Professional Documents

Culture Documents

Design of RC Retaining Walls

Design of RC Retaining Walls

Uploaded by

qaiserkhan001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of RC Retaining Walls

Design of RC Retaining Walls

Uploaded by

qaiserkhan001Copyright:

Available Formats

Department of Civil Engineering, University of Engineering and Technology Peshawar

Lecture - 09

Design of RC Retaining Walls

By: Prof Dr. Qaisar Ali Civil Engineering Department UET Peshawar

drqaisarali@nwfpuet.edu.pk

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Topics

Retaining Walls Terms Related to Retaining Walls Types of Retaining Walls Soil Parameters Earth Pressure for Normal Conditions of Loadings Retaining Wall Failure Drainage and Other Details Design of Cantilever Retaining Wall: Example

Prof. Dr. Qaisar Ali Reinforced Concrete Design II 2

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Walls

Retaining walls are used to hold back masses of earth or other loose material. Used in the construction of railways, highways, bridges, canals, basement walls in buildings, walls of underground reservoirs, swimming pools etc.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Walls

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Terms Related to Retaining Walls

Reinforcement Deflected Applied shape placement loading on wall

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

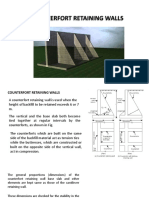

Types of Retaining Walls

Gravity Wall (a), Cantilever Wall (b), Counterfort Wall (c).

Retains the earth Weight on top entirelyof byearth its own of heels contributes weight and containsto stability no reinforcement

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Soil Parameters

Table: Unit weight (), effective angles of internal friction (), and the coefficient of friction with concrete (f)

Should be used as backfill for retaining walls wherever possible The value of may be unconservative under saturated conditions Soil 1. Sand or gravel without fine particles, highly permeable 2. Sand or gravel with silt mixture, low permeability 3. Silty sand, sand and gravel with high clay content 4. Medium or stiff clay 5. Soft clay, silt Unit Weight (s), pcf 110 to 120 120 to 130 110 to 120 100 to 120 90 to 110 (degree) 33 to 40 25 to 35 25 to 30 25 to 35 20 to 35 f 0.5 to 0.6 0.4 to 0.5 0.3 to 0.4 0.2 to 0.4 0.2 to 0.3

the values do not account for probable additional pressures due to pore water, seepage, frost, etc

Prof. Dr. Qaisar Ali Reinforced Concrete Design II

coefficient of friction f between concrete and various soils

7

Department of Civil Engineering, University of Engineering and Technology Peshawar

Earth Pressure for normal conditions of loading

Conditions of Loading:

1. 2. 3.

Horizontal surface of fill at the top of the wall (figure a), Inclined surface of fill sloping up and back from top of the wall (figure b), Horizontal surface of fill carrying a uniformly distributed additional load (surcharge), such as from goods in a storage yard or traffic on a road (figure c).

h = s / s

The increase in pressure caused by uniform surcharge s (figure c) is computed by converting its load into an equivalent imaginary height of earth (h') above the top of the wall such that, h = s / s

Prof. Dr. Qaisar Ali Reinforced Concrete Design II 8

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

A wall may fail in three different ways:

1.

The individual structural parts (stem, toe, heel) of the wall may not be strong enough to resist the acting forces.

2.

The wall as a whole may be bodily displaced by the earth pressure, without breaking up internally.

1. 2.

Overturning Sliding

3.

The soil beneath the wall may fail.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Individual Parts (stem, toe and heel) of Retaining Wall

The stem, heel or toe of the retaining wall may fail in bending and shear such as when a vertical cantilever wall is cracked by the earth pressure acting on it.

The design of these components require the determination of the necessary dimensions, thicknesses, and reinforcement to resist the moments and shears.

