Professional Documents

Culture Documents

WRC 107 For Vertical Internal Clip

WRC 107 For Vertical Internal Clip

Uploaded by

Alvin SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WRC 107 For Vertical Internal Clip

WRC 107 For Vertical Internal Clip

Uploaded by

Alvin SmithCopyright:

Available Formats

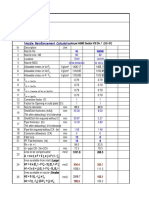

Do not print this sheet, it contains only information as how to design elements of pressure vessel

INPUTS

INPUT CELLS (UNLOCKED) CALCULATIONS BY PROGRAM FORMULAE, NOTATION RESULTS

STEPS 1 Select "0 deg." sheet first. All other sheets will be changed by program

Input values in pink cells ----->

3 4

Results

are shown at "Conclusion" Sheet

Reference of the calculations in this workbook is Pressure Vessel Manual by Mo

ged by program

ure Vessel Manual by Moss

3 of 22

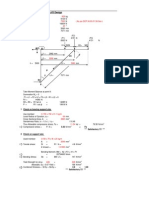

STRESSES IN CYLINDERICAL SHELL ON INTERNAL SUPPORTING CLIP (Vertical)

Vessel Number: D412

At 0 degree

Fig. Dimensions for clips

Notation

Radial load internal design pressure external longitudinal moment external circumferential moment External torsional moment Internal Longitudinal moment Internal Circumferential Moment Longitudinal Shear force Cicumferential Shear Force Radius of Fillet Weld Mean Radius of Shell stress concentration factors Co-efficients to determine for rectangular attachments Longitudinal Membrane Force in Shell Circumferential Membrace Force in Shell Torsional Shear Stress Direct Shear Stress Longitudinal normal stress Circumferential Normal Stress Multiplication Factors for Rectangular Attachments One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Thickness of Attachment Equivalent Thickness of Shell & re-pad Thickness of re-pad Thickness of Shell Leg of Fillet Weld Ratios Based on Vessel & Attachment geometry Pr P ML Mc MT MX M VL Vc r Rm K n, K b K c , K L, K 1, K 2 Nx N lbs/in lbs/in psi psi psi psi in in in in in in in lb psi in-lbs in-lbs in-lbs in-lbs/in in-lbs/in lbs lbs in in

T S x CC , CL C1 C2 h

te tp t w , , 1, 2

Input

4 of 22 internal design pressure Thickness of Shell Leg of Fillet Weld Radius of Fillet Weld Load (on each plate) Impact Factor Radial load (I x Pr) internal design pressure Thickness of Attachment Mean Radius of Shell One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Twice the ratio Fillet Weld radius to Thickness of attachment Membrane Stress concentration factor Bending Stress concentration factor Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Longitudinal Shear force, Circumferential Shear Force Ratio of 1 & 2 External Longitudinal Moment External Circumferential Moment P t w r Pr I Pr P h Rm C1 C2 2r / h Kn Kb 1 2 VL VC c ML MC 1 / 2 4C2Pr / 3 4C1Pr / 3 Rm / t C1/Rm C2/Rm 25 0.55 0.315 0.2 4400 1.2 I x Pr psi in in in lbs

5280 lb 25 psi 0.63 in 84.2 in 2.36 in 2.76 in 0.63 1.65 From Fig. 5-20 1.40 From Fig. 5-20 153.09 0.03 0.03 5280.00 lbs 264.00 lbs 0.86 19430.40 in-lbs 16614.40 in-lbs

h+2w+2t 2r / h

For Radial Load

From Table we compute values of , selecting value of K 1 & K2

If 1 / 2 < 1, then ,

[1-4/3 (1-c)(1-K2)](12) K1 K2 1.48 1.20 0.88 1.25

1.003 1.001 0.999 1.001

N Nx M MX

0.91 1.68 1.76 1.2

For Longitudinal Moment

From Table 5.9 Selecting value of CL & KL & compute value of For Nx and N For M For Mx

3

(122)

KL 3(122) KL 3(122) CL KL

0.031 0.031 0.030 0.033

N Nx M MX

0.89 0.92 0.98 1.05

3

for Circumferential Moment

For Nx and N For M For Mx (122) Kc 3(122) Kc 3(122) CC N Nx M MX KC

0.030 0.030 0.032 0.032

0.97 0.94 1.07 1.1

From graph 5-22 through 5-27 finding dimensionless membrane forces & bending moment Radial Load (Input)

from figure 5-22A from figure 5-22B from figure 5-23A from figure 5-23B NRm /Pr NxRm /Pr M/Pr Mx/Pr 12 15 0.1 0.061

5 of 22

Longitudinal Moment (Input)

from figure 5-24A from figure 5-24B from figure 5-25A from figure 5-25B NRm 2 / ML NxRm 2 / ML MRm / ML MxRm / ML 5 1.5 0.06 0.1

