Professional Documents

Culture Documents

Handout On Shear Design of Beams.2002.Code

Uploaded by

panos2244662864Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Handout On Shear Design of Beams.2002.Code

Uploaded by

panos2244662864Copyright:

Available Formats

Prepared by Professor Panos D.

Kiousis

Last Update:February 27, 2004 Page 1

SHEAR DESIGN OF BEAMS

1. General Principles

Design of cross-sections subjected to shear shall be based on: (ACI equation 11-1). V V

n u

V

u

is the shear force due to the factored loads (e.g. 1.2DL + 1.2LL) at the section that we

consider, and V

n

is the nominal shear strength computed as: (ACI equation (11- V V V

n c s

= +

2).

V

c

is the nominal shear strength provided by concrete and V

s

is the nominal shear strength

provided by shear reinforcement.

Average shear stress v

V

b d

w

=

Beams rarely if ever fail in actual shear. In stead, application of shear forces results in tensile

stresses, in oblique orientations, which in turn cause failure. Thus the average shear stress,

can only provide an indirect measurement or indication of failure.

It becomes clear that the average shear stress definition ignores the reduction of available

cross-section due to bending cracks. It is common practice to incorporate the effects of

bending (reduced available cross-section) in the strength.

In areas of large bending it is common to assume concrete shear strength equal to

(not the equation to use!) v f V f b d

c c c c w

= = 19 19 . ; .

In areas of no bending it is assumed that the concrete shear strength is equal to

v f V f b d

c c c c w

= = 35 35 . ; .

To incorporate the effects of bending and the dowel shear

strength provided by the bending reinforcement, ACI code

(Eq. 11-5) proposes the relation:

(1) V f

V d

M

b d f b d

c c w

u

u

w c w

= +

|

\

|

.

| 19 2500 35 . .

The ratio shall not be taken greater than 1.0 in computing V

c

in the equation above.

V d

M

u

u

The ACI code (Eq. 11-3) allows the use of the simplified equation: (2) V f b d

c c w

= 2

Shear Reinforcement: If a cross section cannot carry the shear load by itself, then shear

reinforcement in the form of stirrups of ties may be used. In essence, stirrups act as nails that keep

the top and bottom pieces of a beam with a shear crack together.

If we assume 45

o

crack, then the horizontal dimension of the crack is equal to the effective depth d.

Prepared by Professor Panos D. Kiousis

Last Update:February 27, 2004 Page 2

If stirrups are spaced at a distance s then there exist n

d

s

=

stirrups over the cracked area. If ultimate capacity of each of

these stirrups is where A

v

is the cross-sectional area of A f

v ys

the stirrup multiplied by the number of vertical legs of the stirrup

configuration. Thus, the shear force that is carried by the

stirrups is:

(3) V A f

d

s

s v y

=

The value of V

s

is commonly known (see Eq. 6). Thus, we can use Eq. 3 to find the maximum

spacing of the stirrups of a required shear reinforcement capacity V

s

:

(4) s

A f d

V

v ys

s

=

2. Practical Information

Shear design is now based on the following equation:

(5) V V V V

u n c s

= = +

where N = 0.75 for shear. From Equation (5) we can see:

(6) V

V V V

V

s

u c u

c

=

=

ACI code requirements:

Calculate the shear strength of the cross-section as:

(7) V f b d

c c w

= 2

or

(8)

V f

V d

M

b d f b d

c c w

u

u

w c w

= +

|

\

|

.

| 19 2500 35 . .

The first relation is preferred due to its simplicity.

Prepared by Professor Panos D. Kiousis

Last Update:February 27, 2004 Page 3

Criteria for design:

1. If : No shear reinforcement is necessary. V

V

u

c

2

2. If then minimum reinforcement is required. This is defined as:

V

V V

c

u c

2

s

A f psi

f b

s

A f psi

b

s

d

v ys

c w

v ys

w

( )

.

