of 20% G4 PAMAM under high speed agitating. Preparation of PtRuPAMAM/CNF catalysts: 6.15 mM H2PtCl6 and 11.8mM RuCl3 and dendrimer encapsulated CNF are mixed by keeping the solution under magnetic stirrer for 3 h. Five milliliters of 0.1 M NaBH4 is added to the solution and kept under evaporation. A schematic of the detailed procedure for the electrocatalyst preparation is shown in Fig. 1. Characterization The phases and lattice parameters of the catalyst are characterized by XRD patterns employing Shimadzu XD-

J Solid State Electrochem (2009) 13:15611566 Fig. 1 Schematic diagram illustrating synthesis of PtRu PAMAM/CNF

1563

D1 diffractometer using Cu K radiation ( =1.5418 ) operating at 40 kV and 48 mA. XRD samples are obtained by depositing composite supported nanoparticles on a glass slide and drying the latter in a vacuum overnight. The scanning electron micrographs are obtained using JEOL JSM-840 model, working at 15 keV. For TEM studies, the composite dispersed in ethanol are placed on the copper grid, and the images are obtained using JEOL JEM-3010 model, operating at 300 keV. Electrochemical measurements All electrochemical measurements are performed using a BAS Epsilon potentiostat. A three-electrode cell is used, which consisted of the glassy carbon (0.07 cm2) as working electrode and Pt foil and Ag/AgCl (saturated by KCl solution) electrodes as counter and reference electrodes, respectively, are used. All the electrochemical experiments are carried out at room temperature in 0.5 M H2SO4 electrolyte. The electrolyte solution is purged with high pure nitrogen for 30 min prior to a series of voltammetric experiments. Preparation of the working electrode Glassy carbon (GC) (Bas Electrode, 0.07 cm ) is polished to a mirror finish with 0.05 m alumina suspensions before each experiment and served as an underlying substrate of the working electrode. In order to prepare the composite electrode, the catalysts are dispersed ultrasonically in water at a concentration of 1 mg ml1 and 20-l aliquot is transferred on to a polished GC substrate. After the evaporation of water, the resulting thin catalyst film is covered with 5 wt.% Nafion solution. Then, the electrode is dried at 353 K and used as the working electrode. A solution of 1 M CH3OH in 0.5 M H2SO4 is used to study the methanol oxidation activity.

2

centered cubic structure can be observed. X-ray scattering from the CNF support is evidenced by the peak at 26 in 2. The diffraction peaks of the catalyst (PtRu/C) are observed to be sharp with a high intensity indicating high crystallinity (Fig. 2a). On the contrary, very broad peaks with weak intensity are observed for PAMAM containing composites (PtRu/PAMAM-CNF), indicating that they are not fully crystalline in nature (Fig. 2 b) as observed for the commercial PtRu/C (JM) (Fig. 2a). Compared with Pt Ru/C, the peak intensities of PtRuPtPAMAM/CNF are lower and the full width at half-maximum (FWHM) for the peaks are bigger. Bigger FWHM indicates a smaller average size of metal nanoparticles on PAMAM/CNF composite. No evidence of peaks related to Ru was found in these catalysts. The absence of diffraction peaks typical for Ru can be due to a number of reasons such as Ru not being dissolved in the Pt lattice, that is, forming a PtRu alloy and/or the Ru being present in the amorphous form, as further discussed below [29, 30]. The position of the Pt (111) peak for the larger (>1.2 nm) sized catalysts is shifted

C (002)

(a) 20% Pt-Ru-PAMAM/CNF (b) 20% Pt-Ru/C

Pt (111)

Intensity (a.u)

(a)

(b)

Result and discussion The crystal structures of the catalysts are examined by XRD as shown in Fig. 2. Characteristic reflections of Pt face-

10

20

30

40

50

60

70

80

2 (degrees)

