Professional Documents

Culture Documents

Lecture 08

Uploaded by

Sanjiv ChCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 08

Uploaded by

Sanjiv ChCopyright:

Available Formats

LECTURE EIGHT

054410 PLANT DESIGN

054410 Plant Design

LECTURE 8: REBOILER CIRCUIT DESIGN

Daniel R. Lewin Department of Chemical Engineering Technion, Haifa, Israel

Ref: Kern, R. Thermosyphon Reboiler Piping Simplified, Hydrocarbon Processing, Dec 1968, 47, No. 12, pp. 118-122

8-1 PLANT DESIGN - Daniel R. Lewin Reboiler Circuit Design

Lecture Objectives

After this lecture, you should: n Understand the physics behind a thermosyphon. o Be familiar with the four main types of reboiler arrangements in use, and their advantages and disadvantages. p Be able to perform sizing calculations for a thermosyphon. q Be able to select and design the appropriate reboiler circuit for a given application.

8-2

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

How reboilers work

Almost as many towers flood because of reboiler problems as because of tray problems.

Theory of thermosyphon, or natural circulation, can be illustrated by the airlift pump.

P =

(HRW ) (DRW ) (HRT )(DRT )

2.31

HRW = hgt of water above base (ft) DRW = S.G. of fluid in riser (in this case 1.0) HRT = hgt of aerated water in riser tube (ft) DRT = S.G. of aerated water in riser tube P = diff. pressure between A and B (psi)

8-3 PLANT DESIGN - Daniel R. Lewin Reboiler Circuit Design

How reboilers work

The driving force to promote flow through this reboiler is the density difference between the fluid in the reboiler feed line and the froth-filled reboiler return line. For the example on the right:

P =

(20 ft ) ( 0.6) (15 ft ) ( 0.061 )

2.31

= 4.71 psig

8-4

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

How reboilers work

The developed P of 4.7 psig is consumed in overcoming frictional losses, due to flow in the inlet line, reboiler, outlet line and nozzles.

If these frictional losses are less than 4.7 psig, the inlet line does not run liquid full. If they are more than the 4.7 psig, the reboiler draw-off pan overflows, and the flow to the reboiler is reduced until the friction losses drop to the available thermosyphon force.

PLANT DESIGN - Daniel R. Lewin Reboiler Circuit Design

8-5

Four Types Considered

Once-through thermosyphon reboilers

Circulating thermosyphon reboilers

p

8-6

Forced-circulation reboilers

PLANT DESIGN - Daniel R. Lewin

Kettle or gravity-fed reboilers

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Once-through Thermosyphon Reboiler

The following statements characterize the operation of a once-through thermosyphon reboiler:

n o p All the liquid from the bottom tray flows to the reboiler. None of the liquid from the bottom of the tower flows to the reboiler. All the bottoms product comes from the liquid portion of the reboiler effluent. None of the liquid from the bottom tray flows to the bottom of the tower. The reboiler outlet temp. is the same as the tower bottoms temp.

PLANT DESIGN - Daniel R. Lewin Reboiler Circuit Design

q r

8-7

Once-through Thermosyphon Reboiler

A once-through thermosyphon reboiler can be equipped with a vertical baffle. The reboiler return liquid goes only to the hot side of the tower bottoms. Putting the reboiler return liquid to the colder side is poor engineering practice.

8-8

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Circulating Thermosyphon Reboiler

In this type of thermosyphon reboiler circuit:

n o The reboiler outlet temp. is always higher than tower bottoms temperature. Some of the liquid from the reboiler outlet will always circulate back into the reboiler feed. Some of the liquid from the bottoms tray ends up as bottoms product. Tower bottoms product temperature and composition is the same as the temperature and composition of the feed to the reboiler.

p q

8-9

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Forced-circulation Reboiler

Similar to a once-through design, but equipped with a pump to impose circulation.

Advantages: 1. Careful calculation of circuit P is not critical. 2. Can overcome large Ps in the reboiler circuit. Disadvantages: Wastes energy. Main usages: (a) If the reboiler is a furnace, where loss of flow will lead to tube damage, and the higher P needs to be overcome; (b) if a number of distinct heat sources supply the reboiler duty.

