Professional Documents

Culture Documents

Van'S Aircraft, Inc.: Nutplate Preparation

Uploaded by

Mark Evan SalutinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Van'S Aircraft, Inc.: Nutplate Preparation

Uploaded by

Mark Evan SalutinCopyright:

Available Formats

VAN'S AIRCRAFT, INC.

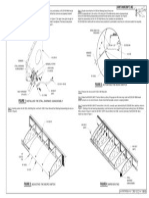

VS-1204 Step 1: Remove the material from the VS-1204 Fwd Skin, called out in Figure 1. Step 2: Remove the material from the VS-1201 Main Skin, called out in Figure 2, Detail A. Step 3: Final-drill #19, the nutplate screw holes in the VS-1204 Fwd Skin per call-out in Figure 1. Step 4: Final-drill #19, the nutplate screw holes in the VS-1201 Main Skin per call-out in Figure 2, Detail B. Deburr all of the final-drilled holes from Steps 3 and 4. Step 5: Dimple the #19 holes in the VS-1204 Fwd Skin using a #8 dimple die as called out in Figure 1. Step 6: Dimple the #19 holes in the VS-1201 Main Skin using a #8 dimple die as called out in Figure 2, Detail B. Step 7: Dimple the nutplate attach rivet holes in the VS-1201 Main Skin using a 3/32 dimple die as called out in Figure 2, Detail B. VS-1201 (SHOWN FLAT) REMOVE AREA SHOWN HATCHED FINAL DRILL, DIMPLE, FLUSH OUTER SURFACE, 26 PLACES REMOVE AREA SHOWN HATCHED NOTE: A small diameter female die is required to dimple the nutplate attach rivet holes on a countersunk nutplate. An alternative would be grinding material from a standard female die to clear the recess of the nutplate. Step 8: Dimple the nutplate attach rivet holes using a 3/32 dimple die as called out in Figure 3. 18 X K1100-08

DIMPLE, 2 PLACES / NUTPLATE

FIGURE 3: NUTPLATE PREPARATION FIGURE 1: FWD SKIN PREPARATION

Step 9: Rivet the previously dimpled K1100-08 Nutplates, to the VS-1201 Main Skin per call-outs in Figure 4.

VS-1201 K1100-08 (DIMPLED) 18 PLACES AN426AD3-3.5 2 PLACES / NUTPLATE

DETAIL A

FINAL DRILL, DIMPLE, FLUSH OUTER SURFACE, 18 PLACES DIMPLE, FLUSH OUTER SURFACE, 36 PLACES

VS-1201 (SHOWN FLAT)

FIGURE 2: MAIN SKIN PREPARATION DETAIL B

PAGE

FIGURE 4: NUTPLATE INSTALLATION

06-06

RV-12

REVISION:

DATE:

01/22/09

You might also like

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- Figure 1: Separating The: Rudder Pedal Support ChannelsDocument1 pageFigure 1: Separating The: Rudder Pedal Support ChannelsMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Detail A-ADocument1 pageVan'S Aircraft, Inc.: Detail A-AMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockDocument1 pageVan'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockMark Evan SalutinNo ratings yet

- Figure 1: Snap Bushing Bracket Separation: Van'S Aircraft, IncDocument1 pageFigure 1: Snap Bushing Bracket Separation: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Lighting Bracket Cockpit Light Wires Connections 40-11 RV-12Document1 pageVan'S Aircraft, Inc.: Lighting Bracket Cockpit Light Wires Connections 40-11 RV-12Mark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Trimming The Top and Bottom CowlDocument1 pageVan'S Aircraft, Inc.: Figure 1: Trimming The Top and Bottom CowlMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: InstallingDocument1 pageVan'S Aircraft, Inc.: Figure 1: InstallingMark Evan SalutinNo ratings yet

- Classic ANSI Lock Installation Manual 20091903Document32 pagesClassic ANSI Lock Installation Manual 20091903elfer04No ratings yet

- Figure 1: Oil Door Assembly Installation: Van'S Aircraft, IncDocument1 pageFigure 1: Oil Door Assembly Installation: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Match-Drilling Map BoxDocument1 pageVan'S Aircraft, Inc.: Figure 1: Match-Drilling Map BoxMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 3: Drilling The Terminal BlockDocument1 pageVan'S Aircraft, Inc.: Figure 3: Drilling The Terminal BlockMark Evan SalutinNo ratings yet

- BHT 206 16 209Document8 pagesBHT 206 16 209edsel jose diaz sarmientoNo ratings yet

- Type I: - Printed Copies Are UncontrolledDocument14 pagesType I: - Printed Copies Are UncontrolledALINo ratings yet

- Sanitation Repair InstructionsDocument179 pagesSanitation Repair InstructionsKostasKastrinos0% (1)

- Van'S Aircraft, Inc.: Figure 1: Installing The Side SkinsDocument1 pageVan'S Aircraft, Inc.: Figure 1: Installing The Side SkinsMark Evan SalutinNo ratings yet

