Professional Documents

Culture Documents

Buckling Free Pipe External Pressure

Uploaded by

Alessandro SerafiniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buckling Free Pipe External Pressure

Uploaded by

Alessandro SerafiniCopyright:

Available Formats

Chapter 2 Buckling of Free Pipe under External Pressure

Chapter 2 Buckling of Free Pipe under External Pressure

In separated-type water tunnel structure, when the point supported steel liner is subjected to the uniform external pressure, the contact between tunnel lining and liner is difficult to happen because the developed compressive hoop thrust in pipe only shortens the circumference of liner and then enlarges the gap between liner and host. Therefore, the buckling of the uniformly point supported liner can be considered a rotary symmetric buckling likely the buckling of free pipe under external pressure. In this chapter, the buckling of free pipe is investigated.

2.1 Introduction

2.1.1 Plain Pipe vs. Stiffened Pipe The choice of plain versus stiffened steel pipe for a tunnel liner is primarily not only a cost issue, but also have to consider other issues such as the safety, constructability, and the inspection/ maintenance. For instance, steel pipe with diameter to thickness ratios of more than about 300 or thickness more than 45mm are usually not practical due to handling limitations. On the other hand, the steel pipe must have the sufficient capacity to resist the internal pressure and external pressure, while the external pressure is vulnerable to cause the buckling of pipe. Generally, the steel pipe thickness designed for external pressure is usually much thicker than that for internal pressure. In engineering practice, plain steel pipe has many advantages as shown in followings, Design and analysis are relatively simple and well understood. Outer diameter of a plain steel pipe is less than a stiffened steel pipe; hence the excavated tunnel diameter can be reduced. Manufacture of a plain steel pipe is simpler, particularly for wall thickness less than about 20mm. The manufacture cost per unit length of stiffened steel pipe is generally higher than a plain pipe with same thickness, considering the required stiffener welding work. However, when the water tunnel is built in deep underground, the groundwater pressure is relatively high and the structure design has to consider the bucking of steel pipe under external pressure principally. In such case, the stiffened pipe is required considering its following advantages, Stiffened steel pipe can be designed lighter than a plain pipe. Buckling mode of a stiffened pipe can be controlled, and the long steel pipe collapse can be avoided if appropriately design. Thinner pipe can be used, hence not only quantities of steel materials but also the welding works are possibly reduced. In addition, the construction of deep water tunnel can become possibility when the steel pipe rolling process is limited in thickness due to available fabrication machinery and other restrained conditions.

- 19 -

Chapter 2 Buckling of Free Pipe under External Pressure

Otherwise, the application of the external circular stiffeners usually called ring stiffener should be considered when the thickness of a plain pipe designed for external pressure exceeds the thickness required by internal pressure. Finally, the design should be carried out based on economic considerations of the following three available options: a) increasing the thickness of the pipe, b) adding external stiffeners to a pipe with thickness required for internal pressure, and c) increasing the thickness of pipe and adding external stiffeners, and satisfy the design requirement for the external pressure. In addition, the economic comparison between plain and stiffened pipe must consider the extra cost of welding, tunnel excavation and backfill. In the current study, the stiffened pipe is considered as the tunnel liner in principle considering the safety and cost of the water tunnel built in urban deep underground. The stiffeners are installed with a constant spacing on the steel pipe, and are welded with fillet welding around and at the exterior of pipe. The stiffener is assumed having sufficient second moment of inertia to avoid buckling of itself, since it is principally used to holding the pipe in a circular shape. As the stiffener types, there are 4 common types as shown in Fig. 2.1, called tee bar, rolled channel stiffener, rolled plate stiffener, and flat bar, respectively. Tee bar is theoretically the most efficient as a stiffener, however the complicated fabrication is the vital shortcoming. Moreover, the available reduction of cross section is limited because the failure of flange or web has to be avoided. Rolled channel stiffener is also structural efficient, by which a greater spacing of stiffener becomes possible because of its larger inertia moment and two connection points with steel pipe. The problem of rolled channel stiffener is that there are no effective means to treat the void created by stiffener. A rolled plate oriented parallel to the steel pipe cannot add the second moment of inertia of steel pipe to resist buckling. It is therefore that the rolled plate is not used as main stiffener, just used for reinforcing the connection of steel pipe. A flat bar (Rolled or cut plate placed perpendicular to pipe) are the most commonly used stiffener due to not only its easily manufacturing but having efficient second moment of inertia to improve the capacity of buckling resistance. Accordingly, in this study, the flat bar is adopted as stiffener in terms of the design and construction of stiffened pipe. The cross-section profile of a pipe stiffened with flat bar is shown in Fig. 2.2, where the related notations about stiffened pipe are shown1). Steel pipe

a) Rolled tee (Tee Bar)

b) Rolled channel

c) Rolled plate d) Rolled /Cut plate (Parallel to pipe) (Perpendicular to pipe) (Flat Bar) Fig. 2.1 Typical stiffeners

- 20 -

Chapter 2 Buckling of Free Pipe under External Pressure

Effective cross-section

hr t R

tr

Neutral axis

Be = 1 . 56 Rt

R0 2S

Rc

Fig. 2.2 Wall cross-section of stiffened pipe

2.1.2 Existing Buckling Theories Review In the past decades, many researchers have studied the buckling problem, for instance, Von Mises, Donnel, Southwell, Timoshenko, Flgger, Tokugawa , etc.., investigated the free pipe with two ends held in circular shape and presented analytical solutions respectively; Kendrick, Bryant etc. investigated the stiffened pipe and presented analytical equations taking into account the flexural rigidity of stiffener, Koter, Yamaki and others investigated the nonlinear theory of thin shells and the influence of imperfection. Plain Pipe When a free pipe is subjected to uniform external pressure, the tangential compressive stress will be developed in pipe and increases with the external pressure increases. When the tangential compressive stress reaches a limit value, the pipe is not able to maintain its initial circular shape, and distorts unstably in buckling. For a finite long free pipe with radius R, thickness t, the buckling has been discussed by Von. Mises2), Donnel3), Southwell4), Timoshenko5), Flgger6), Tokugawa7), etc.. The corresponding buckling equations will be referred in following section for stiffened pipe. However for an infinite long free pipe, the buckling equation can be derived using the Euler buckling theory, by assumed as a ring with the second moment of inertia (I).The buckling equation is expressed as follows,

(n 2 1) EI (n 2 1) E t Pcr = = 12 R R3

(2.1a)

However, if the pipe is longitudinal restrained, Eq. (2.1a) should be modified by considering the Poissons effect. The equation of critical pressure is then given by the following,

- 21 -

Chapter 2 Buckling of Free Pipe under External Pressure

(n 2 1) E t (n 2 1) E ' t Pcr = = 12(1 v 2 ) R 12 R

(2.1b)

Where, the E=E/(1-v2) is often used in practice, commonly called effective elastic modulus. As for a long free pipe, since the lowest critical pressure is always produced when the number of wave n is equal to 2, the number of waves is commonly given 2. Thus the buckling equation of a long pipe can be expressed by Eq. (2.2).

E' t Pcr = 4 R

(2.2)

Moreover, the analytical solution using Eq. (2.2) is only valid for hydrostatic pressure with the acting direction normal to pipe surface. For a conservative load maintaining their direction, the denominator 4 in Eq. (2.2) should be replaced by 3. Stiffened Pipe As the ring-stiffened pipe is generally considered a stiffened cylindrical shell, the following studies should be mentioned. The buckling of ring-stiffened cylindrical shells under external pressure has been studied by the following researchers. Reis and Walker8) analyzed the local buckling strength of ring-stiffened cylindrical shells by non-linear buckling analysis. Y. Yamamoto9) studied the general instability of ring-stiffened cylindrical shells using experiments. S. S. Seleim et al. 10), systemically studied the buckling behavior of ring-stiffened cylinders. From the studies mentioned above, it is confirmed that the buckling behavior of ring-stiffened cylindrical shells involves three types of failure: inter-ring shell buckling, general buckling, and ring-stiffener stripping. Regarding buckling design, Charles P. Ellinas and William J. Supple11) conducted a comprehensive investigation on buckling design for ring-stiffened cylinders. Generally, the studies on buckling of stiffened pipe can be divided into two groups. One group focused the buckling of the shell between adjacent stiffeners, while another group focused the buckling of overall pipe. The two buckling forms are usually called general buckling and local buckling, and their buckling forms are shown in Fig. 2.3, respectively. The representatives of former group include Von Mises, Donnel, Southwell, Timoshenko, Flgger, Tokugawa, etc, while the latter are represented by Kendrick12), Bryant13), etc.. In the research of former group, the stiffened pipe is simply assumed that the two ends of a plain pipe are held in circular shape, and buckling occurs in a rotary-symmetric buckling with sinusoidal wave. The related equations were derived by Southwell in 1913, Von Mises in 1914, Timoshenko in 1938, Flgger in 1960, Tokugawa in 1961, Donnel in 1976. However, since the Timoshenkos equation obtained by Von Mises firstly are usually used in engineering practice.