Circumferential Moment (Input)

from figure 5-26A from figure 5-26B from figure 5-27A from figure 5-27B . NRm 2 / Mc NxRm 2 / Mc MRm / Mc MxRm / Mc 1.5 1.7 0.11 0.062

Radial Load (Results)

membrane forces on the basis of figure 5-22A membrane forces on the basis of figure 5-22B membrane Stress on the basis of figure 5-22A membrane forces on the basis of figure 5-22B bending moment on the basis of figure 5-23A bending moment on the basis of figure 5-23B bending moment on the basis of figure 5-23A bending moment on the basis of figure 5-23B

N Nx x M Mx x

(NRm /Pr) x Pr/Rm (NxRm /Pr) x Pr/Rm

752.49 lb/in 940.62 lb/in 2257.48 psi 2821.85 psi 528.00 in-lbs/in 322.08 in-lbs/in 14661.82 psi 8943.71 psi

Kn N / t Kn Nx / t

(M/Pr) x Pr (Mx/Pr) x Pr

6KbM / t2 6KbMx / t2

Longitudinal Moments (Results)

membrane forces on the basis of figure 5-24A membrane forces on the basis of figure 5-24B membrane Stress on the basis of figure 5-24A membrane forces on the basis of figure 5-24B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B

N Nx x M Mx x

(NRm 2 / ML) x CLML / Rm 2 (NxRm 2 / ML) x CLML / Rm 2

392.00 lb/in 121.56 lb/in 15.00 psi 364.69 psi 454.11 in-lbs/in 706.40 in-lbs/in 12610.07 psi 19615.66 psi

Kn N / t Kn Nx / t

(MRm / ML) x ML / Rm (MxRm / ML) x ML / Rm

6KbM / t2 6KbMx / t2

Circumferential Moments (Results)

membrane forces on the basis of figure 5-26A membrane forces on the basis of figure 5-26B membrane Stress on the basis of figure 5-26A membrane forces on the basis of figure 5-26B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B

N Nx x M Mx x

(NRm 2 / Mc) x CCMC / Rm 2 (NxRm 2 / Mc) x CCMC / Rm 2

115.47 lb/in 126.82 lb/in 346.40 psi 380.45 psi 686.94 in-lbs/in 376.62 in-lbs/in 19075.23 psi 10458.27 psi

Kn N / t Kn Nx / t

(MRm / Mc) x Mc Rm (MxRm / Mc) x Mc Rm

6KbM / t2 6KbMx / t2

Shear Stress Longitudinal

Shear Stress, Longitudinal s s= VL / 4C1t 1016.95 psi

Shear Stress Circumferential

Shear Stress, Circumferential c c= Vc / 4C2t 43.48 psi

6 of 22

STRESSES IN CYLINDERICAL SHELL ON INTERNAL SUPPORTING CLIPS

At 90 degree

Notation

Radial load internal design pressure external longitudinal moment external circumferential moment External torsional moment Internal Longitudinal moment Internal Circumferential Moment Longitudinal Shear force Cicumferential Shear Force Radius of Fillet Weld Mean Radius of Shell stress concentration factors Co-efficients to determine for rectangular attachments Longitudinal Membrane Force in Shell Circumferential Membrace Force in Shell Torsional Shear Stress Direct Shear Stress Longitudinal normal stress Circumferential Normal Stress Multiplication Factors for Rectangular Attachments One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Thickness of Attachment Equivalent Thickness of Shell & re-pad Thickness of re-pad Thickness of Shell Leg of Fillet Weld Ratios Based on Vessel & Attachment geometry Pr P ML Mc MT MX M VL Vc r Rm Kn, Kb Kc, KL, K1, K2 Nx N lbs/in lbs/in psi psi psi psi in in in in in in in lb psi in-lbs in-lbs in-lbs in-lbs/in in-lbs/in lbs lbs in in

T S x CC , CL C1 C2 h

te tp

t w , , 1, 2

Input internal design pressure Thickness of Shell Leg of Fillet Weld Radius of Fillet Weld Load Impact Factor Radial load (I x Pr) internal design pressure Thickness of Attachment Mean Radius of Shell One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Twice the ratio Fillet Weld radius to Thickness of attachment Membrane Stress concentration factor Bending Stress concentration factor Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Longitudinal Shear force, Circumferential Shear Force Ratio of 1 & 2 External Longitudinal Moment External Circumferential Moment For Radial Load From Table we compute values of , selecting value of K 1 & K2

t w

r Pr I Pr P

25 0.55 0.315 0.2 220 1.2 I x Pr

psi in in in lbs

h

Rm

264 lb 25 psi 0.63 in 84.2 in 2.36 in 2.76 in 0.63 1.65 From Fig. 5-20 1.40 From Fig. 5-20

C1 C2 2r / h

Kn Kb

h+2w+2t 2r / h

1 2 VL VC 1 / 2 ML MC

Rm / t C1/Rm C2/Rm

153.09 0.03 0.03 264.00 lbs 13.20 lbs

1 / 2 4C2Pr / 3 4C1Pr / 4

0.86 971.52 in-lbs 830.72 in-lbs

7 of 22

If 1 / 2 < 1, then ,

[1-4/3 (1-c)(1-K2)](12)

