Professional Documents

Culture Documents

A Avesta-2507-P100 Ss en 5

Uploaded by

el_sharkawy20110 ratings0% found this document useful (0 votes)

14 views1 pageSUPER DUPLEX STAINLESS STEEL ELECTRODES

Original Title

A_Avesta-2507-P100_ss_en_5

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSUPER DUPLEX STAINLESS STEEL ELECTRODES

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageA Avesta-2507-P100 Ss en 5

Uploaded by

el_sharkawy2011SUPER DUPLEX STAINLESS STEEL ELECTRODES

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Avesta 2507/P100

TIG rod, high-alloyed, high corrosion resistant

Classification

EN ISO 14343-A AWS A5.9

W 25 9 4 L N ER2594

Characteristics and typical fields of application

Avesta 2507/P100 is intended for welding super duplex alloys such as SAF 2507, ASTM S32760,

S32550 and S31260. It can also be used for welding duplex type 2205 if extra high corrosion

resistance is required, e.g. in root runs in tubes. Avesta 2507/P100 provides a ferritic-austenitic

weldment that combines many of the good properties of both ferritic and austenitic steels. Welding

without filler metal (i.e. TIG-dressing) is not allowed since the ferrite content will increase drastically

and both mechanical and corrosion properties will be negatively affected.

Structure: Austenite with 45 – 55 % ferrite.

Scaling temperature: Approx. 850 °C (air).

Corrosion resistance:

Excellent resistance to pitting and stress corrosion cracking in chloride containing environments.

Pitting resistance is in accordance with ASTM G48-A, better than 40 °C.

Base materials

Outokumpu EN ASTM BS NF SS

®

SAF 2507 1.4410 S32750 - Z3 CND 25-06 Az 2328

Typical analysis of the solid wire (wt.-%)

C Si Mn Cr Ni Mo N Ferrite

wt.-% 0.02 0.35 0.4 25.0 9.5 4.0 0.25 50 FN (WRC-92)

Mechanical properties of all-weld-metal

Heat Yield strength Tensile strength Elongation Impact work

treatment R p0.2 Rm (L 0 =5d 0 ) ISO-V KV J

MPa MPa % +20 °C –40 °C

u 660 860 28 190 170

u untreated, as welded – Shielding gas Ar (99.95 %)

Operating data

Polarity Shielding gas: ø (mm)

DC ( + ) Ar (99.95 %) 1.6

Ar + 2 % N 2 2.0

Gas flow rate: 4 – 8 l/min 2.4

3.2

Heat treatment: Generally none (in special cases quench annealing at 1100 – 1150 °C).

Interpass temperature: max. 100 °C.

Heat input: 0.5 – 1.5 kJ/mm.

Approvals

TÜV, CE

All information provided is based upon careful investigation and intensive research. 10/2014

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- Din 7168-91 PDFDocument7 pagesDin 7168-91 PDFAndres Afanador MuñozNo ratings yet

- Duplex Stainless Steel Quality - ASTM A923 Vs ISO 17781: HistoryDocument4 pagesDuplex Stainless Steel Quality - ASTM A923 Vs ISO 17781: HistoryshojiNo ratings yet

- Duplex Stainless Steels Welding Guidelines EN Juin 2019 WebDocument56 pagesDuplex Stainless Steels Welding Guidelines EN Juin 2019 WebMohamed YousufNo ratings yet

- OpTransactionHistoryUX522-08-2022 23 - 27 - 53Document1 pageOpTransactionHistoryUX522-08-2022 23 - 27 - 53el_sharkawy2011No ratings yet

- Detecting Harmful Phases in Duplex SteelDocument9 pagesDetecting Harmful Phases in Duplex SteelutreshwarmiskinNo ratings yet

- Welding Guidelines For Duplex, Super Duplex and Hyper Duplex Stainless SteelsDocument8 pagesWelding Guidelines For Duplex, Super Duplex and Hyper Duplex Stainless Steelsel_sharkawy2011No ratings yet

- 1 Dec2008Document9 pages1 Dec2008el_sharkawy2011No ratings yet

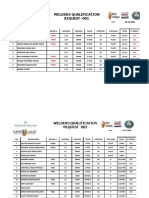

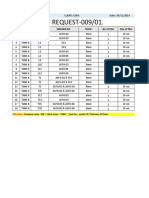

- Welders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJDocument3 pagesWelders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJel_sharkawy2011No ratings yet

- As Run Sheet PQR 051 PDF FreeDocument14 pagesAs Run Sheet PQR 051 PDF Freeel_sharkawy2011No ratings yet

- PCP Workshop Special Items List Fainal 001 QuotedDocument17 pagesPCP Workshop Special Items List Fainal 001 Quotedel_sharkawy2011No ratings yet

- Iso PDFDocument1 pageIso PDFel_sharkawy2011No ratings yet

- Humidity and Temperature FormDocument6 pagesHumidity and Temperature Formel_sharkawy2011No ratings yet

- Welding of Duplex Stainless SteelDocument7 pagesWelding of Duplex Stainless Steelel_sharkawy2011No ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- Humidity and Temperature FormDocument6 pagesHumidity and Temperature Formel_sharkawy2011No ratings yet

- Working IsoDocument2 pagesWorking Isoel_sharkawy2011No ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Calibration Wekding EquipmentsDocument4 pagesCalibration Wekding Equipmentsel_sharkawy2011No ratings yet