Fig. 2 XRD spectra of a PtRu/C, b PtRuPAMAM/CNF

1564

J Solid State Electrochem (2009) 13:15611566

to higher 2 positions than that for pure Pt that has a maxima at 39.7645 [31]. The scanning electron micrograph images of commercial CNFs are shown in Fig. 3a,b. The diameter of the nanofibers is measured using a Leica Qwin Image Analyzer and is found to be in the range of 260250 nm and the length of about 100 m. Figure 3c shows the image of Pt

(a)

(b)

RuPAMAM/CNF. According to the EDX measurements (Fig. 4), catalysts prepared in this work contained 20.1 wt.% of total metal with a Pt/Ru atomic ratio of 1:1.0~1.1, which agrees well with the stoichiometric ratio of 1:1 used in the starting mixture. The TEM image of the prepared PtRuPAMAM/CNF catalysts, shown in Fig. 5, reveals that well-dispersed, spherical particles were anchored onto the external walls of PAMAM/CNF composite support with an average size of 2.6 nm. There is no agglomeration of PtRu nanoparticles in the composite, and the PtRu nanoparticles were found to be uniformly dispersed. In comparison, a commercial Johnson Matthey PtRu catalyst (20 wt.% on Vulcan) had an average particle size of 3 nm. The uniform dispersion of metal nanoparticles on PAMAM/CNF composite is clearly due to the PAMAM dendrimer, which offers large and uniform distributed nitrogen-active sites for anchoring metal ions and metal nanoparticles. In this regard, PAMAM-functionalized CNF composite are far more effective supports than the conventional-acid-oxidized CNF. The conventional-acid oxidation functionalization leads to the structural damage of CNF, which causes a large extent of loss in electrical conductivity and thus potentially reduces the electrocatalytic activity of the catalyst. The three-dimensional structure, smaller particle size, and high dispersion of nanoparticles may result in large valuable Pt surface area and good electrocatalytic properties toward methanol oxidation. The electrocatalytic activities for methanol oxidation of PtRuPAMAM/CNF and commercial PtRu/C electrocatalysts are analyzed by cyclic voltammetry in an electrolyte of 0.5 M H2SO4 and 1 M CH3OH at 50 mV/s. Figure 6 shows the cyclic voltammograms (CVs) of the synthesized PtRuPAMAM/CNF and commercial PtRu/C catalysts in an electrolyte solution of 0.5 M H2SO4 and 1 M CH3OH. There are two irreversible current peak during the

(c)

Fig. 3 SEM images of a, b CNF and c PtRuPAMAM/CNF

Fig. 4 EDX spectrum of PtRuPAMAM/CNF (PtRu 20.1 wt. %; Pt/ Ru=1:1.0~1.1)

J Solid State Electrochem (2009) 13:15611566

1565

Fig. 5 TEM image of 20% PtRuPAMAM/CNF catalyst

electro-oxidation of methanol that are typically attributed on the forward scan peak at around 0.8 V to methanol electro-oxidation and on the backward peak at 0.6 V to the faradic oxidation reaction on the Pt of the residual intermediate species. Both CV curves reveal a similar shape and peak position, which is also in good agreement with previous reports for methanol CVs over supported Pt catalysts. The PtRuPAMAM/CNF composite shows higher electrocatalytic activity of methanol oxidation compared to PtRu/C (JM) catalyst. The enhanced catalytic activity of PtRu/PAMAMCNF composite catalyst is due to higher dispersion of PtRu nanoparticles and may be better oxidation of CO intermediates during methanol oxidation [32, 33]. The ratio of the forward anodic peak current (If) to the reverse anodic peak current (Ib) can be used to describe the catalyst tolerance to accumulation of carbonaceous species

