Professional Documents

Culture Documents

Aug. 23, 1949. J. 5. Barth I 2,479,550 : Temporary Erection Framing

Uploaded by

pcorreia68Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aug. 23, 1949. J. 5. Barth I 2,479,550 : Temporary Erection Framing

Uploaded by

pcorreia68Copyright:

Available Formats

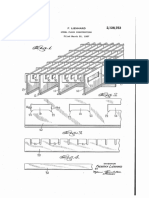

Aug. 23, 1949.

>Filed4Feb; v, 1946 r

J. 5. BARTH

TEMPORARY ERECTION FRAMING

I

v

2,479,550

z Sheets-Sheet 1

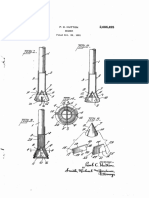

> Aug. 23, ~1949.

J. 5. BARTH ,

2,479,550

TEMPORARY ERECTI~ON FRAMING

Filed Feb. 7,1946 _ ' 2 Sheets-Shet 2

?ag @

I;

II

|

__<______________=;===r:========1============:=:-1====:===1

/5

Patented Aug. 23,_ 1949

2,479,550

UNITED STATES _ v PATENT OFFICE

I . rnnaronaar'zriizzzitsrionrnmme

JamescS. Barth, Chicago, Ill., assignor to Chicago

Bridge 8; Iron Company, "a corporation of Illi

nois .

Application February 7, 1946,,.Serial No. 646,172

52 "Claims. (Cl. Ibalk-354i)

This invention relates to a temporary erection framing to be used for supporting objects pre paratory to assembling said objects. Erection framing'is often necessary in construction work to'suppor't the component parts of objects while

The invention will be described as related to

the embodiment set out in the accompanying

drawings. of the drawings Fig. 1is a fragmen tary plan View of the shell of the ?oating roof tank with the temporary erection framing in place for assembling a floating roof; Fig. 2 is a they are being assembled. One of the places in vertical section taken alongvline 2-2 of Fig. 1; which such erection framing may be used is in Fig. 3 is a vertical section taken along line '3-3 of the assembling of floating roofs to be used in Fig. 2; Fig. 4 is a vertical section taken along line ?oating roof tanks. It has formerlybeen the practice to erectthe shell of the tank and then 10 4-4 of Fig. 1; Fig. 5 is a front elevation of one of the pedestals and pipe members; Fig. 6 is a assemble the roof within the shell on framing side elevation of said pedestal and pipe member; resting on the ?oor of the tank. This Iramingwas Fig. *7 is a plan view of said pedestal and pipe formerly composed of ordinary wooden beams. member; Fig. 8 is a vertical section showingca Such aprocedurahowever, has the disadvantage of being expensive, asit took a lot of time to 1:5 portion ofthe shell of a floating roof tank with a stirrup attachedthereito; and Fig. 9 is a vertical place the beams properly and then to remove section taken along line 9--9 of Fig. '8. them aiterxtherooi had been assembled. Eaohunit of the temporary erection framing In order to enable workment to build ?oating comprises a pedestal Ill, an upwardly extending roofs and other structures more quickly and with less trouble, it was necessary that some other type 20 pipe member H, and an upwardly extending U-shaped member l2 mounted on the top por of temporary erection framing be used. The tion of the pipe member I I. prsent framinghas the advantage of being'easy Each-pedestal III "has the shape of an equi to assemble, taking up very little space, and being lateral triangle with pipe sections I3 at each apex readily disassembled. The new temporary erec tion framing is made up of several pieces of equip 25 of the triangle and with pieces of angle iron I4 connecting the pipe sections I3 to form the equi ment that are light in weight and not bulky. By lateral triangle. All pipe sections are substan the use of the new erection framing much time tially aligned with the center of the triangle and and labor can be saved, and a better job can be bisect the angles formed by the sides of the tri done. The framing can be used over and over again, and can be easily transported from one 30 angle. The pipe member II has an outer diameter job to another. Since using this temporary erec smaller than the inner diameter of the pipe sec tion framing the jobs have been completed faster tions I3. The pipe member may be held within and with less difficulty and less expense. any pipe section I3 with the opposite side Ma of The new erection framing comprises individual the triangle serving as the base of the pedestal. pieces of equipment, with each piece comprising

a pedestal; an adjustable, substantially vertical post member to be held by said pedestal; a sup port for a removable base member, such as a wooden beam; and means for locking said post member on the pedestal to maintain the support 40 at a desired elevation. In a preferred embodi

The pipe member II may be held at any desired elevation and a nut I5 may then be welded to the

pipe member II just above the topmost pipe sec tion I3. This nut prevents the pipe member from sliding further within the pipe section.

