Professional Documents

Culture Documents

04 - Product Traceability Procedure - Asf-Qc-Ptp-001

Uploaded by

Sherif YehiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 - Product Traceability Procedure - Asf-Qc-Ptp-001

Uploaded by

Sherif YehiaCopyright:

Available Formats

QUALITY CONTROL DEPARTMENT REV.

1

PRODUCT TRACEABILITY PROCEDURE Date: 01-03-2019

ASF-QC-PTP-001 Page: 1 of 5

PRODUCT TRACEABILITY PROCEDURE

ASF-QC-PTP-001

PRODUCT TRACEABILITY PROCEDURE

ASF-QC-PTP-001

QUALITY CONTROL DEPARTMENT REV. 1

PRODUCT TRACEABILITY PROCEDURE Date: 01-03-2019

ASF-QC-PTP-001 Page: 2 of 5

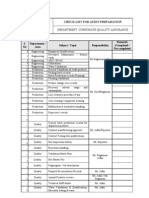

LIST OR REVISIONs

Approved By Reviewed By Prepared By Comment Date Rev

.

Ahmed Safwat Salem Abdel Naby For Implementation 01-01-2019 0

Ahmed Safwat Salem Abdel Naby Change in the procedure number 01-03-2019 1

PRODUCT TRACEABILITY PROCEDURE

ASF-QC-PTP-001

QUALITY CONTROL DEPARTMENT REV. 1

PRODUCT TRACEABILITY PROCEDURE Date: 01-03-2019

ASF-QC-PTP-001 Page: 3 of 5

INDEX

No. DESCRIPTION PAGE

1 OBJECTIVES 4

2 SCOPE 4

3 REFERENCE 4

4 DEFINITIONS 4

5 RESPONSIBILITY 4

6 PROCEDURE 4

7 RECORDS 7

8 ATTACHMENTS 7

PRODUCT TRACEABILITY PROCEDURE

ASF-QC-PTP-001

QUALITY CONTROL DEPARTMENT REV. 1

PRODUCT TRACEABILITY PROCEDURE Date: 01-03-2019

ASF-QC-PTP-001 Page: 4 of 5

1. OBJECTIVES

To define a procedure for identification of finished and un-finished products also to define the method of the product

traceability

2. SCOPE

This procedure describes the Material Traceability procedure of the all types of steel products & Fittings.

3. REFERENCE

3.1. ISO 9001:2015

3.2. AWS D1.1 – Steel Structural Welding Code

3.3. EN 1090 - Technical Requirements of the execution of the steel structure

3.4. ASME – ASME Boilers and Pressure Vessel Codes

3.5. API – American Petroleum Institute

3.6. ASF-QC-PTP-001 – this procedure

4. DEFINITION

PE Production Engineer

:

5. RESPONSIBILITY

The PE shall be responsible for the implementation of this procedure and shall agree with the material control engineer

for establish a method for tracing the material during the fabrication stages and the final inspection stage.

6. PROCEDURE

6.1. RAW MATERIAL IDENTIFICATION AND TRACEABILITY

6.1.1. Product identification starts from the raw material identification using a specific code by ASF for each

heat no. , if required by Project specs.

6.1.2. Customer property is to be defined

6.1.3. All the received raw material shall be identified by writing dimensions or item name of if used for a specified

project name

6.1.4. Traceability is maintained by the inspection report raised by the material inspector

6.1.5. Any material other than carbon Steel shall be stored in isolated area with different unique marking.

6.1.6. The other material products (pipes, flanges, cap, etc.) shall be traceable and shall have its identification directly

stamped on the single products as specified in the standards.

6.1.7. The constituent products shall be traceable to the material by workshop marking (Job No., Drawing No., Pos.

No., Item No.)

6.1.8. These Identification is done by Partially hard stamped, punched or drilled marks used for marking single

components or packages of similar components, unless otherwise specified.

6.2. PRE-FABRICATION IDENTIFICATION

All the steel sections after preparation shall be identified by writing the item code on it either by permanent pen

or hard stamp.