( )

075

50

2

3. If then reinforcement is required:

V V

c u

s

A f d

V

V

A f d

V V

s

d

v ys

u

c

v ys

u c

2

Note that the minimum reinforcement requirements of item 2 are still valid for item 3. So, if the

spacing of item 3 is larger than the spacing mandated in item 2, the one of item 2 controls.

4. In addition: if , then the max spacing is reduced to . V f b d

s c w

4 s d / 4

if , then the cross-section must be redesigned. V f b d

s c w

8

Prepared by Professor Panos D. Kiousis

Last Update:February 27, 2004 Page 4

3. Design Process. Step-by-step.

Consider a beam to be designed for shear reinforcement. The steps for the design are as follows:

1. Select size of stirrups. Usually we start by assuming #3 unless the problem statement requires

otherwise. If later on we find that #3 stirrups results in very small stirrup spacing we can

change to #4 or larger.

2. Calculate factored loads Q

u

3. Calculate and draw shear diagram V

u

due to factored loads.

4. Calculate shear capacity of concrete cross-section: . V f b d

c c w

= 2

5. Calculate the most critical shear V

u - cr

. This is commonly located at distance d from the

supports.

6. In the V

u

diagram locate the values NV

c

and NV

c

/ 2.

7. The region for which NV

c

/2 $ V

u

does not need shear reinforcement.

8. The region for which NV

c

/2 # V

u

# NV

c

is valid, is designed based on criterion 2 of the previous

section:

We calculate spacing and where A

v

is the total stirrup s

A f psi

f b

v ys

c w

=

( )

. 075

s

A f psi

psi b

v ys

w

=

( )

( ) 50

cross-section that is sheared (commonly 2 @A

tie

) and f

ys

is the yield strength of the stirrup steel.

We also calculate spacing as: . We accept the smaller spacing of the three. Note that s

d

=

2

in comparing the first two expressions, the first controls if f'

c

> 4444 psi, (the second controls

otherwise).

10. The region for which NV

c

# V

u

is valid, is designed based on criterion 3 of the previous section:

We calculate the shear that needs to be carried by the stirrups: and then V

V

V

s

u

c

=

spacing (A) s

A f d

V

v ys

s

=

If the cross-section needs to be redesigned (become bigger) to reduce V f b d

s c w

8

V

s

.

If then calculate (B-1) V f b d

s c w

4 s

d

=

4

Otherwise calculate (B-2) s

d

=

2

Accept the smaller of (A) and (B) - whichever of B-1 or B-2 is applicable.

Depending on the size of the range for which NV

c

# V

u

we may wish to apply the process

described in this step for multiple sub-regions to achieve better economy. This is a more

complex process that is described in your textbook but is not necessary here.

11. Make the proper rounding of the spacing values of reinforcement.

Prepared by Professor Panos D. Kiousis

Last Update:February 27, 2004 Page 5

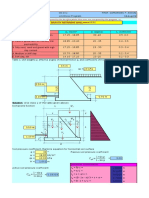

Shear Design Example

Design the beam shown here for shear. We would like to use shear reinforcement consisting of #3,

Grade 40 stirrups.

f'

c

= 4,000 psi; f

y

= 60,000 psi; f

ys

= 40 ksi, Stirrups #3

w

b

= 150 lb/ft

3

x 12 x 28/144/1000 = 0.35 k/ft.

Solution

Simpler approach

1. Stirrup #3 as of problem statement.

2. Factored loads: w

u

= 1.2 x (0.933+0.35) + 1.6 x 1.488 =

3.92 k/ft.

3. Create the shear diagram V

u

:

4. and V f b d lbs

c c w

= = = 2 2 4 000 12 245 37 188 , . ,

NV

c

= 27891 lbs

5. Critical shear section at distance d = 24.5 inches = 2.04 ft from support. At that point shear V

u

= 78.4 - 3.92 @ 2.04 = 70.40 kips.

6. Find the location of NV

c

= 27.9 kips and NV

c

/2 = 14.0 kips on the V

u

diagram. This can be

found from the shear equation or from similar triangles: If we call the distance from the 0 shear

point x then: or x = 3.57 ft. Thus, the location of NV

c

/2 is 3.57 ft from the center of

x

14

20

784

=

.