[3438]. A higher ratio indicates more effective removal of the poisoning species on the catalyst surface. The If/Ib ratios of PtRuPAMAM/CNF and PtRu/C are 1.36 and 0.87, respectively, showing better catalyst tolerance of PAMAM/ CNF composites. There is no much decrease in electrocatalytic activity of the PtRuPAMAM/CNF composite catalysts on subsequent cycles of methanol oxidation compared to the PtRu/C catalysts. This not only demonstrates the reproducibility of the results but also the stability of the nanoparticles on the PAMAM/CNF composite catalysts. Similarly, Fig. 7 shows the chronoamperometric studies of the synthesized sample, which reveals the stability of the PtRuPAMAM/CNF catalyst toward the methanol electrooxidation. The results are consistent with the view that PAMAM is not only stabilizing the PtRu nanoparticles but is also enhancing the methanol oxidation currents under chronoamperometric conditions. PtRu nanoparticles are well stabilized by amine-terminated PAMAM dendrimers. The high electrocatalytic activity of the PtRuPAMAM/ CNF composite electrodes prepared in this work is most probably due to the very high dispersion of PtRu particles and the extensive presence of RuOxHy.

Conclusions In summary, well-dispersed PtRu nanoparticles have been synthesized on PAMAMCNFs composite. The choice of the PAMAM G4-NH2 dendrimer template and terminal amine functional groups provides for uniform preparation of size monodisperse catalysts and facilitates the controlled dispersion. The enhancements in activity and stability over PtRu/PAMAMCNF catalyst have been solely attributed to high dispersion PtRu nanoparticles on the composite.

0.040 0.035 0.030 0.025 0.020 0.015

(a) 20% Pt-Ru-PAMAM/CNF (b) 20% Pt-Ru/C

Current (A)

(a) 0.010 (b) 0.005 0.000 0 500 1000 1500 2000 2500 3000 3500

Fig. 6 Cyclic voltammogram of a PtRuPAMAM/CNF and b Pt Ru/C in electrolyte solution of 0.5 M H2SO4 with 1 M CH3OH at a sweep rate of 50 mV/S at room temperature

Time (s)

Fig. 7 Chronoamperometry of a PtRuPAMAM/CNF, b PtRu/C polarized at +0.6 V in 0.5 M H2SO4/1 M CH3OH

1566

J Solid State Electrochem (2009) 13:15611566 17. Zhao MQ, Crooks RM (1999) Adv Mater 11:217 doi:10.1002/(SICI) 1521-4095(199903)11:3<217::AID-ADMA217>3.0.CO;2-7 18. Zhao MQ, Crooks RM (1999) Chem Mater 11:3379 doi:10.1021/ cm990435p 19. Ye H, Crooks RM (2005) J Am Chem Soc 127:4930 doi:10.1021/ ja0435900 20. Zhao M, Crooks RM (1999) Adv Mater 11:217 doi:10.1002/(SICI) 1521-4095(199903)11:3<217::AID-ADMA217>3.0.CO;2-7 21. Ye H, Crooks RM (2007) J Am Chem Soc 129:3627 22. Ledesma-Garci J, Escalante Garci IL, Rodri FJ, Chapman TW, Godinez LA (2008) J Appl Electrochem 38:515 doi:10.1007/ s10800-007-9466-2 23. Vijayaraghavan G, Stevenson KJ (2007) Langmuir 23:5279 doi:10.1021/la0637263 24. Wasmus S, Kver A (1999) J Electroanal Chem 461:14 doi:10.1016/S0022-0728(98)00197-1 25. Gasteiger HA, Markovic N, Ross PN, Cairns EJ (1994) J Phys Chem 98:617 doi:10.1021/j100053a042 26. Gonzalez-Fuentes MA, Manrquez J, Gutierrez-Granados S, Alatorre-Ordaz A, Godnez LA (2005) Chem Commun 8:898 doi:10.1039/b412442a 27. Kim JW, Choi E-A, Park S-M (2003) J Electrochem Soc 150: E202 doi:10.1149/1.1554727 28. Raghu S, Nirmal RG, Mathiyarasu J, Berchmans S, Phani KLN, Yegnaraman V (2007) Catal Lett 119:40 doi:10.1007/s10562-0079154-1 29. Wang DL, Zhuang L, Lu JT (2007) J Phys Chem C 111:16416 doi:10.1021/jp073062l 30. Guo JS, Sun GQ, Sun SG, Yan SY, Yang WQ, Qi J, Yan YS, Xin Q (2007) J Power Sources 168:299 doi:10.1016/j.jpowsour.2007.02.085 31. Bock C, Paquet C, Couillard M, Botton GA, MacDougall B (2004) J Am Chem Soc 126:8028 doi:10.1021/ja0495819 32. Jarvi TD, Stuve EM (1998) In: Lipkowski J, Ross PN (eds) Electrocatalysis, frontiers of electrochemistry series, Chapter 3. Wiley-VCH, New York, pp 75153 33. Mukerjee S, McBreen J (1998) J Electroanal Chem 448:163 doi:10.1016/S0022-0728(97)00018-1 34. Mu Y, Liang H, Hu J, Jiang L, Wan L (2005) J Phys Chem B 109:22212 doi:10.1021/jp0555448 35. Manoharan R, Goodenough JB (1992) J Mater Chem 2:875 doi:10.1039/jm9920200875 36. Liu Z, Ling XY, Su X, Lee JY (2004) J Phys Chem B 108:8234 doi:10.1021/jp049422b 37. Deivaraj TC, Lee JY (2005) J Power Sources 142:43 doi:10.1016/ j.jpowsour.2004.10.010 38. Maiyalagan T, Nawaz Khan F (2008) J Nanosci Nanotechnol doi:10.1016/j.catcom.2008.10.011

