Professional Documents

Culture Documents

Scafold Check List

Scafold Check List

Uploaded by

ashokkumar_subrama_2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scafold Check List

Scafold Check List

Uploaded by

ashokkumar_subrama_2Copyright:

Available Formats

Checklist for Lift Planning

Planners and reviewers use this checklist to confirm completeness of the lift plan. These items are included as a guide but should not be interpreted as being all-inclusive in the analysis and preparation of a Critical or Preengineered Lift. Sound engineering and planning is still the responsibility of the engineer or project manager associated with the lift. Never vary from the approved Lift Plan without a full review and approval by the Lifting Safety Committee. Subsurface and Foundation Issues hat are the ma!imum loads imposed by the cranes on the soil"facility floor# $s the soil-bearing capacity ade%uate to safely support crane loads# &as a soil investigation program been performed# hat is the assumed load distribution through the timber mats# &as a soil investigation of the area under the path of the tailing crane 'borings( etc.) been performed# hat pressures will be imposed on any underground structures 'sewer lines( etc.)# ransportation and Interim Storage Issues &as the responsible manager and the Safeguards * Security +ivision been notified of movement of the load to the lifting site 'notification at the discretion of the responsible planner)# ,re any permits re%uired# &as load securement been discussed# &as the load transport route to the lift site been checked for overhead obstructions# ,re there any bridges( culverts( pipe ways to cross# ,re they structurally capable of safely supporting the transport loads# here will the crane be assembled# hat route will the crane take from the assembly site to the lift site# &ow will the load transport get to the lift site# &ow will the transport be removed once the load is lifted# Crane Issues hat is the minimum actual clearance between the load and the boom during the lift# &as the radius been double-checked by measuring in the field# ill the crane load change as the lift progresses# &ow many parts of line are needed# &ow was this determined# ill spreaders and other rigging hardware remain safely clear of the boom( the load( and other objects at all times during the lifting operation# $f a tailing crane has to -walk(. is the path level properly compacted# hat efforts have been made to identify obstructions in the lift path and swing path# &ow accurate are these efforts# Can the outriggers be deployed as per manufacturer/s load chart re%uirements# Can rigging personnel safely control and manipulate the load throughout the lifting path# ,re the crane/s operational safety alarms functioning properly# &ow( when( and were they tested# &ave plans been developed to monitor the crane/s stability during lift# &as a procedure been developed to monitor plumbness of load lines 'in two directions)#

0.1"0b10e122.doc

'13"4115)

&as a drawing showing the elevation of the crane during the lift as well as all clearances been developed 'boom to load( and load to other obstructions)# &ave all repairs or modifications to the crane been made in accordance with manufacturer/s written instructions( and are they so certified# &ow will the crane/s electronic safety alarms and interlocks be checked for operation and accuracy# &as the agreed nondestructive e!amination '6+7) of crane components been done and documented# $s the lift line new or has a piece of the lift line been pull-tested# &as a procedure to monitor tail swing of the crane during lifting operations been developed# $s the correct crane load chart for current lift conditions in the cab# $s there ade%uate headroom to ensure that the manufacturer/s minimum allowable two-block distance is maintained for the configuration of the reeve used#

Load !eight " C# Issues &ow was the weight determined when developing the lift plan# &as any margin been added to calculated weights# &as an accurate load weight determination been made before the lift to confirm calculated weight# &ow was this performed# &as the weight of any jibs( au!iliary boom heads( etc. been considered in the calculations# &as all the rigging hardware been included in the weight calculations# ho has determined the center of gravity# &ow was it determined# $s it marked on the load# $s it shown on the lift plan drawings# $s there anything inside the load that could shift during the lift# &as snow or ice accumulated on the load since the weight was determined# $s the surface area large enough to create unusual control problems in the wind# &as all hydrotest water been drained from the load 'vessel) before lifting# $f lifting a dressed device( has the insulation absorbed any water# $f lift is of an e!isting item 'being removed or demolished)( have all anchor bolts and fasteners been removed# $igging Issues &as all rigging hardware been selected to work within the manufacturer/s Safe orking Load# &ave sling angles flatter than 85 degrees been avoided( and have the slings or chains and shackles been chosen to allow for increased loads due to sling angles# &ave softeners been used to protect the rigging where sharp corners could cause damage# +oes the rigging provide positive control of the load to prevent slipping or shifting# ,re shackles and hooks always used in such a manner as to avoid side bending in the hardware# &ave %ualified personnel designed and tested special rigging hardware in accordance with regulations# $s there a plan for removing lifting tackle from the load after it is erected# &ow will the shackle pins be removed after the lift is complete# ill a pin e!tractor be re%uired( and if so( manual or hydraulic# hat level of inspection have the shackles( hooks( slings( etc. been subjected to# ill a pull-test be conducted on the slings# ,re the shackle pins and lifting eyes compatibly si9ed#