- Figure 1: Installing The Instrument Panel: Van'S Aircraft, IncDocument1 pageFigure 1: Installing The Instrument Panel: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Friday, May 20, 2022, 05:04 PM: Page 1 of 4 C:/Users/Dell/Desktop/ANALYSIS/AVINASH - AnlDocument4 pagesFriday, May 20, 2022, 05:04 PM: Page 1 of 4 C:/Users/Dell/Desktop/ANALYSIS/AVINASH - AnlSalman KhanNo ratings yet

- Van'S Aircraft, Inc.: Making The Mid Cowl HingesDocument1 pageVan'S Aircraft, Inc.: Making The Mid Cowl HingesMark Evan SalutinNo ratings yet

- Tuesday, March 09, 2021, 08:48 AM: Warning - All Degrees of Freedom FixedDocument5 pagesTuesday, March 09, 2021, 08:48 AM: Warning - All Degrees of Freedom FixedNoel GragedaNo ratings yet

- Chapter 12 VerticalCloseoutDocument10 pagesChapter 12 VerticalCloseoutMark Evan SalutinNo ratings yet

- NV-SJ200 205 207Document0 pagesNV-SJ200 205 207zilikonNo ratings yet

- Thursday, April 14, 2022 5:44 PM: D:/Atc Rtt/Atc Rj/Jaipur-Nahargarh Road/Std/Jaipur - AnlDocument31 pagesThursday, April 14, 2022 5:44 PM: D:/Atc Rtt/Atc Rj/Jaipur-Nahargarh Road/Std/Jaipur - AnlPankaj SherwalNo ratings yet

- Canon Mp520 Parts CatalogDocument30 pagesCanon Mp520 Parts CatalogelenoremailNo ratings yet

- Machine Compatibility OEM Info Tools: Technical Instructions 1Document9 pagesMachine Compatibility OEM Info Tools: Technical Instructions 1servicerNo ratings yet

- DAC1 24 03 Rev 2Document4 pagesDAC1 24 03 Rev 2vanNo ratings yet

- 212 TB 09 210Document5 pages212 TB 09 210Jose Edwin Roldan RiosNo ratings yet

- IP90v Parts CatalogDocument34 pagesIP90v Parts Cataloglowfat69No ratings yet

- 3600 Molded Cassette Door Catch ReplacementDocument15 pages3600 Molded Cassette Door Catch ReplacementThai TaNo ratings yet

- TM 55 2925 236 40Document57 pagesTM 55 2925 236 40vonsaNo ratings yet

- Figure 3: Activating The Micro Switch: Van'S Aircraft, IncDocument1 pageFigure 3: Activating The Micro Switch: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Design of Beams Column and SlabDocument30 pagesDesign of Beams Column and SlabPrateek NagariaNo ratings yet

- Westinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsDocument28 pagesWestinghouse Ds and DSL Low Voltage Power Circuit Breakers and Cell PartsRodney PimentaNo ratings yet

- Alignment and Installation Procedure For UW EqptsDocument79 pagesAlignment and Installation Procedure For UW EqptsSanthosh Kumar100% (1)

- Figure 3: Rolling The Upper Forward Fuselage Skin: Van'S Aircraft, IncDocument1 pageFigure 3: Rolling The Upper Forward Fuselage Skin: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- 19XR Frame 3, 02XR ComprDocument56 pages19XR Frame 3, 02XR Comprjuan francisco rosarioNo ratings yet

- Disassembly Iq500Document65 pagesDisassembly Iq500Daniel GámezNo ratings yet

- Beam SpliceDocument17 pagesBeam SpliceBoddu Ramakrishna100% (1)

- Exploded Views and Parts List: TascamDocument8 pagesExploded Views and Parts List: TascamToto WaltherNo ratings yet

- Sbrio User GuideDocument52 pagesSbrio User GuideJose Luis Pesantez CorralNo ratings yet

- 206 Asb 19 138Document8 pages206 Asb 19 138Kraven YagamyNo ratings yet

- Machine Compatibility OEM Info Tools: Technical Instructions 1Document8 pagesMachine Compatibility OEM Info Tools: Technical Instructions 1servicerNo ratings yet

- TSB BO023R Door Handle LooseDocument3 pagesTSB BO023R Door Handle LooseBrais Gutierrez RodriguezNo ratings yet

- TB61 - Dta-150-ModDocument9 pagesTB61 - Dta-150-ModJorge MartinelliNo ratings yet

- HB 3700Document2 pagesHB 3700Suehsner Jorge AlbertoNo ratings yet

- User Manual JMP-4C 160Wx250LDocument20 pagesUser Manual JMP-4C 160Wx250LRita VillavicencioNo ratings yet

- Caja Ejb-101008 Crouse HindsDocument14 pagesCaja Ejb-101008 Crouse HindsAlejandro OliveraNo ratings yet

- HP LaserJet 4600 Service Manual UpdateDocument4 pagesHP LaserJet 4600 Service Manual Updaterferrero27No ratings yet

