Professional Documents

Culture Documents

Preliminary Welding Procedure Specification: Code: EN ISO 15609-1

Uploaded by

wentropremOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preliminary Welding Procedure Specification: Code: EN ISO 15609-1

Uploaded by

wentropremCopyright:

Available Formats

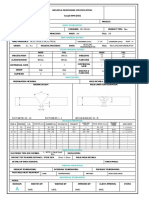

preliminary WELDING PROCEDURE SPECIFICATION

Code : EN ISO 15609-1

WPS

NO.

pWPS/01

REV.

DATE

15/11/13

Location

: Chennai

Examiner or

Examining body

: V.Premchander

Manufacturers

Welding Procedure

Reference No.

: SVPS/WPS/01

Method of preparation

& cleaning

: Grinding and

brushing

WPQR No.

: WPQR/01

Manufacturer

: SVPS

Welding process

: GMAW

Outside diameter (mm)

: NA

Joint Type

: T Joint, Lap Joint

Welding Position

: PB

Parent Metal

Specification

Material thickness

(mm)

: S235J2H

: 10 mm

Welding preparation details

Joint Design

Welding

Sequence

Welding Detailsn

Run

Process

Size of

filler metal

(mm)

Current

(A)

Voltage

(V)

Type of

current/

polarity

GMAW/MI

G(MAG)

1.2mm

230 to 270

27 to 32

DCRP

Designation of welding consumables and trade name

: ER 70S6 / ZOGO

Any special baking or drying

: NA

Gas/ Flux :

: 100% CO2

Run out

length/

travel

speed

(mm/min

)

250 to

300

Other information

:

:

Weld Quality Level acc.

to

: NA

Oscillation: amplitude,

frequency, dwell time

: NA

: NA

Pulse welding details

: NA

: NA

Distance contact tube/

work piece

: 12 to 15mm

: RT

Plasma welding details

: NA

Torch angle

: NA

Shielding

Backing

Wire

feed

speed

(m/min)

: NA

Gas flow rate:

: 12 to 18 lpm

Shielding

Backing

Tungsten electrode

type/ size

Details of back

gouging

Preheat temperature

Inter-pass

: NA

temperature

Post weld heat treatment and or

Ageing

: NA

Time, Temperature, Method

: NA

Heating and cooling rates

: NA

Manufacturer

Name, date and signature

Examiner or examining body

Name, date and signature

Approved by

(For Vestas)

Heat

input

(kJ/mm)

File Name :

Page 2 of 2

You might also like

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- WPQR6Document3 pagesWPQR6Dimitris NikouNo ratings yet

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- ASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies PartsDocument1 pageASME PQR - MMA/SMAW Fillet Welds on OGAP Supplies Partssathi_mechNo ratings yet

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- P-WPS 135 - Mag (S355JR)Document9 pagesP-WPS 135 - Mag (S355JR)Tarun PatelNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPS Welding Procedure SpecificationDocument1 pageWPS Welding Procedure SpecificationburakNo ratings yet

- 5FPipe to plate welding procedureDocument2 pages5FPipe to plate welding procedureTrudie0% (1)

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Report on Welding Procedure Specifications for Single V-Groove JointsDocument15 pagesReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Weld Checklist PQRDocument2 pagesWeld Checklist PQRScott Trainor100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welder Qualification CertificateDocument2 pagesWelder Qualification CertificateNguyen Thanh BinhNo ratings yet

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- Welders CertDocument11 pagesWelders CertAhmed GomaaNo ratings yet

- WPS SumDocument61 pagesWPS SumA. ΒρατσισταNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPS Creation Sample ISODocument1 pageWPS Creation Sample ISOmusheerNo ratings yet

- Write WPS ISO 15614Document10 pagesWrite WPS ISO 15614Hoang LamNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- Asme Sec 9 - ADocument144 pagesAsme Sec 9 - Anidhinchandranvs67% (3)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Tasks and Responsibilities of RWCDocument1 pageTasks and Responsibilities of RWCKDT100% (1)

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- QW-424 Asme Ix 2023Document1 pageQW-424 Asme Ix 2023CARLOS OLIVEROSNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Fillet Weid Break and Macroetch Test PlateDocument1 pageFillet Weid Break and Macroetch Test PlatewijiestNo ratings yet

- Welder Visual Inspection ReportsDocument24 pagesWelder Visual Inspection ReportsKyNo ratings yet

