Professional Documents

Culture Documents

Pt. Alfa Valves Indonesia: Production General Process Flow Chart of Valves

Uploaded by

Zoebair0 ratings0% found this document useful (0 votes)

161 views0 pagesdddd

Original Title

General Flow Chart

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdddd

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

161 views0 pagesPt. Alfa Valves Indonesia: Production General Process Flow Chart of Valves

Uploaded by

Zoebairdddd

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

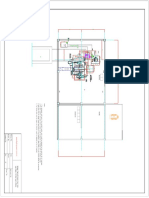

Page : 1 of 4

PT. ALFA VALVES I NDONESI A

JL. Mercedes No. 324, Wanaherang, Gunung Putri, Bogor - Indonesia

Phone : (62 - 21) 8686 0009 ; Fax : (62 - 21) 8686 0008

E-mail : alfavalve@cbn.net.id

PRODUCTION GENERAL PROCESS FLOW CHART of VALVES

Document No. : AVI-P-FC-000

0 Revision No. :

Prepared By : Tunggul H.P

S M h P j i A d B : S. Martahan Panjaitan Approved By

This document and it's content are property of PT. ALFA VALVES INDONESIA. Neither this document nor this its content may be

copied in a whole or in apart thereof or transferred to a third party or used in any other way detrimental to the interest of PT.

ALFA VALVES INDONESIA.

Notice

Issued Date : April 08, 2003

PROCESS

0 2 OF 4

DATE OF ISSUED

PAGE

8-Apr-03

PRODUCTION GENERAL PROCESS FLOW CHART OF VALVES

DOCUMENT REMARK

ALFA VALVES

DOC NO.

REV.

AVI-P-FC-000

START

#

-

-

-

Check for correct content and quantity

Store Personel

materials againts packing list or supplier

supplier D/D / invoice to Alfa. PO.

Discrepancies shall be identifed

for remedial action

Material stock status raised

for Direct Material record

START

INCOMING

MATERIAL

PURCASE ORDER VENDOR PACKING LIST

MATERIALS RECEIVE RETURN'S OUTWARD

DELIVERY MATERIALS CONS.

-

#

-

-

Materials consumable log book

raised for Indirect Material record

o ec a e a eco d

by QC Department.

Visual Flange Finish Surface (MSS-SP 6)

Dimensional Inspection

QC inspector

Material Mill Test Reports will be kept

Visual Surface Inspection(MSS-SP 55)

MATERIALS STOCK

MILL TEST REPORT QC INCOMING

INCOMING MATERIAL

-

*

*

Face to Face/End to End Dimensions

Wafer Check : API Std. 594

Butterfly : API Std. 609

Class 800 & 1500, Threaded, Socket

Weld & Buttweld, End-to-End Refer to

Alf V l t d d API 602

Dimensional Inspection

ASME B16.34

For Ball , Gate, Globe, Check & Plug :

ASME B16.10 ; API 6D ;

Wall thickness (API Std.600 or

QC

INCOMING

INSPECTI-

ON

*

*

*

#

Alfa Valves standard as per API 602

Flange Dimensions

meeting receive reports & decide the

MRB ( Material Review Board)

Height, Handwheel, Stem, Bolts, Nuts

Etc.

ASME B16.5 ; ASME B16.47;

MSS SP-44

NCMR NC T

-

-

# Store Personel

NCMR ( Non Conforming Material

material status

Report )

NC Tag ( Non Conforming Tag )

YES

NO

NCMR NC Tag

OK ?

NON-CONFORMANCE

PROCEDURE (NCP)

RAW

MATERIAL

STORAGE

MATERIAL STOCK INVENTORY STOCK

#

-

# Production AssemblyOperator

Sales Order and / or customer delivery

order

Production Assembly Operator

Production Work Order shall based on

PRODUCTION PRODUCTION WORK

MAT. REQ. / ISSUED

COLLECT

KIT VALVES

ASSY

#

-

# Production Assembly Operator

NO

Production Assembly Operator

Inspect for Quantity and suitability of

parts

YES

REQUEST FOR KIT

COMPLETENESS

PARTS INS.

BEFORE

ASSEMBLY

OK ?

