Professional Documents

Culture Documents

WELDING CONTROL PROCEDURE ASF-QC-WCP-001

Uploaded by

el_sharkawy2011Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WELDING CONTROL PROCEDURE ASF-QC-WCP-001

Uploaded by

el_sharkawy2011Copyright:

Available Formats

QUALITY CONTROL DEPARTMENT REV.

1

WELDING CONTROL PROCEDURE Date: 01-03-2019

ASF-QC-WCP-001 Page: 1 of 7

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

QUALITY CONTROL DEPARTMENT REV. 1

WELDING CONTROL PROCEDURE Date: 01-03-2019

ASF-QC-WCP-001 Page: 2 of 7

LIST OR REVISIONs

Rev. Date Comment Prepared By Reviewed By Approved By

0 01-01-2019 For Implementation Ahmed El-Sharkawy Ahmed Safwat

1 01-03-2019 Change in the procedure number Ahmed El-Sharkawy Ahmed Safwat

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

QUALITY CONTROL DEPARTMENT REV. 1

WELDING CONTROL PROCEDURE Date: 01-03-2019

ASF-QC-WCP-001 Page: 3 of 7

INDEX

No. DESCRIPTION PAGE

1 OBJECTIVES 4

2 SCOPE 4

3 REFERENCE 4

4 DEFINITIONS 4

5 RESPONSIBILITIES 4

6 PROCEDURE 4

7 RECORDS 6

8 ATTACHMENTS 7

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

QUALITY CONTROL DEPARTMENT REV. 1

WELDING CONTROL PROCEDURE Date: 01-03-2019

ASF-QC-WCP-001 Page: 4 of 7

1. OBJECTIVES

The purpose of this procedure is to monitor the welding application, welder qualification and welding procedures as per

governing code, standard and project specifications.

2. SCOPE

This procedure is prepared in order to cover qualification of welders, welding operators and WPSs according to the

project specification, covered by the relevant reference code such AWS D1.1, EN code, API and ASME Code Section IX

3. REFERENCE

3.1. ISO 9001:2015

3.2. AWS D1.1 – Steel Structural Welding Code

3.3. EN 1090 - Technical Requirements of the execution of the steel structure

3.4. EN ISO 9606 Qualification testing of welders — Fusion welding.

3.5. EN ISO 15609 Specification and qualification of welding procedures for metallic materials; General rules.

3.6. EN ISO 15607 Specification and qualification of welding procedures for metallic materials; Welding procedure

specification.

3.7. EN ISO 15614 Specification and qualification of welding procedures for metallic materials; Welding procedure

test.

3.8. ASME IX – ASME Boilers and Pressure Vessel Codes for Welding and Brazing Qualifications

3.9. API 1104 – American Petroleum Institute for Welding of pipelines and related facilities

4. DEFINITION

QCM Quality Control Manager

WE Welding Engineer

WPS Welding Procedure Qualification

PQR Procedure Qualification Record

WPQR Welder Performance Qualification Record

Company ASF

Authorized inspector Any third-party inspection agency

5. RESPONSIBILITIES

5.1. WELDING ENGINEER

5.1.1. The WE responsible for the preparation and qualification of WPSs identifying all essential, non-essential and

when required supplementary essential variables required by the applicable Code of construction,

5.1.2. The WE shall sign the WPS record based on form no. ASF-QC-WCP-003 after its successful qualification. The

WPS shall refer to supporting PQR record form based on form no. ASF-QC-WCP-002

5.1.3. The WE shall arrange the qualification of each WPS, witness the welding of the test coupon and record the

welding variables used for each qualification and fill PQR as run sheet on form no. ASF-QC-ARS-001 for each

PQR.

5.1.4. The WE shall maintain the original copies of WPS and PQR and laboratory test reports in the job file.

5.1.5. The WE responsible to make copy of all qualified WPSs on form no. ASF-QC-WCP-005, for the job undertaken

and provided to the Welding Foreman who instructs the welders who responsible to the production welds.

5.1.6. The WE responsible for training, qualification, certification and assignment of welders and assure that their

qualification is running properly, Evaluate their competency and precision through performance in the

welder’s log record on form no. ASF-QC-WCP-007.