0.1"0b10e122.doc 4 '13"4115)

&ow will side loading"bending of shackles and hooks be avoided# &ave all rigging components such as shackles( hooks( and slings( been inspected for signs of damage or deterioration before use# $s the rigging arranged to have the crane hook directly over the load/s center of gravity with the load hanging level#

$oles " $esponsibility Issues ho is the Person-$n-Charge 'P$C) of the lift# hat are their %ualifications# ho will give the signals to the operator# &as the +epartment"+ivision Safety Committee been involved in the lift planning process or lift plan review# &as the Laboratory Lifting Safety Committee been involved in the lift planning process or lift plan review# &as the lift plan been reviewed with the crane operator( riggers( and others involved in the lifting operation# &as the plan been reviewed with supervisors and workers in adjacent areas# &as a chain of command to operate during the lift been established( and how are the involved people identified# &as a final pre-lift safety meeting been scheduled# ,re there any language difficulties# +oes everyone speak 'fluently) the same language# %perational &nvelope Issues hat are the limits on wind speed for making the lift# &ow and where will wind speed be measured# $s cold weather likely to affect the lift# $s it necessary to derate the crane or any part of the rigging e%uipment due to low temperatures# $s ade%uate lighting e%uipment available for use( if the lifting operation should e!tend beyond normal daylight hours# ,re re%uired personnel 'operations( safety( other) available if the lift operation should e!tend beyond normal hours# ,re there overhead power lines in the operating area# $f so( have minimum clearance re%uirements been established and has a dedicated signal person been assigned to monitor boom( load and"or load line position relative to the power line# $f operating near overhead power lines( are nonconductive taglines being used#

0.1"0b10e122.doc

'13"4115)

&mergency Procedural Issues &ave emergency procedures been determined and communicated to all personnel involved in the lifting operation# $f re%uired( has confirmation of notification to adjacent +epartments"+ivisions and local Security and :ire ;escue been received# &as agreement been established on re%uired actions if operational alarms occur during the lift# &as a review of operational activities planned"occurring during time of lift been performed# &as a review"agreement of safety " barricade"evacuation plans been done# &as a review"agreement of contingency plans in event of a site alarm or operational upset during lift been made# &ave emergency plans been developed by( communicated to( and understood by operating personnel# ,re the operating personnel clear regarding isolation of lines containing to!ic or flammable materials# &ow are the valves identified# +oes the lift plan reflect the philosophy that safety is the top priority#

Load 'esign Follow(up Issues $s the load fragile enough to re%uire lifting from a -strong back. frame or from multiple attachment points to prevent load damage# &as the -strong back. frame been designed by a competent engineer( inspected( and load-tested# &as any re%uired nondestructive testing been done to assess the %uality of welds attaching lifting lugs( pad eyes( trunnions( etc.# &as anyone checked that the shackle pins will fit the holes provided in the lifting lugs# ,re the dimensions of the lifting lugs"pad eyes consistent with the si9e of shackle proposed# ill the shackle be able to -turn. as the load goes from hori9ontal to vertical# &ave the appropriate impact factors been used in designing the lifting lugs( shackles( etc.# $s there enough clearance between the load and the lifting lug"pad eye to get the nut on the shackle pin# hat are the inspection re%uirements for the lifting attachments 'lugs"pad eyes)# ho will do it# &as the load 'tower) design been analy9ed for locali9ed buckling and bending shear stress during the lift operation in order to verify that allowables will not be exceeded during the lift? $f trays or internals are to be installed before lifting( has the possibility of load shift been considered# ,re all engineered lifting components 'spreader bars( lift lugs( etc.) designed to ,S<7 =01.41( =elowthe-&ook Lifting +evices# 'Show calculations). ,re the lifting lugs designed about the weak a!is using a force e%ual to a minimum of 5> of the force of the sling# 'Show calculations). ho has designed the lifting lugs"trunnions# &as design been checked by Safety and &ealth Services# Peripheral Issues ,re radios re%uired# ho will provide them# ,re they safe for use in operating facilities# &as a review"agreement of communications plan during lift 'i.e.( dedicated radio channels) been made# &as the anchor bolt pattern( if re%uired( been checked to confirm the load can be landed properly# ill critical spare parts be available for the crane's) during the lift# ,re mechanics available# &as a drawing showing the barricade plan to be used during the lift been developed# &as the operator's) undergone a drug test#

