Professional Documents

Culture Documents

Heat Straightening Repairs To A Steel Road Bridge

Heat Straightening Repairs To A Steel Road Bridge

Uploaded by

notsofarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Straightening Repairs To A Steel Road Bridge

Heat Straightening Repairs To A Steel Road Bridge

Uploaded by

notsofarCopyright:

Available Formats

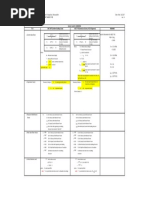

Proceedings of the Institution of Civil Engineers Bridge Engineering 159 March 2006 Issue BE1 Pages 35 42 Paper 14232

Received 07/10/2004 Accepted 29/06/2005 Keywords: bridges/stress analysis/thermal effects Simon K. Clubley Bridge Engineer, Winchester Bridges Group, Mott MacDonald, Winchester, UK Stephen N. Winter Senior Bridge Engineer, Winchester Bridges Group, Mott MacDonald, Winchester, UK Keith W. Turner Design Team Leader, Winchester Bridges Group, Mott MacDonald, Winchester, UK

Heat-straightening repairs to a steel road bridge

S. K. Clubley PhD, S. N. Winter MA, CEng, MICE, MIStructE and K. W. Turner

On 16 July 2002 a low-loader lorry carrying heavy machinery travelling eastbound on the A27 struck the underside of Brockhampton Road new bridge. The bridge suffered structural damage to the main beams and bracing. From an initial emergency inspection, the damage was found to be located close to the point of contraexure in an area where the bottom ange was in tension. It was not considered necessary to impose immediate closures or trafc restrictions. A heat-straightening repair of the damaged beams was proposed. Detailed analysis using both hand calculations and the nite-element method conrmed the structural adequacy of the bridge to undergo the heat-straightening process. These checks encompassed the temporary conditions prior to, during and after the heating. The major heat-straightening process was successfully completed on site in ten days. Impact damage to the beams was repaired within acceptable tolerances and the straightened steel was subjected to hardness and magnetic particle investigation testing. The repairs to Brockhampton Road new bridge were concluded without undue disruption to the travelling public or local residents. BSc(Hons), CEng, MICE the K bracing caused a punching-type deformation in the web of the rst beam. This force was relieved once it reached a magnitude large enough to shear the M24 bolts attaching the web stiffener to the bracing. At this moment, the bottom chord of the bracing buckled. The lorry continued to scrape the underside of the next three beams before being pushed up into the fth beam causing damage to the bottom ange. Fortunately, the reaction generated in this bracing was insufcient to fail either the web or connection bolts. Brockhampton Road new bridge was built with a square, three-span, composite steel plate girder and concrete slab structure. This is supported on reinforced concrete bank seats at the north and south ends, and by two intermediate leaf piers which are 600 mm in thickness. Transverse concrete deck diaphragms are built into the supports making the bridge fully integral. The piers are protected from trafc on the A27 by safety fencing. The span of the centre section is 34.60 m, and the side spans are 14.90 m, to the centreline of the supports. There are two 3.65 m carriageways and two combined cycleway/footways of 2.40 m in width. The deck consists of six grade S355 steel plate girders supporting a 210 mm thick solid reinforced concrete slab. Each main beam is continuously braced in pairs and is 1000 mm deep with 480 mm wide bottom ange and 300 mm wide top ange. The plate thickness is reduced between splices in the main span approximately at the point of contraexure. A bottom ange thickness of 25 mm and web thickness of 12 mm occurs at the location of impact. A major concern was how the structure could be restored to its original condition or at least within the geometrical tolerances given by BS 5400 part 6.1 It was clear from the inspection that sections of steel would have to be cut out and replaced from the web. Although the A27 at this location is a dual two-lane carriageway, it is heavily trafcked by up to 82 000 vehicles per day (average annual daily trafc (AADT) two-way ow). Although it was fortunate that the damage occurred at the point of contraexure, this was offset by the fact that access for repairs would necessitate total closure of the eastbound carriageway. Any diversions would have to be through Havant town centre. This was acceptable between 2100 and 0500 h, but not during the daytime and in particular in the peak rush hours. Any delay or disruption to the road would have been very unpopular. To reduce the work to manageable sections which could be achieved overnight, Mott MacDonald suggested that heat Clubley et al. 35

1. INTRODUCTION Brockhampton Road new bridge replaced an earlier bridge on the same alignment. It carries a busy local road over the A27 Havant bypass in Hampshire, UK. The structure was designed by Scott Wilson and constructed in 2001 by Costain under a Highways Agency design-and-build contract. On 16 July 2002, Mott MacDonald as agent for the Highways Agency was informed by the Hampshire Police in Netley that a vehicle travelling eastbound on the A27 had struck the underside of the bridge. The bridge had suffered structural damage to the main girders and bracing, resulting from the impact of construction plant carried on the rear of a low-loader lorry. Following an initial emergency inspection by Mott MacDonald in July 2002, the structure was inspected in detail by Faireld Mabey using access equipment and trafc management in December 2002. From the emergency inspection, the damage was found to be located close to the point of contraexure in an area where the bottom ange was in tension. It was not considered necessary to impose immediate closures or trafc restrictions. The horizontal force from the impact was redistributed by the bottom ange to the cross-bracings. The reaction generated in Bridge Engineering 159 Issue BE1