- 22 -

Chapter 2 Buckling of Free Pipe under External Pressure

a) Initial shape

b) bucking of inter stiffener shell (Local buckling)

c) buckling of overall pipe (General buckling)

Fig. 2.3 Buckling forms of stiffened pipe The Timoshenko and Von Mises buckling equation for a stiffened pipe with radius R, thickness t and spacing S is given in Eq. (2.3). Where, the approximate wave number can be determined by following Eq. (2.4).

Pcr =

Et R

1

2 R (n 2 1) n 2 + 1 S 2

Et 3 2n 2 1 2 n 1 + + 2 12(1 2 ) R 3 R n 2 + 1 S

(2.3)

n=

t2

R 3 S 12(1 2 ) R 2

(2.4)

When the spacing S in Eq. (2.3) is replaced by the length of a plain pipe L, the Von Mises buckling equation can also be used for a finite long pipe. In Japan, Tokugawa equation is also used in buckling design as shown following,

2 4 Pcr = 2 n2 + 2 2 n 1+ 2

t D0

t 2 + 2 3(1 ) D0

n 4 2n 2 1 2 2 2 n + 2 2 n +2

(2.5)

Where,

D0

2S

D D n = 1.63 0 0 S t

0.5

0.25

- 23 -

Chapter 2 Buckling of Free Pipe under External Pressure

In the latter group, for the buckling of stiffened pipe, Kendrick and Bryant presented their theoretical solutions using the energy approach in 1953, 1954 respectively, based on the phenomenon of buckling deformation that stiffeners and shell distorts simultaneously when buckling occurs. Kendrick and Bryants theoretical equations are given in Eq. (2.6) and Eq. (2.7), respectively.

P cr = P cr =

Ie (n2 1)2 Et 4 + R (n2 + 2 2 1)(n2 + 2 )2 R3S Ie (n2 1)2 4 Et + 2 R (n2 + 2 2 1)(n2 + 2 )2 R0Rc S

(2.6)

(2.7)

Kendricks theoretical solutions was derived by assuming the displacement variations as sinusoidal functions and applying the Rayleigh-Ritz approach, and was experimentally verified by Galletly et al.. Bryant used the same means in derivation of theoretical equation, however, the effect of stiffeners eccentricity and the thickness of shell were taken into account. Moreover, Kendricks equation has been adopted in BS 5500 1994, while Bryants formula has been recommended by the Structural Stability Research Council (SSRC) in America and Associate of Civil Engineer in Japan. Nonlinear and Imperfection Theory When a cylindrical shell is subjected to small external pressure, the small deformation with rotations and strain will occur. In theoretical analysis, the liner expressions for both displacement-strain relation and stress-strain relations can be applied, and the basic governing equations in terms of deformation of shells results in the classical linear theory of elasticity. However, if shells deforms largely, the geometric nonlinear and material nonlinear in terms of displacement-strain relation and stress-strain relations will happen. In such case, the governing equations have to be expressed by adding many nonlinear terms, which results in the nonlinear theory of elasticity. The famous research was carried out by Donnell14) and Yamaki15). The first nonlinear theory of cylindrical shells was established during analysis of torsion buckling of thin-walled pipe by Donnell in 1933. Due to its relative simplicity and practical accuracy, the theory has been most used for analyzing both buckling and post-buckling problems. However, Donnells nonlinear theory was established based on many assumptions as follows, a) shells is sufficiently thin, b) strains are sufficiently small and Hookes law holds, c) there is no deformation in the middle plane, d) points of shells lying initially normal to middle plane remains the normal to middle

- 24 -

Chapter 2 Buckling of Free Pipe under External Pressure

surface of shell after deformation, and e) normal stress in the direction transverse to shells can be disregarded. Where, the assumptions d) and e) consists the so-called Kirchhoff-love hypotheses. From assumptions above, Donnells theory is only suitable for the shallow shell with small deformation, while for the analysis of larger deformation of cylindrical shell it is not applicable. Yamaki found out the problems and presented a modified nonlinear theory based on Flgge theory. Using modified nonlinear theory, the buckling and post-buckling problems were investigated, otherwise the influence of initial imperfection was investigated and corresponding solution was presented. As the imperfection problem of thin shells, the Koitors research should be mentioned. In 1945, Koiter16) clarified the bifurcation stability with the asymptotic analysis of total potential energy of system, by which the initial post-buckling behavior and the influence of small initial imperfections on the critical pressure are reasonably predicted. Moreover, in Koitors research, the general nonlinear theory of thin shells and various simplifications of energy functions were also discussed. Based on the general nonlinear theory, the equations of equilibrium were described in both fundamental state I and an infinitesimally adjacent state II. It was clarified that the energy function for both dead and pressure loading are identical. As the imperfection-sensitivity analysis, the imperfection of a structure is closely related to its initial post-buckling behavior and the theory is exact in the asymptotic sense. As shown in Fig. 2.4, the shape of the secondary initial equilibrium path plays a vital role in determining the influence of the initial imperfections. When the initial portion of the secondary path has a positive curvature (see Fig. 2.4 a)), the structure can develop considerable post-buckling strength and loss of stability of primary path does not result in structural collapse. However, when the initial portion of the secondary path has a negative curvature (see Fig. 2.4 b)) then in most cases buckling will occur violently and the magnitude of the critical load is subject to the degrading influence of initial imperfections. For those cases where as shown in Fig. 2.4, the bifurcation point is symmetric with respect to the buckling deflection, the initial post-buckling behavior is governed by /c=1+b2 (2.8a)

Where, is the applied load (axial load P or external pressure p) and c is the classical buckling load. The amplitude of the buckling displacement normal to the shell w have been normalized with respect to the shell thickness t, thus =w/t. Accordingly, if the post-buckling coefficient b is negative, the equilibrium load falls following buckling and the buckling load of the real structure s is expected to be imperfection-sensitive. In this case, the asymptotic relationship between the buckling load of the imperfect shell and the imperfection amplitude * is (1-s)3/2= 1.5(-3b) 0.5|*|s (2.8b)

- 25 -

Chapter 2 Buckling of Free Pipe under External Pressure

/c

/c

Bifurcation point

/c

Perfect shell

Perfect shell Imperfect shell Limit point Imperfect shell

a) Stable post-buckling b) Unstable post-buckling

Fig. 2.4 Equilibrium paths for perfect and imperfect shells Where, s=s/c and * is the normalized amplitude of the initial imperfection in the form of the classical asymmetric buckling mode17). In the latter the theory was developed and refined by Thompson and Hunt18), etc.. However, as the buckling of stiffened pipe under external pressure, that the imperfection has far less influence on the critical pressure, and in most cases the experimental buckling pressure is higher than the analytical value by as much as 15% has been verified by the Tennyson19). 2.1.3 Numerical Analysis Method and FEM Software20) The numerical analysis is carried out using FEM software MSC.Marc, which has been used to analyze numerous problems successfully in various fields. The buckling analysis provided can estimate the collapse loading / buckling load of a structure in three means: 1) linear buckling analysis in which the eigenvalue analysis is extracted in a linear problem, 2) nonlinear buckling analysis in which eigenvalue analysis is performed in a nonlinear problem based on the incremental stiffness matrices, and 3) Arc-length method which is usually applied for both geometric (large deformation) and material (elasto-plastic material) nonlinear problem. The buckling load can be estimated directly when apply 1) and 2) analysis method. However, the estimation of buckling load requires to investigate the behavior of load and displacement when use the arc-length method. In MSC.Marc, to activate the buckling option in the program, the parameter BUCKLE should be used. If a nonlinear buckling analysis is performed, also use the parameter LARGE DISP. Otherwise, the history definition option BUCKLE can be used to input control tolerances for buckling load estimation (eigenvalue extraction by a power sweep or Lanczos method). The

- 26 -

Chapter 2 Buckling of Free Pipe under External Pressure

buckling load can be estimated after every load increment. However, the BUCKLE INCREMENT option should be used if a collapse load calculation is required at multiple increments. The linear buckling load analysis is correct when one takes a very small load step in increment zero, or makes sure the solution has converged before buckling load analysis (if multiple increments are taken). Although the linear buckling (after increment zero) can be done without using the LARGE DISP parameter, in which case the restriction on the load step size no longer applies, the estimated bucking load should be used with caution, as it is not conservative in predicting the actual collapse of structures. Generally, for a buckling problem that involves material nonlinearity (for example, plasticity), the nonlinear problem must be solved incrementally because a failure to converge in the iteration process or non-positive definite stiffness can signal the plastic collapse during the analysis. Moreover, for extremely nonlinear problems, since the BUCKLE option cannot produce accurate results, the history definition option AUTO INCREMENT should be used to allow automatic load stepping in a quasi-static fashion for both geometric large displacement and material (elastic-plastic) nonlinear problems. By the option the elastic-plastic snap-through phenomena can be handled and the post-buckling behavior of structures can be analyzed. In the liner buckling analysis, the buckle option solves the following eigenvalue problem by the inverse power sweep or Lanczos method using the following matrix formula.