K1 K2

N Nx M MX

0.91 1.68 1.76 1.2

1.48 1.2 0.88 1.25

1.003 1.001 0.999 1.001

For Longitudinal Moment

From Table 5.9 Selecting value of CL & KL & compute value of For Nx and N For M For Mx

3

(122)

KL 3(122) KL 3(122) CL KL

0.031 0.031 0.030 0.033

N Nx M MX

0.89 0.92 0.98 1.05

3

for Circumferential Moment

For Nx and N For M For Mx (122) Kc 3(122) Kc 3(122) CC N Nx M MX KC

0.030 0.030 0.032 0.032

0.97 0.94 1.07 1.1

From graph 5-22 through 5-27 finding dimensionless membrane forces & bending moment Radial Load (Input)

from figure 5-22A from figure 5-22B from figure 5-23A from figure 5-23B NRm/Pr NxRm/Pr M/Pr Mx/Pr 12 15 0.1 0.061

Longitudinal Moment (Input)

from figure 5-24A from figure 5-24B from figure 5-25A from figure 5-25B NRm2 / ML NxRm2 / ML MRm / ML MxRm / ML 5 1.5 0.06 0.1

Circumferential Moment (Input)

from figure 5-26A from figure 5-26B from figure 5-27A from figure 5-27B . NRm2 / Mc NxRm2 / Mc MRm / Mc MxRm / Mc 1.5 1.7 0.11 0.062

Radial Load (Results)

membrane forces on the basis of figure 5-22A membrane forces on the basis of figure 5-22B membrane Stress on the basis of figure 5-22A membrane forces on the basis of figure 5-22B bending moment on the basis of figure 5-23A bending moment on the basis of figure 5-23B bending moment on the basis of figure 5-23A

N Nx x M Mx

(NRm/Pr) x Pr/Rm (NxRm/Pr) x Pr/Rm

37.62 lb/in 47.03 lb/in 112.87 psi 141.09 psi 26.40 in-lbs/in 16.10 in-lbs/in 733.09 psi

KnN / t KnNx / t

(M/Pr) x Pr (Mx/Pr) x Pr

6KbM / t2

8 of 22

bending moment on the basis of figure 5-23B

6KbMx / t

447.19 psi

Longitudinal Moments (Results)

membrane forces on the basis of figure 5-24A membrane forces on the basis of figure 5-24B membrane Stress on the basis of figure 5-24A membrane forces on the basis of figure 5-24B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B

N Nx x M Mx x

(NRm2 / ML) x CLML / Rm2 (NxRm2 / ML) x CLML / Rm2

19.60 lb/in 6.08 lb/in 15.00 psi 18.23 psi 22.71 in-lbs/in 35.32 in-lbs/in 630.50 psi 980.78 psi

KnN / t KnNx / t

(MRm / ML) x ML / Rm (MxRm / ML) x ML / Rm

6KbM / t2 6KbMx / t

2

Circumferential Moments (Results)

membrane forces on the basis of figure 5-26A membrane forces on the basis of figure 5-26B membrane Stress on the basis of figure 5-26A membrane forces on the basis of figure 5-26B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B

N Nx x M Mx x

(NRm2 / Mc) x CCMC / Rm2 (NxRm2 / Mc) x CCMC / Rm2

5.77 lb/in 6.34 lb/in 17.32 psi 19.02 psi 34.35 in-lbs/in 18.83 in-lbs/in 953.76 psi 522.91 psi

KnN / t KnNx / t

(MRm / Mc) x Mc Rm (MxRm / Mc) x Mc Rm

6KbM / t2 6KbMx / t2

Shear Stress Longitudinal

Shear Stress, Longitudinal s s= VL / 4C1t 50.85 psi

Shear Stress Circumferential

Shear Stress, Circumferential c c= Vc / 4C2t 2.17 psi

9 of 22

STRESSES IN CYLINDERICAL SHELL ON INTERNAL SUPPORTING CLIPS

Fig. Dimensions for clips

At 180 degree Pr P ML Mc MT MX M VL Vc r Rm Kn, Kb Kc, KL, K1, K2 Nx N lbs/in lbs/in psi psi psi psi in in in in in in in lb psi in-lbs in-lbs in-lbs in-lbs/in in-lbs/in lbs lbs in in

Notation

Radial load internal design pressure external longitudinal moment external circumferential moment External torsional moment Internal Longitudinal moment Internal Circumferential Moment Longitudinal Shear force Cicumferential Shear Force Radius of Fillet Weld Mean Radius of Shell stress concentration factors Co-efficients to determine for rectangular attachments Longitudinal Membrane Force in Shell Circumferential Membrace Force in Shell Torsional Shear Stress Direct Shear Stress Longitudinal normal stress Circumferential Normal Stress Multiplication Factors for Rectangular Attachments One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Thickness of Attachment Equivalent Thickness of Shell & re-pad Thickness of re-pad Thickness of Shell Leg of Fillet Weld Ratios Based on Vessel & Attachment geometry