MAT. REQ. / ISSUED

A

AVI-P-FC-000

AVI-P-FC-000

0

PRODUCTION GENERAL PROCESS FLOW CHART OF VALVES

ALFA VALVES

DOC NO.

REV.

DATE OF ISSUED

PAGE

8-Apr-03

3 OF 4

#

*

PROCESS DOCUMENT

Work Instructions

REMARK

Production Assembly Operator

Refer to Valves Drawing and Assembling

A

PARTS

ASSEMBLY

ASSY IN-PROCESS

#

#

-

NO NO

YES

YES

MRB

Functional Inspection

J oint Torques Inspection

Production Assembly Operator

OK ?

TRIAL &

ERROR

OK ? NCP

NCMR

ASSEMBLY DAILY

PERFORMANCE

REPORT

VALVE

ASSY

-

#

YES

J oint Torques Inspection

NO NO

MRB

ASSY

INSPECTI-

ON

NCMR

OK ?

TRIAL &

ERROR

OK ? NCP

#

-

-

-

-

-

#

Shell Test

NO

API 598 or API 6D

MRB

(Upon Customer's Requirements)

Low-Pressure Closure Test

Production Testing Operator

High-Pressure Closure Test

Backseat ( if any)

YES

VALVE

PRESSURE

TESTING

TESTING DAILY

PERFORMANCE

REPORT

#

NO

Production Painting Operator

YES

NON-CONFORMANCE

PROCEDURE (NCP)

OK ?

NCMR NC Tag

COATING

COATING DAILY

PERFORMANCE

REPORT

#

-

-

#

-

Inspection Form"

Production Packing Operator

Production will advise QC that valves

practicable position

Completing a"Request for QC

are ready for final Inspection by

QC Inspector

The Plates are mounted in the most

INSTALL ID

PLATE

FINAL

INSPECT-

ION

REQUEST for QC QC FINAL INSPECTION

QC FINAL INSPECTION

#

NO

QC Inspector

Inspection Form

OK ?

NON-CONFORMANCE

PROCEDURE (NCP)

NCMR CORRECTIVE ACTION

B

AVI-P-FC-000

PRODUCTION PROCESS FLOW CHART OF FLOATING BALL VALVE

ALFA VALVES

DOC NO.

REV.

DATE OF ISSUED

PAGE 0 4 OF 5

8-Apr-03 AVI-P-FC-001

#

PROCESS DOCUMENT

Production Assembly Operator

REMARK

B

BOLTING

CAP ASSY

INTO BODY

ASSY WITH

STUDBOLTS

#

Production Assembly Operator

STUD BOLTS

& NUTS

INSTALL

STOPPER &

SNAP RING

INTO LEVER

ASSY IN-PROCESS

#

#

-

NO NO

YES

YES

Production Assembly Operator

For Gear Operator Ball Valves, Install

Bevel Gear Operator Assembly into

Valve Body.

MRB

OK ?

TRIAL &

ERROR

OK ? NCP

INSTALL

LEVER ASSY

INTO BODY

NCMR

ASSY IN-PROCESS

#

#

-

NO

YES

Head Bolts.

MRB

For Gear Operator Ball Valves,

NO

into Body Mounting Pad with Hex

Bolting Bevel Gear Operator Assy

Production Assembly Operator

OK ?

TRIAL &

ERROR

OK ? NCP

BOLTING

LEVER WITH

SET SCREW

NCMR

ASSY IN-PROCESS

#

#

-

-

MRB

NO NO

YES

J oint torques Inspection

Production Assembly Operator

Functional Inspection

OK ?

TRIAL &

ERROR

OK ? NCP

NCMR

ASSEMBLY DAILY

PERFORMANCE REPORT VALVE ASSY

INSPECTION

#

#

-

-

-

YES

API 598 API 6D

Low-Pressure Closure Test

High-Pressure Closure Test

Production Testing Operator

NO

Shell Test

NO

MRB

OK ?

TRIAL &

ERROR

OK ? NCP

VALVE

PRESSURE

TESTING

TESTING DAILY

PERFORMANCE REPORT

NCMR

-

#

YES

NO

API 598 or API 6D

(Upon Customer's Requirements)

MRB

C

NON-CONFORMANCE OK ?