Heat-straightening repairs to a steel road bridge

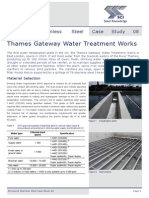

straightening be used to repair damage to the bottom anges and restore the plan straightness of the rst and fth beams. In conjunction with the heat straightening, a series of additional repairs were required to reinstate buckled stiffeners, K bracing, web and cracked welds near the impact zones. New protective paint coatings were also needed on all affected areas. The heat-straightening method provided the most cost-effective solution for repairing the damage to the bridge beams. Heat straightening has many advantages over beam replacement with respect to the issue of reduced delay and disruption to the travelling public. The justication for the use of heat straightening was based on the knowledge that the mechanical properties of steel return unchanged for temperatures up to 6008C. Advice was sought from the Highways Agency regarding previous repairs using heat straightening. The mitigation for this method was based upon the following estimated added value. (a) Monetary: heat straightening, 90 000 versus beam replacement, 450 000. (b) Non-monetary: reduction in delay and disruption when using heat straightening. This equated to an added value of 360 000. Figure 1 shows a recent photograph of the structure illustrating the general arrangement and the position of the A27 dual carriageway. 2. THE HEAT -STRAIGHTENING PROCESS Heat straightening is a relatively new method of repair for highway structures in the United Kingdom. By comparison, the technique has been used quite successfully for many years in the United States, combining both ongoing research and practical experience. The heat straightening of Brockhampton Road New Bridge was carried out in accordance with the guidance of US Department of TransportationFederal Highway Administration document: Heat Straightening Repairs of Damaged Steel BridgesA Technical Guide and Manual of Practice.2 Two formal departures from standard were required to cover the use of this document and the method of heat straightening structural steelwork. Concentrated local heating of certain areas will produce expansion of the steel and a lowering of the yield stress.

If surrounded by cooler steel, a restraining action will occur which will cause the heated area to yield if a sufciently high temperature has been used. This restraint produces a contraction as the metal cools, the effect of which is to yield and deform its prole. By using carefully designed heating patterns, this process of deformation can be used to return damaged steel to its original prole. The careful placement of additional external jacking forces can improve the recovery during the cooling phase. The most critical aspect of the heat straightening is the through-thickness temperature of the metal. Any applied heating must remain clearly below the lower transition temperature (approximately 7238C), to prevent permanently changing the physical properties. A maximum temperature between 600 and 6508C should not be exceeded for steels manufactured in the UK a cherry red colour will be visible on the steel surface if the temperature is too high. The attainment of the correct temperature is indicated by a silver colour under the ame, surrounded by a brown and blue area. During this process the yield stress of the material will reduce temporarily by approximately 50%. A molecular phase change in steel occurs when the temperature exceeds the lower transition point. At this temperature, the body-centred cubic structure of the steel begins to assume a face-centred cubic form. This composition carries a larger percentage of carbon in solution. A careful cooling process is required to return the molecular structure successfully to the body-centred cubic arrangement. Uncontrolled cooling of the steel may not allow this reversal to occur, which will produce a hard but brittle material known as martensite. This material has low fracture strength and is particularly susceptible to cyclic loads. There are several possible methods for monitoring the temperature during the heat-straightening process. Typically, this is most easily achieved by observing the colour of the steel, which is a skill that is largely dependent upon experience. Unfortunately, this method can be signicantly erroneous. Research by Roeder3 and Avent et al.,4 has shown that even experienced practitioners when judging temperature consistently misjudged by 568C and in some instances in excess of 1008C. Alternative methods of surface temperature measurement are possible using special heat-sensitive crayons, thermocouples or digital infrared pyrometers. Although it is not advisable to overheat the steel above the transition temperature during heat straightening, it does not immediately necessitate the replacement of the member. Further engineering judgement is always required. During the heat straightening of Brockhampton Road new bridge, digital infrared pyrometers were used. This form of temperature monitoring proved to be very convenient as the pyrometers were used from remote distances on the carriageway below.

3. IMPACT DAMAGE As previously mentioned, Brockhampton Road new bridge suffered structural damage to two main beams and K bracing, following the impact of a low-loader lorry. Both global and local Heat-straightening repairs to a steel road bridge Clubley et al.

Fig. 1. General view towards southern abutment

36

Bridge Engineering 159 Issue BE1

deformation of the bottom anges and web were immediately visible after the accident. The structure was inspected in detail which established, fortunately, that the impact was located close to the point of contraexure. Fig. 2 illustrates the bending moment and shear force prole at the location of impact. At the damage point, the bottom ange of the beam is in tension. The exural stresses in the steel were calculated to be low. The low-loader lorry struck the rst main beam on the eastbound carriageway, subsequently scraping the bottom of the next three beams and nally striking the bottom ange of the fth main beam. Despite a satisfactory loaded trailer height, impact occurred due to improperly secured machinery bouncing upwards as the vehicle moved. All of the damage to the structure had occurred before the driver could stop the lorry in time. Fig. 3 shows the damage to the rst and fth main beams. A summary of the localised and global damage is given in the following subsections.

600 mm height. The bottom ange adjacent to the damage was found to be out of level by 12 mm over its 480 mm width. At 9.0 m from the face of the north pier, the web was pushed outwards at the nearest bracing. There was a large crack in the web parallel to the bottom ange just above the web-to-ange llet weld. The K bracing between the rst and second beams closest to the point of impact buckled at the bottom chord level. This bracing was fabricated from 120 120 12 mm rolled steel angle. The end of the bracing on the rst beam was no longer attached to the web stiffener. A tapered global deformation of 50 mm lateral deection was recorded. This global displacement ceased at approximately 8 m either side of the impact point.