Prepared by Professor Panos D. Kiousis

Last Update:February 27, 2004 Page 6

the beam or 16.43 ft. from the support. Similarly, or x = 7.12 ft. Thus, the location

x

27 9

20

784 . .

=

of NV

c

is 7.12 ft. from the center or 12.88 ft. from the support.

7. Note that the region from 17.02 to 20 ft (and its mirror image on the right half of the beam) has

V

u

that is less than NV

c

/2 and thus does not need reinforcement.

8. From 12.88 ft to 16.43 (and its mirror image on the right half of the beam) we have the design

case 2: Range = 16.43-12.88 = 3.55 ft.

(note that this equation controls because f'

c

< 4444 psi) s in

=

( . )

.

2 011 40000

50 12

14 7

and Thus s = 12.25 in. s in =

245

2

12 25

.

. .

9. In the range from 0 to 12.88 ft we have shear design case 3:

(Eq. 6) which is less than

V kips

s

= =

704

075

37 2 567

.

.

. .

4 4000 12 24 5 74377 = . lbs

and Thus s#3.80 in. s in

=

075 2 011 40 245

704 0 75 37 2

380

. ( . ) .

. . .

. . s in =

245

2

12 25

.

. .

10. From 0 to 12.88 ft: s#3.80 in. We shall use s = 3 in. which over 12.88 ft requires 52 stirrups

(the first one is placed 3 inches from the left support). The total length occupied by the stirrups

is 52x3 = 156 in. or 13 ft. Thus the first range is from 0 to 13 ft. We use 52 #3's at 3 in.

From 13 to 16.43 ft s# 12.25 in. We shall use s = 12 in. which over 3.43 ft. requires 4 stirrups

(for a total of 48 in. or 4.00 ft). Thus the second range is 4 ft long or from 13 to 17 ft. We use

4#3's at 12 in.

The final design becomes:

0.00 to 13.00 ft. : 52 #3's at 3 in (the first one is placed 3 in. from support).

13.00 to 17.00 ft: 4#3's at 12 in.

17.00 to 23.00 ft: No stirrups

23.00 to 27.00 ft: 4#3's at 12 in.

27.00 to 40.00 ft: 52 #3's at 3 in.

Total number of stirrups needed : 112.

Prepared by Professor Panos D. Kiousis

Last Update:February 27, 2004 Page 7

More complex (and potentially less expensive) approach .

Basic philosophy:

At any point of the beam we need to know the magnified applied shear load V

u

/N and the nominal

shear strength V

c

. Then, by examining the relative values of applied load vs. shear strength, we

decide whether we are in design case (1), (2), or (3) and design using the proper equations.

In designing beams for shear, it is usually sufficient to check a few points along the span and select

the stirrup spacing based on those points. In this design we shall use a more detailed (overkill)

approach taking advantage of the fact that the V and M equations are easy to produce and also the

fact that it is easy to place all calculations in a spread sheet.

Reactions: R

A

= wL/2 = 3.92@40 / 2 = 78.4 kips

M

A

= -wL

2

/12 = 3.92@40

2

/12 = -522.67 ft-k

Shear equation : V(x) = 78.4 - 3.92 @ x

Moment equation : M(x) = -522.67 + 78.4 x - 3.92@x

2

/2

x(ft) V

u

(k) M

u

(in-k) V

u

d/M

u

2500DV

u

d/M

u

NV

c

NV

c

/2 V

u

-NV

c

V

u

-NV

c

/2 V

s

s (in)