8 - 10 PLANT DESIGN - Daniel R. Lewin

Figure 5.6

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Kettle Reboiler

In this type of thermosyphon reboiler circuit:

n Liquid flows from the column sump to the bottom of the kettles shell. It is partially vaporized. The domed top section of the reboiler separates the vapor and the liquid. The vapor flows back into the tower via the riser. The liquid overflows the baffle, which is set high enough to keep the tubes submerged. This liquid is the bottoms product.

PLANT DESIGN - Daniel R. Lewin

o p

q r

p o

n s

8 - 11

Reboiler Circuit Design

Kettle Reboiler

8 - 12

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Kettle Reboiler

The level in the tower sump is the sum of the following:

n o p Nozzle exit losses. Liquid feed-line P. The shell-side exchanger pressure drop, including the effect of the baffle height. The vapor-line P, including the vapor outlet nozzle loss.

q z z

Note:

z

8 - 13

Pressure in reboiler is always higher than tower pressure. Thus, increase in duty will lead to an increase in sump level. Sump level is not controlled!

PLANT DESIGN - Daniel R. Lewin

n p o

Reboiler Circuit Design

Once-through Reboiler Design

Natural circulation is maintained if P (driving force) p (frictional losses) Driving force for circulation. P1 P2 = P = (1 144 ) ( 1H1 2H2 ) Pi pressure [psi] i density [lb/ft3 ] H1 head [ft] Introducing a safety factor of 2: P = (1 288 ) ( 1H1 2H2 ) Friction Losses. p = pd + pe + pr

2

H2

1

H1

pe reboiler P [psi] usually 0.25-0.5 psi pd downcomer P [psi] pd + pr = 0.1-1 psi/100 ft by design pr riser P [psi]

8 - 14 PLANT DESIGN - Daniel R. Lewin Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Once-through Reboiler Design

Horizontal Reboilers: The minimum downcomer nozzle elevation above a horizontal reboiler centerline is: 288p ( H ) 2 H1 1 2 where H = H1 H2. Kern (1968) recommends a head difference of 3 ft: H = 3. In which case:

288p 32 1 2 The density of fluid in riser is:

2

H2

1

H1

H1

2 =

W WL L +WV V

Wi mass flows [lb/hr]

8 - 15 PLANT DESIGN - Daniel R. Lewin Reboiler Circuit Design

Circulating Reboiler Design

Note that draw-off is from the bottom here!

Horizontal Reboilers:

P = (1 288 ) ( 1H1 2H2 )

As before, the driving force must be at least equal to the frictional losses:

P p = pd + pe + pr

Here H2 = H1 + H3. Thus, the minimum downcomer nozzle elevation is limited to: 288p + 2H3 H1 1 2

8 - 16

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Circulating Reboiler Sizing

Vertical Reboilers (bottom draw-off): Conservative estimate of the exchanger H3 fluid density: 3 = ( 1 + 2 ) 2 Thus, P = (1 288 ) 1H1 2H2 3H 4

P p = pd + pe + pr

However, since H1 + H3 = H2 + H 4 :

288p + 2 (H 4 H3 ) + 3H 4 1 2

H1'

H1

The vertical reboiler should be flooded. The maximum elevation of the top tube-sheet should not be higher than the minimum liquid level in the tower, thus at minimum, H1 = H 4 and H3 = H2 and:

P = (1 288 ) H1 ( 1 3 ) 2H2 and H1 =

8 - 17 PLANT DESIGN - Daniel R. Lewin

288p + 2H3 1 2

Reboiler Circuit Design

Once-through Reboiler Design

Vertical Reboilers (top draw-off): Here, P = (1 288 ) 1H1 2H2 3H 4 Following Kerns recommendation:

H1 = 3 + H2 + H 4

The minimum draw-off nozzle elevation is:

288p 2 (H 4 + 3) + 3H 4 1 2

H1

8 - 18

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Fraction of Fluid Evaporated

Source: Andrew Sloley, Distillation Group Inc. The amount of incoming feed a thermosyphon reboiler can vaporize is typically between 30-40%. For any given exchanger the limit depends upon the construction details and the system involved. For some installations, it can be as low as 20-25%. Others have achieve levels as high as 45-50% in special circumstances. There are two reason for this: (a) critical heat flux limitations; (b) vaporization blanketing. Both phenomena limit the amount of heat that can be transferred to a boiling fluid to an upper limit which leads to the upper limitation in vaporization.