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

QUALITY CONTROL DEPARTMENT REV. 1

WELDING CONTROL PROCEDURE Date: 01-03-2019

ASF-QC-WCP-001 Page: 5 of 7

6. PROCEDURE

6.1. WELDING PROCEDURE QUALIFICATION

6.1.1. WPS are prepared by the WE and approved by the QCM and shall include all welding variables required for

the welding process by the governing code plus any additional variables required by the applicable

construction Code and the intended range of production welding. The required qualification tests are

prepared under the supervision of the WE. Examine and testing welding samples at authorized laboratory;

WE is responsible to review the laboratory test reports. If acceptable he prepares and certifies, by signature

and date, the PQR record based on form no. ASF-QC-WCP-002. The PQR shall include at least all essential

variables used in welding of test coupon.

6.1.2. Copies of the qualified WPS and PQR are provided to the Production Manager and Production Engineer for

the purpose of application in the production welding.

6.1.3. Welding Map on form no. ASF-QC-WCP-008 will be prepared by the WE and approved by the QCM, which

specifies the WPS for each individual welded joint. The Welding Map is submitted to the Production Manager

and the Production Engineer for implementation

6.1.4. WPS may be revised whenever there is a change in a non-essential variable. Whenever there is a change in an

essential or supplementary essential variable, a new WPS and PQR is required

6.2. QUALIFICATION OF WELDERS

6.2.1. All Welders at shop or site shall be qualified according to reference code/construction code of the job, under

the supervision of the WE. Welders are either qualified by mechanical testing or by volumetric NDE

examination (RT or UT). Testing welding samples is performed by an approved testing laboratory. When

volumetric examination (RT or UT) is used in lieu of mechanical test, it shall be performed by qualified NDE

level II operator and report is reviewed by WE, and if the NDE reports are acceptable; WE prepare and certify

Welder Performance Qualification Record (WPQR) on form no. ASF-QC-WCP-004. The WPQR documents

contain the essential variables which actually used in welding test in addition to the qualified ranges

6.2.2. A WPQR is also issued for Welder who have welded a test coupon to qualify a WPS, based on the performance

essential variables used, and provided the test results meet the Code requirements.

6.2.3. send copy of qualified welders list to production department; The original WPQR record are retained in the

Welding Engineer's file.

6.2.4. The WE issue Qualified Welders List according to the relevant form no. ASF-QC-WCP-006, which approved by

QCM.

6.3. REQUALIFICATION OF WELDERS

Welders requalification is required according to clause 6.1 to clause 6.3.

6.3.1. change in WPQR essential variables.

6.3.2. Welder who not practice welding for six months or more after qualification.

6.3.3. When there is a specific reason to test his ability to get a sound

6.3.4. The welding Inspector has reason to test Welders’ ability to get a sound weld

6.4. RENEWAL OF QUALIFICATION

6.4.1. Renewal of welders’ certification by welding a single test coupon of either plate or pipe, of any material,

thickness or diameter, in any position, by inspection the test coupon as required by governing code; A

successful test renewal his previous qualification or by checking last UT or RT report of the welders

6.4.2. Welders whose qualifications have been revoked for any reason under 6.2 shall be re-qualified in the same

process of the initial qualification.

6.4.3. Welding engineer is responsible to update the qualified welders list according to applied code; and approved

by QCM

6.5. PRELONGATION OF WELDER’S QUALIFICATION.

6.5.1. the welding engineer is responsible to record all welder’s activity based on form number ASF-QC-WCP-007 for

the monthly evaluation.

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

QUALITY CONTROL DEPARTMENT REV. 1

WELDING CONTROL PROCEDURE Date: 01-03-2019

ASF-QC-WCP-001 Page: 6 of 7

6.5.2.When welders’ certificates are expired The WE is responsible to determine the continuity or

requalification is required for each welder based on his record in welder log and last UT or RT report.

6.6. PRODUCTION WELDING

6.6.1. The production engineer verifies that all production welders are qualified to get a sound welding foreman is

responsible to select welders from the qualified welders list, as well as welders using the applicable WPS,

both documents are prepared by the WE and approved by the QCM.

6.6.2. Each qualified welder shall have a unique stamp; each weld made by a welder shall be identified by stamping

adjacent to the weld and in case stamping is not possible, the identification is recorded on the welding map.

when a welder leaves the company; his stamp will not be reissued for other again.

6.6.3. Any tack welds made by qualified Welders using the qualified WPS designated on the Welding Map, if left tacking

in place, the ends of each tack weld shall be ground to ensure complete fusion; After that each tack weld is

visually examined by the QC Inspector, and if there are any defective, it shall be completely removed.