These findings suggest that PtRuPAMAM/CNF should be considered a good electrocatalyst material for direct methanol fuel cells. Though more work is needed to understand the fundamentals of the interaction between metal nanoparticles and dendrimers, particularly PtRu PAMAM/CNF, they show a potential as new electrocatalysts for low temperature fuel cells.

References

1. McNicol BD, Rand DAJ, Williams KR (2001) J Power Sources 83:47 doi:10.1016/S0378-7753(01)00882-5 2. Carrette L, Friedrich KA, Stimming U (2001) Fuel Cells (Weinh) 1:5 doi:10.1002/1615-6854(200105)1:1<5::AID-FUCE5>3.0.CO;2-G 3. Uchida M, Aoyama Y, Tanabe N, Yanagihara N, Eda N, Ohta A (1995) J Electrochem Soc 142:2572 doi:10.1149/1.2050055 4. Antolini E (2007) Appl Catal B Enviromental 724:324 doi:10.1016/j.apcatb.2007.03.002 5. Matsumoto T, Komatsu T, Arai K, Yamazaki T, Kijima M, Shimizu H, Takasawa Y, Nakamura J (2004) Chem Commun 7:840 doi:10.1039/b400607k 6. Bessel CA, Laubernds K, Rodriguez NM, Baker RTK (2001) J Phys Chem B 105:1115 doi:10.1021/jp003280d 7. Steigerwalt ES, Deluga GA, Lukehart CM (2002) J Phys Chem B 106:760 doi:10.1021/jp012707t 8. Li WZ, Liang CH, Zhou WJ, Xin Q (2003) J Phys Chem B 107:6292 doi:10.1021/jp022505c 9. Kim C, Kim YJ, Kim YA, Yanagisawam T, Park KC, Endo M, Dresselhaus MS (2004) J Appl Phys 96:5903 doi:10.1063/1.1804242 10. Wang C, Waje M, Wang X, Tang JM, Haddon RC, Yan YS (2004) Nano Lett 4:345 doi:10.1021/nl034952p 11. Maiyalagan T (2008) Appl Catal B Enviromental 89:286 doi:10.1016/j.apcatb.2007.11.033 12. Maiyalagan T, Viswanathan B, Varadaraju UV (2005) Electrochem Commun 7:905 doi:10.1016/j.elecom.2005.07.007 13. Yoshitake T, Shimakawa Y, Kuroshima S, Kimura H, Ichihashi T, Kubo Y (2002) Physica B 323:124 doi:10.1016/S0921-4526(02)00871-2 14. Hyeon T, Han S, Sung YE, Park KW, Kim YW (2003) Angew Chem Int Ed 42:4352 doi:10.1002/anie.200250856 15. Yu RQ, Chen LW, Liu QP (1998) Chem Mater 10:718 doi:10.1021/cm970364z 16. Knecht MR, Wright DW (2004) Chem Mater 16:4890 doi:10.1021/cm049058t