- Welder CertificateDocument6 pagesWelder CertificateA. ΒρατσισταNo ratings yet

- Model WopqDocument2 pagesModel WopqAnilkumarGopinathanNairNo ratings yet

- CIGWELDDocument244 pagesCIGWELDrodastrid5653100% (1)

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- WPS 136 FWDocument1 pageWPS 136 FWsocaugusto100% (1)

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- WPQR TIG Fillet Welding ProcedureDocument3 pagesWPQR TIG Fillet Welding ProcedureDimitris NikouNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- 7c FumigationManualDocument18 pages7c FumigationManualBryanTamaraBarusNo ratings yet

- Production and ME Confilicts AssessDocument18 pagesProduction and ME Confilicts AssesswentropremNo ratings yet

- Bend AllowanceDocument2 pagesBend AllowancewentropremNo ratings yet

- Solidworks K-Factors Sheet for Bending CalculationsDocument9 pagesSolidworks K-Factors Sheet for Bending CalculationsashkansoheylNo ratings yet

- Declare Medical Device ConformityDocument1 pageDeclare Medical Device ConformityIstu PataiNo ratings yet

- Bolt torque sequences and specifications for flangesDocument2 pagesBolt torque sequences and specifications for flangeswentropremNo ratings yet

- Al 3-26-12Document9 pagesAl 3-26-12wentropremNo ratings yet

- What Is The Best Way To Clean Aluminum Before WeldingDocument1 pageWhat Is The Best Way To Clean Aluminum Before WeldingwentropremNo ratings yet

- Internal Audit Checksheet EMS-OHSASDocument32 pagesInternal Audit Checksheet EMS-OHSASwentropremNo ratings yet

- Bolting Procedures: The Following Is A Sample Bolting Procedure Using A Manual or Hydraulic Torque WrenchDocument4 pagesBolting Procedures: The Following Is A Sample Bolting Procedure Using A Manual or Hydraulic Torque WrenchKyaw Kyaw AungNo ratings yet

- Bolt Torque SpecsDocument2 pagesBolt Torque SpecswentropremNo ratings yet

- A Comparison of Ultrasonics and Radiography For Weld InspectionDocument8 pagesA Comparison of Ultrasonics and Radiography For Weld InspectionwentropremNo ratings yet

- Metric FastenersDocument5 pagesMetric FastenerswentropremNo ratings yet

- A Short Guide To Metric Nuts and BoltsDocument10 pagesA Short Guide To Metric Nuts and BoltsSandra FerrellNo ratings yet

- 2.5 SLMTA Receipt Checklist v1Document2 pages2.5 SLMTA Receipt Checklist v1wentropremNo ratings yet

- Ultrasonic Testing FormulasDocument4 pagesUltrasonic Testing FormulasNavneet Singh100% (1)

- Staff Suggestion FormDocument1 pageStaff Suggestion FormwentropremNo ratings yet

- Bolt Torque SpecsDocument2 pagesBolt Torque SpecswentropremNo ratings yet

- New Drug UpdateDocument16 pagesNew Drug UpdateDhaivat JoshiNo ratings yet

- Self Regulating ArcDocument1 pageSelf Regulating ArcwentropremNo ratings yet

- Astm b210mDocument13 pagesAstm b210mwentropremNo ratings yet

- ISO9001ChkDemo (Element)Document3 pagesISO9001ChkDemo (Element)wentropremNo ratings yet

- IMOA Shop Sheet 104Document2 pagesIMOA Shop Sheet 104Aneesh JoseNo ratings yet

- Checklist OHSAS AuditDocument3 pagesChecklist OHSAS AuditwentropremNo ratings yet

- Internal Audit Checksheet ReviewDocument32 pagesInternal Audit Checksheet ReviewRambir KaushikNo ratings yet

- Your Company Name: Suggestion SheetDocument2 pagesYour Company Name: Suggestion Sheetwentroprem100% (1)

- 409 Data SheetDocument2 pages409 Data SheetMatthieuNo ratings yet

- ISO Standards On WeldingDocument6 pagesISO Standards On WeldingwentropremNo ratings yet

- On Site Assessment TemplateDocument8 pagesOn Site Assessment TemplatewentropremNo ratings yet

- Quality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NameDocument7 pagesQuality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NamewentropremNo ratings yet