T S x CC , CL C1 C2 h

te tp

t w , , 1, 2

Input internal design pressure Thickness of Shell Leg of Fillet Weld Radius of Fillet Weld Load (on each plate) Impact Factor Radial load (I x Pr) internal design pressure Thickness of Attachment Mean Radius of Shell One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Twice the ratio Fillet Weld radius to Thickness of attachment Membrane Stress concentration factor Bending Stress concentration factor Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Longitudinal Shear force, Circumferential Shear Force Ratio of 1 & 2 External Longitudinal Moment External Circumferential Moment

t w

r Pr I Pr P

25 psi 0.55 in 0.315 in 0.2 in 4400 lbs 1.2 I x Pr 5280 lb 25 psi 0.63 in 84.2 in 2.36 in 2.76 in 0.634921 1.65 From Fig. 5-20 1.4 From Fig. 5-20

h

Rm

C1 C2 2r / h

Kn Kb

h+2w+2t 2r / h

1 2 VL VC c ML MC

Rm / t C1/Rm C2/Rm

153.0909 0.028029 0.032779 5280 lbs 264 lbs

1 / 2 4C2Pr / 3 4C1Pr / 4

0.855072 19430.4 in-lbs 16614.4 in-lbs

For Radial Load

10 of 22

From Table we compute values of , selecting value of K 1 & K2 If 1 / 2 < 1, then ,

[1-4/3 (1-c)(1-K2)](12)

K1 K2

N Nx M MX

0.91 1.68 1.76 1.2

1.48 1.2 0.88 1.25

1.003 1.001 0.999 1.001

For Longitudinal Moment

From Table 5.9 Selecting value of CL & KL & compute value of For Nx and N For M For Mx

3

(122)

KL 3(122) KL 3(122) CL KL

0.031 0.031 0.030 0.033

N Nx M MX

0.89 0.92 0.98 1.05

3

for Circumferential Moment

For Nx and N For M For Mx (122) Kc 3(122) Kc 3(122) CC N Nx M MX KC

0.030 0.030 0.032 0.032

0.97 0.94 1.07 1.1

From graph 5-22 through 5-27 finding dimensionless membrane forces & bending moment Radial Load (Input)

from figure 5-22A from figure 5-22B from figure 5-23A from figure 5-23B NRm/Pr NxRm/Pr M/Pr Mx/Pr 12 15 0.1 0.061

Longitudinal Moment (Input)

from figure 5-24A from figure 5-24B from figure 5-25A from figure 5-25B NRm2 / ML NxRm2 / ML MRm / ML MxRm / ML 5 1.5 0.06 0.1

Circumferential Moment (Input)

from figure 5-26A from figure 5-26B from figure 5-27A from figure 5-27B . NRm2 / Mc NxRm2 / Mc MRm / Mc MxRm / Mc 1.5 1.7 0.11 0.062

Radial Load (Results)

membrane forces on the basis of figure 5-22A membrane forces on the basis of figure 5-22B membrane Stress on the basis of figure 5-22A membrane forces on the basis of figure 5-22B bending moment on the basis of figure 5-23A bending moment on the basis of figure 5-23B

N Nx x M Mx

(NRm/Pr) x Pr/Rm (NxRm/Pr) x Pr/Rm

752.49 lb/in 940.62 lb/in 2257.48 psi 2821.85 psi 528.00 in-lbs/in 322.08 in-lbs/in

KnN / t KnNx / t

(M/Pr) x Pr (Mx/Pr) x Pr

11 of 22

bending moment on the basis of figure 5-23A bending moment on the basis of figure 5-23B

6KbM / t 2 6KbMx / t

14661.82 psi 8943.71 psi

Longitudinal Moments (Results)

membrane forces on the basis of figure 5-24A membrane forces on the basis of figure 5-24B membrane Stress on the basis of figure 5-24A membrane forces on the basis of figure 5-24B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B

N Nx x M Mx x

(NRm2 / ML) x CLML / Rm2 (NxRm2 / ML) x CLML / Rm2

392.00 lb/in 121.56 lb/in 15.00 psi 364.69 psi 454.11 in-lbs/in 706.40 in-lbs/in 12610.07 psi 19615.66 psi

KnN / t KnNx / t

(MRm / ML) x ML / Rm (MxRm / ML) x ML / Rm

6KbM / t 6KbMx / t2

Circumferential Moments (Results)

membrane forces on the basis of figure 5-26A membrane forces on the basis of figure 5-26B membrane Stress on the basis of figure 5-26A membrane forces on the basis of figure 5-26B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B

N Nx x M Mx x

(NRm2 / Mc) x CCMC / Rm2 (NxRm2 / Mc) x CCMC / Rm2

115.47 lb/in 126.82 lb/in 346.40 psi 380.45 psi 686.94 in-lbs/in 376.62 in-lbs/in 19075.23 psi 10458.27 psi