NCMR NC Tag

AVI-P-FC-001

AVI-P-FC-000

0 4 OF 4

PRODUCTION GENERAL PROCESS FLOW CHART OF VALVES

ALFA VALVES

DOC NO.

REV.

DATE OF ISSUED

PAGE

8-Apr-03

#

REMARK PROCESS DOCUMENT

Production Packing Operator

B

PACKAGING

& DESPATCH

SALES ORDER

ALFA PACKING LIST

PACKING LABEL

#

-

-

-

-

-

-

COC=Certificate of Compliance & Test

MTR=Material Test Report

DVIR=Dimensions & Visual Ins. Report

QC Inspector

MDR=Manufacturing Data Record

PTR=Pressure Test Report

(if i d b t )

PCR=Protective Coating Report

DOCUMENT

ATION

ALFA PACKING LIST

COC MTR

PTR DVIR

WARRANTY VALVES DATA LOG

# Store Personel

(if required by customers)

SHIPMENT

END

SHIPMENT SCHEDULE DELIVERY DOCKET

VALVES STOCK INVENTORY STOCK

END

AVI-P-FC-000

You might also like

- Gate & Globe PDFDocument0 pagesGate & Globe PDFZoebairNo ratings yet

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedDocument4 pagesStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaNo ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Manufacturing Quality PlanDocument4 pagesManufacturing Quality PlanDIENSHNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Company Logo Added to QAP DocumentDocument4 pagesCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- 04 - Product Traceability Procedure - Asf-Qc-Ptp-001Document5 pages04 - Product Traceability Procedure - Asf-Qc-Ptp-001Sherif Yehia0% (1)

- GSB-Form-247 Dimension Inspection Report (Nozzle)Document1 pageGSB-Form-247 Dimension Inspection Report (Nozzle)Made GileeNo ratings yet

- Technical Delivery Condition: Applicable To Parts: Ring WCFN0055Document4 pagesTechnical Delivery Condition: Applicable To Parts: Ring WCFN0055Balram JiNo ratings yet

- Carbon Steel Plates TDCDocument3 pagesCarbon Steel Plates TDCshazanNo ratings yet

- BOLT Torquing ReportDocument4 pagesBOLT Torquing ReportSumith Kumar S MNo ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- 8615 Nozzle Orientation Report 01Document4 pages8615 Nozzle Orientation Report 01Bsc Aditya Singh Dinkar100% (1)

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- QC FORMDocument3 pagesQC FORMRicardo LourençoNo ratings yet

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- Deviation List & FormDocument2 pagesDeviation List & FormRohit AttriNo ratings yet

- Itp GRPDocument4 pagesItp GRPJo FrancescNo ratings yet

- Setco PDFDocument3 pagesSetco PDFPrafullachandra ParikhNo ratings yet

- Dimensional Inspection Report: Sample Production Lot/BatchDocument1 pageDimensional Inspection Report: Sample Production Lot/BatchCristina TinaNo ratings yet

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 pagesProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNo ratings yet

- Assure Solutions: Hydro Test ReportDocument1 pageAssure Solutions: Hydro Test ReportKailas NimbalkarNo ratings yet

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- Wps Pip Gtaw - ArabianDocument1 pageWps Pip Gtaw - ArabianIshack MohammedNo ratings yet

- Desmet Ballestra India PVT LTD: Inspection Test PlanDocument2 pagesDesmet Ballestra India PVT LTD: Inspection Test Plansameer patilNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Pull Off Test Report RefinaryDocument3 pagesPull Off Test Report RefinaryZaid Raslan AyoubNo ratings yet

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportDocument2 pagesWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiNo ratings yet

- In Process QC FormatDocument9 pagesIn Process QC FormatSunil ChaubeyNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- NCR Trend Analysis for Barzan Onshore ProjectDocument15 pagesNCR Trend Analysis for Barzan Onshore ProjectrmdarisaNo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- eni Iraq b.v. - Zubair Oil Field Development Project Work Package Welder Qualification CertificateDocument1 pageeni Iraq b.v. - Zubair Oil Field Development Project Work Package Welder Qualification CertificateSamer BayatiNo ratings yet