[ K + i K G (u, u, )]i = 0

(2.9a)

Where, K is the stiffness matrix of structure, KG is assumed a linear function of the load increment P to cause buckling. The geometric stiffness KG used for the buckling load calculation is based on the stress and displacement state change at the start of the last increment. However, the stress and strain states are not updated during the buckling analysis. The buckling load Pcr is therefore estimated by:

Pcr = P0 + i P

(2.9b)

Where, for increments greater than 1, P0 is the load applied at the beginning of the increment prior to the buckling analyses, and i is the ith mode value obtained by the power sweep or Lanczos method. As the control tolerances, the maximum number of iterations and the convergence tolerance can be inputted. For the inverse power sweep method, the power sweep terminates when the difference between the eigenvalues in two consecutive sweeps divided by the eigenvalue is less than the tolerance. The Lanczos method concludes when the normalized difference between all eigenvalues satisfies the tolerance. In the current study, the numerical analysis for investigation of buckling behavior is conducted applying linear buckling analysis, considering the non-linear characteristics has little

- 27 -

Chapter 2 Buckling of Free Pipe under External Pressure

influence on the elastic buckling of a perfect cylindrical under uniformly external pressure. As the analysis result, the estimated critical load can be used to evaluate whether material nonlinearities occurred before buckling. Moreover, the buckling mode should be plotted and studied, by which whether the modeled mesh size is sufficient to describe the collapse mode can be checked.

- 28 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.2 Buckling Behavior of Ring-Stiffened Pipe

2.2.1 Generalization on Buckling of Stiffened Pipe In general, the buckling of stiffened pipe is much more complicated than that of plain pipe, the bucking form (type) include a) buckling between stiffeners (local buckling ), b) buckling of general pipe (general buckling), and, c) tripping of stiffeners. As shown in Fig.2.5, the local buckling occurs in the cylinder between stiffeners and distorts into several waves, while the stiffeners remain circular shape; the general buckling stands for the buckling of overall stiffened pipe accompanied with stiffeners and pipe deformed in same waves. The tripping of stiffener is same as the buckling of a plate with a clamped edge twist about its point of attachment to shell, and can be avoided if the aspect of cross section is ensured21).

Pipe Stiffener Pipe Stiffener

Local buckling

Pipe

Stiffener Pipe Stiffener

General buckling Fig. 2.5 Local buckling and general buckling However, in practice, an un-appropriate conception is prevailing until present that the buckling between stiffeners will occur in a stiffened pipe with relatively heavy stiffeners, while general buckling failure will occur in a stiffened pipe with the light stiffener. Actually, the buckling failure type of stiffened pipe is determined not only by the flexural rigidity of stiffeners but the spacing of stiffeners and the geometries of pipe. Buckling behavior of stiffened pipe with respect to buckling type has been investigated by author using numerical analysis method, where the uniformly stiffened pipe is focused, and the second moment of inertia referring the flexural rigidity of stiffener is briefly named stiffness, since Youngs modulus is a constant22) 23).

- 29 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.2.2 Investigation through Numerical Analysis The buckling behavior of stiffened pipes was investigated using numerical analysis. Since the un-stiffened cylindrical shells always occurs general buckling, while stiffened cylindrical shells have three types of buckling types, the decisive element can be considered the ring stiffeners.

Ir Therefore the effects of stiffeners in terms of its stiffness and spacing should be investigated

first. Meanwhile, the influence of the pipe dimensions is examined. Pipe dimensions of the analysis models and their material properties are given in Table 2.1 and Table 2.2 respectively. However, where to prevent ring stiffener from stripping failure, the ratio of height and thickness hr/ht is set less than 17 based on Eq.(2.10).

model 1 2 3 4 10 3

Table 2.1 Analysis Models

Pipe geometries R(m) t(mm) L(m) Stiffener variations S(m) Ir(m4)

1.5 1.0 0.5 1.50 10 10 5.0 5.0 5.0 7.5 6 9 3 6 9 3 1.0 1.0 1.0 1.0 1.0 1.0

hr 0.4 t r

E fy

(2.10)

5 6

hr/tr

17

The buckling behavior is discussed from the two aspects of: a) effects of stiffness and spacing of stiffeners b) effect of the pipe dimensions. Effects of Stiffness and Spacing of Stiffeners The buckling behavior is investigated in terms of buckling wave and critical pressure, as well as the effects of stiffness and spacing of stiffener, as shown in Fig.2.6

7 8 9

Table 2.2 Material properties

Yong's Modulus E(N/mm2) 2.1+E5 Poissons Ratio 0.3 Yield Stress y (N/mm2) 325

3500

14 12

II

2 2 Critical pressure Pcr (kN/m ) ) Buckling Pressure Pcr (kN/m

Model1 Model2 Model3

II

General buckling lobes (Model1)

3000 2500

Model1 Model2 Model3

II I : General buckling

Number of lobes n

10 8 6 4 2 0 0

II I I

I : General buckling II: Local buckling

20 40 60 80 100

4 Second moment inertia of stiffeners Ir(cm ) 4 Second moment ofof area of ring stiffeners Ircm

2000

I

1500

II: Local buckling II

Local buckling lobes (Model1)

1000

I I

II

500

0 0

4 4) Second moment of area of ring stiffeners Ir (cm Second moment of inertia of stiffeners Ir (cm )

20

40

60

80

100

120

a) Buckling waves

b) Critical pressure

Fig.2.6 Effects of stiffness and spacing on buckling of uniformly stiffened pipe

- 30 -

Chapter 2 Buckling of Free Pipe under External Pressure

Fig.2.6 a) and b) show the buckling behavior with changing of the stiffness and spacing of ring stiffeners. Where, the curves of the stiffness of ring stiffeners, Ir, versus the number of lobes, n, and the critical external pressure, Pcr, are presented for different spacing of ring stiffeners. Fig.2.7 a) indicates that all models experience two buckling types with the increasing of stiffeners stiffness. The first one is the general buckling with deformation of pipe and ring stiffeners as one cylinder in the form of sinusoid waves. The second one is the local buckling with deformation of the inter-stiffener shell in a form of diamond waves. The number of buckling waves is not successive: it is less when in general buckling, and then becomes a greater constant value when in local bucking. As the effect of spacing, with the spacing of ring stiffeners decreasing, the number of waves decrease in general buckling and increase in local buckling. Fig.2.7 b) continuously increases in general buckling and then maintains the maximum value of general buckling when in local buckling. Where the limit stiffness is defined as the second moment of inertia of stiffener at which the buckling behavior changes from general buckling to local buckling. However, the buckling pressure changes with the change of the spacing: in general the smaller the spacing is, the larger the

2 Critical pressure Pcr (kN/m Buckling Pressure Pcr (kN/m )

1500

1200

2 2 ) Critical pressure Pcr (kN/m Pcr(kN/m )

Model6 MODEL6 Model9 MODEL9 Model2 MODEL1

t=10mm

indicates that the buckling pressure

900

600

t=7.5mm

300

t=5mm

0 0 5 10 15 20 25 30

4

35

40

Ir(cm ) Second moment of inertia of stiffeners 4 I )

a) Wall thickness

L=3.0 m L=6.0 m L=9.0 m

500

2

t=5mm

Model6 Model7 Model8

forms

t=10mm

Model2 Model4 Model5

2000

buckling pressure is for both general buckling and local buckling, with respect to same stiffness of ring stiffeners. Effects of Pipe Geometries The effect of the geometries including length and thickness of pipe on buckling behavior is shown in Fig.2.7. Figure 2.7 indicates that the buckling behavior are all identical in terms of alteration from general buckling to local buckling with increasing stiffeners, of and the the stiffness critical of ring pressure

)

400

Buckling Pressure Pcr (kN/m 2)

300

1000 200

500 100

0 20 40 60 80 100

4 Second moment of area of ring of stiffeners Ir (cm I) Second moment of inertia stiffeners r(cm )

0 120 4

b) Length and thickness Fig.2.7 Effects of pipe dimensions on buckling of uniformly stiffened pipe

increasing in general buckling while

- 31 -

Critical pressure Pcr (kN/m2)