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Purposive Communication 1st Year 1st SemesterDocument47 pagesPurposive Communication 1st Year 1st SemesterJhon Keneth NamiasNo ratings yet

- Is Starting A Business Right For YouDocument33 pagesIs Starting A Business Right For YouSorom ComputerNo ratings yet

- Production Time Used For Each Unit Produced: Available Working Hours Per Week Plant Doors (Hours) Windows (Hours)Document3 pagesProduction Time Used For Each Unit Produced: Available Working Hours Per Week Plant Doors (Hours) Windows (Hours)ninja vibelNo ratings yet

- Review On Recent Progress in Nitrogen-Doped Graphene Synthesis, Characterization, and Its Potential ApplicationsDocument14 pagesReview On Recent Progress in Nitrogen-Doped Graphene Synthesis, Characterization, and Its Potential Applicationskutty79No ratings yet

- V-Mn-MCM-41 Catalyst For The Vapor Phase Oxidation of O-XyleneDocument13 pagesV-Mn-MCM-41 Catalyst For The Vapor Phase Oxidation of O-XyleneT MaiyalaganNo ratings yet

- Performance of Carbon Nanofiber Supported Pd-Ni Catalysts For Electro-Oxidation of Ethanol in Alkaline MediumDocument6 pagesPerformance of Carbon Nanofiber Supported Pd-Ni Catalysts For Electro-Oxidation of Ethanol in Alkaline MediumsuniloveNo ratings yet

- Electrochemical Oxidation of Methanol On Pt-V2O5-C Composite CatalystsDocument4 pagesElectrochemical Oxidation of Methanol On Pt-V2O5-C Composite Catalystskutty79No ratings yet

- Catalytic Activity of Platinum-Tungsten Oxide Nanorod Electrodes Towards Electro-Oxidation of MethanolDocument5 pagesCatalytic Activity of Platinum-Tungsten Oxide Nanorod Electrodes Towards Electro-Oxidation of Methanolshankar8572No ratings yet

- Maiyalagan Fabrication and Characterization of Uniform TiO2 Nanotube Arrays by Solgel Template MethodDocument4 pagesMaiyalagan Fabrication and Characterization of Uniform TiO2 Nanotube Arrays by Solgel Template MethodT MaiyalaganNo ratings yet

- Nitrogen Containing Carbon Nanotubes As Supports For Pt-Alternate Anodes For Fuel Cell ApplicationsDocument8 pagesNitrogen Containing Carbon Nanotubes As Supports For Pt-Alternate Anodes For Fuel Cell Applicationsshankar8572No ratings yet

- Fabrication, Morphology and Structural Characterization of Tungsten Oxide NanorodsDocument5 pagesFabrication, Morphology and Structural Characterization of Tungsten Oxide NanorodsT MaiyalaganNo ratings yet

- Class 12th Biology Solved Sample Paper 1Document14 pagesClass 12th Biology Solved Sample Paper 1cbsestudymaterialsNo ratings yet

- DSA Theory Mini Project Submission TemplateDocument6 pagesDSA Theory Mini Project Submission TemplateSanjay PriyadarshiNo ratings yet

- Grundfosliterature 776429Document96 pagesGrundfosliterature 776429Орце АндовNo ratings yet

- Edu 431 Week 5 AssignmentDocument4 pagesEdu 431 Week 5 Assignmentapi-368359457No ratings yet