- Welders Continuity Log: Name Welder ID ProcessDocument4 pagesWelders Continuity Log: Name Welder ID ProcessMacelNo ratings yet

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisNo ratings yet

- Oriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesDocument18 pagesOriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesTejas ShahNo ratings yet

- Define of WPS & PQRDocument16 pagesDefine of WPS & PQRThanh Hua100% (1)

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Welders ManagementDocument11 pagesWelders ManagementStanley AlexNo ratings yet

- Welding Repair Procedure for PT. Juhdi Sakti EngineeringDocument4 pagesWelding Repair Procedure for PT. Juhdi Sakti EngineeringRiky SumantriNo ratings yet

- NDE Requirements for Header Box WeldsDocument9 pagesNDE Requirements for Header Box Weldsrony16novNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNo ratings yet

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- Welding Inspection ReportDocument1 pageWelding Inspection ReportbimboNo ratings yet

- Report on Welding Procedure Specifications for Single V-Groove JointsDocument15 pagesReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Ovality Limits Cylindrical ShellsDocument4 pagesOvality Limits Cylindrical ShellsDeepakNo ratings yet

- Alfa Valves Production Flow ChartDocument0 pagesAlfa Valves Production Flow ChartZoebairNo ratings yet

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Document7 pagesInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarNo ratings yet

- 1 12 (End)Document17 pages1 12 (End)ZoebairNo ratings yet

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocument9 pagesInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairNo ratings yet

- Appendix B - 20100903 - 145453Document25 pagesAppendix B - 20100903 - 145453AkoKhalediNo ratings yet

- 90 Series (ET1590) InstructionsDocument24 pages90 Series (ET1590) InstructionsZoebairNo ratings yet

- TurbinesDocument19 pagesTurbinesSamarakoon BandaNo ratings yet

- Quality Conference TTL KUDocument6 pagesQuality Conference TTL KUZoebairNo ratings yet

- Type of ThreadDocument13 pagesType of ThreadVils ArabadzhievaNo ratings yet

- Spring-Supported Thrust BearingsDocument4 pagesSpring-Supported Thrust BearingsZoebairNo ratings yet

- Structures and Mechanisms Classifications GuideDocument1 pageStructures and Mechanisms Classifications GuideminakirolosNo ratings yet

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Document1 page8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairNo ratings yet

- Ratle Enm Reply Tecnical Prebid Points 080212Document42 pagesRatle Enm Reply Tecnical Prebid Points 080212ZoebairNo ratings yet

- ENZX TechDocument30 pagesENZX TechZoebairNo ratings yet

- 1 Technical Data Sheets TurbineDocument7 pages1 Technical Data Sheets TurbineZoebairNo ratings yet

- Installation and Operating Procedures: Manual Grease InterceptorsDocument8 pagesInstallation and Operating Procedures: Manual Grease InterceptorsZoebairNo ratings yet

- Calculate The Number of Extinguishers Needed in A BuildingDocument3 pagesCalculate The Number of Extinguishers Needed in A BuildingZoebairNo ratings yet

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- Datasheet TurbineDocument2 pagesDatasheet TurbineZoebairNo ratings yet

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDocument3 pagesANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairNo ratings yet

- Solutions EngDocument6 pagesSolutions EngZoebairNo ratings yet

- 1 - Layout of H-FrancisDocument1 page1 - Layout of H-FrancisZoebairNo ratings yet

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocument3 pagesPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNo ratings yet

- INDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESDocument6 pagesINDIGENOUS MANUFACTURERS OF SMALL HYDRO TURBINESZoebairNo ratings yet

- Scada SystemDocument1 pageScada SystemZoebairNo ratings yet

- Load AcceptanceDocument2 pagesLoad AcceptanceZoebairNo ratings yet

- Construction Specification 71-Water Control Gates: Instructions For UseDocument2 pagesConstruction Specification 71-Water Control Gates: Instructions For UseZoebairNo ratings yet

- ANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsDocument3 pagesANDRITZ HYDRO Valves Ensure Lifetime Safety and Reliability in Hydropower PlantsZoebairNo ratings yet

- PJPR0 V 200 Ucturing 0 Data 0 SheetDocument3 pagesPJPR0 V 200 Ucturing 0 Data 0 SheetZoebairNo ratings yet