8 - 19

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Critical Heat Flux in Boiling Duty

8 - 20

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

10

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Example Calculation

Downcomer: Liquid: 186,850 lb/hr 1 = 36.7 lb/ft3 Riser: (30% vapor) Liquid: 130,750 lb/hr L = 36.7 lb/ft3 vapor: 56,100 lb/hr V = 1.32 lb/ft3 100 2 = 70 30.7 + 30 1.32

= 4.06 lb/ft3

8 - 21

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

Example Calculation

Available driving force:

P = (1 288 ) ( 1H1 2H2 ) = (1 288 ) (36.7 16 4.06 13) = 1.86 psi Frictions losses:

p (psi)

p (psi)

8 10 0.19 0.10 0.43 0.39 0.35 1.46

pd

nozzles

8 8

0.19 0.10 1.13 0.95 0.35 2.71

pr

nozzles

pe p

8 - 22

Minimum draw-off nozzle elevation: 288p 32 288 1.46 3 4.06 H1 = = 36.7 4.06 1 2

= 13 ft --- 16 ft in actual design

, 9

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

11

Daniel R. Lewin, Technion

LECTURE EIGHT

054410 PLANT DESIGN

Selection of Reboiler Type

Source: Andrew Sloley, Distillation Group Inc. Many factors influence reboiler type selection. In the end, all these factors reduce to economics. Every plant will weight the trade-off between these factors differently. No one-size fits all selection exists. Major factors include: o Plot space available o Total duty required o Fraction of tower liquid traffic vaporized o Fouling tendency o Temperature approach available o Temperature approach required

8 - 23 PLANT DESIGN - Daniel R. Lewin Reboiler Circuit Design

Summary

After reviewing this lecture, you should: n Understand the physics behind a thermosyphon. o Be familiar with the four main types of reboiler arrangements in use, and their advantages and disadvantages. p Be able to perform sizing calculations for a thermosyphon. q Be able to select and design the appropriate reboiler circuit for a given application.

8 - 24

PLANT DESIGN - Daniel R. Lewin

Reboiler Circuit Design

12

Daniel R. Lewin, Technion

You might also like

- Pile Length CalculationDocument3 pagesPile Length CalculationCivilax.comNo ratings yet

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Reboiler Circuit DebottleneckDocument8 pagesReboiler Circuit DebottleneckstreamtNo ratings yet

- Reboiler Calculations Design GuideDocument12 pagesReboiler Calculations Design Guidec_nghia83% (6)

- CIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumDocument8 pagesCIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumEmil-Wendtland100% (1)

- Process Engineering: Facts, Fiction and FablesFrom EverandProcess Engineering: Facts, Fiction and FablesRating: 3 out of 5 stars3/5 (2)

- Thermosiphon ReboilerDocument6 pagesThermosiphon Reboilerme12m11350% (2)

- Sloley - Properly Design Thermosyphon ReboilersDocument14 pagesSloley - Properly Design Thermosyphon Reboilersbltzkrig100% (4)

- Design of A Vertical Thermosyphon ReboilerDocument6 pagesDesign of A Vertical Thermosyphon ReboilerhurrikenNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Design of Distillation TraysDocument25 pagesDesign of Distillation Trayssatishchemeng100% (8)

- Understand Heat Flux Limitations On Reboiler Design PDFDocument10 pagesUnderstand Heat Flux Limitations On Reboiler Design PDFthawdarNo ratings yet

- Design and Simulation of Continuous Distillation Columns PDFDocument33 pagesDesign and Simulation of Continuous Distillation Columns PDFnghiemta18No ratings yet

- Case 4 Sakhalin 1 ProjectDocument29 pagesCase 4 Sakhalin 1 ProjectashmitNo ratings yet

- Vapor Liquid Separator PDFDocument10 pagesVapor Liquid Separator PDFClemenNo ratings yet

- Vertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyDocument9 pagesVertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyPuskar GuptaNo ratings yet

- Prescribing and Describing: Popular and Academic Views of "Correctness"Document17 pagesPrescribing and Describing: Popular and Academic Views of "Correctness"zaid ahmed100% (2)

- IMTPDocument16 pagesIMTPDHAVALESH AMNo ratings yet

- Thermosiphon ReboilersDocument7 pagesThermosiphon Reboilerssj_scribd100% (1)

- Distillation Column Troubleshooting Part IIDocument8 pagesDistillation Column Troubleshooting Part IINishat M PatilNo ratings yet

- Shortcut Methodsofdistillation Design PDFDocument15 pagesShortcut Methodsofdistillation Design PDFAle SanzNo ratings yet

- Thermosyphon Reboiler HydraulicsDocument6 pagesThermosyphon Reboiler Hydraulicsnghiemta180% (2)

- 4 Sep - hor.ReEntrainment Articulo1Document10 pages4 Sep - hor.ReEntrainment Articulo1Humberto Pallares100% (1)

- Tray Distillation ColumnsDocument27 pagesTray Distillation ColumnsRajeshkumar Elango0% (1)

- Standard Hook-Up Wires & Cables For ElectronicsDocument124 pagesStandard Hook-Up Wires & Cables For ElectronicsdlstoneNo ratings yet

- Reboiler HydraulicDocument3 pagesReboiler Hydraulic54yreyeNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Location of Reboiler Return Inlet Nozzle in ColumnDocument10 pagesLocation of Reboiler Return Inlet Nozzle in Columnxaaabbb_550464353No ratings yet

- Efficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer ChemtechDocument31 pagesEfficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer Chemtechmisscolgate100% (1)

- A Computer Design Method For Vertical Thermosyphon ReboilersDocument13 pagesA Computer Design Method For Vertical Thermosyphon ReboilersSrihari Kodimela100% (1)

- Handbook for Transversely Finned Tube Heat Exchanger DesignFrom EverandHandbook for Transversely Finned Tube Heat Exchanger DesignNo ratings yet

- ATM Documentation DOCUMENTDocument122 pagesATM Documentation DOCUMENTSuhan Dheer67% (3)

- Process Calculation: Flare Diameter (D)Document2 pagesProcess Calculation: Flare Diameter (D)kristian08100% (1)

- Design Practices-ReboilerDocument7 pagesDesign Practices-Reboileragarwalashwin32100% (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- DesignII Lecture 02 ReboilerDesignDocument19 pagesDesignII Lecture 02 ReboilerDesignRam L Rao100% (1)

- Reboilers PDFDocument0 pagesReboilers PDFtpchoNo ratings yet

- Heat-Exchanger Bypass Control: William L. LuybenDocument9 pagesHeat-Exchanger Bypass Control: William L. LuybenHens Christian FuentesNo ratings yet

- Applying Relief Load Calculation MethodsDocument9 pagesApplying Relief Load Calculation MethodsKamil Marszałek100% (1)

- Kettle ChoiceDocument5 pagesKettle ChoiceHow Jie WeiNo ratings yet

- Seleccion de EbullidoresDocument5 pagesSeleccion de EbullidoresDaniela Jurado100% (2)

- OGJ Hot Vapor Bypass DesignDocument6 pagesOGJ Hot Vapor Bypass DesignJesse Haney III100% (2)

- Design of Valve TrayDocument4 pagesDesign of Valve TrayVirendra BhagatNo ratings yet

- Jan11 GSO PDFDocument10 pagesJan11 GSO PDFChakravarthy BharathNo ratings yet

- CE325 - 16 Pile CapacityDocument45 pagesCE325 - 16 Pile CapacityAhmadAliAKbarPhambraNo ratings yet

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocument10 pagesEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyNo ratings yet

- Select The Right ReboilerDocument2 pagesSelect The Right ReboilerSteven A McMurray100% (2)

- Reboilers - Kettle Versus Thermosiphon DesignsDocument3 pagesReboilers - Kettle Versus Thermosiphon Designschem_iaf100% (1)