1500

Chapter 2 Buckling of Free Pipe under External Pressure

almost maintaining the maximum critical pressure of general buckling in local buckling. However, from Fig.2.7 a), that the critical pressure and limit stiffness increase with the increase of wall thickness can be observed. In terms of the length of stiffened pipe, as shown in Fig.2.7 b), the limit stiffness of ring stiffeners, is required to be larger with an increase of pipe length, while the local buckling pressures are almost the same values, which are determined only by inter-ring shells. Moreover, the influence of length change on the limit stiffness and critical pressure becomes greater with the thickness increase. Summary From this study, the buckling behavior was clarified as shown in Fig.2.8. For an individual stiffened pipe, with the increase of flexural rigidity of stiffener briefly named stiffness the critical pressure increases in first phase of general buckling, while almost maintains constant in second phase of local buckling. Furthermore, the buckling type is always general buckling before the stiffener stiffness reaches the limit value, then turns to local buckling once exceeds the limit value. Also, from Fig.2.8, a similar behavior is shown for pipe stiffened with a different spacing. However, the changes in terms of limit stiffness of stiffeners and the critical pressure due to the spacing change are expressed significantly. Generally the wider the spacing is the smaller the limit stiffness of stiffeners, and the smaller the critical pressure. As the effects of pipe dimensions, the length, radius, and wall-thickness of pipe affect the buckling behavior in terms of the critical pressure and the limit stiffness of stiffeners. Generally, the limit stiffness decreases with the increasing of the ratio of radius to thickness (R/t), as well as the critical pressure. Similarly, with the increasing of length, the limit stiffness and critical pressure decreases.

Pcr

P2L cr

L P1cr

S2 S1

Local buckling

P cr :Critical pressure P cr0 :Critical pressure of pipe

0 Pcr

P crL :Critical pressure of local buckling I r : Second moment of inertia of stiffener

General buckling

L r

:Limit second moment of inertia

I 1Lr I 2Lr

Ir

Fig.2.8 Buckling behavior of uniformly stiffened pipe (spacing S1>S2)

- 32 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.2.3 Consideration and Subject From the results mentioned above, it is clear that the buckling behavior of uniformly stiffened pipe is more complicated. For a stiffened pipe, there are two potential buckling types, and the buckling type is determined not only by stiffness and spacing of stiffeners but also by the pipe dimensions. The complex buckling behavior makes the solution of buckling problem more difficult in terms of the critical pressure and buckling mode, because the mechanisms of two buckling types are far distinct and there is not an existing method to estimate the buckling types previously. The obtained bucking behavior brings a light to solve the buckling problem of stiffened pipe. If the limit stiffness of stiffeners is known previously, the buckling type can be predicated by comparing the stiffness of existing stiffeners with limit stiffness, since the local buckling happens only when the stiffness of stiffeners exceeds the limit value. As the limit stiffness of stiffener, its magnitude can be obtained considering that the maximum critical pressure of general buckling is identical to that of local buckling at the limit stiffness. However, the theoretical analysis for buckling of stiffened pipe requires the corresponding buckling equations to calculate the critical pressure. For local buckling, the theoretical equation may be simple because only the inter-stiffener shell is concerned. Whereas the general buckling, that the theoretical equation is much complicated because the stiffener has to be taken into account, and the interaction between stiffener and pipe shell still remains a difficult question. The theoretical equations will be introduced as well as its utilization method in the next section.

- 33 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.3 Derivation of Theoretical Buckling Equations for Ring-stiffened Pipe24)

The buckling behaviors of uniformly stiffened pipe have been clarified. In particular, the buckling type that will eventually change from general buckling to local buckling with the increasing of stiffness of ring stiffeners was identified. Since the general buckling is far different from the local buckling, and the pipe and stiffeners is required to consider simultaneously, the accurate critical pressure of an arbitrary stiffened pipe can be obtained only if the buckling type is known previously. In flowing paragraphs, the theoretical equations of critical pressure are derived taking into account characteristics of general buckling and local buckling first. The solution for buckling of stiffened pipe is then presented based on the theoretical equations. Finally, the verification of the theoretical equations and the presented solution are carried out using numerical analysis and existing experiments. 2.3.1 Introduction As discussed above, since the buckling of stiffened pipe involves two buckling types of general buckling and local buckling, it is necessary to derive the theoretical equations in terms of general buckling and local buckling, respectively. As for the initial imperfection25), its

2 1/2 2 influence on critical pressure is smaller in the case that Baterdf parameter Z L /R/t b Zb=(1-v )

is greater than 103, while can be reduced due to supporting of stiffeners in the case that Z is smaller than 102. Furthermore, since the imperfection of stiffened pipe is still in the research stage and there is not a practical solution until present, in the current study, the imperfection is disregarded in theoretical analysis, however will be taken into account in stiffened pipe design using safe factor. Otherwise, the material stress state is another important issue for buckling analysis, because the elastic or inelastic buckling is determined by whether the stress level of material is beyond the proportional limit or not. In [Buckling Design Specification]26) published by JSCE, a simple formula as shown in Eq. (2.11) has been given to estimate the instability type for a cylindrical shell. If Kc1.2, the buckling is elastic buckling, or inelastic buckling. For an infinite long stiffened pipe, the buckling can always be considered elastic buckling generally considering of the infinite long length.

Kc = ( 2 R 3 / 4 Lf y 1 / 2 ) ( ) t 2 RE

(2.11)

On the other hand, for the theoretical analysis, in the case that it is difficult to determine the exact buckling load in complex structures using the Euler formula due to the difficulty in organizing the constant stiffness matrix, the buckling load is often approximated using energy conservation. This means that predicting buckling load is often referred to as the energy method in structural analysis27), 28), 29). Therefore, in the current study, the theoretical equations based on buckling behavior are discussed using the energy method disregarding the imperfection and

- 34 -

Chapter 2 Buckling of Free Pipe under External Pressure

nonlinear of material, while the solution for buckling pressure uses the Ritz method30), which is a variational method named after Walter Ritz, and one effective method for finding approximations to the lowest energy eigenstate or ground state in mechanics. 2.3.2 Strains in Shell The strains of pipe can be discussed using Timoshenkos bending theory of thin shells. The arbitrary infinitely small element is presented in Fig. 2.9 a), which is obtained through cutting off from shell by two pairs of adjacent planes normal to the middle surface of shell and containing its principal curvatures. In addition, when the lateral sides of the element are displaced parallel to themselves owing to stretching of middle surface, the deformation of element is shown in Fig. 2.9 b), where x, y and z denote axial, tangential and radial direction in terms of cylindrical coordinate. From the Fig. 2.9, the unit elongations (strain) of a thin lamina at a distance z from the middle surface can be given as,

0 x = x z(

Middle surface

Middle surface

y x z

0 xy

0 yx

ds

x(y) z

0 y

0 x(y) ds

x xy

0 x

yx y

Focused lamina

Rx(y) O

z

Focused Rx(y) lamina O

Ry O

Rx

a)

b)

Fig. 2.9 Variations of an infinite small element and flexural deformation

1 1 0 ) = x 0 z ' x Rx Rx

(2.12)

0 y = y z(

1 1 0 ) = y 0 z ' y Ry Ry

(2.13)

0 0 0 , y and x0 , y are strains and curvature Where, x and y are strains of the lamina, x change of middle surface respectively, with respect to x and y directions Furthermore, the shear

strain of focused lamina during bending of shell should be taken into account. Considering that

0 0 it is consisted of twisting of focused element xy and the shearing strain in middle surface xy ,

the shear strain of the lamina can be given as Eq. (2.14).

0 xy = xy 2 z 0

xy

(2.14)

From the equations discussed above, the strains of arbitrary point of pipe can be obtained, upon the strain and curvature change of middle surface were given.