The U-shaped member I2 which serves as a

fork has a hole in its bottom plate through which ment the pedestal comprises a substantially equi the pipe member II extends with the member lateral triangle having sections of pipe at each welded to the U-shaped member. Wooden beams apex thereof with all the pipes substantially aligned with the center of the triangle. The pipe 45 I5 may be held in place on either or both sides of the top of the pipe member II, and may be -member may be held within any pipe section to fastened by nails II driven through holes I8 pro extend upwardly, and the opposite side of the triangle will then serve as the base of the pedestal. The pipe member may be locked at a desired

vided in the sides of the U-shaped member. It is preferred that the nails be not driven all the way height by any means desired. The top end of 50 in so that they can be easily withdrawn (Fig. 5). The bottom portion of the U-shaped member I2 is the pipe member will hold an upwardly extend

ing forked member with the pipe member extend

ing through the base of the fork so that base members may be held within the fork on either

preferably provided with upwardly extending

sharp points I9 which may be formed by punch

ing a hole through the base with a square punch. 55 These points help anchor the wooden beams I6.

side of the pipe member.

2,479,550

one embodiment of the same, it is my intention that the invention be not limited by the details

When using such temporary erection framing

for erecting ?oating roofs the shell 20 and bottom

2| of the tank are assembled. Stirrups 22 are Welded to the shell 20 at a desired elevation to hold the outer ends of substantially radial beams I6. These stirrups have ?at bottoms 23 and up

of description unless otherwise speci?ed, but rather be construed broadly within its spirit and

scope as set out in the accompanying claims.

I claim: wardly extending side portions 24 and 25. One of 1. Temporary erection framing comprising: a the side portions 24 is higher than the other side pedestal, an adjustable substantially vertical pipe portion, 25. The high portion has an edge slop member to be held by said pedestal, a support for ing toward the shell, While the other side portion 10 a removable beam member mounted on said pipe 25 has an edge sloping away from the shell. The member, said support including an upwardly-ex shorter side portion 25 is provided with a hole 26, tending forked member attached to the pipe through which a nail may be driven to hold its member with said pipe member extending

' through and beyond the base of the forked mem The pedestals l0 and the pipe members II are 15 ber whereby beam members may be held within then placed at their proper locations, and the the fork on either side of and spaced by the pipe pipe members adjusted to the desired height. As member, and means for locking said pipe mem pointed out the pipe members are held at their ber on the pedestal to maintain said support at desired elevation by welding nuts IS on each pipe a desired elevation. member. The wooden beams l6 are then placed 20 2. Temporary erection framing comprising: a in the U-shaped members l2 and nailed in place. pedestal having the shape of a substantially equi A typical assembly showing one arrangement of lateral triangle, a pipe at each apex of the tri the temporary erection framing is shown in Fig. angle, said pipes being in the plane of the tri 1. Any other arrangement may of course be angle and being substantially aligned with the used, depending upon the particular structure to 25 center of the triangle, an adjustable substantial wooden beam I6.

be assembled.