3.2. Beam 5 At approximately 3.5 m from the splice plate, the west side of the bottom ange was bent upwards by 20 mm. This deformation occurred over an 800 mm lengththe web adjacent to the damage was found to be still vertical. The bottom ange was found to be horizontal. There was no visible damage to the bracing between the fth and sixth beams. Permanent formwork used during construction prevented inspection of the concrete deck soft. There were no visible defects in the formwork or signs of distress. Damage to the beams in between comprised of supercial paint scraping only. The minimum headroom of the structure was maintained at 5.4 m.

3.1. Beam 1 At 8.0 m from the face of the north pier, the outer (west) half of the bottom ange was bent upwards by 70 mm. This deformation occurred over an 800 mm length. The web adjacent to the damage was found to be out of verticality by 30 mm over a

Fig. 2. Location of vehicle collision (dimensions in mm)

Bridge Engineering 159 Issue BE1

Heat-straightening repairs to a steel road bridge

Clubley et al.

37

arrangement. The frame was supported on elastic springs modelling the thrust and retardation of the soil strata. A transition between cracked and uncracked section properties occurred at the main span splices, approximately 5.2 m after the leaf pier support. The analysis was linear elastic. Stresses in the anges and web plate were calculated using staged composite construction. The factored tensile design strength for Grade S355 steel plates subjected to heat straightening was reduced by 50% to 161 N/mm2, including the partial factor for material properties, gm, in accordance with Federal Highway Administration document: FHWA-IF-99-004 1998.2 Fig. 2 illustrates the bending moment and shear force prole for reference. For dead and superimposed dead loading the analysis found that stresses in both the damaged rst and fth main beams did not currently exceed 70 N/mm2, a satisfactory value less than the factored tensile design strength of 161 N/mm2. Results were output between a location 1 m either side of the impact point. This 2 m region encapsulated the expected area of heat straightening. Loading on the beam comprised only dead and superimposed dead loads, as before. The structural integrity was checked for each stage of repair. This included the addition of new cruciform stiffening and nally, removal of the damaged web section. The modied steel section with web cut-out was checked in accordance with BS 5400 Part 3: 20005 for yield and buckling. However, this guidance does not directly incorporate an allowance for deformed or damaged sections when checking these criteria. A plate panel check for an undamaged web, using BS 5400 Part 3: 20005 produced a structural adequacy of 2.6 and 4.8 for the yield and buckling criteria, respectively.

Fig. 3. Damage to the main beams: (a) beam 1, west elevation; (b) beam 5, view towards south abutment

4. ANALYSIS AND MODELLING OF THE STRUCTURE A heat-straightening repair of the damaged plate girders required the application of selective heating patterns. These comprised vee heats for global deformation and line heats to correct local distortion in the bottom ange. Passive restraint by using hydraulic jacks was proposed in order to improve the straightening during cooling. The heat-straightening process was to be applied on the bottom anges of the rst and fth beams, and to a lesser extent, the web of the rst beam. In conjunction with the design of the main heat-straightening process it was necessary to assess the bridge in its temporary condition during the additional repairs. These repairs fell into two categories. First, it was necessary to investigate a possible 50% reduction in strength due to the heat-straightening process and second, supporting calculations were required to conrm that repairs could be conducted subject to dead and superimposed dead loading without temporary supports to the damaged beams. These repairs included the removal of web stiffeners, lateral bracing and a section of buckled web to be cut out. The maximum stresses in the bottom ange and web were checked in accordance with an expected 50% reduction in the yield strength of the steel beam when heated to a maximum of 6008C. Trafc management over the bridge was required to prevent live loads from acting on each beam during the repairs. This dictated the position of trafc ow so that all vehicular loads were moved to the opposite side of the deck.

4.2. Finite-element analysis A nite-element model of the damaged beam was constructed to conrm the results derived using the frame analysis, particularly the effects of localised damage on yield and buckling. Using volumetric meshing the stress conditions in the steel were examined in detail. In accordance with the portal frame analysis, the model represented the rst beam as that was the most severely damaged. This was subjected to identical dead and superimposed dead loads. The entire composite beam over the full length was modelled with restraints representing the bracing. Fig. 4 shows the nite-element model. To improve the numerical accuracy of the solution in the region of the heat straightening, further renement of the mesh was

4.1. Frame analysis The temporary condition dened the effects on the structure during the initial repair process and in preparation for the heat-straightening works. An analysis of the temporary condition was required to investigate the following. (a) Flexural stresses in the anges incorporating a potential temporary reduction in yield strength. (b) Combined bending and shear in the web plate, including the web cut-out. (c) Removal of vertical web stiffeners. (d ) Yield and buckling of the web panel. The bridge was modelled using the software Lusas Bridge Plus. A portal frame was constructed to represent the integral 38 Bridge Engineering 159 Issue BE1

Fig. 4. Construction of the nite-element model

Heat-straightening repairs to a steel road bridge

Clubley et al.