6.7. WELDING MATERIAL

6.7.1. All welding material shall be received by the WE, who is responsible to verify that marking on the package and

filler metal and randomly checks its quality according to form no. ASF-QC-MRI-003

6.7.2. Welding material is stocked in dry storage space and issued to welding Forman by the Storekeeper using issue

request.

6.7.3. Low hydrogen electrodes are received and stored in hermetically sealed containers, when opened, the

electrodes are placed in heated oven maintained at the temperature recommended by the manufacturer, before

issue to Welders.

6.7.4. Coated low hydrogen electrodes are issued only in a quantity sufficient to complete the welds during the shift

and maintained by the welder in the portable oven at the recommended temperature.

6.7.5. examine remaining coated low hydrogen welding electrodes with welders before it back to storage in the holding

furnace; if there are Damaged or unidentified electrodes will not use for Code work.

6.8. PRODUCTION TEST PLATES

6.8.1. Welded test plates for impact tests of base metal, weld metal and heat affected zones. The production test

plates are prepared in accordance with a procedure prepared by the WE, which includes number, identification,

type, orientation, location and dimensions of required specimens, required preheat temperature, PWHT

conditions, minimum design metal temperature and Charpy impact test temperatures.

6.8.2. The QC engineer supervises the welding of the test plates using during the test specimens from which specimens

are prepared and tested by a qualified testing laboratory whose test report is reviewed by the WE for acceptance

of results or need for retest. test results are submitted to the authorized inspector for his review. the authorized

inspector may witness the tests if he desires.

6.9. WELDERS NOT EMPLOYED BY THE COMPANY.

6.9.1. the company can use welders from outsource to do some specific jobs, the WE is responsible to ensure from

their qualification according to the job code.

6.9.2. All the welding shall according to a qualified WPS.

6.9.3. All Welders shall be qualified and the qualification or requalification record must be retained according to as in

the above from clause 6.2 to clause 6.5.

6.9.4. The QCM and the WE have the authority to exclude Welders based on their discretion.

6.9.5. The welding engineer submit the WPQR and welder’s list to the authorized inspector for review and approval

before starting code welding.

7. RECORDS

All data related to the welding material, qualified procedures and welder’s qualification certification shall be retained in

the WE job file.

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

QUALITY CONTROL DEPARTMENT REV. 1

WELDING CONTROL PROCEDURE Date: 01-03-2019

ASF-QC-WCP-001 Page: 7 of 7

8. ATTACHMENT

8.1. Procedure Qualification Record – form no. ASF-QC-WCP-002

8.2. Welding Procedure Specification – form no. ASF-QC-WCP-003

8.3. Welder Performance Qualification Record – form no. ASF-QC-WCP-004

8.4. Welding procedure Specification List – form no. ASF-QC-WCP-005

8.5. Qualified Welders List – form no. ASF-QC-WCP-006

8.6. Welders Log – form no. ASF-QC-WCP-007

8.7. Welding Map – form no. ASF-QC-WCP-008

8.8. Welding Receiving Material Inspection Report – form no. ASF-QC-MRI-003

8.9. PQR As run sheet – form no. ASF-QC-ARS-001

WELDING CONTROL PROCEDURE

ASF-QC-WCP-001

You might also like

- Welding Consumable Receiving LogDocument11 pagesWelding Consumable Receiving LogKandula Raju100% (1)

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- KON 8.2 QA PRO 0020 C1 Welding Control ProcedureDocument15 pagesKON 8.2 QA PRO 0020 C1 Welding Control ProcedureAlizamin Salmanov100% (1)

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- Procedure - Fit-Up & AssemblyDocument8 pagesProcedure - Fit-Up & AssemblyRakesh RanjanNo ratings yet

- Procedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)Document8 pagesProcedure For Receipt, Storage and Handling of Welding Consumable (Rev 1)dee1985100% (2)

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanNo ratings yet

- Visual Weld InspectionDocument7 pagesVisual Weld InspectioninsiderrNo ratings yet

- Welder TrainingDocument13 pagesWelder Trainingויליאם סן מרמיגיוסNo ratings yet

- Dimensional Control ProcedureDocument12 pagesDimensional Control ProcedureBethel NdifonNo ratings yet

- Welding Parameter Record SheetDocument2 pagesWelding Parameter Record SheetPravin Patil100% (1)

- QCP For Control of Welding ConsumablesDocument9 pagesQCP For Control of Welding ConsumablesUmair Awan100% (1)

- Exhibit No.34 - Welding Consumables Receiving Inspection RecordDocument1 pageExhibit No.34 - Welding Consumables Receiving Inspection RecordMohammed KamalNo ratings yet