- 35 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.3.3 General Buckling Equation As discussed before, general buckling is the buckling type that the pipe and stiffeners deformed in same waves. Accordingly, the curvature change of stiffeners can be assumed to be the same as that of pipe. Fig. 2.10 shows the model, loading as well as the cylindrical coordinate, where u, v and w are the displacements of axial, tangential, and radial direction

y Plat stiffener t z R w

External pressure P

Pipe u x L

Fig. 2.10 Schematic of model and loading

respectively. Also, the detailed information of longitudinal cross section of stiffened pipe can be referred to Fig. 2.2. Stiffened pipes are reasonably considered to have orthotropic properties in most applications because of the deformation of stiffened pipe resulted from interaction of bending behaviors of ring beam and thin shells. In the current study, the stiffened pipe as orthotropic structure is discussed through investigating the pipe and stiffeners respectively. However, out-of-plane bending, torsional and warping strain of the stiffeners are disregarded because they are found that their effects can be negligible for isotropic stiffened pipe in previous studies not expected to be significant for the orthotropic case. However, for such a complicated system, the solution of buckling of stiffened pipe need to use the potential energy theory. The potential energy of the ring-stiffened cylinder is expressed as follows:

= U V p Vs

12), 31)

, and are

(2.15)

Where, : total potential energy of stiffened pipe Vp: strain energy of pipe Vs : strain energy of ring stiffeners U : work done by external pressure during buckling Strain Energy in Pipe The general strain energy of a thin shell can be written as follows:

V =

1 [ x x + y y + z z + xy xy + xz xz + yz yz ]dxdydz 2

(2.16)

Where, the assumption for thin shells and the stress-strain relationships from Hock are introduced as follows:

- 36 -

Chapter 2 Buckling of Free Pipe under External Pressure

yz = xz = 0

z = 0

(2.17a) (2.17b) (2.18a) (2.18b) (2.18c)

x = y =

E ( x + y ) 1 2 E ( y + x ) 1 2 E xy 2(1 + )

xy =

Substituting Eqs. (2.18) into Eq. (2.16), the strain energy then can be written into Eq. (2.19),

V=

1 E 1 2 2 [ 2 +y +2 xy + (1) xy ]dxdydz 2 x 2 (1 ) 2

(2.19)

Since the pipe is treated as the isotropic thin shells, substituting Eq. (2.12), Eq. (2.13) and Eq. (2.14) into Eq. (2.19), the strain energy of pipe then can be written as

2 1 E 1 0 0 02 02 { 0 + 2 x y +y + (1 ) xy 2 x 2 (1 ) 2

Vp =

0 0 0 0 0 0 0 0 2 z[ x x + y + y y + x + (1 ) xy xy ]

0 0 0 0 0 + z 2[ x + 2 x y + y + 2 (1 ) xy ]} dxdydz 2 2 2

(2.20)

Integrating Eq. (2.20) with respect to t from -0.5t to 0.5t and rearranging the equation, the strain energy of pipe is then expressed by bending strain energy (Vp1) and extensional strain energy (Vp2) of pipe.

V p = V p1 + V p 2

Where

(2.21)

Vp1 =

Et3 0 0 2 0 0 02 [(x + y ) 2(1 )(x y xy )]dxdy 2 24(1 )

Vp2 =

Et 1 02 0 0 02 0 2 [ x + 2 x y + 2 + (1 ) xy ]dxdy 2 2(1 ) 2

Strain Energy in Stiffener The strain energy of stiffeners is computed using curve beam theory. The plain strain is assumed to distribute invariably. Using cross-section area Ar, second moment of inertia I r0 , the strain energy of a stiffener can be expressed as

Vs =

EAr 2

2 y dxdy +

EI r0 2 y dxdy 2

(2.22)

- 37 -

Chapter 2 Buckling of Free Pipe under External Pressure

Since the stiffeners deformation is identical with shells strain for general buckling, the curvature change is same as that of shell. In addition, the strains produced due to axial force is relatively smaller than that due to bending deflection, the strains can be expressed using the curvature change of shell. Thus, the strain energy of a stiffener can be written as Eq. (2.23), where, Ir is expressed as Eq. (2.24), is defined as effective second moment of inertia.

EA h + t EI 0 0 2 Vs = r ( r r ) 2 + r ( y ) dxdy 2 2 2 EI 0 2 = r ( y ) dxdy 2

(2.23)

I r = Ar ( hr + t ) 2 4 + I r0

Where,

(2.24)

Ar = dA = hr br

I r0 = t r hr 12

Moreover, since the pipe is stiffened uniformly, the number of stiffeners then can be computed as L/S for a stiffened pipe. Accordingly, the strain energy of all stiffeners is obtained as shown below,

Vs =

L EI r 02 y dy S 2

(2.25)

Work done by External Pressure The work done by external pressure is estimated from the bending deformation of infinite element (see Fig. 2.11). When pipe is subjected to external pressure, the axial force Ny develops around stiffened pipe before buckling, and the structural stability is kept. However, once buckling occurs, the radial displacement is developed, which induces a relative rotation angle yRd/2 between middle surface and axial force. The axial force then can be divided into perpendicular force and tangential force Nysin(yRd/2) Nycos(yRd/2) with respect to deflected middle surface. Considering the assumption of

Deflected Ny Rd w Initial R p Ny

y Rd / 2

N y cos( y Rd / 2)

y Rd / 2

d

y Rd / 2 N y sin( y Rd / 2)

Ny

Fig.2.11 Work mechanism of infinite small element during buckling

- 38 -

Chapter 2 Buckling of Free Pipe under External Pressure

inextensional deformation of cylindrical shell, the work done by tangential force can be disregarded, the work done by external pressure during buckling is therefore equal to that done by perpendicular force. The Eq. (2.26) expresses the work done by external pressure for a infinite element

N y sin( y Rd / 2) wdx

(2.26)

Moreover, since yRd/2 is very small and relative rotation angle y is identical to curvature change of middle surface of pipe, the total works can be written as follows,

U =

where

R 0 Nyy wddx 2

(2.27)

N y = pR

(2.28)

Substituting Eq. (2.28) into Eq. (2.27), the total works done by external pressure of stiffened pip can be expressed as shown in Eq. (2.29).

U =

pR 2 2

0 y

wddx

(2.29)

Total Potential Energy and Solution Based on the above discussion, the overall potential energy can be obtained by substituting Eq. (2.20), Eq. (2.25) and Eq. (2.29) into Eq. (2.15), as shown in following equation.

pR 2 = U V p Vs = 2

0 y

wd dx

Et3 0 2 0 0 02 [( x + 0 dxdy y ) 2(1 )( x y xy )] 2 24(1 )

Et 2

02 x

0 0 0 + 2 x y + 2 +

1 L EI r 0 2 (1 ) xy ]dxdy 2 S 2

02 y

dy

(2.30)

As similar with other variational method, a trial wave function is required on the system in Ritz method. The trial function should be selected to meet boundary conditions (and any other physical constraints). Since the exact function is not known previously the trial function should contain one or more adjustable parameters, which are varied to find a lowest energy configuration. Where, the displacements in x, y and z direction denoted u, v and w respectively are expressed by trial wave function as shown below, taking into account the support boundary at two ends and the buckling deformations.

- 39 -

Chapter 2 Buckling of Free Pipe under External Pressure

u = A sin n cos v = B cos n sin w = C sin n sin

where

mx L mx L mx L

(2.31a) (2.31b) (2.31c)

AB and Cconstant factors of displacement u, v and w mnumber of longitudinal buckling waves nnumber of circumferential buckling waves As for the strain-displacement relation, the equations can be given as follows according to Flggers cylindrical shell theory:

0 x =

u x

(2.32a) (2.32b) (2.32c) (2.32d) (2.32e) (2.32f)

0 y =

1 v ( w) R

0 = xy

v 1 u + x R 2w x 2

0 = x

0 = y

1 2w ( + w) R 2 2 1 2 w v + ) ( R x x

0 xy =

Additionally dy= Rd, substituting it and Eqs. (2.32) into Eq. (2.30) and integrating, the total potential energy of stiffened pipe can be written as following equation.

2 2 Et 1 1 2 2 2 2 2 2 (1 ) m A m ( 1 ) n B Arn2 + n2 + + 2 4R 1 2 2 tl

2 1 2 I r (n 2 1) 2 1 2 t2 2 2 2 2 p(n 1) + m + n 1 + Ar (1 + C ) + 1 2 2 Et tl Ar R 12 R 2

1 2 r 1 2 (1 + )mnAB 2n + A BC m AC tl

(2.33)

Moreover, based on the assumption of in-extensional deformation of a cylindrical shell, C= Bn

- 40 -

Chapter 2 Buckling of Free Pipe under External Pressure

can be obtained by substituting equations (2.31b and c) into Eq. (2.32b). Omitting the smaller terms and rearranging, the total potential energy of stiffened pipe can be briefly written as Eq. (2.34).

L Et 2 2 2 1 A m + (1 )n2 + AC[(1 )m ] 2 4R 1 2

1 2 2 t2 1 2 I r (n 2 1) 2 (1 )m 2 2 2 2 2 )+ p(n2 1) + m n 1 C 2 + + 12R2 tS R2 2n 2 Et

(2.34)

where =

R

L

Critical Pressure and Buckling Wave To obtain the buckling equation, the minimum total potential energy principle is adopted with respect to the overall potential energy of stiffened pipe. Since the displacement variations are reduced from three to two, the minimum total potential energy principle can be written as Eq. (2.35), on account of two constant factors A and C with respect to axial and radial displacements. The main advantage of this method is that the potential energy is minimized at equilibrium with respect to any unconstrained internal variables for a closed system, besides the reduction in the number of variables is a useful simplification.