Impact damage

(a)

(b)

Fig. 5. Local stress analysis: (a) in-service exural stresses, (b) shear stresses with web cut-out incorporated. The web cut-out was conservatively approximated without a smooth corner radius. As a result, a small stress raiser is shown at the corners. The analysis type was again linear elastic. Figure 5(a) illustrates the exural stresses in the rst damaged beam subject to identical loading and shows the point of contraexure using a white colour. The nite-element model exhibited better load distribution with a maximum bottom ange stress of 50 N/mm2. Introduction of a 500 mm 500 mm web cut-out and cruciform stiffening produced stresses approximately 30 to 40 N/mm2 higher. Fig. 5(a) conrmed the fortunate location of the lorry impact near the point of contraexure. Figure 5(b) visually illustrates the concentrated shear stress in the web panel with the damaged steel removed. The nite-element model was modied to approximate the localised deformation recorded during the detailed inspections. Both the hand calculations and nite-element analysis conrmed a satisfactory web plate buckling factor of 0.21. The nite-element analysis was further extended to examine the same beam given a localised failure of the bottom ange due to a hypothetical gross mis-heating. During the heat-straightening process the applied temperature is restricted to below 6008C. Should the maximum permissible temperature be exceeded, the material properties of the steel will become permanently altered. This would potentially have serious consequences on both the immediate and future in-service performance, particularly fatigue. A section of the bottom ange was removed from the nite-element model at the location of heat straightening. The analysis conservatively showed the stresses in the web and anges did not exceed 130 N/mm2, still below the reduced factored tensile design strength. 5. DESIGN OF THE HEAT STRAIGHTENING Design of the heat straightening was based upon advice from experienced contractor Faireld Mabey and information gathered from desk studies. The structure was inspected in detail using access equipment and Bridge Engineering 159 Issue BE1 trafc management in December 2002. This report included magnetic particle inspection (MPI) testing to all impacted areas plus MPI and hardness tests to all yielded steel. The decision whether to use the method of heat straightening was based upon a damage strain ratio calculation. Federal Highway Administration document FHWA-IF-99-004 19982 recommends heat straightening can be carried out on North American steel products if the damage strain ratio is less than 100. As the manufacturing process of steel in the UK differs from that used in North America, the Highways Agency has currently adopted a maximum strain ratio of 50. The strain ratio is calculated using equations 3.1, 3.2 and 3.9 in Federal Highway Administration document FHWA-IF-99-004 1998.2 For brevity, the damage strain ratio calculation is summarised in equation (1).

Damage strain ratio m

Eymax Rf y

where E is the modulus of elasticity of steel; ymax is the distance from the centroid to the extreme bre of the element; R is the radius of curvature; and fy is the yield stress. The strain ratio was calculated for local and global damage considering both the rst and fth beams. A damage strain ratio not exceeding 30 was determined based upon the detailed survey measurements. This conrmed an acceptable assessment status for all the proposed heat-straightening repairs. A summary is shown in Table 1. A series of passive jack restraints were designed for use during the heat-straightening process. The careful placement of additional jacking forces can substantially improve the recovery during the cooling phase, therefore reducing the Beam 1: global damage Beam 1: local damage (plan view) 30.06 Acceptable Beam 1: local damage (elevation view) 25.07 Acceptable Beam 5: local damage 3.85 Acceptable

Strain ratio, m Assessment status

5.56 Acceptable

Table 1. Damage strain ratios Heat-straightening repairs to a steel road bridge Clubley et al. 39

number of heating cycles. A different arrangement was required for local and global straightening. Fig. 6 shows the set of inclined jacks restraining global movement while a single vertical jack assists local ange straightening. It was very important that none of the jacks was over-pressurised causing cold mechanical straightening of the steel. A strict monitoring programme was designed to prevent any damage occurring in this manner. The permissible jack restraint forces were calculated in accordance with FHWA-IF-99-004 1998.2 To prevent mechanical straightening, they were required to satisfy two key criteria. (a) First two heating cycles: loads should not produce bending moments greater than 16% of the plastic moment capacity of the member. (b) Subsequent heating cycles: loads should not produce bending moments greater than 33% of the plastic moment capacity of the member. Based upon the plastic moment capacity of the bottom ange, the jacking loads at 16 and 33% were 33 and 67 kN, respectively. 5.1. Heating patterns There are four main damage categories that can be repaired using heat straightening. (a) (b) (c) (d ) Category S: bending about the strong or major axis. Category W: bending about the weak or minor axis. Category T: torsion or twisting about the longitudinal axis. Category L: localised ange or web buckling, web crippling, small bends or crimps in the plate.

the open mouth of the vee causing the section to move in the direction of the vee. If the initial expansion is restrained, the overall movement is increased. Importantly, the welding torch passes across the vee shape in a snake S shape on both sides of the plate. With care, this technique helps prevent an undesirable concentrated heating effect. Line heats are a heating pattern used to repair Category W bending about the minor axis. This method of straightening is conducted using a straight transition of the welding torch between two points. Line heating can in some circumstances require an external jacking restraint to accelerate the straightening. Successful heat straightening is largely dependent upon operator skill and for line heats the speed of the torch over the metal is crucial to success. Figure 6 shows the pattern of heating used to correct both local and global damage of the rst beam. A combination of vee heats and line heats together with the raking restraints guided the global correction of the bottom ange. A vertical restraint and concentrated vee heat on both sides of the ange was used to straighten the localised damage.