- Group A EDC Solar Transportation Project Report - Compressed PDFDocument81 pagesGroup A EDC Solar Transportation Project Report - Compressed PDFganesh SawantNo ratings yet

- Plcsim Advanced Docu v10 enDocument47 pagesPlcsim Advanced Docu v10 enRafaelNo ratings yet

- Irvingia Gabonensis Seed Extract 10-1 IGSE-181011Document1 pageIrvingia Gabonensis Seed Extract 10-1 IGSE-181011Sophia XieNo ratings yet

- Improvements To Shankarpally To Marpally Road From Km.0/0 To 4/0 in Ranga Reddy District. Detailed Cum Abstract Estimate Name of WorkDocument34 pagesImprovements To Shankarpally To Marpally Road From Km.0/0 To 4/0 in Ranga Reddy District. Detailed Cum Abstract Estimate Name of Worksandeep bandaruNo ratings yet

- Minor Project Report-OSPF ChampDocument5 pagesMinor Project Report-OSPF Champsmrutiranjan1991100% (1)

- General Physics 1: Laws of MotionDocument4 pagesGeneral Physics 1: Laws of MotionRobert RosarioNo ratings yet

- Virtual Reality ArticleDocument17 pagesVirtual Reality ArticlesoikcalebNo ratings yet

- Office Electrical SafetyDocument13 pagesOffice Electrical Safety101arNo ratings yet

- Co-Hoc-Vat-Ran-Bien-Dang - T.-Nguyen-Thoi-,-T.-Vo-Duy - Chapter - 4 - New-Material-Behavior - Linear-Elastic-Solid - (Cuuduongthancong - Com)Document27 pagesCo-Hoc-Vat-Ran-Bien-Dang - T.-Nguyen-Thoi-,-T.-Vo-Duy - Chapter - 4 - New-Material-Behavior - Linear-Elastic-Solid - (Cuuduongthancong - Com)19020852 Lường Thị QuyênNo ratings yet

- Ancient Age: Three Age SystemDocument5 pagesAncient Age: Three Age SystemCheska DocumentsNo ratings yet

- Gradall Xl3310V Steel Mill Maintenance Manual PDFDocument2 pagesGradall Xl3310V Steel Mill Maintenance Manual PDFWellinton Adolfo Marroquín de PazNo ratings yet

- Thermal Power PlantDocument139 pagesThermal Power PlantSadiq AntuNo ratings yet

- Consolidated Drained Direct Shear Test: (IS: 2720 (Part 13) - 1986)Document1 pageConsolidated Drained Direct Shear Test: (IS: 2720 (Part 13) - 1986)Biplab dattaNo ratings yet

- Mapeh 7 DLLDocument8 pagesMapeh 7 DLLFrancheska Venize Barola RevillosaNo ratings yet

- Foundation Engineering II Course Outline 2016Document2 pagesFoundation Engineering II Course Outline 2016Ewnet YashenefalNo ratings yet

- KinetisV - Peripheral Module ReferenceDocument103 pagesKinetisV - Peripheral Module Referenceb_dupNo ratings yet

- Partnering With Dell EMC ServicesDocument20 pagesPartnering With Dell EMC ServicesAdnan JavaidNo ratings yet

- Post Cha FomDocument3 pagesPost Cha FomAjay Bochare100% (1)

- NCSE 2006 Mathematics Paper 1Document10 pagesNCSE 2006 Mathematics Paper 1Christian PatriceNo ratings yet

- Endogenic and Exogenic ProcessesDocument13 pagesEndogenic and Exogenic ProcessesJohndee Mozart Dela CruzNo ratings yet

- EMA Process ValidationDocument15 pagesEMA Process Validationdr3azzamNo ratings yet

- Question No: 1 Pipe Junction - Problem DescriptionDocument37 pagesQuestion No: 1 Pipe Junction - Problem DescriptionvenkateshNo ratings yet

- Micro Turbine Generator SystemDocument28 pagesMicro Turbine Generator Systemraj_turaka0072365100% (2)