=0 A

=0 C

(2.35a) (2.35b)

Substituting Eq. (2.34) into Eq. (2.35), the simultaneous equations Eq. (2.36) are obtained.

A 2m2 2 + (1 )n 2 (1 )mC = 0

(2.36a)

2 2 2 1 2 I r (n2 1) (1 )m2 2 pR(1 ) 2 t2 2 2 2 (n 1) (1 )mA = 0 2C 2 m + n 1 + + 2 2 Et tS R 2n 12R

) (

(2.36b) The two equations can be satisfied by putting A and C equal to zero, which corresponds to a uniformly compressed circular form of equilibrium of shell. However a buckled form of equilibrium becomes possible only if Eq. (2.36) yields for A and C solutions different from zero; this requires the determinant of these equations becomes zero. In this manner the equation for determining the critical load is obtained. The equation has the matrix form as follows.

- 41 -

Chapter 2 Buckling of Free Pipe under External Pressure

X 11 X 21

X 12 X 22

=0

(2.37)

In whichX11, X12, and X22 have the following meanings:

X 11 = 2m 2 2 + (1 )n 2 X 12 = X 21 = (1 )m

2 2 2 2 2 1 2 I r (n2 1) + (1 )m pR(1 ) (n2 1) t2 2 2 2 X 22 = 2 m + n 1 + 2 Et 2n2 tS R2 12R

(2.38a) (2.38b) (2.38c)

) (

Substituting Eq. (2.38) into Eq. (2.37) and solving, the following equation can be obtained,

2 2 2 2 1 Ir (n 1 ) (1)m22 pR(1 2 ) 2 (1 )2 m2 2 t2 2 2 2 (2.39) 2 2 m + n 1 + + ( n 1 ) = 2 2 2 tS R2 2n2 Et 2m + (1 )n 12R

After omitting the small terms which have very little effect on the magnitude of the critical pressure, the critical pressure can be obtained in which the potential energy becomes the smallest. Where, the longitudinal waves is assumed as m=1. The critical pressure equation can be rewritten after rearranging,

G P cr =

Et t 2 ( 2 + n2 1)2 Ir (n2 1)2 4 + + 2 2 (n2 1)R tR2S 2 + n2 12(1 )R

(2.40)

However, the circumferential waves (n) is demanded when computes the critical pressure. The minimum energy principle is applied to find the number of circumferential waves. Assuming

< 1 and n>2 and substituting into Eq. (2.40), the Eq. (2.40) can be simplified as follows,

G Pcr =

Et t 2n2 I r n2 4 + + 2 2 R tR 2 S n 6 12(1 ) R

(2.41)

To obtain the smallest critical pressure, the Eq. (2.41) should satisfy the Eq. (2.42). Substituting Eq. (2.41) into Eq. (2.42), the equation of wave to get critical pressure can be obtained as shown in Eq. (2.43).

G Pcr =0 n

(2.42) (2.43)

3 4 n= K

8

where

K=

t2 Ir + 2 2 2 12(1 ) R tR S

- 42 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.3.4 Local Buckling Equation

The local buckling is the buckling type in which, the stiffeners remains its initial circular shape while the inter-stiffener steel plate deforms with several waves around pipe and a wave along pipe. Hence the theoretical buckling can be investigated only considering the inter-stiffener pipe. The corresponding expression of potential energy can be obtained from Eq. (2.34) by omitting the terms related to stiffeners and replacing the overall length by spacing of stiffener.

S Et 2 2 2 1 A m + (1 )n2 + AC[(1 )m ] 2 4R 1 2

(1 )m 2 2 1 2 2 t2 2 2 2 + p(n 2 1) + m n 1 C 2 + 2n 2 12 R 2 Et

(2.44)

In the same way, the equation of critical pressure can be obtained using the minimum principle of potential energy and omitting the small terms, as written in Eq. (2.45).

L P cr =

4 Et t 2 ( 2 + n2 1)2 + 2 2 2 (n2 1)R 2 + n2 12(1 )R

(2.45)

In the same way, the equation to find the number of circumferential waves can be obtained.

n=8

where

3 4 K

t2 12(1 2 ) R 2

(2.46)

K=

R

S

- 43 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.4 Application and Verification of Buckling Equations

2.4.1 Two-stage Method

From the above discussion, that the stiffened pipe has two buckling types and the critical pressure equations of two buckling forms vary from each other has been confirmed. It is therefore, the critical pressure of stiffened pipe should be calculated with respect to the corresponding buckling type. In this study, the two-stage method is presented by which, the critical pressure can be obtained through two stages of judging the buckling type and estimating critical pressure. As the first stage, the buckling type is judged using the critical pressure equations derived above. The procedure is given by followings, 1) estimate all the respective critical pressure with the corresponding theoretical equations (Eq. (2.40) and Eq. (2.45)) in terms of general buckling and local buckling; 2) compare the two estimated critical pressure and judge the buckling type. If the critical pressure of general buckling is greater than that of local buckling, the local buckling occurs first is judged, or the general buckling, based on the buckling behavior of stiffened pipe. It therefore the bucking type of the stiffened pipe can be determined. In the second stage, the critical pressure of the stiffened pipe can be estimated by using critical pressure of judged buckling type. As the result, the accurate and practical critical pressure can be estimated by the two-stage method for any stiffened pipe. However, since the study is conducted based on the assumption of elastic buckling, the identification of elastic buckling should be carried out. The work can be done through checking the stress of pipe under critical pressure which is given by Eq. (2.47), where cr is the critical stress fy the yield strength. If cr<fy ,it can be judged that the buckling of stiffened pipe is elastic buckling.

cr =

RPcr t

(2.47)

To simplify the identifying work, the limit pressure of elastic buckling (PL ) is introduced and used to judge buckling state by comparing with the critical pressure. Where, the limit pressure of elastic buckling (PL ) is the acting external pressure when the critical stress is equal to yielding strength, and its magnitude can be calculated by Eq. (2.48)Accordingly, the elastic buckling can also be judged if the critical pressure is smaller than the limit pressure.

PL =

tf y R

(2.48)

Furthermore, although the stiffener should be taken into account for general buckling, the judgment method presented above is adopted for all buckling forms disregarding the reinforcing effects of stiffeners, because the share of axial force by stiffeners is relatively smaller comparing with that by pipe for a stiffened pipe subjected to uniform external pressure.

- 44 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.4.2 Verification of Two-stage Method

The verification of two-stage method is carried out using the experimental results of previous studies and the existing theoretical equations. As for the experiments, although there are many previous experimental studies10),32),33) on the buckling of stiffened pipe, the experimental studies on the buckling behaviors has limited except the study of Seleim et al. In this study, the buckling behaviors in terms of buckling type and critical pressure were investigated using ten stiffened pipes with different stiffeners from many equally spaced weak rings to a few heavy rings. Moreover, the ideal critical pressure (experimental critical pressure) was estimated using Southwell method34) based on the measured displacement besides the collapse pressure. Here, their experiment results are used to verify the theoretical analysis presented above. The experimental

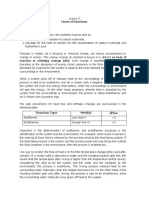

Table 2.3 Test models

Stiffener Models spacing S(mm)

Model1 Model2,9 Model3,10 Model4 Model5 Model6 Model 7,8

Aluminum

Height hr(mm)

7.37 17.27 8.38 13.46 9.14 11.43 9.91

thickness tr(mm)

3.56 8.64 4.06 6.60 4.57 5.59 5.08

pipe (Al-6061 )

Radius: R=128mm Length: L=889mm thickness: t=2mm

49.28 222.25 63.50 148.08 74.17 111.25 88.90

Table 2.4 Aluminum (Al-6061) properties

Youngs Modus E (N/mm2) 6.9E4 Poison Yield strength

0.33

y (N/mm2)

276

models and material properties are shown in Table 2.3 and Table 2.4. Where, because the test models of Model29Model78, and Model310 are identicalthey are investigated as a analytical model respectively with respect to the theoretical analysis. Moreover, for verification of elastic buckling, the limit pressure of elastic buckling is estimated by Eq. (2.48), as PL=4.31 N/mm2. Otherwise, the existing buckling equations of Bryant, Kendrick, Tokugawa and Timoshenko are examined through comparing with the results of two-stage method and experiment.