As the pedestals H] are substan

tially planar and stand on edge, adjacent ped

estals for any beam I6 may be turned at right angles to each other in order to give the struc

ture stability. _

ly vertical pipe member insertable through any of said pipes, the side of the triangle opposite the

apex at which the pipe member is inserted serv ing as a base for the pedestal, a support for a re

simple. The framing may then be transported to another job and used over and over again.

movable beam member mounted on the pipe After the ?oating roof or other structure has 30 member and means for locking said pipe member been assembled the pedestals l0, pipe members on the pedestal to maintain saidsupport at a ll, wooden beams t8, and stirrups '22 are re desired elevation. , moved. As each portion of the framing is rela JAMES S. BARTH. _ tively small the disassembling of the framing is 35

REFERENCES CITED

The following references are of record in the ?le of this patent:

Any apex of each pedestal it may be used to hold a pipe member I I so that if one pipe section 13 is damaged the pedestal is not ruined, but can be used with either of the other two pipe sections to

hold the pipe member. '

40

Number

UNITED STATES PATENTS

Name . Date

Having disclosed my invention as related to

1,685,445

Bash ____________ __ Sept. 25, 1928

You might also like

- Bailey Bridge PDFDocument373 pagesBailey Bridge PDFdunglxNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- US1685447Document5 pagesUS1685447Redirecting DecoyNo ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDocument7 pagesNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaNo ratings yet

- Metal Turning LatheDocument12 pagesMetal Turning LatheEugen50% (2)

- U.S. Patent 652,520, Entitled Capotasto To Inventor T.M. Pletcher, Dated June 26, 1900.Document3 pagesU.S. Patent 652,520, Entitled Capotasto To Inventor T.M. Pletcher, Dated June 26, 1900.Anonymous a7S1qyXNo ratings yet

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgeNo ratings yet

- BYY "So: June 7, 1966 M, A Brown 3,254,776Document7 pagesBYY "So: June 7, 1966 M, A Brown 3,254,776Yu YangNo ratings yet

- US898276Document5 pagesUS898276Jacob LukaNo ratings yet

- (Diy) - Metalworking - Model Engineer Aug53' - Surface Grinding & Milling MachineDocument6 pages(Diy) - Metalworking - Model Engineer Aug53' - Surface Grinding & Milling MachineFernanda Duarte100% (4)

- Simple Mini Tube Bender InstructionsDocument4 pagesSimple Mini Tube Bender InstructionsMartin OngNo ratings yet

- May 21, 1946-B. C. Stevenson 2,400,852Document5 pagesMay 21, 1946-B. C. Stevenson 2,400,852kkd108No ratings yet

- Us 993244Document3 pagesUs 993244Ye PhoneNo ratings yet

- Hamilton Rifle ConstructionDocument5 pagesHamilton Rifle Constructionposchul2003No ratings yet

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- Foot-Powered Scroll SawDocument8 pagesFoot-Powered Scroll SawJan Steinman100% (1)

- A Single ShontgunDocument3 pagesA Single ShontgunyuehanNo ratings yet

- Dec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LDocument5 pagesDec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LcheesewizzNo ratings yet

- Bailey Bridges Fm5 277Document373 pagesBailey Bridges Fm5 277jmcc2No ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- No. 792,843, PATENTED JUNE 20, 1905, Galwanometer.: E, F, NorthrupDocument6 pagesNo. 792,843, PATENTED JUNE 20, 1905, Galwanometer.: E, F, Northrupmohamed hemdanNo ratings yet

- @et E7, 96? J. P. Yates: Filed March l2, 1965Document3 pages@et E7, 96? J. P. Yates: Filed March l2, 1965Ye PhoneNo ratings yet

- April 27, 1948. E. A. Bender 2,440,427: Filed Jan. 12, 1945 2 Sheets-SheetDocument6 pagesApril 27, 1948. E. A. Bender 2,440,427: Filed Jan. 12, 1945 2 Sheets-SheetAbu SayedNo ratings yet

- Tài liệu5Document12 pagesTài liệu5Hoàng ĐứcNo ratings yet

- Arts5.: in RunDocument4 pagesArts5.: in RunMuzammil AmirNo ratings yet

- Description: (OCR Text May Contain Errors)Document6 pagesDescription: (OCR Text May Contain Errors)geeNo ratings yet

- John /AL/QQ: Filed May 19, 71922 4 Sheets-Sheet 1Document9 pagesJohn /AL/QQ: Filed May 19, 71922 4 Sheets-Sheet 1sukanta60No ratings yet

- 2,418,540 April 8, 1947.: R. E. BresslerDocument5 pages2,418,540 April 8, 1947.: R. E. Bresslerricva_rjNo ratings yet