6. SITE OPERATIONS All site operations were conducted at night during the closure and temporary diversion of the eastbound A27 carriageway. Work commenced on 17 November 2003 and by 29 November 2003 the site had been cleared and all aspects of the project had been completed with the exception of the application of a full protective coating system to the steel. Following the removal of the buckled bracing and web stiffeners, a series of trial heat cycles were carried out at ground level on sections of steel plate. These were of similar thickness and grade to those occurring in the bridge where heat straightening was required. The trial sections were heated, using vee heat patterns, until the colour of the steel below the ame was silver, with a brown and blue surround. An infrared digital pyrometer was used to conrm that temperatures in the range 550 to 6208C were attained. All operatives working on the bridge carried out the trial. One trial section was marked up such that tensile and Charpy impact tests could be carried out on both heated and unheated steel. The results of these tests conrmed that no signicant

Heat straightening should only be applied in the vicinity of a yield zone. A yield zone is an area in which inelastic deformation has occurred. Any permanent bulges or thickening found in the heated zone after cooling is called upsetting. The different heating patterns available for selection were: vee heats, line heats, spot heats, strip heats and edge heats. Repair of the local and global damage to the beams utilised a careful combination of line heats and vee heats, applied to both sides of the bottom ange. Vee heats are the most fundamental heating pattern used to straighten Category S bending about the major axis. Direct heating causes an expansion which increases the deection but cooling causes a subsequent larger contraction correcting the original damage. The largest contraction occurs at

Fig. 6. Repair of damage to beam 1: (a) passive jacking restraints to correct global damage (alternate vee heat pattern shown); (b) jacking restraint to correct local damage (concentrated vee heat pattern shown); (c) local restraint and web cut-out; (d) cruciform repair stiffening 40 Bridge Engineering 159 Issue BE1 Heat-straightening repairs to a steel road bridge Clubley et al.

changes in tensile strength or ductility occurred during the trial heat cycle. Global heat straightening of beam 1 began after the completion of the trial heat cycles. Blast cleaning of the steel was carried out and the lateral restraints were jacked to the design loads before the heating started. Once a series of clearly marked vee heat patterns had been marked on the bottom ange the rst heat cycle was carefully applied. The steel was subsequently allowed to cool to below 1208C before beginning the second cycle. Temperatures were monitored by observing colour and by using infrared digital pyrometers. After the second heat cycle, it was ascertained that the maximum horizontal deection had reduced from 52 to 31 mm. Three more heat cycles were applied, reducing the maximum horizontal deection further to 21 mm. This was considered within tolerance and it was decided to carry out no further global straightening. In contrast, a series of nine heat cycles using line patterns and vee heats were required to straighten the local damage in the bottom ange to within an acceptable tolerance. Restraining jacks were utilised between the top and bottom anges to assist the corrective movement during the cooling phase. Following the global and local straightening of beam 1, work began to rectify the buckled web plate. This involved the removal and reinstatement of the damaged section using ame cutting followed by manual metal arc welding. Prior to cutting out the deformed web, a cruciform arrangement of four web stiffeners was welded in position to restrain the adjacent web areas in the temporary condition (see Fig. 6). After repair of the web, some cruciform stiffeners were removed to allow the installation of the new vertical web stiffener. Accordingly, the replacement K bracing system was then attached to the vertical web stiffener by HSFG Part 1 bolts. Fig. 7 shows the nal straightened prole of the rst beam. The heat straightening was completed by the repair of beam 5. The distortion caused by impact damage was straightened using passive restraints between the top and bottom anges, and a series of four line heating cycles. Overall vertical distortion was reduced from 22 to 8 mm. This marginally exceeded the target value of 6 mm but, after consideration of the likelihood of further heating improving the distortion by a nal 2 mm, it was decided to accept the correction value.

Fig. 7. Repaired bottom ange following heat straightening

been applied. Using comparisons with BS 970,6 this would indicate a reduction in tensile strength at ultimate limit state from 550 to 400 N/mm2. The ultimate tensile strength (UTS) requirement to BS EN 100257 for grade S355 steel of this thickness is 490 N/mm2. It should be noted that the application of one heat cycle to the trial sections did not cause the UTS to be reduced when tested by destructive methods, producing a value of approximately 580 N/mm2. Accordingly, the estimated UTS using hardness values was considered to form an indicative guide. In view of the apparent reduction in hardness readings resulting from the application of multiple heat cycles, it was recommended that for future similar projects, the number of cycles applied to trial panels is increased to six. Destructive testing of the trial sections prior to starting work would thereby be more representative of the heat straightening. After consideration of the location of the repairs, which was close to the point of contraexure, a reduction in UTS to 400 N/mm2 would not constitute a theoretically overloaded section of girder. The maximum factored tensile stresses resulting from 30 units HB and associated HA loading at the locations where heat cycles were applied did not exceed 90 N/mm2. If the factored tensile design strength for grade S355 steel is reduced from its normal value of 307 N/mm2 in proportion to the apparent decrease in UTS, a maximum stress of 256 N/mm2 is obtained, which exceeds the applied stresses by a considerable amount.