- Welding Consumable Control Procedure 1Document9 pagesWelding Consumable Control Procedure 1eklavyak076757100% (4)

- Welding Control ProcedureDocument9 pagesWelding Control ProcedureRomi Abdul RahmanNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- Inspection Test Plan For FabricationDocument4 pagesInspection Test Plan For FabricationAshwani Dogra100% (9)

- Welding Inspection ProcedureDocument7 pagesWelding Inspection ProcedureVaradaraj CkNo ratings yet

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument11 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJaveed A. Khan100% (1)

- WELDING QualityPlanSampleDocument20 pagesWELDING QualityPlanSamplemullanji100% (3)

- QC Sample Manual GenericDocument34 pagesQC Sample Manual GenericIan Stewart PorterNo ratings yet

- Welding Consumables Handling Procedure.Document5 pagesWelding Consumables Handling Procedure.Mohammed Kamal78% (23)

- Electrode Handling Procedure - Simple - SMAWDocument7 pagesElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- The Welding Inspection Services Are Define in Three Stages As BelowDocument9 pagesThe Welding Inspection Services Are Define in Three Stages As BelowdeliNo ratings yet

- Tack Welding Method Welding Sequence For Carbon SteelDocument6 pagesTack Welding Method Welding Sequence For Carbon SteelansarALLAAHNo ratings yet

- Welding Repair Procedure for Diesel Fuel TankDocument4 pagesWelding Repair Procedure for Diesel Fuel Tankgstketut100% (2)

- Welding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Document2 pagesWelding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Go MocNo ratings yet

- 038-Pro Welding Consumable Control Procedure PDFDocument20 pages038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- Control of Welding Consumables ProcedureDocument16 pagesControl of Welding Consumables Procedureimran100% (1)

- Procedure For Material Identification & Traceability (Rev.0)Document27 pagesProcedure For Material Identification & Traceability (Rev.0)jishnunelliparambil100% (3)

- Weld Repair Procedure Rev0Document2 pagesWeld Repair Procedure Rev0aszliza100% (1)

- Qualification of Welding Procedure Specification FCDocument14 pagesQualification of Welding Procedure Specification FCmister pogi100% (4)

- Welding QA Quidelines For FabricationDocument12 pagesWelding QA Quidelines For FabricationRyan Vizcarra FerrerNo ratings yet

- Welding Consumables ProcedureDocument7 pagesWelding Consumables ProcedureSenthil Kumaran100% (1)

- Structural Steel Procedure.Document9 pagesStructural Steel Procedure.Janardhan Surya100% (1)

- WI Dimensional Control Sign1Document6 pagesWI Dimensional Control Sign1gusyahri001No ratings yet

- Fabrication Procedure for Structural SteelDocument14 pagesFabrication Procedure for Structural SteelDanang Edi Prasetyo70% (10)

- Welding Procedures and Welding Qualiy Control For PipingDocument18 pagesWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNo ratings yet

- Fabrication ProcedureDocument17 pagesFabrication ProcedureThi Pham100% (9)

- Method Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Document4 pagesMethod Statement: Pt. Duta Graha Indah TBK Welding Procedure (Preparation)Nigin Parambath50% (2)

- Electrode Baking RegisterDocument1 pageElectrode Baking RegisterSuresh Rathod100% (4)

- Welding QA/QC Manual SampleDocument18 pagesWelding QA/QC Manual SampleDanem Halas100% (1)

- Weld Map & NDE Extent of Pressure VesselDocument32 pagesWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- Fabrication ProcedurDocument7 pagesFabrication ProcedurHarry PangestuNo ratings yet

- Fabrication Inspection ProcedureDocument11 pagesFabrication Inspection Procedurewill_herry100% (6)

- 04 - Product Traceability Procedure - Asf-Qc-Ptp-001Document5 pages04 - Product Traceability Procedure - Asf-Qc-Ptp-001Sherif Yehia0% (1)

- 02 - Calibration Procedure - Asf-Qc-Cal-001Document7 pages02 - Calibration Procedure - Asf-Qc-Cal-001Sherif YehiaNo ratings yet

- 02 - Calibration Procedure - Asf-Qc-Cal-001Document7 pages02 - Calibration Procedure - Asf-Qc-Cal-001Sherif YehiaNo ratings yet

- UGFC-PQCP-49, Rev01 March 01Document7 pagesUGFC-PQCP-49, Rev01 March 01Mahaboob PashaNo ratings yet