6.3. FIT-UP IDENTIFICATION AND TRACEABILITY

6.3.1. After the fit-up all products shall be identified b hard stamp ed on the product

6.3.2. The hard stamp shall contain:

a) Project Reference

b) Item code

PRODUCT TRACEABILITY PROCEDURE

ASF-QC-PTP-001

QUALITY CONTROL DEPARTMENT REV. 1

PRODUCT TRACEABILITY PROCEDURE Date: 01-03-2019

ASF-QC-PTP-001 Page: 5 of 5

c) Job order

6.3.3. To ensure traceability, the quality inspector must issue dimension report as per the product inspection and

testing procedures

6.4. WELDING TRACEABILITY

If mentioned in the contract the welder code number shall be hard stamped beside the weld line to trace the

welder performance

6.5. PAINTED OR GALVANIZED PRODUCT IDENTIFICATION

6.5.1. If the hard stamp of the products is not clear after painting or galvanization the code shall be written beside

the hard stamp

6.5.2. Traceability is maintained by product release, dimension certificates and visual report if mentioned in contract

or on the inspection and test plan for the project

7. Records

All the records of dimension, visual and release shall be recorded accordingly after each step

8. ATTACHMENT

Non

PRODUCT TRACEABILITY PROCEDURE

ASF-QC-PTP-001

You might also like

- NCR Procedure Rev. 0Document8 pagesNCR Procedure Rev. 0Ganjar Dreadlocks NugrahaNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- QSP-010 R0 QSP For Field Inspection & Test PlanDocument21 pagesQSP-010 R0 QSP For Field Inspection & Test PlanjennyNo ratings yet

- Pt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesDocument0 pagesPt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesZoebairNo ratings yet

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- Welders ManagementDocument11 pagesWelders ManagementStanley AlexNo ratings yet

- Material Traceability ProcedureDocument12 pagesMaterial Traceability Procedureqamar qateebNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Visual Check List For Control Valve: Rock Payvand Sanat ArvandDocument1 pageVisual Check List For Control Valve: Rock Payvand Sanat Arvandarmin heidariNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Long Seam Inspection ProcedureDocument4 pagesLong Seam Inspection ProcedureDeepak100% (1)

- F-05 Corrective Action FormDocument1 pageF-05 Corrective Action Formsuhara hussainNo ratings yet

- Welding Repair Procedure for PT. Juhdi Sakti EngineeringDocument4 pagesWelding Repair Procedure for PT. Juhdi Sakti EngineeringRiky SumantriNo ratings yet

- Quality ControlDocument51 pagesQuality ControlOprisor CostinNo ratings yet

- Deviation List & FormDocument2 pagesDeviation List & FormRohit AttriNo ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Document Issue RecordDocument1 pageDocument Issue RecordcoolariesatulNo ratings yet

- In Process QC FormatDocument9 pagesIn Process QC FormatSunil ChaubeyNo ratings yet

- Internal Audit Observation ReportDocument2 pagesInternal Audit Observation Reportsenk197100% (1)

- Supplier ITP Inspection PlanDocument4 pagesSupplier ITP Inspection PlanHassan SajidNo ratings yet

- Company Logo Added to QAP DocumentDocument4 pagesCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- 8 Material ControlDocument8 pages8 Material ControlPrakash RajNo ratings yet

- LGT - WHD - QP03-Material Handling and Storage Control ProcedureDocument7 pagesLGT - WHD - QP03-Material Handling and Storage Control ProcedureGregorNo ratings yet

- Iso9001 AsmeDocument2 pagesIso9001 AsmeAnonymous wKvJXBJ2iNo ratings yet

- Laboratories Limited Corporate QA Department: Corporate Quality AssuranceDocument3 pagesLaboratories Limited Corporate QA Department: Corporate Quality AssurancePurushothaman SubramanianNo ratings yet

- QG-QSP-08 Procedure For Control of Non-Conformance Product.Document5 pagesQG-QSP-08 Procedure For Control of Non-Conformance Product.omprakash yadavNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- Manufacturing Quality Plan (MQP)Document2 pagesManufacturing Quality Plan (MQP)Ranjit Singh100% (3)

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

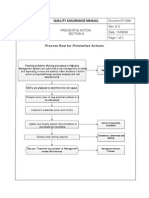

- Quality Assurance Manual Process FlowDocument2 pagesQuality Assurance Manual Process FlowNgonidzashe ZvarevasheNo ratings yet

- QC Sample Manual GenericDocument34 pagesQC Sample Manual GenericIan Stewart PorterNo ratings yet

- Cutting Procedure GuideDocument3 pagesCutting Procedure Guiderial100% (1)

- Nde Map & Nde Procedure (Sudah Di Revisi)Document4 pagesNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangNo ratings yet

- Sampling System Inspection Process Flow Chart 1Document1 pageSampling System Inspection Process Flow Chart 1sakshi patilNo ratings yet

- Welding Control ProcedureDocument18 pagesWelding Control ProceduresumitNo ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Control flow diagram for GACC's new welder qualification processDocument1 pageControl flow diagram for GACC's new welder qualification processSiddiqui Abdul KhaliqNo ratings yet