KnN / t KnNx / t

(MRm / Mc) x Mc Rm (MxRm / Mc) x Mc Rm

6KbM / t 6KbMx / t

2 2

Shear Stress Longitudinal

Shear Stress, Longitudinal s s= VL / 4C1t 1016.95 psi

Shear Stress Circumferential

Shear Stress, Circumferential c c= Vc / 4C2t 43.48 psi

12 of 22

STRESSES IN CYLINDERICAL SHELL ON INTERNAL SUPPORTING CLIPS

At 270 degree

Notation

Radial load internal design pressure external longitudinal moment external circumferential moment External torsional moment Internal Longitudinal moment Internal Circumferential Moment Longitudinal Shear force Cicumferential Shear Force Radius of Fillet Weld Mean Radius of Shell stress concentration factors Co-efficients to determine for rectangular attachments Longitudinal Membrane Force in Shell Circumferential Membrace Force in Shell Torsional Shear Stress Direct Shear Stress Longitudinal normal stress Circumferential Normal Stress Multiplication Factors for Rectangular Attachments One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Thickness of Attachment Equivalent Thickness of Shell & re-pad Thickness of re-pad Thickness of Shell Leg of Fillet Weld Ratios Based on Vessel & Attachment geometry Pr P ML Mc MT MX M VL Vc r Rm Kn, Kb Kc, KL, K1, K2 Nx N lbs/in lbs/in psi psi psi psi in in in in in in in lb psi in-lbs in-lbs in-lbs in-lbs/in in-lbs/in lbs lbs in in

T S x CC , CL C1 C2 h

te tp

t w , , 1, 2

Input internal design pressure Thickness of Shell Leg of Fillet Weld Radius of Fillet Weld Load Impact Factor Radial load (I x Pr) internal design pressure Thickness of Attachment Mean Radius of Shell One-Half Circumferential width of rectangular attachment One-Half Longitudinal width of rectangular attachment Twice the ratio Fillet Weld radius to Thickness of attachment Membrane Stress concentration factor Bending Stress concentration factor Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Ratios Based on Vessel & Attachment geometry Longitudinal Shear force, Circumferential Shear Force Ratio of 1 & 2 External Longitudinal Moment External Circumferential Moment For Radial Load From Table we compute values of , selecting value of K1 & K2 If 1 / 2 < 1, then ,

t w

r Pr I Pr P

25 0.55 0.315 0.2 220 1.2 I x Pr

psi in in in lbs

h

Rm

264 lb 25 psi 0.63 in 84.2 in 2.36 in 2.76 in 0.63 1.65 From Fig. 5-20 1.40 From Fig. 5-20

C1 C2 2r / h

Kn Kb

h+2w+2t 2r / h

1 2 VL VC 1 / 2 ML MC

Rm / t C1/Rm C2/Rm

153.09 0.03 0.03 264.00 lbs 13.20 lbs

1 / 2 4C2Pr / 3 4C1Pr / 4

0.86 971.52 in-lbs 830.72 in-lbs

[1-4/3 (1-c)(1-K2)](12)

13 of 22

K1 N Nx M MX

K2

0.91 1.68 1.76 1.2

1.48 1.2 0.88 1.25

1.003 1.001 0.999 1.001

For Longitudinal Moment

From Table 5.9 Selecting value of CL & KL & compute value of For Nx and N For M For Mx

3

(122)

KL 3(122) KL 3(122) CL KL

0.031 0.031 0.030 0.033

N Nx M MX

0.89 0.92 0.98 1.05

3

for Circumferential Moment

For Nx and N For M For Mx (122) Kc 3(122) Kc 3(122) CC N Nx M MX KC

0.030 0.030 0.032 0.032

0.97 0.94 1.07 1.1

From graph 5-22 through 5-27 finding dimensionless membrane forces & bending moment Radial Load (Input)

from figure 5-22A from figure 5-22B from figure 5-23A from figure 5-23B NRm/Pr NxRm/Pr M/Pr Mx/Pr 12 15 0.1 0.061

Longitudinal Moment (Input)

from figure 5-24A from figure 5-24B from figure 5-25A from figure 5-25B NRm2 / ML NxRm2 / ML MRm / ML MxRm / ML 5 1.5 0.06 0.1

Circumferential Moment (Input)

from figure 5-26A from figure 5-26B from figure 5-27A from figure 5-27B . NRm2 / Mc NxRm2 / Mc MRm / Mc MxRm / Mc 1.5 1.7 0.11 0.062

Radial Load (Results)

membrane forces on the basis of figure 5-22A membrane forces on the basis of figure 5-22B membrane Stress on the basis of figure 5-22A membrane forces on the basis of figure 5-22B bending moment on the basis of figure 5-23A bending moment on the basis of figure 5-23B bending moment on the basis of figure 5-23A bending moment on the basis of figure 5-23B