- 3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalDocument2 pages3DS Net OrthoGen For Intergraph CADWorx Plant ProfessionalThanadkitBunkaewNo ratings yet

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocument7 pagesCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairNo ratings yet

- 3 Tables Friction Loss AquacultureDocument10 pages3 Tables Friction Loss AquacultureZoebairNo ratings yet

- CTR Ball JointDocument19 pagesCTR Ball JointTan JaiNo ratings yet

- Basic Features of The Microcredit Regulatory Authority Act, 2006Document10 pagesBasic Features of The Microcredit Regulatory Authority Act, 2006Asif Hasan DhimanNo ratings yet

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDocument8 pagesExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazNo ratings yet

- Product Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966Document1 pageProduct Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966shama093No ratings yet

- Money Laundering in Online Trading RegulationDocument8 pagesMoney Laundering in Online Trading RegulationSiti Rabiah MagfirohNo ratings yet

- Bala Graha AfflictionDocument2 pagesBala Graha AfflictionNeeraj VermaNo ratings yet

- Statistical Decision AnalysisDocument3 pagesStatistical Decision AnalysisTewfic SeidNo ratings yet

- Galaxy Owners Manual Dx98vhpDocument10 pagesGalaxy Owners Manual Dx98vhpbellscbNo ratings yet

- Oxygen Cost and Energy Expenditure of RunningDocument7 pagesOxygen Cost and Energy Expenditure of Runningnb22714No ratings yet

- Audi Q5: First Generation (Typ 8R 2008-2017)Document19 pagesAudi Q5: First Generation (Typ 8R 2008-2017)roberto100% (1)

- Mpu 2312Document15 pagesMpu 2312Sherly TanNo ratings yet

- UD150L-40E Ope M501-E053GDocument164 pagesUD150L-40E Ope M501-E053GMahmoud Mady100% (3)

- Pfr140 User ManualDocument4 pagesPfr140 User ManualOanh NguyenNo ratings yet

- OS LabDocument130 pagesOS LabSourav BadhanNo ratings yet

- The Service Marketing Plan On " Expert Personalized Chef": Presented byDocument27 pagesThe Service Marketing Plan On " Expert Personalized Chef": Presented byA.S. ShuvoNo ratings yet

- Endangered EcosystemDocument11 pagesEndangered EcosystemNur SyahirahNo ratings yet

- Speed Reducer GearboxDocument14 pagesSpeed Reducer Gearboxعبد للهNo ratings yet

- Desana Texts and ContextsDocument601 pagesDesana Texts and ContextsdavidizanagiNo ratings yet

- Flowmon Ads Enterprise Userguide enDocument82 pagesFlowmon Ads Enterprise Userguide ennagasatoNo ratings yet

- Technical specifications for JR3 multi-axis force-torque sensor modelsDocument1 pageTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTANo ratings yet

- Vector 4114NS Sis TDSDocument2 pagesVector 4114NS Sis TDSCaio OliveiraNo ratings yet

- Rapport DharaviDocument23 pagesRapport DharaviUrbanistes du MondeNo ratings yet

- Evil Days of Luckless JohnDocument5 pagesEvil Days of Luckless JohnadikressNo ratings yet

- Ailunce HD1 Software ManualDocument33 pagesAilunce HD1 Software ManualMarc LaBarberaNo ratings yet

- Dermatology Study Guide 2023-IvDocument7 pagesDermatology Study Guide 2023-IvUnknown ManNo ratings yet

- EC GATE 2017 Set I Key SolutionDocument21 pagesEC GATE 2017 Set I Key SolutionJeevan Sai MaddiNo ratings yet

- H I ĐĂNG Assigment 3 1641Document17 pagesH I ĐĂNG Assigment 3 1641Huynh Ngoc Hai Dang (FGW DN)No ratings yet

- The Dominant Regime Method - Hinloopen and Nijkamp PDFDocument20 pagesThe Dominant Regime Method - Hinloopen and Nijkamp PDFLuiz Felipe GuaycuruNo ratings yet

- Fast Aldol-Tishchenko ReactionDocument5 pagesFast Aldol-Tishchenko ReactionRSLNo ratings yet