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- Contract Review-QMP-MK-01Document5 pagesContract Review-QMP-MK-01Rohit VishwakarmaNo ratings yet

- Incoming Inspection-Qmp-Qc-01Document2 pagesIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNo ratings yet

- Fixture Validation ChecklistDocument2 pagesFixture Validation Checklistvvv5452No ratings yet

- PPAP Training OverviewDocument17 pagesPPAP Training OverviewRicky MarkNo ratings yet

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Inspection Test Plan: Grinding, Build Up & ResurfaceDocument3 pagesInspection Test Plan: Grinding, Build Up & Resurfacemohd as shahiddin jafriNo ratings yet

- Form - Scar LogDocument18 pagesForm - Scar LogHarie BongkyNo ratings yet

- Product Identification and Traceability ProcedureDocument5 pagesProduct Identification and Traceability ProcedureJamal Mohamed Rahamathullah100% (1)

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Document5 pagesStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomNo ratings yet

- Contract Review RecordDocument1 pageContract Review RecordXionNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- WELDING CONTROL PROCEDURE ASF-QC-WCP-001Document7 pagesWELDING CONTROL PROCEDURE ASF-QC-WCP-001el_sharkawy2011100% (1)

- 02 - Calibration Procedure - Asf-Qc-Cal-001Document7 pages02 - Calibration Procedure - Asf-Qc-Cal-001Sherif YehiaNo ratings yet

- 02 - Calibration Procedure - Asf-Qc-Cal-001Document7 pages02 - Calibration Procedure - Asf-Qc-Cal-001Sherif YehiaNo ratings yet

- 04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Document8 pages04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Sherif YehiaNo ratings yet

- Punching Validation-FACTORY 1Document3 pagesPunching Validation-FACTORY 1Sherif YehiaNo ratings yet

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Document1 page(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- UntitledDocument1 pageUntitledSherif YehiaNo ratings yet

- Regulamentul UE 305.2011 ENGLEZADocument39 pagesRegulamentul UE 305.2011 ENGLEZAhalexing5957No ratings yet

- Welding Fabrication Standards CrackedDocument95 pagesWelding Fabrication Standards CrackedNatraji100% (2)

- Punching Validation-FACTORY 1Document3 pagesPunching Validation-FACTORY 1Sherif YehiaNo ratings yet

- Heat Resistant Silicone Coating for Steel up to 450°CDocument2 pagesHeat Resistant Silicone Coating for Steel up to 450°CSherif YehiaNo ratings yet

- UntitledDocument1 pageUntitledSherif YehiaNo ratings yet

- FPC AsfDocument24 pagesFPC AsfSherif YehiaNo ratings yet

- 01 Qulaity Control Plan - Asf QC QCP 001Document8 pages01 Qulaity Control Plan - Asf QC QCP 001Ahmad Nabil ElsharkawyNo ratings yet

- Quality Analysis of Steel Structure Projects in EgyptDocument5 pagesQuality Analysis of Steel Structure Projects in EgyptSherif YehiaNo ratings yet

- FPC AsfDocument24 pagesFPC AsfSherif YehiaNo ratings yet

- 04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Document8 pages04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Sherif YehiaNo ratings yet

- Iso 4624 2002 en FR PDFDocument6 pagesIso 4624 2002 en FR PDFSherif YehiaNo ratings yet

- 01 - Asf-Qc-Itp-002Document4 pages01 - Asf-Qc-Itp-002Sherif YehiaNo ratings yet

- 05 - Fabrication Procedure - Asf-Qc-Fab-001Document6 pages05 - Fabrication Procedure - Asf-Qc-Fab-001Sherif YehiaNo ratings yet

- Paint technology overviewDocument51 pagesPaint technology overviewWilfredo gabuay100% (1)

- 07 - Painting and Touch Up Procedure - Asf-Qc-Pp-001Document9 pages07 - Painting and Touch Up Procedure - Asf-Qc-Pp-001Sherif YehiaNo ratings yet

- 04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Document8 pages04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Sherif YehiaNo ratings yet

- DSD ProcedureDocument20 pagesDSD ProcedureSherif YehiaNo ratings yet

- 02 - Calibration Procedure - Asf-Qc-Cal-001Document7 pages02 - Calibration Procedure - Asf-Qc-Cal-001Sherif YehiaNo ratings yet

- BS en ISO 5817 2014 Acceptance For NDTDocument38 pagesBS en ISO 5817 2014 Acceptance For NDTSherif YehiaNo ratings yet

- 02 - Calibration Procedure - Asf-Qc-Cal-001Document7 pages02 - Calibration Procedure - Asf-Qc-Cal-001Sherif YehiaNo ratings yet