0.1"0b10e122.doc

'13"4115)

$s a back-up operator available in case of emergency# ,re crane maintenance personnel available during the lift#

0.1"0b10e122.doc

'13"4115)

You might also like

- Sample Lifting Plan and Rigging StudyDocument13 pagesSample Lifting Plan and Rigging StudyKhawaja Arslan Ahmed87% (15)

- PGBM141 Professional Management and Leadership DevelopmentDocument4 pagesPGBM141 Professional Management and Leadership DevelopmentyiranNo ratings yet

- Isolation Work Instruction TemplateDocument5 pagesIsolation Work Instruction TemplateppnNo ratings yet

- Green Building Material LeedDocument4 pagesGreen Building Material Leeddep_vinNo ratings yet

- List of Activities For A Green Field Project A. Site DevelopmentDocument2 pagesList of Activities For A Green Field Project A. Site Developmentarajamani78No ratings yet

- Factories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulations, 1970 Ve - Pua5 - 1970Document46 pagesFactories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulations, 1970 Ve - Pua5 - 1970Exsan OthmanNo ratings yet

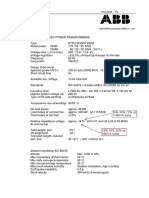

- ABB 3wdg TRAFO Data SheetDocument2 pagesABB 3wdg TRAFO Data SheetKunik SwaroopNo ratings yet

- Trench Rescue Technician 2021 Cts GuideDocument48 pagesTrench Rescue Technician 2021 Cts GuideCarlos AmaroNo ratings yet

- Adams Township Audit ReportDocument35 pagesAdams Township Audit ReportGere GobleNo ratings yet

- 70b f2022 Eem Aaa PcsubmittalsDocument1,788 pages70b f2022 Eem Aaa PcsubmittalsLuiz Gouveia0% (1)

- PSU Energized Electrical Safety ProgramDocument30 pagesPSU Energized Electrical Safety ProgramLeo Boy Veloria CasugoNo ratings yet

- Paint Booth GuidelinesDocument2 pagesPaint Booth GuidelinesbinayperiwalNo ratings yet

- Checklist1101 - Structural Steelwork - Fabrication - UnlockedDocument2 pagesChecklist1101 - Structural Steelwork - Fabrication - UnlockedsouravrobinNo ratings yet

- Saes T 744 PDFDocument4 pagesSaes T 744 PDFabdullah sahibNo ratings yet

- ILD LDC RL Industrial Mechanics Millwright 10L 20L 30LDocument53 pagesILD LDC RL Industrial Mechanics Millwright 10L 20L 30LVolodymyr Herasymiuk100% (1)

- HDPE FittingsFeb2013Document117 pagesHDPE FittingsFeb2013Felicia Glass100% (1)

- b4310 Boysen PrimeguardDocument7 pagesb4310 Boysen Primeguarddep_vin100% (1)

- Sample Method StatementDocument13 pagesSample Method StatementHasif MohammedNo ratings yet

- SSSS RequirementDocument15 pagesSSSS RequirementWanping TangNo ratings yet

- Septic Tank Installation - Regular SoilDocument2 pagesSeptic Tank Installation - Regular SoilKelly MartinNo ratings yet

- Vehicle Inspection ManualDocument50 pagesVehicle Inspection ManualA.t. BelagamaNo ratings yet

- 420 HSB Recommended Practice For Electrical Preventive MaintenanceDocument13 pages420 HSB Recommended Practice For Electrical Preventive MaintenanceAris CahyonoNo ratings yet

- Crane Rail AlignmentDocument13 pagesCrane Rail AlignmentsamyukthaiNo ratings yet

- Managing RisksDocument42 pagesManaging RisksmafroewNo ratings yet

- Failure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresDocument10 pagesFailure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresGECJNo ratings yet

- V-0226025110-0044 Paint Matrix - Reviewed Without Comments - Rev.4Document7 pagesV-0226025110-0044 Paint Matrix - Reviewed Without Comments - Rev.4Thanh Hoàng Gia100% (1)

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocument7 pagesLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- Electrical SafetyDocument10 pagesElectrical SafetyUrsula JohnsonNo ratings yet

- Resume of Ronaldo Romero - Project EngineerDocument11 pagesResume of Ronaldo Romero - Project EngineerOchie RomeroNo ratings yet

- Gantrail Welded Base Fixing: SpecificationsDocument2 pagesGantrail Welded Base Fixing: Specificationsaandueza_1No ratings yet