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

2.00 70.56 -373.71 0.32 16.46 30.13 15.06 40.43 55.50 53.91 4.00

3.00 66.64 -305.11 0.37 19.04 30.69 15.35 35.95 51.29 47.93 4.50

4.00 62.72 -240.43 0.45 22.74 31.51 15.76 31.21 46.96 41.61 5.18

5.00 58.80 -179.67 0.56 28.53 32.79 16.39 26.01 42.41 34.68 6.22

6.00 54.88 -122.83 0.76 38.94 35.08 17.54 19.80 37.34 26.39 8.17

7.00 50.96 -69.91 1.00 51.02 37.75 18.87 13.21 32.09 17.62 12.24

8.00 47.04 -20.91 1.00 51.02 37.75 18.87 9.29 28.17 12.39 12.25

9.00 43.12 24.17 1.00 51.02 37.75 18.87 5.37 24.25 7.16 12.25

10.00 39.20 65.33 1.00 51.02 37.75 18.87 1.45 20.33 1.94 12.25

11.00 35.28 102.57 0.59 29.98 33.11 16.55 2.17 18.73 2.90 12.25

12.00 31.36 135.89 0.39 20.11 30.93 15.47 0.43 15.89 0.57 12.25

13.00 27.44 165.29 0.28 14.47 29.69 14.84 0.00 12.60 0.00 12.25

14.00 23.52 190.77 0.21 10.75 28.87 14.43 0.00 9.09 0.00 12.25

15.00 19.60 212.33 0.16 8.05 28.27 14.14 0.00 5.46 0.00 12.25

16.00 15.68 229.97 0.12 5.94 27.81 13.90 0.00 1.78 0.00 12.25

17.00 11.76 243.69 0.08 4.21 27.42 13.71 0.00 0.00 0.00 0.00

18.00 7.84 253.49 0.05 2.70 27.09 13.55 0.00 0.00 0.00 0.00

19.00 3.92 259.37 0.03 1.32 26.79 13.39 0.00 0.00 0.00 0.00

20.00 0.00 261.33 0.00 0.00 26.50 13.25 0.00 0.00 0.00 0.00

Note that the absolute values of V/M are used to calculate V

c

Prepared by Professor Panos D. Kiousis

Last Update:February 27, 2004 Page 8

Notes on the tabulated calculations:

1. For x $17 ft, we have that V

u

< NV

c

/2 (negative values are marked as 0 in column 9). Thus

(case a) no stirrups are required.

2. For 13 # x #17 ft. we have that NV

c

/2 < V

u

< NV

c.

(negative values of V

u

- NV

c

mark the

beginning of this region and are marked as 0 in column 8) In this region we require minimum

reinforcement-case b. Stirrups are decided based on

s

A f psi

psi b

in

s

d

in

v y

w

=

=

= =

( )

( )

. ,

. .

.

. .

50

2 011 40 000

50 12

14 7

2

245

2

12 25

3. For 0 <x<13 ft V

u

> NV

c

, thus producing a requirement for shear bearing stirrups. The amount

of shear carried by the stirrups is shown in the table column with the V

s

heading. In this region,

the shear reinforcement is calculated as follows:

s

A f d

V V V V

and

d

in

v ys

u c u c

=

=

075 2 011 40 245

075

2

12 25

. . .

.

. .

where, V

u

is the shear force diagram value at the specific location, and V

c

is the nominal shear

strength at the same location. As can be seen from the table, the d/2 value was the governing

value for part of this region. (8 to 12 ft.)

The result of all these calculations is a spacing distribution as shown if the last column of the table. In

practice, it makes no sense to allow variation of the spacing for every footing. This is a more practical

spacing:

0 < x < 4 ft s = 4.0 in. (12 stirrups)

4 < x < 7 ft 4 in. s = 5 in. (10 stirrups)

7 ft 4 in < x <16 ft 4 in. s = 12 in. ( 9 stirrups)

16ft 4 in. < x < 20 ft No stirrups

From 20 ft to 40 ft reinforce in mirror image symmetry.