N Nx x M Mx x

(NRm/Pr) x Pr/Rm (NxRm/Pr) x Pr/Rm

37.62 lb/in 47.03 lb/in 112.87 psi 141.09 psi 26.40 in-lbs/in 16.10 in-lbs/in 733.09 psi 447.19 psi

KnN / t KnNx / t

(M/Pr) x Pr (Mx/Pr) x Pr

6KbM / t2 6KbMx / t2

Longitudinal Moments (Results)

membrane forces on the basis of figure 5-24A membrane forces on the basis of figure 5-24B

N Nx

(NRm2 / ML) x CLML / Rm2 (NxRm2 / ML) x CLML / Rm2

19.60 lb/in 6.08 lb/in

14 of 22 membrane Stress on the basis of figure 5-24A membrane forces on the basis of figure 5-24B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B bending moment on the basis of figure 5-25A bending moment on the basis of figure 5-25B

x M Mx x

KnN / t KnNx / t

(MRm / ML) x ML / Rm (MxRm / ML) x ML / Rm

15.00 psi 18.23 psi 22.71 in-lbs/in 35.32 in-lbs/in 630.50 psi 980.78 psi

6KbM / t2 6KbMx / t2

Circumferential Moments (Results)

membrane forces on the basis of figure 5-26A membrane forces on the basis of figure 5-26B membrane Stress on the basis of figure 5-26A membrane forces on the basis of figure 5-26B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B bending moment on the basis of figure 5-27A bending moment on the basis of figure 5-27B

N Nx x M Mx x

(NRm2 / Mc) x CCMC / Rm2 (NxRm2 / Mc) x CCMC / Rm2

5.77 lb/in 6.34 lb/in 17.32 psi 19.02 psi 34.35 in-lbs/in 18.83 in-lbs/in 953.76 psi 522.91 psi

KnN / t KnNx / t

(MRm / Mc) x Mc Rm (MxRm / Mc) x Mc Rm

6KbM / t2 6KbMx / t2

Shear Stress Longitudinal

Shear Stress, Longitudinal s s= VL / 4C1t 50.85 psi

Shear Stress Circumferential

Shear Stress, Circumferential c c= Vc / 4C2t 2.17 psi

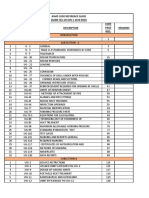

Combined Stress Table

Note = See Sheets: 0, 90, 180, 270

Stress Due to

0 deg Radial Load, P ( Sign is (+) for out ward load & (-) for inward load Membrane Bending Membrane Longitudinal Moment, ML Bending Membrane Circumferential Moment, Mc Bending = PRm / t = Internal Pressure, P x = PRm / 2t = 1913.64 1913.64 90 deg 47.03 16.10

x

180 deg 940.62 322.08 121.56 454.11 706.40 6.34 18.83 706.40 5.77 6.34 34.35 18.83 3827.27 1913.64 1913.64 3827.27 270 deg 47.03 528.00 322.08 121.56 16.10 392.00 26.40

0 deg 752.49 90 deg 37.62 180 deg 752.49 528.00 392.00 454.11 5.77 34.35 270 deg 37.62 26.40

N Nx M Mx N Nx M Mx N Nx M Mx

940.62

3827.27

3827.27

4004

2002

4004

2002

5954

3931

5954

3931

Conclusion

Material Shel YP. at room Temp. Shell YP at 650 F Shell's allowable Strength Maximum induced Stress

= = = = =

SA-516 Gr. 70 38000 Psi 26700 Psi 16020 Psi 5954 Psi Maximum of combined stresses (From combined stress table) 3 times shells's allowable 3 x Allowable Strength SAFE

Allowable stress

48060 Psi Total Stresses <

Design is =

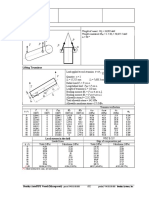

Fig. 5-20 Stress Concentration factor (Ref. Pressure Vessel Manual by Moss)

NRm/Pr

NxRm/Pr

Fig. 5-22: Membrane force on a cylinder due to radial load on attachment.

M/Pr

Mx/Pr

Fig. 5-23: Bending Moment in a Cylinder due to a radial load on attachment.

NRm / ML

NxRm / ML

Fig. 5-24: Membrane Force in a cylinder due to radial load on attachment

MRm / ML

MxRm / ML

Fig. 5-25: Bending Moment ina cylinder due to longitudian moment on attachment.

NRm / Mc

NxRm / Mc

Figure: 5-26 Membrane force in a cylinder due to circumferential moment on attachment.

MRm / Mc

MxRm / Mc

Fig.5-27: Bending Moment in a cylinder due to circumferential moment on attachment.