Verification by Experiment

The two-stage method is examined in terms of judgment of buckling types and critical pressure. All the experimental models shown in Table 2.3 are investigated by two-stage method. First, the buckling type of respective model is judged and examined through comparing with the experimental result. Then, the critical pressure corresponding to the judged buckling type is used and compared with the experimental result. The analytical buckling type and critical pressure are summarized as shown in Table 2.5 for all models, as well as the corresponding experimental results including buckling types, critical pressure and collapse pressure. Where,

- 45 -

Chapter 2 Buckling of Free Pipe under External Pressure

the experimental critical pressure is ideal pre-buckling pressure of perfect structure estimated by Southwell method by plotting measured pressure to displacement curve of geometrically imperfect model, while the collapse pressure is the measured pressure when the testing model collapses. Moreover, from Table 2.5, that all the model buckles in elastic buckling can be found because the critical pressure of all models is smaller than limit pressure of elastic buckling PL (4.31 N/mm2 ). The same result was also given by judging the strains obtained from the experiment, which all of them are less than yield strain. The bucking types judged by two-stage method are identical to experimental results for almost models except model7. The model7 and model8 have the same dimensions and material properties, however, the buckling types vary each other with general buckling in model7 and local buckling in model 8. The complex buckling phenomenon was explained in the referring article, that the model7,8 failed in one of the two possible types (primary type) but their behavior and ultimate collapse was influenced by the presence of the other type (secondary type). The interaction role played by the secondary buckling type in buckling behavior was found to affect the buckling type and deformation pattern but not the buckling pressure. It is therefore more reasonable only to investigate buckling pressure for such case. As the feature of respective buckling type, it can be indicated by the failure deformation. For those buckling which failed by the shell instability form (local buckling), the collapse was always confined to one bay only. Other bays were either not affected by the excessive deformations at the collapse bay or developed a different pattern of deformation at collapse. Such behavior characterized the localized nature of the shell instability form. On the other hand, for the models failed in the general buckling, the deformation patterns of all the bays were forced to reshapes into the same final buckling pattern. This characterizes the overall nature of the general buckling type. As the buckling critical pressure, the errors of theoretical values obtained by two-stage method are 529 and 524, while those calculated by Kendricks equations in Table 2.5 Comparison between analytical and experimental results ( unit: N/mm2 )

Buckling forms Judgment Model Model2 Model4 Model6 Model7 Model9 Model1 Model3 Model5 Model8 Model10 General PGcr 8.77 5.4 4.14 3.4 8.77 2.35 2.7 3.08 3.4 2.7 Local PLcr 1.30 2.04 2.87 3.81 1.30 8.70 6.08 4.87 3.81 6.08 Type L. L. L. G. L. G. G. G. G. G. Theoretical results Critical Pcr 1.30 2.04 2.87 3.40 1.30 2.35 2.70 3.08 3.40 2.70 Waves n 6 7 8 2 6 2 2 2 2 2 Collap Pu 1.57 2.26 3.26 2.94 1.36 3.03 2.83 3.19 3.52 3.12 Experimental results Critical Pe 1.61 2.36 3.6 4.06 1.36* 3.03 2.96 3.28 3.58 3.17 Waves n 6 8 8 8 6 3 3 3 3 3 Type L. L. L. L. L. G. G. G. G. G. Error Pe Pu Pcr Pcr 1.21 1.11 1.14 0.86 1.05 1.29 1.05 1.04 1.04 1.16 1.24 1.16 1.25 1.19 1.05 1.29 1.10 1.06 1.05 1.17

*:Model9, the collapse pressure is used for critical pressure due the experiment failure

- 46 -

Chapter 2 Buckling of Free Pipe under External Pressure

Seleims article are 1233 and 1927 less than corresponding experimental results for general buckling and local buckling, respectively. It is therefore some more valid to use the two-stage method for investigating the buckling of stiffened pipe, especially under the condition of known buckling types if use the two-stage method. Moreover, the Kendricks equation is well known of use for general buckling, the application for local buckling is not demonstrated well although used in the study of Seleim et al.. Furthermore, as the most interest to engineering practice, the theoretical pressure is always less than experimental value. This means the influence of imperfection is so little that can be ignored. The explanation can be considered as follows: the influence of imperfection on a stiffened pipe is far different from a plain thin wall pipe because the buckling resistance capacity is determined not only by the pipe shell but also the stiffeners for stiffened pipe; in addition, the interaction of pipe shell and stiffeners may reduce the influence of imperfection; otherwise, the theoretical critical pressure may be underestimated due to the modeling with shell and beam element for pipe and stiffeners respectively and disregarding the effect of interaction between pipe and stiffeners in theoretical analysis. In Tennysons study, the same results that the theoretical critical pressure is 15% less than experimental value has been mentioned. Accordingly, it should be correct to consider that the effect is greater due to interaction of stiffeners and pipe than imperfection in practical buckling behaviors of stiffened pipe under lateral pressure. From the above studies, it was verified that the two-stage method is rather valid solution for analysis of stiffened pipe buckling, because not only the buckling type but also the more accurate critical pressure can be predicted. Furthermore, since the two-stage method always gives conservative critical pressure, the stiffened pipe may also be designed safely when apply this method.

Comparison between Two-stage Method and Existing Buckling Equations

As discussed above, the buckling theory of stiffened pipe has been studied by Tokugawa, Timoshenko, Bryant and Kendrick, and the corresponding solution equations have been given. However, the validation of all the theories for an arbitrary stiffened pipe should be examined. In this study, the examinations are carried out through comparing theoretical results with experimental results and the analytical results by two-stage method for all test models, in terms of the number of buckling waves and critical pressure. The comparison results with respect to the number of buckling waves and the critical pressure are shown in Figs. 2.12, 2.13, 2.14, 2.15 and 2.16, respectively. Where, the number of buckling waves and theoretical pressures are calculated using the respective buckling equations presented previously.

- 47 -

Chapter 2 Buckling of Free Pipe under External Pressure

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Two-stage method Timoshenko

Local buckling

Kendrick Tokugawa

Btyant Experiment

General buckling

Number of buckling Waves

mo

mo mo mo mo mo mo mo mo mo de de de de de de de de de de l10 l8 l5 l3 l1 l9 l7 l6 l4 l2

Fig. 2.12 Comparison of numbers of buckling waves Form Fig. 2.12, all the number of buckling waves calculated by two-stage method generally agrees with corresponding experimental result can be found. On the other hand, the number of buckling waves predicted from the buckling theory of Tokogawa and Timoshenko agrees with experimental result in local buckling, while is far different from that in general buckling. In contrary, the buckling wave number of Bryant and Kendrick coincides with experimental result well in general buckling while far less in local buckling. This may imply the existing buckling theories should be selected according to the buckling type when applied.

10.0 Critical/Collapse pressureN/mm 2 9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0

Critical/Collapse pressureN/mm 2

Two-stage method Kendrick Experimental critical pressure Experimental collapse pressure Local buckling General buckling

10.0 9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0

Two-stage method Byant Experimental critical pressure Experimental collapse pressure Local buckling General buckling

mo d

e l2

mo d

e l4

mo d

e l6

mo de

l7

mo d

e l9

mo mo mo mo mo de de de de de l1 l3 l5 l8 l10

mo d

e l2

mo d

e l4

mo d

e l6

mo d

e l7

mo d

e l9

mo d

e l1

mo d

e l3

mo d

e l5

mo d

e l8

mo d

e l1

Fig. 2.13 Comparison with Kendrick theory

Fig. 2.14 Comparison with Bryant theory

- 48 -

Chapter 2 Buckling of Free Pipe under External Pressure

10.0 Critical/Collapse pressureN/mm 2 9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0

Critical/Collapse pressureN/mm 2

Two-stage method Tokugawa Experimental critical pressure Experimental collapse pressure Local buckling General buckling

10.0 9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0

Two-stage method Timoshenko Experimental critical pressure Experimental collapse pressure Local buckling General buckling

mo mo mo mo mo mo mo mo mo mo de de de de de de de de de de l2 l6 l4 l7 l9 l1 l5 l10 l3 l8

mo d

e l2

mo d

e l4

mo d

e l6

mo d

e l7

mo d

e l9

mo d

e l1

mo d

e l3

mo d

e l5

mo d

e l8

mo d

e l1

Fig. 2.15 Comparison with Tokugawa theory

Fig.2.16 Comparison with Timoshenko theory

The implication is tested by the subsequently calculated critical pressure. As shown in Figs. 2.13 and 2.14, the experimental results generally are coincident with Bryant and Kendricks critical pressure in general buckling, however there is great difference existing in local buckling. Inversely, as shown in Fig. 2.15 and 2.16, the critical pressure from Tokogawa and Timoshenkos equations agrees well with the experimental results in local buckling while disagrees with those in general buckling. However, with respect to difference between the existing buckling theories, there is little difference between Tokogawa and Timoshenkos critical pressure in general buckling, while Bryants solution presents more conservational critical pressure than Kendricks in general buckling. On the other hand, only the critical pressures estimated by tow-stage method are satisfied with experimental results in all general and local buckling. Consequently, it is more rational and reasonable to consider that the buckling theories of Tokugawa and Timoshenko are only suitable for local buckling and those of Kendrick and Bryant are suitable for general buckling. While for an arbitrary stiffened pipe with buckling type unknown previously, the critical pressure should be estimated using the two-stage method.