The usual load factors and strength reduction factors of the ACI Code may be applied.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

10

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Individual Parts of Retaining Wall

ACI load factors relating to structural design of retaining walls are summarized below (ACI 9.2):

U = 1.2D + 1.6L + 1.6H U = 0.9D + 1.6H U = 1.2D + 1.6L

Table: ACI Load Factors

Location

Pressure of Soil Weight of Toe Slab Weight of Heel Slab Weight of Surcharge

Prof. Dr. Qaisar Ali Reinforced Concrete Design II

Load Factor

1.6 0.9 1.2 1.6

11

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Individual Parts of Retaining Wall

Reinforcement requirements in stem, toe and heel of a RC retaining wall 0.0015Ag

(ACI 14.3.2)

Maximum horizontal

spacing and

for

both

vertical

reinforcement: 3h or18 0.0025Ag

(ACI 14.3.3)

As,main (3 (fc)/fybd 200bd/fy)

Supporting bars (#4 @ 18) approximately

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

12

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure Due to Bodily Displacement of Retaining Wall

To safeguard the wall against bodily displacements, i.e., to ensure its external stability, the overall factors of safety is evaluated by comparing resisting forces to maximum loads acting under service conditions.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

13

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure Due to Bodily Displacement of Retaining Wall

Factor of safety against overturning about toe:

(FOS)OT = Stabilizing moment / overturning moment = W a / P y 1.5

Where a is the distance of the resultant W = Rv from the toe

Factor of safety against sliding:

(FOS)S = Rv / P 1.5 ; where Rv = W

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

14

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure Due to Bodily Displacement of Retaining Wall

Determination of a: a can be determined by taking moment of applied loads about toe (point O).

Taking moment of all forces about toe edge: Rva Py = W1x1 + W2x2 + W3x3 + W4x4 Where, Rv = W1 + W2 + W3 + W4 Therefore, {W1x1 + W2x2 + W3x3 + W4x4 Py} a= Rv Wx Py a= Rv

Prof. Dr. Qaisar Ali

x4 x3 W3 W4

Rv

x2 O

a

W2 x1 W1

Reinforced Concrete Design II

15

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Soil Beneath the Wall

If the pressure of the wall on the soil beneath exceeds the maximum allowable limits, the soil beneath the wall may fail.

Computed

soil

bearing

pressures,

for

service

load

conditions, are compared with allowable values set suitably lower than ultimate bearing values.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

16

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Soil Beneath the Wall

Soil pressure distribution for various locations of resultant R of Rv and P.

R = Rv R

R = P + Rv R

R = P + Rv R

R = P + Rv

R at mid location

Prof. Dr. Qaisar Ali

R within middle third

R at edge of middle third

R outside middle third

17

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Soil Beneath the Wall

Bearing Pressure Calculation

When Resultant of vertical and horizontal loads lie in middle third of base slab (a > l/3)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

18

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Soil Beneath the Wall

Bearing Pressure Calculation

When Resultant of vertical and horizontal loads lie just at the edge of middle third of base slab (a = l/3)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

19

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Soil Beneath the Wall

Bearing Pressure Calculation

When Resultant of vertical and horizontal loads lie outside the middle third of base slab (a < l/3)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

20

10

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Failure of Soil Beneath the Wall

It is good practice, in general, to have the resultant located within the middle third.

If, as is mostly the case, the resultant strikes within the middle third, adequate safety against overturning exists and no special check need be made.

If the resultant is located outside the middle third, a factor of safety of at least 1.5 should be maintained against overturning.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

21

Department of Civil Engineering, University of Engineering and Technology Peshawar

Drainage and Other Details

Failures or damage to retaining walls, in most cases, occur due to one of two causes:

1. 2.

Overloading of the soil under the wall with consequent forward tipping, and Insufficient drainage of the backfill.

Allowable bearing pressures should be selected with great care.

Soil immediately underlying the footing and the deeper layers should necessarily be investigated.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

22

11

Department of Civil Engineering, University of Engineering and Technology Peshawar

Drainage and Other Details

Drainage ways: can be provided in various

Continuous back drain: Most efficient but expensive if material not available locally Longitudinal Drains: To prevent outflow to seep into the soil underneath the wall Weep Holes: usually spaced horizontally at 5 to 10 ft.