- 04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Document8 pages04 - Material Receiving Inspection Procedure - Asf-Qc-Mri-001Sherif YehiaNo ratings yet

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiNo ratings yet

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsNo ratings yet

- NSH-SAOMPP-CMS-PI-004-tie in WorksDocument11 pagesNSH-SAOMPP-CMS-PI-004-tie in WorksNeil JavierNo ratings yet

- NSH-SAOMPP-CMS-PI-001 Piping FabricationDocument13 pagesNSH-SAOMPP-CMS-PI-001 Piping FabricationNeil JavierNo ratings yet

- Duplex Stainless Steels Welding Guidelines EN Juin 2019 WebDocument56 pagesDuplex Stainless Steels Welding Guidelines EN Juin 2019 WebMohamed YousufNo ratings yet

- Duplex Stainless Steel Quality - ASTM A923 Vs ISO 17781: HistoryDocument4 pagesDuplex Stainless Steel Quality - ASTM A923 Vs ISO 17781: HistoryshojiNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- Din 7168-91 PDFDocument7 pagesDin 7168-91 PDFAndres Afanador MuñozNo ratings yet

- 1 Dec2008Document9 pages1 Dec2008el_sharkawy2011No ratings yet

- Welding of Duplex Stainless SteelDocument7 pagesWelding of Duplex Stainless Steelel_sharkawy2011No ratings yet

- Welding Guidelines For Duplex, Super Duplex and Hyper Duplex Stainless SteelsDocument8 pagesWelding Guidelines For Duplex, Super Duplex and Hyper Duplex Stainless Steelsel_sharkawy2011No ratings yet

- OpTransactionHistoryUX522-08-2022 23 - 27 - 53Document1 pageOpTransactionHistoryUX522-08-2022 23 - 27 - 53el_sharkawy2011No ratings yet

- As Run Sheet PQR 051 PDF FreeDocument14 pagesAs Run Sheet PQR 051 PDF Freeel_sharkawy2011No ratings yet

- Humidity and Temperature FormDocument6 pagesHumidity and Temperature Formel_sharkawy2011No ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- Detecting Harmful Phases in Duplex SteelDocument9 pagesDetecting Harmful Phases in Duplex SteelutreshwarmiskinNo ratings yet

- A Avesta-2507-P100 Ss en 5Document1 pageA Avesta-2507-P100 Ss en 5el_sharkawy2011No ratings yet

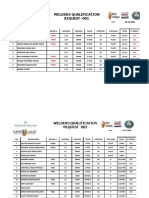

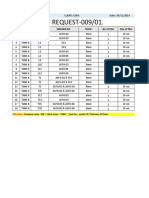

- Welders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJDocument3 pagesWelders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJel_sharkawy2011No ratings yet

- Humidity and Temperature FormDocument6 pagesHumidity and Temperature Formel_sharkawy2011No ratings yet

- PCP Workshop Special Items List Fainal 001 QuotedDocument17 pagesPCP Workshop Special Items List Fainal 001 Quotedel_sharkawy2011No ratings yet

- Working IsoDocument2 pagesWorking Isoel_sharkawy2011No ratings yet

- Eslam Abdelhameed Asme Ix IdDocument1 pageEslam Abdelhameed Asme Ix Idel_sharkawy2011No ratings yet

- PCP Workshop Special Items List Fainal 001 QuotedDocument17 pagesPCP Workshop Special Items List Fainal 001 Quotedel_sharkawy2011No ratings yet

- Measuring and Testing Equipment List: Page 1 of 2Document2 pagesMeasuring and Testing Equipment List: Page 1 of 2el_sharkawy2011No ratings yet

- Calibration Wekding EquipmentsDocument4 pagesCalibration Wekding Equipmentsel_sharkawy2011No ratings yet

- Liquid Penetrant Report: SER Iso No SH# SP# Joint No Joint Type DIA Welder Stamp Evaluation Remarks 1 2 3 4 5 6 7 8 9 10Document1 pageLiquid Penetrant Report: SER Iso No SH# SP# Joint No Joint Type DIA Welder Stamp Evaluation Remarks 1 2 3 4 5 6 7 8 9 10el_sharkawy2011No ratings yet

- RFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20Document1 pageRFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20el_sharkawy2011No ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Corregation Test Sample #1Document2 pagesCorregation Test Sample #1el_sharkawy2011No ratings yet

- 7-Material ASME VIIIDocument23 pages7-Material ASME VIIIel_sharkawy2011No ratings yet