A total of 62 stirrups are needed.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Modal Design in Structural DynamicsDocument8 pagesModal Design in Structural Dynamicspanos2244662864No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- GeotechMaster-1 0 8 0-UsersManualDocument49 pagesGeotechMaster-1 0 8 0-UsersManualpanos2244662864No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Basis of Calculations - Geotech MasterDocument15 pagesBasis of Calculations - Geotech Masterpanos2244662864No ratings yet

- Modal Design in Structural DynamicsDocument8 pagesModal Design in Structural Dynamicspanos2244662864No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Steel W-Sections (Metric)Document5 pagesSteel W-Sections (Metric)panos2244662864No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Mixed multiple DOF systemsDocument13 pagesMixed multiple DOF systemspanos2244662864100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Dynamics of Structures and Soils: Deterministic Structural Dynamics. Random Stochastic or Random Structural DynamicsDocument11 pagesDynamics of Structures and Soils: Deterministic Structural Dynamics. Random Stochastic or Random Structural Dynamicspanos2244662864No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Beams Train EnergyDocument2 pagesBeams Train Energypanos2244662864No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Modal Design in Structural DynamicsDocument8 pagesModal Design in Structural Dynamicspanos2244662864No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 001 - Fundamentals of ConcreteDocument6 pages001 - Fundamentals of Concretepanos2244662864No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- AdvancedStructuralAnalysis Notes - Vol 01 Rev04bDocument41 pagesAdvancedStructuralAnalysis Notes - Vol 01 Rev04bpanos2244662864No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hardening Laws in PlasticityDocument4 pagesHardening Laws in Plasticitypanos2244662864No ratings yet

- Note On Stability of StructuresDocument6 pagesNote On Stability of Structurespanos2244662864100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hardening Laws in PlasticityDocument4 pagesHardening Laws in Plasticitypanos2244662864No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Numerical Solutions For Linear SDOF Systems.1Document9 pagesNumerical Solutions For Linear SDOF Systems.1panos2244662864No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Proportioning Concrete Mixes.001Document5 pagesProportioning Concrete Mixes.001panos2244662864No ratings yet

- Concrete Seismic DesignDocument31 pagesConcrete Seismic Designpanos2244662864No ratings yet

- SEISMIC DESIGN-Concrete StructuresDocument30 pagesSEISMIC DESIGN-Concrete Structurespanos2244662864No ratings yet

- Handout Introduction To Nonlinear Mechanics - 2013Document9 pagesHandout Introduction To Nonlinear Mechanics - 2013panos2244662864No ratings yet

- Hand Out On Concrete MaterialsDocument3 pagesHand Out On Concrete Materialspanos2244662864No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HandoutonDesignOfShortColumns 2008Document5 pagesHandoutonDesignOfShortColumns 2008panos2244662864No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Soil-Structure Interaction Due To Subsidence - PDK - 2!29!2012Document8 pagesSoil-Structure Interaction Due To Subsidence - PDK - 2!29!2012panos2244662864No ratings yet

- Bridge Design Example - GreekDocument38 pagesBridge Design Example - Greekpanos2244662864No ratings yet

- EquivalentFrameMethodExample 2Document13 pagesEquivalentFrameMethodExample 2panos2244662864No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Handout On Shear Design of Concrete Beams.2002.CodeDocument8 pagesHandout On Shear Design of Concrete Beams.2002.Codepanos2244662864No ratings yet

- 001 - Fundamentals of ConcreteDocument6 pages001 - Fundamentals of Concretepanos2244662864No ratings yet

- Design of Gravity Retaining WallDocument36 pagesDesign of Gravity Retaining WallCarmel Buniel Sabado100% (10)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Introduction To Nonlinear Mechanics - CNDocument7 pagesIntroduction To Nonlinear Mechanics - CNpanos2244662864No ratings yet

- HandOut On Concrete Beam DeflectionsDocument7 pagesHandOut On Concrete Beam Deflectionspanos2244662864No ratings yet

- Mullion CheckDocument3 pagesMullion CheckHiếu Nguyễn TấnNo ratings yet

- BENCHMARK 1 Hole Expansion of A High Strength Steel Sheet: 1. OverviewDocument10 pagesBENCHMARK 1 Hole Expansion of A High Strength Steel Sheet: 1. OverviewSergio PluchinskyNo ratings yet