Prof. Dr. Qaisar Ali Reinforced Concrete Design II 23

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Design the cantilever retaining wall for the following data: 400 lb/ft2 (Live load surcharge)

Unit weight of soil, s = 120 pcf Angle of internal friction, = 30o

11-6

(with adequate drainage to be provided) Base friction coefficient, f = 0.5 Kah = 0.333, Kph = 3.0

3-6

c = 150 pcf; fc = 4500 psi; fy = 60000 psi

Allowable bearing pressure (qa) = 8000 psf

Prof. Dr. Qaisar Ali Reinforced Concrete Design II 24

12

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes

Trial dimensions for cantilever retaining wall can be calculated as shown in figure below using thumb rules

R.C.C Design by Sushil Kumar). (reference: topic 24.7, pg 705, Treasures of

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

25

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes

Let, B = 0.65h = 0.65 15 = 9.75 D = h/10 = 15/10 = 1.5 Top width of arm of retaining wall = 8 Width of arm at bottom = h/12 = 15/12 = 1.25 = 15 Length of toe = B/3 = 9.75/3 = 3.25 Equivalent depth of surcharge (h) = s / s = 0.4 / 0.120 = 3.33

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

26

13

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes (Stability checks)

Active earth pressure at base (see figure) of retaining wall for the case of horizontal backfill surface with surcharge is given as: (Pa) = (1/2){Kahsh(h + 2 h)}

Here h = total height of retaining wall = 15 Pa = (1/2)(0.333 0.120 15)(15 + 2 3.33) = 6.43 kips

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

27

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes (Stability checks)

And location of resultant from base of retaining wall is: y = (h2 +3hh)/3(h+2h) = (152 + 3 15 3.33)/3 x (15 + 2 3.33) = 5.77

Therefore, Overturning moment (OTM) = Pay = 6.43 x 5.77 = 37.10 ft-k Now calculate the weights of areas and take their moment about toe edge (shown next).

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

28

14

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes (Stability checks)

Table: Weights and moments about front edge (toe) of retaining wall.

S.No 1 2 3 4 5 6 0.15 0.15 0.15 0.12 0.12 0.12 Area (A) (8/12) 13.5 = 9 (1/2)(7/12)(13.5) = 3.94 9.75 1.5 = 14.625 3.25 2 = 6.5 (1/2)(7/12)(13.5) = 3.94 5.25 16.83 = 88.35 W = A 1.35 0.591 2.2 0.78 0.4728 10.602 W=Rv =16.00 k

Prof. Dr. Qaisar Ali

x (from toe) 3.58 4.11 4.875 1.625 4.31 7.125

Wx 4.83 2.43 10.73 1.27 2.04 75.54 (Wx)= 96.84 k

29

13.5

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes (Stability checks)

F.O.S against OT = (Wx) / OTM = 96.84 / 37.10 = 2.61 > 1.5 O.K.

Factor of Safety against sliding = Rv / Pa Total horizontal force sliding the wall (Pa) = 6.43 kips = tan 0.577 Resistance to sliding = Rv = 0.577 16.00 = 9.23 kips Factor of safety against sliding = Rv / Pa = 9.23 / 6.43 = 1.44.

This is slightly less than the recommended value of 1.5 and can be regarded as adequate. However, FOS can be increased by providing key.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

30

15

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes (Stability checks)

Check for Allowable Pressure: Rv = 16.00 kips

To find the point of action a of Rv, take moment of forces about the toe of wall: aRv = (Wx) OTM a = {(Wx) OTM}/Rv = (96.84 37.10)/ 16.00= 3.73 l/3 = 9.75/3 = 3.25 < 3.73

The resultant lies within the middle third.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

31

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes (Stability checks)

qmax = (4l 6a) Rv/l2 qmin = (6a 2l) Rv/l2 l = 9.75; a = 3.73; and Rv = 16.00 kips qmax = (4 9.75 6 3.73) 16.00/9.752 = 2.80 ksf

qmin = (6 3.73 2 9.75) 16.00/9.752 = 0.48 ksf

Allowable pressure = 8000 psf or 8 ksf > qmax, O.K. If not, increase the width (B) of the retaining wall.

Reinforced Concrete Design II 32

Prof. Dr. Qaisar Ali

16

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 01: Sizes

Selected dimensions.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

33

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 02: Loads (Toe Slab)

Factored Self weight of toe = Ignored Factored earth fill load from above= Ignored

b = Unit width

Factored soil pressure at exterior end of toe slab = 1.6 2.80 1= 4.48 k/ft Factored soil pressure at interior end of toe slab = 1.6 2.03 = 3.25 k/ft

0.48

0.48

h=1.5

2.80 2.03

3.25 Prof. Dr. Qaisar Ali Reinforced Concrete Design II 34

17

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 02: Loads (Heel)