7. MATERIAL TESTING Magnetic particle investigation testing was carried out on all areas of steel where heat cycles were applied, prior to and after certain stages of the work. A nal MPI test was carried out on completion of the heat treatment. No defects were recorded. All new llet welds were tested by MPI and all new butt welds were tested by MPI and ultrasonic testing. Again, no defects were recorded. Hardness testing was carried out on the distorted bottom ange areas prior to the heat straightening and after certain heat cycles for both beams. It was noted that, following the heat straightening, the hardness test results (Vickers) reduced from approximately 165 to 125 HV where the maximum heat had Bridge Engineering 159 Issue BE1

8. SUMMARY Heat-straightening repairs to structural steelwork on Brockhampton Road New Bridge were successfully completed, pending new protective coatings, in ten days. Impact damage to the beams was repaired within acceptable tolerances and the straightened steel was subjected to hardness and MPI testing. The implementation of the repair works reinstated the affected members to their original designed strength capacities. This case study illustrates the future potential of the heat-straightening method for structural steelwork repairs in the UK. The mitigation for the scheme demonstrated an added value of approximately 360 000. Repairs to Brockhampton Road Clubley et al. 41

Heat-straightening repairs to a steel road bridge

New Bridge were completed without undue disruption to the travelling public or local residents. 3. 9. ACKNOWLEDGEMENTS The assessment and analysis of Brockhampton Road New Bridge was conducted by Mott MacDonald on behalf of the Highways Agency Area 3 commission. Gratitude is extended to the Highways Agency for permission to publish this paper. 4.

5.

REFERENCES

1. BRITISH STANDARDS INSTITUTION . Code of Practice for the Design of Steel, Concrete and Composite BridgesSpecication for Materials and Workmanship. BSI, London, 1999, BS 5400: Part 6. 2. US DEPARTMENT OF TRANSPORTATION . Heat Straightening Repairs of Damaged Steel BridgesA Technical Guide and Manual of Practice. Federal Highway Administration, 6.

7.

Washington DC, USA, October 1998, Report No. FHWA-IF-99004. ROEDER C. W. Use of Thermal Stress for Seismic Damage Repair. Final report on NSF Grant CEE-82-05260, University of Washington, Seattle, 1985. AVENT R. R., MUKAI D. J., ROBINSON P. F. and BOUDREAUX R. J. Heat straightening damaged steel plate elements. Journal of Structural Engineering, ASCE, 2000, 126, No. 7, 747754. BRITISH STANDARDS INSTITUTION . Code of Practice for the Design of Steel, Concrete and Composite Bridges. BSI, London, 2000, BS 5400: Part 3. BRITISH STANDARDS INSTITUTION , General Inspection and Testing Procedures and Specic Requirements for Carbon, Carbon Manganese, Alloy and Stainless Steel. BSI, London, 1996, BS 970: Part 1. BRITISH STANDARDS INSTITUTION . Hot Rolled Products of Nonalloy Structural SteelsTechnical Delivery Conditions. BSI, London, 1993, BS EN 10025.

What do you think? To comment on this paper, please email up to 500 words to the editor at journals@ice.org.uk Proceedings journals rely entirely on contributions sent in by civil engineers and related professionals, academics and students. Papers should be 2000 5000 words long, with adequate illustrations and references. Please visit www.thomastelford.com/journals for author guidelines and further details.

42

Bridge Engineering 159 Issue BE1

Heat-straightening repairs to a steel road bridge

Clubley et al.

You might also like

- ETABS-Example-RC Building With Shear WallDocument58 pagesETABS-Example-RC Building With Shear WallJason Guzman85% (53)

- Cambodia Seismic LoadDocument1 pageCambodia Seismic LoaddantevariasNo ratings yet

- Box Girder 2Document8 pagesBox Girder 2steelageNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Case Studies of Some Concrete Structural FailuresDocument96 pagesCase Studies of Some Concrete Structural FailuresBandilung TzNo ratings yet

- The Design and Construction of Geo Geum Grand BridgeDocument12 pagesThe Design and Construction of Geo Geum Grand BridgeGonzalo NavarroNo ratings yet

- Concrete Construction Article PDF - Solving Reinforcement Congestion ProblemsDocument3 pagesConcrete Construction Article PDF - Solving Reinforcement Congestion ProblemsridminjNo ratings yet

- What Is Asphalt?Document4 pagesWhat Is Asphalt?Clar CabundocanNo ratings yet

- R 02 Danieli Corus - Blast Furnace Cast HouseDocument11 pagesR 02 Danieli Corus - Blast Furnace Cast HouseSaptarshi Sengupta100% (1)

- MyCESMM2 Class H - Piling Work - LDocument5 pagesMyCESMM2 Class H - Piling Work - LFairus Ithnin100% (1)

- CVS 415 Notes 2021Document20 pagesCVS 415 Notes 2021Imani LughoNo ratings yet

- Beam Bending FormulaDocument22 pagesBeam Bending FormulaBeniamine SarmientoNo ratings yet

- WSI Corrosion Control by Weld Overlay (Boilers)Document11 pagesWSI Corrosion Control by Weld Overlay (Boilers)Claudia Mms100% (1)

- Corbel ProgramDocument16 pagesCorbel ProgramShem BarroNo ratings yet

- Modern High Strength Niobium Microallyed Structural SteelsDocument26 pagesModern High Strength Niobium Microallyed Structural SteelsimetallurgyNo ratings yet

- ToS Case StudiesDocument44 pagesToS Case Studieskshipra gandhi100% (1)

- Aci Structural Journal 3 PDFDocument258 pagesAci Structural Journal 3 PDFgustavoNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Composite Steel-Concrete Bridges With Double Composite ActionDocument7 pagesComposite Steel-Concrete Bridges With Double Composite ActionOanh PhanNo ratings yet