- 49 -

Chapter 2 Buckling of Free Pipe under External Pressure

2.4.3 Buckling Behavior Simulation

The two-stage method is a very useful and rational tool to solve the problem of stiffened pipe buckling under external pressure has been confirmed from the above discussion. However, as for the bucking design, the theoretical analysis of buckling behavior is required in many cases other than the buckling critical pressure. Until present, the investigation of buckling behavior can only be carried out using the numerical analysis (FEM) or experiment because there is no a reliable analytical solution. Since the investigation for the buckling behavios of pipe usually requires much time and cost, no matter using numerical analysis or experiments, the theoretical solution should be discussed. In the following paragraph, an effective and simple theoretical analysis method using two-stage method will be presented, and be examined by conventional methods of numerical analysis. Meanwhile, the more detailed description on buckling behavior will also be given. Where, the testing models used in former paragraphs, are adopted in the analytical models with respect to the numerical and theoretical analyses.

Theoretical Analysis by Two-stage Method

The buckling behavior is discussed from the following three aspects: a) buckling behavior with changing of the second moment of inertia of stiffeners with respect to a particular spacing, b) buckling behavior with changes in the spacing of stiffeners, and, c) influence of the geometry of cylindrical shells. Accordingly, the analysis of buckling behavior using two-stage method can be carried out as follows: 1) increase the rigid stiffness of stiffeners and calculate the corresponding buckling critical pressure using two-stage method; 2) repeat step 1) with respect to the constant pipe with a alterative spacing of stiffeners; and, 3) repeat step 1) with respect to a alterative pipe with a constant spacing of stiffeners. Thus, the buckling behavior of any an arbitrary stiffened pipe can be obtained in terms of the relation of critical pressure to second moment of inertia of stiffener.

Numerical Analysis by Finite Element Method

The numerical analysis is carried out using FEM software MSC.Marc. In the current study, the investigation of buckling behavior is conducted by applying linear buckling analysis, considering the non-linear characteristics has little influence on the elastic buckling of a perfect cylindrical under uniformly external pressure. As for the modeling of stiffened pipe, considering the interaction between pipe and stiffeners is mainly due to transverse shear, the stiffener and pipe are modeled using bilinear thick-shell element, which is a four-node, thick-shell element with global displacements and rotations as degrees of freedom. Bilinear interpolation is used for the coordinates, displacements and the rotations. The membrane strains are obtained from the displacement field; and the curvatures are

- 50 -

Chapter 2 Buckling of Free Pipe under External Pressure

from the rotation field. The transverse shear strains are calculated at the middle of the edges and interpolated to the integration points. In this way, a very efficient and simple element is obtained which exhibits correct behavior in the limiting case of thin shells. The element can be used in curved shell analysis as well as in the analysis of complicated plate structures. For the latter case, the element is easy to use since connections between intersecting plates can be modeled without tying. Due to its simple formulation comparing to the standard higher order shell elements, it is less expensive and, therefore, very attractive in nonlinear analysis. The element is not very sensitive to distortion, particularly if the corner nodes lie in the same plane. All constitutive relations can be used with this element.

Verification of Buckling Behavior

The buckling behaviors of all models are simulated using theoretical and numerical analysis, which are shown in Figs.2.17~2.23, respectively. Meanwhile, the experimental results are also given in the corresponding figure. In addition, the limit stiffness of stiffener and the buckling deformation profile of respective model are also shown in these figures. Otherwise, to illustrate the buckling deformation type and counting method of the number of buckling waves, the buckling deformation are demonstrated in Fig. 2.24, in terms of 3D view and plan view, where the bucking deformation of a general buckling and two patterns of local buckling are shown. The deformed location varies with the spacing of stiffeners; generally for large spacing the buckling deforms all inter-stiffener shells of overall stiffened pipe, while inter-stiffener shell at the end of stiffened pipe deforms for narrow spacing. As the number of buckling waves, it is equivalent to the number of outer wave peaks for general buckling and pattern 1 of the local buckling, half of number of outer wave peaks for pattern 2 of the local buckling. Figures 2.17~2.23 indicate that all the buckling behavior obtained by two-stage method agree well with the corresponding numerical analysis results. The buckling behavior expresses the feature that the buckling type changes from general buckling to local buckling when the stiffness of stiffeners reaches the limit stiffness; the critical pressure increases with the increase of stiffeners stiffness in general buckling, while maintains the maximum critical pressure of general buckling in local buckling. In addition, that the experimental results of buckling type and critical pressure are satisfied well by corresponding numerical and theoretical analysis results is illustrated except model7. It is therefore easy to consider that an arbitrary stiffened pipe can be estimated in terms of the buckling type and critical pressure if the buckling behavior is known. However, it may be noted that there is a little difference between numerical and theoretical analysis in local buckling. The critical pressure obtained from numerical analysis has a trend of increasing with the enlargement of stiffener. The reason may be considered that the supports at two ends of inter-stiffener shell become stronger and the spacing decrease with the increase of stiffness of stiffeners.

- 51 -

Chapter 2 Buckling of Free Pipe under External Pressure

Numerical Theoretica l Experimenta l

10.0 9.0 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0 0

2 ) (N/mm Critical pressure P c r (N/mm )

2 2 Critical pressure P c r (N/mm ) (N/mm )

Numerical

Theoretica l

Experimenta l

1.8 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 0

L.B. domain

L.B. domain

G.B. G.B. domain 697 3899

L.B.

G.B. domain

949

2500 5000 7500

G.B.

L.B.

17604

4

1000 2000 3000 4000 5000 6000 7000 8000 9000 4 2 (mm4 ) Moment of inertia of stiffener I r (mm )

10000 12500 15000 17500 20000

4 ) 2Ir(mm Moment inertia of stiffener ) r (mm of 2 I

Fig. 2.17 Buckling behavior (Model1)

2 2 Critical pressure P c r (N/mm ) (N/mm )

Fig. 2.18 Buckling behavior (Model2,9)

2.8 2.5 2.3 2.0 1.8 1.5 1.3 1.0 0.8 0.5 0.3 0.0 0

2 2 Critical pressure P c r (N/mm ) ) (N/mm

8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0 0

Numerical

Theoretica l Experimenta l

Numerical

Theoretica l

Experimenta l

L.B. domain

L.B. domain

G.B.

G.B. domain

L.B.

G.B. G.B. domain 1980

1000 2000 3000

L.B.

1123

3278

8000

4000 5000 6000

4

6678

7000 8000

1000 2000 3000 4000 5000 6000 7000 4 )4 ) (mm Moment inertia of2stiffener of 2 I r (mm

4 ) 2 (mm Moment of inertia of stiffener I r (mm ) 2

Fig. 2.19 Buckling behavior (Model3, 10)

2 2 Critical pressure P c r (N/mm ) ) (N/mm

Fig. 2.20 Buckling behavior (Model4)

Critical pressure P c r 2 (N/mm 4 )

4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 0 1000 Numerical Theoretica l Experimenta l

6.0 5.0 4.0 3.0 2.0 1.0 0.0 0

Numerical

Theoretica l

Experimenta l

L.B. domain

(N/mm )

L.B. domain

G.B. G.B. domain 1597

1000 2000

L.B.

G.B. domain 2500

2000

G.B.

L.B.

2970

3000

4000 5000

4

3589

3000 4000 5000

6000

4 2 (mm ) Moment of stiffener I (mm ) r inertia of 2

4 4 Moment of stiffener(mm I r (mm ) ) of inertia 2

Fig. 2.21 Buckling behavior (Model5)

5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 0

2 2 Critical pressure P c r (N/mm ) (N/mm )

Fig. 2.22 Buckling behavior (Model6)

Numerical

Theoretica l

Experimenta l

L.B. domain

G.B.

G.B. domain

L.B.

2204

1000 2000

2622

3000

4000 5000

4

n=3

6000

n=10

n=8

4 (mm )) Moment of stiffener I r (mm inertia of 2 2

a) General buckling b) Locally local buckling c) Generally local buckling

Fig. 2.23 Buckling behavior (Model7,8 ) - 52 -

Fig. 2.24 Buckling deformation

Chapter 2 Buckling of Free Pipe under External Pressure