Factored Self weight of heel = 1.2conchb =1.2 0.15 1.5 1= 0.27 k/ft Factored earth fill load = 1.6fillhfillb = 1.6 0.12 13.5 1= 2.592 k/ft Factored surcharge load = 1.6fillhsurchargeb = 1.6 0.12 3.33 1 = 0.639 k/ft Total factored load on heel = 0.27 + 2.592 + 0.639 = 3.50 k/ft

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

35

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 03: Analysis (Arm)

Analysis for flexure

General equation of factored active earth pressure w.r.t bottom of arm is: Pa = 1.6 (1/2)(0.333 0.120h)(h + 2 3.33)

Taking moment at the base of the arm. Moment arm will be equal to: y = {(h2 +3h 3.33)/3}(h+2 3.33)

Mu = Pay

(neglecting passive earth pressure for safety)

= 1.6(1/2) (0.3330.120h) (h + 2 3.33) (h2 +3h 3.33)/3(h+2 3.33) = (0.0319h2 + 0.212h) (h2 +9.99h)/3(h + 6.66) Using this equation, bending moment diagram for arm can be drawn for various values of h..

Prof. Dr. Qaisar Ali Reinforced Concrete Design II 36

18

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 03: Analysis (Arm)

Analysis for flexure

Mu = Pay = (0.0319h2 + 0.212h) (h2 +9.99h)/3(h + 6.66) 0 < h < 13.5

0 3 6 Pa 9 y 12 33.54 kip-ft 45.49 kip-ft

Prof. Dr. Qaisar Ali Reinforced Concrete Design II 37

1.24 kip-ft 6.11 kip-ft 16.34 kip-ft Mnmin = 39.14 kip-ft

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 03: Analysis of Arm for Shear

Kahs(h + h)h/ (h+h) = Kahsh = 0.3330.120 3.33 = 0.133 kip

0 12.46 3 6

0.63 kips

Factored Shear (Vu) = 1.6 4.75 = 7.6 kip

9 12

Kahs(h + h) = 0.3330.120 (13.5+3.33) = 0.67 kips

4.75 kip

Shear force diagram

Load causing shear at critical section Prof. Dr. Qaisar Ali Reinforced Concrete Design II 38

19

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 03: Analysis (Toe)

Analysis for flexure and shear

Vu = 6.51 kips

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

39

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 03: Analysis (Heel)

Analysis for flexure and shear

Vu = 14.14 kips

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

40

20

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Arm)

Design for flexure: For h = 13.5; Mu = 45.49 ft-kip/ft = 545.87 in-kip/ft Asmin = 3{(4500)}/60000)bd = 0.0034 12 (15 2 0.5) = 0.51 in2/ft Mn = Asminfy (d-a/2) = 0.9 0.51 60 (12.5 - 0.66/2) = 469.7 in-k/ft (39.14 ft-kip/ft)

Mn < Mu, therefore using trial method As = 0.846 in2, (#8 @ 11.17) Maximum spacing for main steel reinforcement is:

3h = 3 x 15 = 45 ; 18

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

41

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Arm)

Similarly for other depths, the design is given in tabular form as below:

Table: Design of main bars in arm of retaining wall.

Depth (h), ft Thickness of arm (w), in Moment (M) (in-k/ft) Asmin Mn,min Governing Governing Moment Area of (in-k/ft) steel Design spacing Maximum spacing allowed by ACI Final Spacing for #8 Bars

0 3 6 9 12 13.5

8.00 9.56 11.11 12.67 14.22 15.00

0 14.89 73.36 196.09 403.74 545.87

0.224 0.287 0.351 0.414 0.478 0.51

58.81 98.98 149.52 210.45 281.75 321.3

58.81 98.98 149.52 210.45 403.74 545.87

0.224 0.287 0.351 0.414 0.66 0.846

42 32 26 24 14 11

18 18 18 18 18 18

18 18 18 9 9 9

Therefore, from a depth of 13.5 ft to 9 ft, provide #8 @ 9. And from 9 ft to top end, provide #8 @ 18.

Reinforced Concrete Design II 42

Prof. Dr. Qaisar Ali

21

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Arm)

Horizontal Bars:

According to ACI 14.3.3, Ast = 0.0025bh (for deformed bars larger than #5) Ast = 0.0025 12 15 = 0.45 in2/ft (3/4 @ 11.73) Use 3/4 @ 9 c/c

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

43

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Arm)

Although not required by the Code for cantilever retaining walls, vertical steel equal to 0.0012 times the gross concrete area will also be provided on exposed face of wall.