- Kettle ReboilersDocument6 pagesKettle ReboilersHow Jie WeiNo ratings yet

- Reboilers SelectionDocument4 pagesReboilers SelectionPramod Dixit100% (1)

- MC Kee - Thermosiphon Reboileres A ReviewDocument7 pagesMC Kee - Thermosiphon Reboileres A Reviewbltzkrig100% (1)

- IntroKGTowerV2 0 PDFDocument14 pagesIntroKGTowerV2 0 PDFrasyid93No ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- FRI Internal Design Vol4Document55 pagesFRI Internal Design Vol4syamsudin2006No ratings yet

- RISER DIAGRAM ModelDocument1 pageRISER DIAGRAM ModelMhel Cenidoza50% (2)

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Multipass Tray DesignDocument12 pagesMultipass Tray DesignAyoun Ul HaqueNo ratings yet

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksNo ratings yet

- How To Use Vertical Thermosyphon Reboiler CalculatorDocument2 pagesHow To Use Vertical Thermosyphon Reboiler CalculatorMahesh KumarNo ratings yet

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsNo ratings yet

- Thermosyphon Reboiler HydraulicsDocument2 pagesThermosyphon Reboiler HydraulicsMichael HaiseNo ratings yet

- Thermosiphon ReboilersDocument3 pagesThermosiphon ReboilersMuhammadNo ratings yet

- ParaViewGuide-5 5 2 PDFDocument260 pagesParaViewGuide-5 5 2 PDFIvan GómezNo ratings yet

- Skiold Trough Augers: SkioldgroupDocument2 pagesSkiold Trough Augers: SkioldgroupLuis NunesNo ratings yet

- Evaluation of Digital Divide.Document8 pagesEvaluation of Digital Divide.Jojie Mae GabunilasNo ratings yet

- Architect Laurie BakerDocument116 pagesArchitect Laurie BakerSuvarna456100% (5)

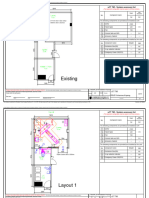

- Desain Ruangan CT-ScanDocument3 pagesDesain Ruangan CT-ScannewmanonmarsNo ratings yet

- 4 Bit Manchester AdderDocument14 pages4 Bit Manchester AdderHacking_Deface0% (2)

- HMC 045Document12 pagesHMC 045Mohamed ElmakkyNo ratings yet

- 1 Historical AntecedentsDocument12 pages1 Historical AntecedentshithereNo ratings yet

- #SM4J Recap Fall 2019Document5 pages#SM4J Recap Fall 2019Damian RadcliffeNo ratings yet

- DR External Axis Controller (1L4805A-E-3) PDFDocument160 pagesDR External Axis Controller (1L4805A-E-3) PDFdavidNo ratings yet

- IBM IVA White PaperDocument4 pagesIBM IVA White PaperTarek FahimNo ratings yet

- Lab Exercise - Ethernet: ObjectiveDocument11 pagesLab Exercise - Ethernet: ObjectiveTakaskiNo ratings yet

- 5528 PDFDocument33 pages5528 PDFPham The TuNo ratings yet

- Bomb Oil AisinDocument38 pagesBomb Oil AisinMAURICIONo ratings yet

- Panel Simplex 2008Document86 pagesPanel Simplex 2008JhonyLazoNo ratings yet

- Online Shopping Portal Project ReportDocument33 pagesOnline Shopping Portal Project ReportSagar Chauhan50% (2)

- WI - C.4.1 Set Up Site Documentation V1.1aDocument5 pagesWI - C.4.1 Set Up Site Documentation V1.1ayoen_anNo ratings yet

- References PDFDocument7 pagesReferences PDFresigjeflinNo ratings yet

- Manual Sales Order Processing System: Vanessa GabriellaDocument1 pageManual Sales Order Processing System: Vanessa GabriellaVanessa GabriellaNo ratings yet

- Emulate 500 Instruction ExceptionsDocument3 pagesEmulate 500 Instruction ExceptionsSebastian Gallardo VerdugoNo ratings yet

- Sophie Greaves Resume 2015Document1 pageSophie Greaves Resume 2015Sophie GreavesNo ratings yet