- IES 2017 - Paper - 1 - SolvedDocument31 pagesIES 2017 - Paper - 1 - Solvedmadivala nagarajaNo ratings yet

- Timber Column With Biaxial Bending and Compression ExampleDocument4 pagesTimber Column With Biaxial Bending and Compression ExampleHor Ka WaiNo ratings yet

- Design of Toe Wall PDFDocument15 pagesDesign of Toe Wall PDFaselabambarandageNo ratings yet

- Ce 241 - Materials Science: Mechanical Properties of MaterialsDocument11 pagesCe 241 - Materials Science: Mechanical Properties of Materialsyasin yttNo ratings yet

- Seismic design loads and combinationsDocument15 pagesSeismic design loads and combinationsAmey Gudigar100% (1)

- Nickel in HardmetalsDocument9 pagesNickel in Hardmetalsandrea assanelliNo ratings yet

- Coconut Fiber CEB BlocksDocument2 pagesCoconut Fiber CEB BlocksBilly SchipperNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pin ConnectionDocument10 pagesPin ConnectionngocnnNo ratings yet

- Amodel PPA Design Guide en PDFDocument92 pagesAmodel PPA Design Guide en PDFSudhanshu Goswami ReikidivinityNo ratings yet

- Basic ElectronicsDocument25 pagesBasic ElectronicsKumar shantanu Basak100% (1)

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- Magnetic Recording Materials and Technologies for High Density Data StorageDocument18 pagesMagnetic Recording Materials and Technologies for High Density Data StorageRohit PalNo ratings yet

- Lateral Bracing of Beams Provided by Standing Seam Roof System Concepts and Case StudyDocument11 pagesLateral Bracing of Beams Provided by Standing Seam Roof System Concepts and Case Studyjackcan501No ratings yet

- DriftDocument4 pagesDriftsunilr_60No ratings yet

- RA - Vol.28.No.1-2, Jan-Apr 2018 PDFDocument84 pagesRA - Vol.28.No.1-2, Jan-Apr 2018 PDFMymoon MoghulNo ratings yet

- RISA-3D Report DataDocument4 pagesRISA-3D Report DatagertkroonNo ratings yet

- 3 - Assignment - PH 401 (EE) - MODULE - 3 (Magnetostatics)Document3 pages3 - Assignment - PH 401 (EE) - MODULE - 3 (Magnetostatics)saifi_786No ratings yet

- STEEL HARDNESS CONVERSION TABLE REFERENCE GUIDEDocument2 pagesSTEEL HARDNESS CONVERSION TABLE REFERENCE GUIDEJannes PandianganNo ratings yet

- Ductile To Brittle Transition PDFDocument10 pagesDuctile To Brittle Transition PDFhjvNo ratings yet

- Drilled ShaftDocument17 pagesDrilled ShaftRagib Nur Alam ShuvoNo ratings yet

- CHAPTER 13 - ThermodynamicsDocument7 pagesCHAPTER 13 - ThermodynamicsGerry Lou QuilesNo ratings yet

- EN380 HW5 SolutionDocument5 pagesEN380 HW5 SolutionHagere EthiopiaNo ratings yet

- Durvinil E 34/42 PVC Pipe Technical DataDocument2 pagesDurvinil E 34/42 PVC Pipe Technical DataMarius-Daniel ZlotaNo ratings yet

- Columns and Struts Structural AnalysisDocument25 pagesColumns and Struts Structural AnalysisBiplab SadhukhanNo ratings yet

- Strength Analyses of Sandwich Pipes For Ultra Deep PDFDocument172 pagesStrength Analyses of Sandwich Pipes For Ultra Deep PDFClaudio PazNo ratings yet

- Deflection1 Bhatt BookDocument10 pagesDeflection1 Bhatt BookthirumalaichettiarNo ratings yet

- CivilFEM 2016 .Beam - DesignDocument29 pagesCivilFEM 2016 .Beam - DesignSharathBanakarNo ratings yet

- Glossary CorreiaDocument41 pagesGlossary CorreiaAmilton filho100% (1)