As = 0.0015 12 15 = 0.27 in2 Using 3/4 dia bar with area Ab = 0.44 in2 Spacing =Area of one bar (Ab)/Ast = (0.44 in2/0.27 in2/ft) 12 = 19.5 (using #6 @ 19.5)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

44

22

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Arm)

Design for Shear:

Vu = 7.6 kips Shear Capacity is given as: Vc = 2(4500) 12 12.5/1000 = 15.09 kips > 7.6 kips O.K.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

45

Department of Civil Engineering, University of Engineering and Technology Peshawar

Retaining Wall Failure

Solution: Detailing in arm of retaining wall.

0.0012Ag (#6 @ 18)

(#8 @ 18)

Horizontal reinforcement (#6 @ 9)

(#8 @ 9)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

46

23

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Toe)

Design for flexure:

Mu = 258 in-k/ft Asmin = 3{(4500)/60000)bd = 0.0034 12 (18 3 0.5) = 0.592 in2/ft Mn = Asminfy (d a/2) = 0.9 0.592 60 (14.5 0.774/2) = 451.16 in-k/ft

Mn > Mu, therefore As = Asmin = 0.592 in2/ft (#8 @ 16) Maximum spacing for main steel reinforcement:

3h = 3 18 = 54; 18 Finally use #8 @ 16 c/c.

Also provide #4 @ 18 c/c as supporting bars for main bars.

47

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Toe)

Design for Shear:

Vu = 6.51 kip Vc = 2 0.75 (4500) 12 14.5/ 1000 = 17.51 kip > 6.794 kip, O.K. If not O.K, then increase thickness of toe.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

48

24

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Heel)

Design for Flexure:

Mu = 578.8 in-kip/ft Asmin = 3{(4500)/60000)bd = 0.0034 12 (18 3 0.5) = 0.592 in2/ft Mn = Asminfy (d-a/2)= 0.9 0.592 60 (14.5 0.774/2) = 451.16 in-kip/ft

Mn < Mu, therefore using trial method As = 0.765 in2,(#8 @ 12.39) Maximum spacing for main steel reinforcement:

3h = 3 x 18 = 54 ; 18 Finally use #8 @ 12 c/c.

Also provide #4 @ 18 c/c as supporting bars for main bars.

49

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Heel)

Design for Shear:

Vu = 14.14 kips Vc =2 0.75 (4500) 12 14.5/ 1000 = 17.51 kips > 14.14 kips, O.K. If not, increase thickness of heel.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

50

25

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example

Solution:

Step No 4: Design (Heel)

Development length check of Arm reinforcement in Heel slab

Thickness of heel slab = 1-6 = 18 ldh =(0.02fy/fc)db > 8db or 6 in (whichever is greater) (ACI 12.5)

ldh = (0.0260000/ (4500))(1) = 17.88 < hheel . Increase depth or change steel grade. If grade 40 steel is used, ldh = (0.0240000/ (4500))(8/8) = 11.92. Therefore either revise the design, specially of arm, using grade 40 steel or increase depth of base slab to at least 22. When depth is increased, the revision of design is not required.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

51

Department of Civil Engineering, University of Engineering and Technology Peshawar

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

52

26

Department of Civil Engineering, University of Engineering and Technology Peshawar

References

ACI 318 Design of Concrete Structures (13th Ed.) by Nilson, Darwin and Dolan.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

53

Department of Civil Engineering, University of Engineering and Technology Peshawar

The End

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

54

27

You might also like

- Design of Reinforced Concrete Water TanksDocument71 pagesDesign of Reinforced Concrete Water Tanksace1205100% (3)

- Modular ConstructionDocument68 pagesModular ConstructionPranavNanda71% (7)

- Energy Management - W. R. Murphy and G. A. Mckay PDFDocument142 pagesEnergy Management - W. R. Murphy and G. A. Mckay PDFBaskar El50% (4)

- Steel Connection DesignDocument68 pagesSteel Connection DesignPushkar KokaneNo ratings yet