- Release For Shipment and Installation Note: HEX-V6109 16-200-001 3Document7 pagesRelease For Shipment and Installation Note: HEX-V6109 16-200-001 3Mohd AshrafNo ratings yet

- Edited - Flange Joint Assembly ChecklistDocument2 pagesEdited - Flange Joint Assembly ChecklistvivekkumarenzoNo ratings yet

- WeldingDocument73 pagesWeldingTeodor EzaruNo ratings yet

- Harmony VA1Document5 pagesHarmony VA1TSHEGOMOTEBELE0% (2)

- Installation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008Document14 pagesInstallation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008j_herndz100% (1)

- Punch List: Guy Wire Support Flare Stack System Piping DetailDocument1 pagePunch List: Guy Wire Support Flare Stack System Piping DetailMuhammad SaifNo ratings yet

- Corrosion Control InspectionDocument6 pagesCorrosion Control InspectionAutumn SimonNo ratings yet

- Cca A Overhead Crane ChecklistDocument3 pagesCca A Overhead Crane ChecklistAlejandro CarosiNo ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- General Inspection Test PlanDocument7 pagesGeneral Inspection Test PlanAnonymous yypq4pNo ratings yet

- Is 3832 2005 PDFDocument18 pagesIs 3832 2005 PDFSachin5586No ratings yet

- Tabla HDPE-Pipe PDFDocument4 pagesTabla HDPE-Pipe PDFBerinssonScottHernandezSucsoNo ratings yet

- Common Causes of Bolted Joint LeakageDocument2 pagesCommon Causes of Bolted Joint LeakageAnonymous avGU1iNo ratings yet

- 5.21.1 - Electrical Work PermitsDocument17 pages5.21.1 - Electrical Work PermitsMubasser Iqbal100% (1)

- MOS For Roof Water Tank InstallatinDocument2 pagesMOS For Roof Water Tank InstallatinpulangratzNo ratings yet

- Method of Statement-SamsungDocument7 pagesMethod of Statement-Samsunggururaj100% (1)

- Installation of Monorail CraneDocument28 pagesInstallation of Monorail CraneVijay Bhushan EkkaNo ratings yet

- SWPP ListDocument18 pagesSWPP ListAnonymous hNpF6I0% (1)

- Tks RP Retrieval Tool: Installation, Operation & Maintenance InstructionsDocument30 pagesTks RP Retrieval Tool: Installation, Operation & Maintenance Instructionssaiful anwarNo ratings yet

- F - OPN - 05 R1 Assessment Form - Earthmoving EquipmentDocument1 pageF - OPN - 05 R1 Assessment Form - Earthmoving EquipmentJanaoo. comNo ratings yet

- Electrofusion WeldingDocument11 pagesElectrofusion WeldingZuberYousufNo ratings yet

- Risks in Facility Build Quality and Project Handover: What Happened?Document3 pagesRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863No ratings yet

- Trench Excavation OSHA Fact SheetDocument2 pagesTrench Excavation OSHA Fact SheetandinumailNo ratings yet

- WSH (Work at Heights) Regulations 2013Document22 pagesWSH (Work at Heights) Regulations 201388sanNo ratings yet

- RZEIN - Lessons Learned in Engineering Development in Major Projects PDFDocument25 pagesRZEIN - Lessons Learned in Engineering Development in Major Projects PDFhussnainreflect100% (1)

- 33 PACS Quick Build PanelsDocument44 pages33 PACS Quick Build PanelsOrianNo ratings yet

- User'S Manual: MANUAL NO - GL240-UM-153Document150 pagesUser'S Manual: MANUAL NO - GL240-UM-153Ta100% (1)

- 07 - Lifting Handbook - Risk Assessment and Lift PlanDocument10 pages07 - Lifting Handbook - Risk Assessment and Lift PlanMithun RavalnathkarNo ratings yet

- MAM-HSE-INS 149 IS BHP Accident in Lifting Operations DESDE 01jan21Document2 pagesMAM-HSE-INS 149 IS BHP Accident in Lifting Operations DESDE 01jan21Pablo Painen GonzalezNo ratings yet

- Course Material For Rigger-Latest - Final CHVR 2010Document138 pagesCourse Material For Rigger-Latest - Final CHVR 2010Tarek Ahmed100% (1)

- Cranes Hoists Truck CranesDocument26 pagesCranes Hoists Truck Cranesrajesh_jeev100% (1)

- Bo QDocument9 pagesBo QAdnan Ali ChaudhryNo ratings yet

- Crack WidthDocument7 pagesCrack WidthAdnan Ali ChaudhryNo ratings yet

- Ground ImprovementDocument40 pagesGround ImprovementAdnan Ali ChaudhryNo ratings yet