- Fabrication Procedure2020Document6 pagesFabrication Procedure2020Sherif YehiaNo ratings yet

- Workshop LogDocument23 pagesWorkshop LogYeferson FuentesNo ratings yet

- ZE550KL Update Error Temporary FixDocument7 pagesZE550KL Update Error Temporary FixИгорь КуприяновNo ratings yet

- Winshuttle at PM: Rüdiger Weiss - RocheDocument20 pagesWinshuttle at PM: Rüdiger Weiss - Rochemahesh_rai44No ratings yet

- Light Is Networked: Hubsense: A New Experience of Com-Missioning Radio-Based Lighting ControlDocument6 pagesLight Is Networked: Hubsense: A New Experience of Com-Missioning Radio-Based Lighting ControlAbdelKarim BaariniNo ratings yet

- The Relational ModelDocument34 pagesThe Relational Modellouarianedlr17No ratings yet

- HEC-HMS Application Sri Lanka Devanmini and Najim 2013Document8 pagesHEC-HMS Application Sri Lanka Devanmini and Najim 2013Macklera MrutuNo ratings yet

- Lab 3Document14 pagesLab 3Maitha SaeedNo ratings yet

- Prognostics and Health Management (PHM)Document16 pagesPrognostics and Health Management (PHM)Gaurav Jyoti GogoiNo ratings yet

- 1115 Lab Cybersecurity Case StudiesDocument2 pages1115 Lab Cybersecurity Case StudiessetyabudhiNo ratings yet

- Universal Remote Troubleshooting ManualDocument75 pagesUniversal Remote Troubleshooting ManualМаксим ИвановNo ratings yet

- Technology For Teaching and Learning in The Elementary GradesDocument8 pagesTechnology For Teaching and Learning in The Elementary GradesGerwin VicenteNo ratings yet

- The Technology Adoption in the PhilippinesDocument7 pagesThe Technology Adoption in the Philippinesadbgabot09No ratings yet

- C Lang Interview QuestionsDocument2 pagesC Lang Interview QuestionspoojaNo ratings yet

- KPrime BIOCHROMATOGRAPHY SYSTEMDocument8 pagesKPrime BIOCHROMATOGRAPHY SYSTEMTuyền KimNo ratings yet

- Removing the UEPP Display and Input DevicesDocument10 pagesRemoving the UEPP Display and Input Devicesرانا راشدNo ratings yet

- Node JS Formation - Backend DevelopmentDocument9 pagesNode JS Formation - Backend DevelopmentManel GharbiNo ratings yet

- Swami - SCM: Devops EngineerDocument3 pagesSwami - SCM: Devops EngineerAlbacore EnterprisesNo ratings yet

- SERVICE Manual For 761BF, 961BF, 961BW, 961BG, 961GWDocument99 pagesSERVICE Manual For 761BF, 961BF, 961BW, 961BG, 961GWNewsletter ForNo ratings yet

- Module 1: Introduction To Production ManagementDocument46 pagesModule 1: Introduction To Production ManagementJhen-Jhen Geol-oh BaclasNo ratings yet

- Generating Patterns Part 3Document28 pagesGenerating Patterns Part 3Rondex PabloNo ratings yet

- English Lecture NotesDocument118 pagesEnglish Lecture NotesHimanish KoyalkarNo ratings yet

- Iot Mini ProjectDocument13 pagesIot Mini ProjectNALIN KUMARINo ratings yet

- OpenLDAP Admin GuideDocument267 pagesOpenLDAP Admin Guidejonas leonel da silvaNo ratings yet

- Kushagra DSADocument37 pagesKushagra DSAJaymin SheladiaNo ratings yet

- Ca Mid1 2017Document9 pagesCa Mid1 2017hruitNo ratings yet

- SDT170 User Manual enDocument141 pagesSDT170 User Manual enELIO FRANCISCO REVILLA PÉREZNo ratings yet

- BGS3 - Hardware Interface Descriptor - CinterionDocument109 pagesBGS3 - Hardware Interface Descriptor - CinterionAdriano RamosNo ratings yet

- S3 Lab - Create Bucket, Upload Objects & Manage Access (40Document11 pagesS3 Lab - Create Bucket, Upload Objects & Manage Access (40Hector AndradeNo ratings yet

- Topic 4 CSSDocument22 pagesTopic 4 CSSPratiksha JadhavNo ratings yet

- 01-09-2022 To 30-09-2022 KPTCL Scheduled Power Interruption For The Month of SEPTEMBERDocument19 pages01-09-2022 To 30-09-2022 KPTCL Scheduled Power Interruption For The Month of SEPTEMBERravi lingamNo ratings yet