- Portal BridgeDocument123 pagesPortal Bridgenandu523No ratings yet

- Magnesium Alloys Containing Rare Earth MetalsDocument27 pagesMagnesium Alloys Containing Rare Earth Metalsoğuz kağanNo ratings yet

- Roller Compacted ConcreteDocument24 pagesRoller Compacted ConcreteArun PandianNo ratings yet

- 1 Selection of Retaining Walls E (Clause 3.1) S: WallDocument3 pages1 Selection of Retaining Walls E (Clause 3.1) S: Wallashwani kumar100% (1)

- Learn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareDocument108 pagesLearn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareRahul Kumar100% (2)

- Retaining Walls With Relief ShelvesDocument13 pagesRetaining Walls With Relief ShelvesMike VictorNo ratings yet

- Retrofitting of Well FoundationDocument32 pagesRetrofitting of Well FoundationfaumijkNo ratings yet

- Sesmic Structural Design StepsDocument16 pagesSesmic Structural Design StepsGeorge GeorgianNo ratings yet

- Analysis and Design of Deck Slab Bridge (IRC)Document6 pagesAnalysis and Design of Deck Slab Bridge (IRC)Rey Balza TornoNo ratings yet

- Skew Bridges N-Rajagopalan PDFDocument26 pagesSkew Bridges N-Rajagopalan PDFMichael RushNo ratings yet

- Numerical Analysis of Piled Raft Foundation in Sandy and Clayey SoilsDocument4 pagesNumerical Analysis of Piled Raft Foundation in Sandy and Clayey Soilspperic13No ratings yet

- Long Span Beams 2Document14 pagesLong Span Beams 2ashNo ratings yet

- Retaining Wall With Relief SlabDocument7 pagesRetaining Wall With Relief Slabrajivkannan100% (2)

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112Rupendra palNo ratings yet

- Earth-Retaining StructuresDocument4 pagesEarth-Retaining StructuresJulie BajadoNo ratings yet

- Rankine Earth Pressure Theory PDFDocument4 pagesRankine Earth Pressure Theory PDFgitrixNo ratings yet

- Design and Detailing of Approach SlabsDocument1 pageDesign and Detailing of Approach SlabsIsaac Mureithi MainaNo ratings yet

- Bridge Deck Slab Design ProcedureDocument12 pagesBridge Deck Slab Design ProcedurePravin Awalkonde100% (1)

- 7x7 Culvert-Personal ClientDocument1 page7x7 Culvert-Personal ClientNishimonKonwarNo ratings yet

- Bridge Beam DesignDocument8 pagesBridge Beam DesignAnonymous KQtFm3No ratings yet

- Design of CorbelDocument16 pagesDesign of Corbelgrkvani10No ratings yet

- Describe The Importance of Raft and Mat FoundationDocument4 pagesDescribe The Importance of Raft and Mat FoundationIZni AZemiNo ratings yet

- A Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodDocument4 pagesA Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodEditor IJTSRDNo ratings yet

- Manual On The Design and Construction of Well and Pile FoundationsDocument140 pagesManual On The Design and Construction of Well and Pile FoundationsRajeshNo ratings yet

- Paper On Floating ColumnDocument8 pagesPaper On Floating Columnমোঃ হাসান ইমামNo ratings yet

- Civil Engg PDFDocument53 pagesCivil Engg PDFSatyadev RanaNo ratings yet

- Braced CutsDocument24 pagesBraced CutsMeral KayaNo ratings yet

- List of Irc CodesDocument2 pagesList of Irc CodesMichael ChangNo ratings yet

- Integral BridgesDocument12 pagesIntegral Bridgessoniafaisal100% (1)

- Analysis of Mat Foundation Using FeaDocument15 pagesAnalysis of Mat Foundation Using FeaShadin Asari ArabaniNo ratings yet

- Study On Various Slabs Systems For Large Span: Under The Guidance of Dr. A. MallikaDocument29 pagesStudy On Various Slabs Systems For Large Span: Under The Guidance of Dr. A. MallikaNeeta RautelaNo ratings yet

- Bridge Drawings 2019-09-02Document13 pagesBridge Drawings 2019-09-02yasirjurabaNo ratings yet

- 5-Design of Raft FoundationDocument2 pages5-Design of Raft FoundationheshamNo ratings yet