- MACHINING RIFLE BARRELSDocument64 pagesMACHINING RIFLE BARRELSj miller100% (2)

- Method for constructing and assembling a multiple valve unitDocument4 pagesMethod for constructing and assembling a multiple valve unitscibduser001No ratings yet

- This Home-Made 3-1/2in. Lathe Has Novel Features: George B. RoundDocument3 pagesThis Home-Made 3-1/2in. Lathe Has Novel Features: George B. Roundwienslaw5804No ratings yet

- Lathe Cross-Sli Olders.: " DuplexDocument3 pagesLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- Nitttttttt-Iii: June 12, 1951Document3 pagesNitttttttt-Iii: June 12, 1951Erin GokNo ratings yet

- F. Hennebioue.: No. 6,907. Construction of Joists, Girders, and The LikeDocument3 pagesF. Hennebioue.: No. 6,907. Construction of Joists, Girders, and The LikeguillermoNo ratings yet

- Mini Dobrador de Tubos DIYDocument4 pagesMini Dobrador de Tubos DIYw4rh4ck3r-scribdNo ratings yet

- Ryan v. Hard, 145 U.S. 241 (1892)Document5 pagesRyan v. Hard, 145 U.S. 241 (1892)Scribd Government DocsNo ratings yet

- Till 2-t "It: Aug. 30, 1938. F. Lienhard 2,128,753 Filed March 20, 1937Document4 pagesTill 2-t "It: Aug. 30, 1938. F. Lienhard 2,128,753 Filed March 20, 1937MariaPaulaSávioNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- Full download book Microeconomics 3 pdfDocument22 pagesFull download book Microeconomics 3 pdfdanny.broad150100% (12)

- US49409Document6 pagesUS49409ReggieNo ratings yet

- Neral Capítulo.9 PDFDocument24 pagesNeral Capítulo.9 PDFtrinoNo ratings yet

- Full Download Ebook PDF Issues and Ethics in The Helping Professions Updated With 2014 Aca Codes 9Th Edition Ebook PDF Docx Kindle Full ChapterDocument23 pagesFull Download Ebook PDF Issues and Ethics in The Helping Professions Updated With 2014 Aca Codes 9Th Edition Ebook PDF Docx Kindle Full Chapterpaul.shropshire768100% (31)

- Guide elevators and counterweights with adjustable tracksDocument3 pagesGuide elevators and counterweights with adjustable tracksGino CastroNo ratings yet

- Control of Ovality in Pipe Bending-A New ApproachDocument5 pagesControl of Ovality in Pipe Bending-A New ApproachJuan AlmeidaNo ratings yet

- US2427676Document4 pagesUS2427676udrogono2No ratings yet

- Cloth Tow Target Sleeve (1935)Document6 pagesCloth Tow Target Sleeve (1935)CAP History LibraryNo ratings yet

- Torrent Arms Lumber Co. v. Rodgers, 112 U.S. 659 (1885)Document7 pagesTorrent Arms Lumber Co. v. Rodgers, 112 U.S. 659 (1885)Scribd Government DocsNo ratings yet

- Berthier Us1446635Document12 pagesBerthier Us1446635cll19680% (1)

- Dénventor - L: 971,733. Patented Oct. 4,, MMDocument4 pagesDénventor - L: 971,733. Patented Oct. 4,, MMpouyaNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- Sample Resumes and Cover Letters Technical MajorsDocument53 pagesSample Resumes and Cover Letters Technical MajorsDeepak SinhaNo ratings yet

- API 650 Welded Steel Tanks For Oil Storage - 2003, de MikeDocument280 pagesAPI 650 Welded Steel Tanks For Oil Storage - 2003, de MikeMichael CastilloNo ratings yet

- Process Plant Piping OverviewDocument133 pagesProcess Plant Piping Overviewskdalalsin100% (8)

- Process Plant Piping OverviewDocument133 pagesProcess Plant Piping Overviewskdalalsin100% (8)

- Aço Sa 537 cl1Document23 pagesAço Sa 537 cl1pcorreia68100% (1)

- S 355 JRDocument4 pagesS 355 JRpcorreia68No ratings yet