- Iso PDFDocument1 pageIso PDFel_sharkawy2011No ratings yet

- Tanks RT REQUESTDocument4 pagesTanks RT REQUESTel_sharkawy2011No ratings yet

- MT ReportDocument11 pagesMT Reportel_sharkawy2011100% (1)

- RT Request-003-1&-2Document2 pagesRT Request-003-1&-2el_sharkawy2011No ratings yet

- Standard ECDIS Requirements PDFDocument16 pagesStandard ECDIS Requirements PDFBright Okunkpolor100% (2)

- Lotus Domino Mock Test - AdministrationDocument10 pagesLotus Domino Mock Test - AdministrationLotusLearnsNo ratings yet

- V3300-E & V3800-DI-E Engine ManualDocument36 pagesV3300-E & V3800-DI-E Engine ManualcommorilNo ratings yet

- Casing Head Casing HeadDocument3 pagesCasing Head Casing HeadMohsin AwanNo ratings yet

- VIQ 7.17 Revised - Annex 13-100 (D5) Contractor's FamiliarizationDocument3 pagesVIQ 7.17 Revised - Annex 13-100 (D5) Contractor's FamiliarizationHtet lynnNo ratings yet

- NZM Catalog 02 2012 enDocument234 pagesNZM Catalog 02 2012 enengenhariamaccari100% (2)

- Plcwxu30 PDFDocument130 pagesPlcwxu30 PDFСергей КапустянNo ratings yet

- FAG Tapered Roller BearingDocument56 pagesFAG Tapered Roller Bearingpassword100% (1)

- Red JacketDocument8 pagesRed JacketTok NazriNo ratings yet

- resume-Business-Presentation-Specialist-(Trainee)-BengaluruDocument1 pageresume-Business-Presentation-Specialist-(Trainee)-BengaluruDakshesh SoodNo ratings yet

- drf400 450 Brochure PDFDocument20 pagesdrf400 450 Brochure PDFCharles Callahan100% (1)

- PLDTDocument3 pagesPLDTKirk Kervin OrpillaNo ratings yet

- Data Sheet - Air Compressor - Atlas CopcoDocument3 pagesData Sheet - Air Compressor - Atlas CopcoMaaz JunaidiNo ratings yet

- Pre Inspection MeetingDocument6 pagesPre Inspection Meetingwendypost73100% (1)

- Security Manager Technical TrainingDocument26 pagesSecurity Manager Technical TrainingdimitriclNo ratings yet

- Lab Manual Web EngineeringDocument44 pagesLab Manual Web Engineeringvijay ghagreNo ratings yet

- Bts Site Installation Involve Many StagesDocument47 pagesBts Site Installation Involve Many StagesAvinash Kumar SinghNo ratings yet

- DNV 1-503-1 - 2009Document7 pagesDNV 1-503-1 - 2009hadiNo ratings yet

- Python IteratorsDocument8 pagesPython Iteratorssaad_plivo0% (1)

- Finance Focus: Basic Excel TrainingDocument30 pagesFinance Focus: Basic Excel Trainingrajeshaisdu009No ratings yet

- PID CONTROLLER COMMUNICATIONDocument28 pagesPID CONTROLLER COMMUNICATIONgovardhan50No ratings yet

- Onibus 174 o FilmeDocument3 pagesOnibus 174 o Filmeanon-978291No ratings yet

- Tavant Selenium FrameworkDocument6 pagesTavant Selenium Frameworkgirivprasad7721No ratings yet

- Decrypt STOPDjvu v.1.0.0.1Document1,265 pagesDecrypt STOPDjvu v.1.0.0.1Marheni RifaiNo ratings yet

- Eskom Rotek Industries: Providing Critical Engineering ServicesDocument4 pagesEskom Rotek Industries: Providing Critical Engineering Serviceszwanesbu1No ratings yet

- Thytronic Manual Na016-2017Document70 pagesThytronic Manual Na016-2017Ricardo Astocondor Rabanal100% (1)

- Telilabs 8605sr RouterDocument3 pagesTelilabs 8605sr RouterZeebraaAttireNo ratings yet

- Commissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidDocument18 pagesCommissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidKimberly ConleyNo ratings yet

- Angus Hi-Vol SystemsDocument12 pagesAngus Hi-Vol Systemszelda1022No ratings yet

- ABB Motors for Hazardous AreasDocument65 pagesABB Motors for Hazardous Areaslaem269No ratings yet