- Set No. 1Document8 pagesSet No. 1Soundarya MaryNo ratings yet

- F16 AvionDocument26 pagesF16 AvionJuan Carlos AlvaradoNo ratings yet

- SB 14 BC 03 PDFDocument19 pagesSB 14 BC 03 PDFmates isNo ratings yet

- 2001 Oldsmobile Aurora 2000 Pontiac Bonneville 2000 Buick Lesabre Collision Repair ManualDocument25 pages2001 Oldsmobile Aurora 2000 Pontiac Bonneville 2000 Buick Lesabre Collision Repair ManualPedro Angel Alvarez NarvaezNo ratings yet

- Beam 2Document4 pagesBeam 2Pipeco SyahmieNo ratings yet

- Brother DP-550CJ, LW-840ic Parts ManualDocument41 pagesBrother DP-550CJ, LW-840ic Parts ManualDuplessisNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: Routing Line Through Ribs Figure 3: Terminal Bracket InstallationDocument1 pageVan'S Aircraft, Inc.: Figure 1: Routing Line Through Ribs Figure 3: Terminal Bracket InstallationMark Evan SalutinNo ratings yet

- Wednesday, February 24, 2021, 02:50 PM: Page 1 of 5 D:/ZNO C121-New Project/0. STAAD CALCULATIONS/8. BEAM/BEAM-SLAB - AnlDocument5 pagesWednesday, February 24, 2021, 02:50 PM: Page 1 of 5 D:/ZNO C121-New Project/0. STAAD CALCULATIONS/8. BEAM/BEAM-SLAB - AnlNoel GragedaNo ratings yet

- Monday, August 19, 2019, 01:29 AM: Page 1 of 9 C:/Users/ECO CIVIL/Desktop/FINAL/SBR CHK/3.Actuator Frame - AnlDocument9 pagesMonday, August 19, 2019, 01:29 AM: Page 1 of 9 C:/Users/ECO CIVIL/Desktop/FINAL/SBR CHK/3.Actuator Frame - Anlepe civil0% (1)

- Lexmark T 520 Summit WebDocument10 pagesLexmark T 520 Summit WebservicerNo ratings yet

- Daihatsu Sirion Model m300 Series Service Manual No9890 Windshield WindowglassmirrorDocument32 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 Windshield WindowglassmirrorMarx RedzNo ratings yet

- JVC Mini Note Mp-Xv941de 841de 841gb 841gbex 841usDocument17 pagesJVC Mini Note Mp-Xv941de 841de 841gb 841gbex 841usSoporte Tecnico Buenos AiresNo ratings yet

- Ignition Cables and Igniter Installation PDFDocument6 pagesIgnition Cables and Igniter Installation PDFMark Evan SalutinNo ratings yet

- Poly FIber BR-8600 Blush RetarderDocument2 pagesPoly FIber BR-8600 Blush RetarderMark Evan SalutinNo ratings yet

- Ignition System - Inspection Check PDFDocument4 pagesIgnition System - Inspection Check PDFMark Evan SalutinNo ratings yet

- Ignition System - Inspection Check PDFDocument4 pagesIgnition System - Inspection Check PDFMark Evan SalutinNo ratings yet

- High Low Tension Ignition Comparison PDFDocument4 pagesHigh Low Tension Ignition Comparison PDFMark Evan SalutinNo ratings yet

- Agard 406351 Ground Effect MachinesDocument169 pagesAgard 406351 Ground Effect MachinesMark Evan SalutinNo ratings yet

- Material Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet For Odorized Propane: 1. Chemical Product and Company IdentificationShemi KannurNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingDocument10 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and of The Company/UndertakingMark Evan SalutinNo ratings yet

- Poly Fiber Reducer R65-75Document2 pagesPoly Fiber Reducer R65-75Mark Evan SalutinNo ratings yet

- Poly Fiber Poly-SprayDocument2 pagesPoly Fiber Poly-SprayMark Evan SalutinNo ratings yet

- Power CleanDocument2 pagesPower CleanMark Evan SalutinNo ratings yet

- Aluminum Flux PasteDocument10 pagesAluminum Flux PasteMark Evan SalutinNo ratings yet

- Sting-X II, Aerosol Certified LabsDocument4 pagesSting-X II, Aerosol Certified LabsMark Evan SalutinNo ratings yet

- Sonnen Honing OilDocument5 pagesSonnen Honing OilMark Evan SalutinNo ratings yet

- Spotcheck Reg Cleaner Remover SKC-HFDocument3 pagesSpotcheck Reg Cleaner Remover SKC-HFMark Evan SalutinNo ratings yet

- Poly Fiber Poly-SprayDocument2 pagesPoly Fiber Poly-SprayMark Evan SalutinNo ratings yet

- Soldering Flux PasteDocument9 pagesSoldering Flux PasteMark Evan SalutinNo ratings yet

- Silver Brazing FluxDocument9 pagesSilver Brazing FluxMark Evan SalutinNo ratings yet

- Blue Chalk-Standard MsdsDocument4 pagesBlue Chalk-Standard MsdsMark Evan SalutinNo ratings yet

- 1201 Alodine, AKA DX 503Document7 pages1201 Alodine, AKA DX 503Mark Evan SalutinNo ratings yet

- Msds For KeroseneDocument6 pagesMsds For KeroseneMahadeva PrasadNo ratings yet