- Liquid Penetrant Report: SER Iso No SH# SP# Joint No Joint Type DIA Welder Stamp Evaluation Remarks 1 2 3 4 5 6 7 8 9 10Document1 pageLiquid Penetrant Report: SER Iso No SH# SP# Joint No Joint Type DIA Welder Stamp Evaluation Remarks 1 2 3 4 5 6 7 8 9 10el_sharkawy2011No ratings yet

- 7-Material ASME VIIIDocument23 pages7-Material ASME VIIIel_sharkawy2011No ratings yet

- RFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20Document1 pageRFE For Unit 42HA - 41HA - 32HA - 31HA 22HA - 21HA - 12HA - 11HA 2015 - 21-SAG-PSP-T-000886 2016-09-20el_sharkawy2011No ratings yet

- Measuring and Testing Equipment List: Page 1 of 2Document2 pagesMeasuring and Testing Equipment List: Page 1 of 2el_sharkawy2011No ratings yet

- PCP Workshop Special Items List Fainal 001 QuotedDocument17 pagesPCP Workshop Special Items List Fainal 001 Quotedel_sharkawy2011No ratings yet

- Corregation Test Sample #1Document2 pagesCorregation Test Sample #1el_sharkawy2011No ratings yet

- Tanks RT REQUESTDocument4 pagesTanks RT REQUESTel_sharkawy2011No ratings yet

- RT Request-003-1&-2Document2 pagesRT Request-003-1&-2el_sharkawy2011No ratings yet

- MT ReportDocument11 pagesMT Reportel_sharkawy2011100% (1)

- Eslam Abdelhameed Asme Ix IdDocument1 pageEslam Abdelhameed Asme Ix Idel_sharkawy2011No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chem LiteDocument2 pagesChem LiteICPL-RWPNo ratings yet

- A380 WING RIB Feet CrackingDocument9 pagesA380 WING RIB Feet CrackinggygjhkjnlNo ratings yet

- Dismantle, Inspect and Assemble DPA PumpDocument3 pagesDismantle, Inspect and Assemble DPA PumpNduati JohnNo ratings yet

- Dobeckot EH-411 & 505CDocument2 pagesDobeckot EH-411 & 505CDeependraNo ratings yet

- Kits Opcionais DoosanDocument75 pagesKits Opcionais DoosanChakroune100% (2)

- 16mo3 - EN NOOODocument2 pages16mo3 - EN NOOOM Refaat FathNo ratings yet

- Email - Tridhaatu - Sita Sadan PDFDocument47 pagesEmail - Tridhaatu - Sita Sadan PDFvinujohnpanickerNo ratings yet

- P12 ASME Code Section VIII Division 2Document2 pagesP12 ASME Code Section VIII Division 2muhammad0umar-4No ratings yet

- Michler enDocument3 pagesMichler enMiguel FuentesNo ratings yet

- Asme CCase 2038-4Document2 pagesAsme CCase 2038-4ADAMJSRAONo ratings yet

- Types of Pipe FittingsDocument20 pagesTypes of Pipe FittingsPrashant Kumar mishraNo ratings yet

- BoQ For Water TankDocument10 pagesBoQ For Water TankMenaka GurusingheNo ratings yet

- AHLSTAR PumpDocument6 pagesAHLSTAR PumpJustin TerrellNo ratings yet

- Stress & Strain LectureDocument5 pagesStress & Strain LectureVincentNo ratings yet

- Materi 1 - ACI CertificationDocument35 pagesMateri 1 - ACI CertificationYuzuar AfrizalNo ratings yet

- Construction Method of Steel BridgeDocument95 pagesConstruction Method of Steel BridgeAce Joker100% (2)

- Me 581 Machine Tool Design Section 5 Design of Spindles and Spindle SupportsDocument54 pagesMe 581 Machine Tool Design Section 5 Design of Spindles and Spindle SupportsMlhhemreNo ratings yet

- 8311 Pressure Regulators Technical BulletinDocument16 pages8311 Pressure Regulators Technical BulletinEduardo RodriguesNo ratings yet

- BRDF MEC QAC DJS 502 007 - 1 - SAT Procedure For Overhead CraneDocument16 pagesBRDF MEC QAC DJS 502 007 - 1 - SAT Procedure For Overhead CraneIchsan BahrilNo ratings yet

- Dupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsDocument12 pagesDupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsFernando Tapia GibsonNo ratings yet

- Shear Box TestDocument7 pagesShear Box Testcedric iradukundaNo ratings yet

- Engineering Data Sheet: Bill of MaterialDocument7 pagesEngineering Data Sheet: Bill of MaterialJairo andres Guarnizo SuarezNo ratings yet

- Plastic Vessel Pressure DesignDocument12 pagesPlastic Vessel Pressure Designr1p2100% (1)

- Black Knight 1000 BrochureDocument2 pagesBlack Knight 1000 BrochureAdamMitchellNo ratings yet

- Enventory 1Document11 pagesEnventory 1Albert Jay Oring TuicoNo ratings yet

- Sequence of Well Drilling StepsDocument83 pagesSequence of Well Drilling StepsRobert KochNo ratings yet

- 1735 1-2003Document97 pages1735 1-2003Sean LiongNo ratings yet

- Effective Strengthening of Reinforced Concrete Corbels Using Post-TensioningDocument17 pagesEffective Strengthening of Reinforced Concrete Corbels Using Post-TensioningAlaa tahaNo ratings yet

- Sub Grade PrepDocument3 pagesSub Grade Prepgrace evaristoNo ratings yet

- N.Sharma Construction provides greenhouse quotationDocument2 pagesN.Sharma Construction provides greenhouse quotationSandhya NundahNo ratings yet