- CE 533 Lecture 2 Introduction To Foundation EngineeringDocument22 pagesCE 533 Lecture 2 Introduction To Foundation EngineeringAbhishek Singh100% (2)

- CH-2 Caissons and CofferdamsDocument9 pagesCH-2 Caissons and CofferdamsAsegid Bezabih100% (1)

- Design of RCC ColumnsDocument14 pagesDesign of RCC Columnsprashmce100% (1)

- Introduction To Counterfort Retaining WallDocument12 pagesIntroduction To Counterfort Retaining WallOmkarNo ratings yet

- 1.retaining Walls (1-2Document43 pages1.retaining Walls (1-2Anonymous MDDp1Ryi100% (1)

- CH 6 - Diaphragm - Analysis - Fundamentals and Design ExampleDocument164 pagesCH 6 - Diaphragm - Analysis - Fundamentals and Design ExampleCarson Baker100% (1)

- Analysis of Well FoundationDocument5 pagesAnalysis of Well FoundationSumit Jadhav0% (1)

- Learning Outcome 4 Retaining WallsDocument9 pagesLearning Outcome 4 Retaining WallsChris FindlayNo ratings yet

- Counterfort Wall - Stability and Toe SlabDocument26 pagesCounterfort Wall - Stability and Toe SlabGuransh Singh100% (1)

- Retainingwall 140712100253 Phpapp02 PDFDocument67 pagesRetainingwall 140712100253 Phpapp02 PDFDr-Hany HashishNo ratings yet

- Design of Mechanically Stabilzed Earth Walls (Msew)Document22 pagesDesign of Mechanically Stabilzed Earth Walls (Msew)SUNDARAVELNo ratings yet

- Retaining Walls: A.B.C.MDocument23 pagesRetaining Walls: A.B.C.MnilminaNo ratings yet

- R.C.C DesignDocument14 pagesR.C.C DesignVinayan PuthukadNo ratings yet

- FC-WCJ-18016-CSW6ST101-001 Cal - PDFDocument205 pagesFC-WCJ-18016-CSW6ST101-001 Cal - PDFSaravanan SKNo ratings yet

- Bridges. Piers and ColumnsDocument22 pagesBridges. Piers and ColumnsSergio GómezNo ratings yet

- Gravity Retaining Wall - VakapalliDocument6 pagesGravity Retaining Wall - VakapalliD.V.Srinivasa RaoNo ratings yet

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112imamtaNo ratings yet

- Design of Raft FoundationDocument4 pagesDesign of Raft FoundationDayo Idowu100% (2)

- Economic Design of RCC Box Culvert ThrouDocument7 pagesEconomic Design of RCC Box Culvert ThrouOscarKonzultNo ratings yet

- Design and Construction of Mat (Raft) Foundations - BookDocument10 pagesDesign and Construction of Mat (Raft) Foundations - BookbatteekhNo ratings yet

- Flat Slab DetailsDocument65 pagesFlat Slab DetailsFABDXB100% (1)

- 28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Document3 pages28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Ahmad Badsha QuadriNo ratings yet

- 2018-Retaining Walls, Indian Highways IRCDocument8 pages2018-Retaining Walls, Indian Highways IRCRajendra ChalisgaonkarNo ratings yet

- VM 01 Gravity WallDocument31 pagesVM 01 Gravity WallD SRINIVASNo ratings yet

- Launching and Erection TechniquesDocument10 pagesLaunching and Erection Techniqueswim hoeckmanNo ratings yet

- FDTDocument15 pagesFDTqaiserkhan001No ratings yet

- Railway Track SleepersDocument31 pagesRailway Track Sleepersqaiserkhan001No ratings yet

- Admission Form: of Science & Information Technology, Peshawar PhotoDocument1 pageAdmission Form: of Science & Information Technology, Peshawar Photoqaiserkhan001No ratings yet

- Impact of A Jet: Experiment 4Document6 pagesImpact of A Jet: Experiment 4Eye IqbalNo ratings yet

- Technical Education & Vocational Training Authority: Government of The PunjabDocument30 pagesTechnical Education & Vocational Training Authority: Government of The Punjabqaiserkhan001No ratings yet

- PrecipitationDocument23 pagesPrecipitationqaiserkhan001100% (1)