- 1175 ItpDocument2 pages1175 ItpAdnan Ali ChaudhryNo ratings yet

- Callibration CertsDocument6 pagesCallibration CertsAdnan Ali ChaudhryNo ratings yet

- ADM Manual July08Document64 pagesADM Manual July08Adnan Ali Chaudhry60% (5)

- Biometric Authentication - Person Identification Using Iris RecognitionDocument5 pagesBiometric Authentication - Person Identification Using Iris RecognitionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chemistry For Dummies-71-82Document12 pagesChemistry For Dummies-71-82Rahmi maydayeniNo ratings yet

- Code of Ethics of The Medical TechnologistDocument2 pagesCode of Ethics of The Medical TechnologistDan Christian Blance100% (1)

- Maxtreat SC250: Product Information Boiler TreatmentDocument2 pagesMaxtreat SC250: Product Information Boiler TreatmentYlm PtanaNo ratings yet

- Deep Gas Well Completion Practices: H. E. Lindsey, JR., Member AIME, MWL Tool and Supply CoDocument13 pagesDeep Gas Well Completion Practices: H. E. Lindsey, JR., Member AIME, MWL Tool and Supply Cosabilco13No ratings yet

- Numerical Solution To The Van Der Pol Equation With Fractional DampingDocument5 pagesNumerical Solution To The Van Der Pol Equation With Fractional DampingLakshmi BarathiNo ratings yet

- SAD WireframeDocument1 pageSAD WireframeRhene LlonaNo ratings yet

- Lab - Unit 5 - It Act 2000Document15 pagesLab - Unit 5 - It Act 2000Disha MohantyNo ratings yet

- Grade 3 Fraction Word Problems A3Document3 pagesGrade 3 Fraction Word Problems A3fafa nuraNo ratings yet

- McWilliams Center For Counseling, Inc. Community Support Office - 438Document2 pagesMcWilliams Center For Counseling, Inc. Community Support Office - 438James BennettNo ratings yet

- Understanding API ICP653 Reading 12-Worksheet-8Document290 pagesUnderstanding API ICP653 Reading 12-Worksheet-8Charlie Chong100% (1)

- PELSDenverSlides PDFDocument71 pagesPELSDenverSlides PDFFernando Sobrino-Manzanares MasNo ratings yet

- Workover and Analysis Well ProblemsDocument61 pagesWorkover and Analysis Well ProblemsTeddy GeovanieNo ratings yet

- Recipe Book: Classic Tinolang Manok RecipeDocument6 pagesRecipe Book: Classic Tinolang Manok RecipeCatherine MangloNo ratings yet

- Background of The Study ResosrtDocument6 pagesBackground of The Study Resosrtsphinkz28No ratings yet

- Wizard Magazine 009 (1992) (No Guide)Document93 pagesWizard Magazine 009 (1992) (No Guide)Teddy Ray Carian100% (2)

- Da Li Smo Krenuli KaDocument15 pagesDa Li Smo Krenuli KaFatima IbranovićNo ratings yet

- Portes Five AnalysisDocument7 pagesPortes Five AnalysisDotecho Jzo EyNo ratings yet

- English Final Exam-Music and FilmssDocument10 pagesEnglish Final Exam-Music and FilmssKhalis PrimaNo ratings yet

- Gender and Sexuality in Popular FictionDocument19 pagesGender and Sexuality in Popular FictionJacksonNo ratings yet

- JV Small WorldDocument74 pagesJV Small WorldPrem PanigrahiNo ratings yet

- Oracles RMCSDocument34 pagesOracles RMCSsharas77No ratings yet

- OMM - Marine Classification Society (MCS) Control PanelDocument9 pagesOMM - Marine Classification Society (MCS) Control Paneljordan navarroNo ratings yet

- $HKP25/C SET 1: SeriesDocument30 pages$HKP25/C SET 1: SeriesDEEPAK RATHORNo ratings yet

- Procedure For UtDocument12 pagesProcedure For UtMohammad SyeduzzamanNo ratings yet

- 2015 SALN FormDocument2 pages2015 SALN FormCHERRYMIE DIONSONNo ratings yet

- Hospice Documentation in The Hot Seat!: Laura Montalvo, BSN, RN, COS-C, HCS-D Chief Clinical OfficerDocument41 pagesHospice Documentation in The Hot Seat!: Laura Montalvo, BSN, RN, COS-C, HCS-D Chief Clinical OfficerAnonymous FXvNa8W100% (1)

- Cause and EffectDocument2 pagesCause and EffectJoyna GettruidaNo ratings yet