You might also like

- Orifice Sizing CalculationDocument24 pagesOrifice Sizing Calculationjamestpp67% (3)

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- Post-Tension Flat Slab Design ExampleDocument17 pagesPost-Tension Flat Slab Design ExampleAwni Alkhteeb92% (12)

- Spec For Process Strainer 7Document4 pagesSpec For Process Strainer 7Alvin SmithNo ratings yet

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- Painting SpecDocument54 pagesPainting Specashim_scribd100% (4)

- T3000CS2264744 - 0 Calculation - Blast Wall SupportsDocument104 pagesT3000CS2264744 - 0 Calculation - Blast Wall SupportsnpwalNo ratings yet

- WRC 297 RWE NODE 6340 25febDocument4 pagesWRC 297 RWE NODE 6340 25febnamasralNo ratings yet

- New Microsoft Excel WorksheetDocument29 pagesNew Microsoft Excel WorksheetAbdullahMofarrahNo ratings yet

- Platform Calculation (Jan 22-2012)Document28 pagesPlatform Calculation (Jan 22-2012)SAMER OSMANNo ratings yet

- Design As Per APIDocument82 pagesDesign As Per APINeeraj BhallaNo ratings yet

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Specification For Painting-Piping & EquipmentDocument21 pagesSpecification For Painting-Piping & EquipmentAlvin Smith100% (2)

- EC2 Continuous Beam DesignDocument14 pagesEC2 Continuous Beam Designikanyu79No ratings yet

- Analytical Considerations The Code Qualification Piping SystemsDocument17 pagesAnalytical Considerations The Code Qualification Piping SystemsMahendra RathoreNo ratings yet

- Sizing Calculation FCVDocument3 pagesSizing Calculation FCVYawar QureshiNo ratings yet

- WRC Nozzle LoadsDocument3 pagesWRC Nozzle LoadsGovindan KrishnamoorthybashyamNo ratings yet

- Evaluation of Flanged Connections Due To Piping L.oaoDocument9 pagesEvaluation of Flanged Connections Due To Piping L.oaoSJNo ratings yet

- Wind Design - ASCE 7-16Document22 pagesWind Design - ASCE 7-16Nguyen Tan PhatNo ratings yet

- ABC QC ManualDocument45 pagesABC QC ManualFanny McWinkerbeanNo ratings yet

- F - Deludge SystemDocument11 pagesF - Deludge Systemkelvin_totNo ratings yet

- Nozzle Reinforcement Calculation Excel SheetDocument3 pagesNozzle Reinforcement Calculation Excel Sheetramesh punjabiNo ratings yet

- Allowable Nozzle LoadsDocument7 pagesAllowable Nozzle LoadsSiva baalanNo ratings yet

- Datasheet of Deluge ValveDocument2 pagesDatasheet of Deluge ValveAlvin SmithNo ratings yet

- PV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2Document15 pagesPV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2SYedZYnAleNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Three Saddle Supports For Horizontal VesselDocument7 pagesThree Saddle Supports For Horizontal VesselhuangjlNo ratings yet

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsAlvin Smith100% (1)

- Pressure Safety Valve Sizing Calculation Rev.01 APUDocument10 pagesPressure Safety Valve Sizing Calculation Rev.01 APUAlvin SmithNo ratings yet

- Code Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2Document2 pagesCode Case 2901 - Consideration of External Loads On ASME B16.5 Standard Flanges Under ASME Code Section VIII, Division 1 & 2msn1981No ratings yet

- Concession Request FormDocument2 pagesConcession Request FormAlvin Smith88% (8)

- Fatigue Analysis SeminarDocument42 pagesFatigue Analysis SeminarDavid JeongNo ratings yet

- Stress Young Modulus and Thermal Expansion Coefficients of SteelsDocument51 pagesStress Young Modulus and Thermal Expansion Coefficients of Steelswili_ab8040No ratings yet

- Pipe Size CalculationDocument22 pagesPipe Size CalculationShaik FaridhNo ratings yet

- Relay Settings Tables - 12mar12Document5 pagesRelay Settings Tables - 12mar12Alvin SmithNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument14 pagesCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- SIF CalculatorDocument4 pagesSIF CalculatorKannaphat Wattanaphan100% (1)

- Tutorial of WRC 107 For TrunnionDocument9 pagesTutorial of WRC 107 For TrunnionAlvin SmithNo ratings yet

- Tutorial of WRC 107 For TrunnionDocument9 pagesTutorial of WRC 107 For TrunnionAlvin SmithNo ratings yet

- Technical DataDocument48 pagesTechnical Datashekhar2681No ratings yet

- Wall Thickness Calculation of Offshore PipelinesDocument1 pageWall Thickness Calculation of Offshore PipelinesAlvin Smith0% (1)

- Wall Thickness Calculation of Offshore PipelinesDocument1 pageWall Thickness Calculation of Offshore PipelinesAlvin Smith0% (1)

- ASME Section VIII - Div. 2 - Interpretations Volume 63Document16 pagesASME Section VIII - Div. 2 - Interpretations Volume 63Luis Arturo RodríguezNo ratings yet

- US5711350 - Piping System Providing Minimal Acoustically Induced Structural Vibrations and Fatigue, Eisinger PDFDocument10 pagesUS5711350 - Piping System Providing Minimal Acoustically Induced Structural Vibrations and Fatigue, Eisinger PDFYh LeongNo ratings yet