- University of Maryland: Department of Civil and Environmental EngineeringDocument2 pagesUniversity of Maryland: Department of Civil and Environmental Engineeringqaiserkhan001No ratings yet

- 8.3.1. Symmetrical Beam: H SpanDocument1 page8.3.1. Symmetrical Beam: H Spanqaiserkhan001No ratings yet

- Solved ProblemsDocument55 pagesSolved ProblemsJamaal JallowNo ratings yet

- Elasticity Applications 04 Beam TheoryDocument28 pagesElasticity Applications 04 Beam Theoryqaiserkhan001No ratings yet

- Table A-6 Basic Tension Development-Length Ratio, (In./in.) / DDocument1 pageTable A-6 Basic Tension Development-Length Ratio, (In./in.) / Dqaiserkhan001No ratings yet

- Apex Floor Guard Shade CardDocument6 pagesApex Floor Guard Shade CardSTUDENTS OF DOE CUSATNo ratings yet

- CH 11 Compressible FlowDocument76 pagesCH 11 Compressible FlowEssa RasanNo ratings yet

- XTB XTK XTWA XTWL CatalogDocument2 pagesXTB XTK XTWA XTWL CatalogAENo ratings yet

- (PIPE Catalogue) MechanicPipesDocument28 pages(PIPE Catalogue) MechanicPipesairsnowNo ratings yet

- Plate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGDocument38 pagesPlate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGArnoldo OlivaNo ratings yet

- Prescriptive Wood Framing Design Training 1 25 2023Document9 pagesPrescriptive Wood Framing Design Training 1 25 2023bauyonmeljessaNo ratings yet

- Made in Qatar Exhibit List 2023Document12 pagesMade in Qatar Exhibit List 2023Parienda MehtaNo ratings yet

- Eps Geofoam OverviewDocument39 pagesEps Geofoam OverviewPa HeNo ratings yet

- Heat Transfer Operations: CBE 322aDocument19 pagesHeat Transfer Operations: CBE 322atsaipeterNo ratings yet

- Boekel 145600 Dispensador de ParafinaDocument8 pagesBoekel 145600 Dispensador de ParafinaEnno EisenkolbNo ratings yet

- STI03 Yield and FailureDocument30 pagesSTI03 Yield and FailureDeepak ChachraNo ratings yet

- GSL-NA1108 Warman GSL BrochureDocument4 pagesGSL-NA1108 Warman GSL BrochureJHONY TEODORO ALBORNOZ DIONICIONo ratings yet

- Nitronic 50 SheetDocument3 pagesNitronic 50 SheetSam PeñaNo ratings yet

- FHWA-TFHRC Update On Development and DeliveryDocument44 pagesFHWA-TFHRC Update On Development and DeliveryMiguel Angel Contreras OrtizNo ratings yet

- ALia ApartmentsDocument2 pagesALia ApartmentsGeorge DanielNo ratings yet

- Practice Exam Test Questions TLE 1Document7 pagesPractice Exam Test Questions TLE 1Jasmine EnriquezNo ratings yet

- Effects of Repeated Blasting On A Wood-Frame HouseDocument94 pagesEffects of Repeated Blasting On A Wood-Frame HouseAbu AlAnda Gate for metal industries and Equipment.No ratings yet

- 5b Kirislerde Kayma GerilmeleriDocument13 pages5b Kirislerde Kayma Gerilmelerisedat5454No ratings yet

- Schedule Concrete GF CPC MD 2344Document1 pageSchedule Concrete GF CPC MD 2344QHSETIGARAKSA QHSENo ratings yet

- Leg Mechanism - WikipediaDocument5 pagesLeg Mechanism - WikipediaSumantharajNo ratings yet

- Loading On CanopyDocument9 pagesLoading On CanopyanbuaedNo ratings yet

- Chi Instalacion de Puerta Seccional PDFDocument40 pagesChi Instalacion de Puerta Seccional PDFElmer HuamanNo ratings yet

- Surface Condenser Specification Sheet: DesignDocument1 pageSurface Condenser Specification Sheet: DesignboeiniNo ratings yet

- Weight - Tetra ProductsDocument4 pagesWeight - Tetra ProductsNoor'ain AbasNo ratings yet

- Composite MaterialDocument24 pagesComposite MaterialManish JhadhavNo ratings yet

- ProgresDocument3 pagesProgresindra allureNo ratings yet