- Formwork PDFDocument27 pagesFormwork PDFKandarp Rajyaguru100% (1)

- FRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughDocument14 pagesFRP Bridges 2012 Dawlish Footbridge Paper Kendall Smith GoughDavid Kendall100% (1)

- Concrete Slab RepairDocument6 pagesConcrete Slab Repairsrk2002No ratings yet

- Boq of BridgeDocument6 pagesBoq of BridgeMuzamil Rather100% (1)

- Case Studies of Some Concrete Structural Failures ICEDocument96 pagesCase Studies of Some Concrete Structural Failures ICEAhmed Nurul100% (1)

- Hydrogen Permeability and Integrity of Hydrogen Transfer PipelinesDocument52 pagesHydrogen Permeability and Integrity of Hydrogen Transfer PipelineslaercioudescNo ratings yet

- PHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor BoltDocument14 pagesPHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor Boltchristian210789No ratings yet

- The Rehabilitation of The Oldest Transit Tunnel in The United StatesDocument8 pagesThe Rehabilitation of The Oldest Transit Tunnel in The United StatesHarold TaylorNo ratings yet

- 2017 Bridge KimptonDocument11 pages2017 Bridge KimptonErick PowerNo ratings yet

- Singh PDFDocument10 pagesSingh PDFAhmad Dzikri FauzanNo ratings yet

- Bren 2006 159 1 35Document8 pagesBren 2006 159 1 35rohanZorbaNo ratings yet

- Steel As A Structural MaterialDocument10 pagesSteel As A Structural MaterialFaisal ShahzadNo ratings yet

- Prestressed Concrete Box WagonDocument15 pagesPrestressed Concrete Box WagonPratap Singh GangwarNo ratings yet

- Life Extension of Bridges, 2010Document6 pagesLife Extension of Bridges, 2010LvisionNo ratings yet

- Solidification of High Speed SteelsDocument4 pagesSolidification of High Speed SteelsAleš NagodeNo ratings yet

- Repair and Maintenance of Berth No 6, Port of PortlandDocument5 pagesRepair and Maintenance of Berth No 6, Port of Portlandmehdi_hoseineeNo ratings yet

- Missing: Arch Bridge DetailsDocument2 pagesMissing: Arch Bridge DetailsbmnNo ratings yet

- Optimising Electrochemical Remediation For Historic Steel Framed StructuresDocument10 pagesOptimising Electrochemical Remediation For Historic Steel Framed StructuresAliNo ratings yet

- Effect of Degree of Corrosion On The Properties of ReinforcingDocument8 pagesEffect of Degree of Corrosion On The Properties of ReinforcingabdulghafrNo ratings yet

- Seaview Wharf: A Concrete CP Case StudyDocument8 pagesSeaview Wharf: A Concrete CP Case StudyLy KhoaNo ratings yet

- CIGRE b2-305Document8 pagesCIGRE b2-305Jorge Pinto RochaNo ratings yet

- Jack Pesch Bicycle and Pedestrian Bridge (QLD)Document4 pagesJack Pesch Bicycle and Pedestrian Bridge (QLD)yyanan1118No ratings yet

- Design, Retrofit and Inspection of Railway Bridges in New ZealandDocument23 pagesDesign, Retrofit and Inspection of Railway Bridges in New Zealandatac101No ratings yet

- The Design of The Ruck-A-Chucky BridgeDocument7 pagesThe Design of The Ruck-A-Chucky BridgeAbdelaziz AbdelazizNo ratings yet

- Journal of Materials Processing TechnologyDocument8 pagesJournal of Materials Processing TechnologyHARIMETLYNo ratings yet

- Niobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener ApplicationsDocument7 pagesNiobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener Applicationsnvc_vishwanathanNo ratings yet

- Stonecutters Bridge, Hong Kong - Design An Construction of The Composite Upper Tower in Stainless SteelDocument8 pagesStonecutters Bridge, Hong Kong - Design An Construction of The Composite Upper Tower in Stainless SteelVictor GutiérrezNo ratings yet

- Post-Damage Repair of Prestressed Concrete GirdersDocument10 pagesPost-Damage Repair of Prestressed Concrete GirdersNikhil JainNo ratings yet

- Bulb Tee Girder PossibilitiesDocument4 pagesBulb Tee Girder PossibilitiesUpaliFernandoNo ratings yet

- New Welding Tubular Joint Used For JacketDocument6 pagesNew Welding Tubular Joint Used For JacketTien Hong DoNo ratings yet

- Design and Construction of Mizen Head Footbridge, NewzealandDocument12 pagesDesign and Construction of Mizen Head Footbridge, NewzealandivpraviNo ratings yet

- Civil & Structural Design ReportDocument10 pagesCivil & Structural Design ReportElilragiGanasanNo ratings yet

- The Design and Construction of Concrete-Filled Steel Tube Column FramesDocument12 pagesThe Design and Construction of Concrete-Filled Steel Tube Column FramesrohitNo ratings yet

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDocument27 pagesComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirNo ratings yet

- Tappen Zee Bridge ReplacementDocument19 pagesTappen Zee Bridge Replacementmkeit123No ratings yet