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet

- Input Echo, Leg & Lug Item 1, Description: New Leg/LugDocument2 pagesInput Echo, Leg & Lug Item 1, Description: New Leg/LugEngr Khurram Jaan RamayNo ratings yet

- ASME e EN STDDocument23 pagesASME e EN STDmatteo2009No ratings yet

- WRC-107 by Paresh PDFDocument18 pagesWRC-107 by Paresh PDFishu vohraNo ratings yet

- Asme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)Document2 pagesAsme Code Reference Guide (Asme Sec - Viii Div.1 2019 Edn)anu radhaNo ratings yet

- Tank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeDocument1 pageTank Baffle Thickness Calculation: Baffle Provided Thickness Is Greater Than Require Thickness Hecnc Design Is SafeABIDEEN BAMNENo ratings yet

- 09 Job Procedure For Fire ProofingDocument4 pages09 Job Procedure For Fire ProofingAlvin Smith100% (2)

- Platform - Bracing SupportDocument12 pagesPlatform - Bracing Supportpandiangv100% (1)

- Code Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsDocument1 pageCode Case 2901 Nozzle S1 SL No Description Unit Value: Provided Nozzle Flange Is Safe For External LoadingsguravdrNo ratings yet

- WRC 297Document94 pagesWRC 297joshuamaagNo ratings yet

- WRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)Document3 pagesWRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)naim100% (1)

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- Motor Detail Specification PDFDocument6 pagesMotor Detail Specification PDFAlvin SmithNo ratings yet

- BA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsDocument9 pagesBA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsBhavana ValetiNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Auto PipeDocument18 pagesAuto PipeAdi Sutardi100% (1)

- Ccopps WebinarDocument36 pagesCcopps WebinarAkenathon71No ratings yet

- COADE's Application of Welding Research Council Bulletins 107, 297 and 368Document3 pagesCOADE's Application of Welding Research Council Bulletins 107, 297 and 368shivabtowin3301100% (3)

- WRC Buletin 297Document3 pagesWRC Buletin 297Alexandre OgrandeNo ratings yet

- WRC 107 and WRC 297Document2 pagesWRC 107 and WRC 297Harshal JadhavNo ratings yet

- Comparison of The ASME, BS and CEN Fatigue Design Rules For Pressure Vessels (October 2003)Document2 pagesComparison of The ASME, BS and CEN Fatigue Design Rules For Pressure Vessels (October 2003)sagar1503No ratings yet

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Document2 pagesBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikNo ratings yet

- PveliteDocument5 pagesPveliteprachi chauhanNo ratings yet

- Shell Calculations NotesDocument35 pagesShell Calculations NotesRamakrishnan SrinivasanNo ratings yet

- Hinge DesignDocument2 pagesHinge Designpare222No ratings yet

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Vortex Excitation of Metal BellowsDocument8 pagesVortex Excitation of Metal BellowsMourad BenabderrahmaneNo ratings yet

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- 4.3 Moment Magnification PDFDocument13 pages4.3 Moment Magnification PDFChetan ChaudhariNo ratings yet

- A Slip Factor Calculation in Centrifugal Impellers Based On Linear Cascade DataDocument21 pagesA Slip Factor Calculation in Centrifugal Impellers Based On Linear Cascade DatajavadamniNo ratings yet

- Wind LoadDocument6 pagesWind LoadRajasekar Meghanadh0% (1)

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Comments On GAD Ball ValveDocument2 pagesComments On GAD Ball ValveAlvin SmithNo ratings yet

- Pressure Instruments: Engineers India LimitedDocument2 pagesPressure Instruments: Engineers India LimitedAlvin SmithNo ratings yet

- Comments On GAD Ball ValveDocument2 pagesComments On GAD Ball ValveAlvin SmithNo ratings yet

- Anurudh - Hazira FWNDocument2 pagesAnurudh - Hazira FWNAlvin SmithNo ratings yet

- 3-1643-0408 - Rev - 1 Support Legend IBRDocument1 page3-1643-0408 - Rev - 1 Support Legend IBRAlvin SmithNo ratings yet

- 3-1643-0402 - Rev - 2 Index of IBR DocumentsDocument1 page3-1643-0402 - Rev - 2 Index of IBR DocumentsAlvin SmithNo ratings yet

- 3-1643-0406 Rev 1 Isometrics Line Index IBRDocument1 page3-1643-0406 Rev 1 Isometrics Line Index IBRAlvin SmithNo ratings yet

- Engineers India Limited: Specification REV Plant: 003 Ongc, MehsanaDocument1 pageEngineers India Limited: Specification REV Plant: 003 Ongc, MehsanaAlvin SmithNo ratings yet

- (Lt'Ldla) : Offshore Hook - Uf Construction ServisesDocument1 page(Lt'Ldla) : Offshore Hook - Uf Construction ServisesAlvin SmithNo ratings yet