- Overview of Pearlitic Rail Steel: Accelerated Cooling, Quenching, Microstructure, and Mechanical PropertiesDocument26 pagesOverview of Pearlitic Rail Steel: Accelerated Cooling, Quenching, Microstructure, and Mechanical PropertiesTempest014No ratings yet

- 58 - 58.138s (Journal of Light Metal Welding)Document7 pages58 - 58.138s (Journal of Light Metal Welding)Amar DJEDIDNo ratings yet

- TriboroDocument2 pagesTriboroRavikirankv007No ratings yet

- Matecconf gcmm2017 03024 PDFDocument7 pagesMatecconf gcmm2017 03024 PDFreza39No ratings yet

- Welding The Vessel of The FRM-II ReactorDocument6 pagesWelding The Vessel of The FRM-II ReactorschummerNo ratings yet

- 86 Weld Ability of Corten SteelsDocument1 page86 Weld Ability of Corten SteelsNattawat LeelapeerapongNo ratings yet

- IJIRAE:: Construction Peculiarities of Bottom Outlet Tunnel, Its Air Vent and Energy Dissipater at Upper Gotvand DamDocument6 pagesIJIRAE:: Construction Peculiarities of Bottom Outlet Tunnel, Its Air Vent and Energy Dissipater at Upper Gotvand DamIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Cathodic Protection of A Multi-Storey Building, Method of Project Delivery and Long-Term MaintenanceDocument10 pagesCathodic Protection of A Multi-Storey Building, Method of Project Delivery and Long-Term MaintenanceCoevicNo ratings yet

- Cross-Sectional Optimization of CFS ChannelsDocument28 pagesCross-Sectional Optimization of CFS ChannelsAlaa AssiNo ratings yet

- Thames Gateway Water Treatment enDocument5 pagesThames Gateway Water Treatment enlucidbaseNo ratings yet

- 2011 Bridge SarkadyDocument17 pages2011 Bridge SarkadyTan Duy LeNo ratings yet

- Repair of Rails On-Site by WeldingDocument5 pagesRepair of Rails On-Site by Weldingnsprasad88No ratings yet

- Steel Seismic DesignDocument24 pagesSteel Seismic DesignsenthilcivilNo ratings yet

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Fdot Design Standards: 21100 1 Strip Seal Expansion JointDocument5 pagesFdot Design Standards: 21100 1 Strip Seal Expansion JointAnonymous Vs0jh0TvXCNo ratings yet

- Irc - Gov .In .SP .052.1999 PDFDocument76 pagesIrc - Gov .In .SP .052.1999 PDFkailashNo ratings yet

- Forensic Structural Engineering - Zeulenroda BridgeDocument8 pagesForensic Structural Engineering - Zeulenroda Bridgesantodejar469No ratings yet

- Moment Speed Form For PilecapsDocument22 pagesMoment Speed Form For PilecapsDarren WanNo ratings yet

- Reinforced Concrete ProjectDocument22 pagesReinforced Concrete ProjectRon Oliver LonzagaNo ratings yet

- Melamchi 13Document61 pagesMelamchi 13Sudip PudasainiNo ratings yet

- Last DayDocument58 pagesLast DayAnshu RajNo ratings yet

- Ractangular Over Head Water Tank (Complete)Document43 pagesRactangular Over Head Water Tank (Complete)Hailemariyam SewagegnNo ratings yet

- Prestressed Structural Concrete: New Developments and ApplicationsDocument17 pagesPrestressed Structural Concrete: New Developments and Applicationspyay kanung kyawNo ratings yet

- Tile Works: Calculations Toilet Floor To Be EstimatedDocument8 pagesTile Works: Calculations Toilet Floor To Be Estimatedcarlo jay collamatNo ratings yet

- Diseño Y Chequeo Muros Pantalla de Concreto Bloque 2: Table: Shear Wall Pier Design Summary - ACI 318-14, Part 1 of 5Document2 pagesDiseño Y Chequeo Muros Pantalla de Concreto Bloque 2: Table: Shear Wall Pier Design Summary - ACI 318-14, Part 1 of 5Uriel Vélez OrejuelaNo ratings yet

- Exposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementDocument8 pagesExposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementIJIRSTNo ratings yet

- A Proposed Three Storey Building For Algorithm Computer ServicesDocument32 pagesA Proposed Three Storey Building For Algorithm Computer ServicesjohnkensagaNo ratings yet

- CB Disc Spring CatalogueDocument28 pagesCB Disc Spring Cataloguekjagu87No ratings yet

- Tennis Court - CentComDocument4 pagesTennis Court - CentComEppNo ratings yet

- Unit-IV. Design of Deep FoundationDocument91 pagesUnit-IV. Design of Deep FoundationRwagatare civilcontractorsNo ratings yet

- High-Rise Buildings Raffles City in Hangzhou ChinaDocument16 pagesHigh-Rise Buildings Raffles City in Hangzhou ChinaIendP 20No ratings yet

- Ce6506-Construction Techniques and Practice: Prepared by Er.N.NAGARAJANM.E.,M.B.A.Document38 pagesCe6506-Construction Techniques and Practice: Prepared by Er.N.NAGARAJANM.E.,M.B.A.Nagarajan NarayanasamyNo ratings yet

- CIV 4235 ExamDocument9 pagesCIV 4235 Exammalumius100% (2)

- Modern Soil Stabilization TechniquesDocument25 pagesModern Soil Stabilization TechniquesSagar Jha100% (3)