Professional Documents

Culture Documents

22 - 07 - 00 - Plumbing Insulation PDF

Uploaded by

Agung Pramu AjiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

22 - 07 - 00 - Plumbing Insulation PDF

Uploaded by

Agung Pramu AjiCopyright:

Available Formats

Guide Specification

SECTION 22 07 00-PLUMBING INSULATION PART 1 - GENERAL 1.1 SUMMARY A. Section Includes: 1. 2. 1.2 Plumbing piping insulation, jackets and accessories. Plumbing equipment insulation, jackets and accessories.

REFERENCES A. Comply with appropriate standards 1. 2. 3. 4. 5. 6. ASTM International: ASTM California Plumbing Code: CPC Los Angeles Plumbing Code: LAPC Los Angeles Department of Building and Safety: LADBS Americans with Disabilities Act: ADA City of Los Angeles Disabled Access: DA a. ASTM A240/A240M - Standard Specification for Chromium and ChromiumNickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications. ASTM A666 - Standard Specification for Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Bar. ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate. ASTM C195 - Standard Specification for Mineral Fiber Thermal Insulating Cement. ASTM C449/C449M - Standard Specification for Mineral Fiber HydraulicSetting Thermal Insulating and Finishing Cement. ASTM C450 - Standard Practice for Fabrication of Thermal Insulating Fitting Covers for NPS Piping, and Vessel Lagging. ASTM C533 - Standard Specification for Calcium Silicate Block and Pipe Thermal Insulation. ASTM C534 - Standard Specification for Preformed Flexible Elastomeric Cellular Thermal Insulation in Sheet and Tubular Form. ASTM C547 - Standard Specification for Mineral Fiber Pipe Insulation. ASTM C553 - Standard Specification for Mineral Fiber Blanket Thermal Insulation for Commercial and Industrial Applications. ASTM C578 - Standard Specification, Cellular Polystyrene Thermal Insulation. ASTM C585 - Standard Practice for Inner and Outer Diameters of Rigid Thermal Insulation for Nominal Sizes of Pipe and Tubing (NPS System). ASTM C591 - Standard Specification for Unfaced Preformed Rigid Cellular Polyisocyanurate Thermal Insulation.

b. c. d. e. f. g. h. i. j. k. l. m.

PLUMBING INSULATION 22 07 00 - 1

Plumbing Systems

Guide Specification

n. o. p. q. r. s. t. u. v. 1.3 SUBMITTALS

ASTM C612 - Standard Specification for Mineral Fiber Block and Board Thermal Insulation. ASTM C795 - Standard Specification for Thermal Insulation for Use in Contact with Austenitic Stainless Steel. ASTM C921 - Standard Practice for Determining the Properties of Jacketing Materials for Thermal Insulation. ASTM C1136 - Standard Specification for Flexible, Low Permeance Vapor Retarders for Thermal Insulation. ASTM D1785 - Standard Specification for Rigid Poly (Vinyl Chloride) (PVC) Compounds and Chlorinated Poly (Vinyl Chloride) (CPVC) Compounds. ASTM E84 - Standard Test Method for Surface Burning Characteristics of Building Materials. ASTM E96/E96M - Standard Test Methods for Water Vapor Transmission of Materials. ASTM E84. ASTM E223.

A. Product Data: Submit product description, thermal characteristics and list of materials and thickness and jackets for each service, and location. B. C. Manufacturer's Installation Instructions: Submit manufacturers published literature indicating proper installation procedures. Manufacturer's Certificate: Certify products meet or exceed specified requirements.

D. LEED Submittal: 1. Product data for cedit EQ4.1: For adhesives and sealants, including printed statement of VOC content.

1.4

QUALITY ASSURANCE A. Installer Qualifications: Skilled mechanics who have successfully completed an apprenticeship program or another craft training program certified by the Department of Labor, Bureau of Apprenticeship and Training. B. Fire-Test-Response Characteristics: Insulation and related materials shall have fire-testresponse characteristics indicated, as determined by testing identical products per ASTM E 84, by a testing and inspecting agency acceptable to authorities having jurisdiction. Factory label insulation and jacket materials and adhesive, mastic, tapes, and cement material containers, with appropriate markings of applicable testing and inspecting agency. 1. 2. Insulation Installed Indoors: Flame-spread index of 25 or less, and smoke-developed index of 50 or less. Insulation Installed Outdoors: Flame-spread index of 75 or less, and smoke-developed index of 150 or less.

PLUMBING INSULATION 22 07 00 - 2

Plumbing Systems

Guide Specification

C.

Mockups: Before installing insulation, build mockups for each type of insulation and finish listed below to demonstrate quality of insulation application and finishes. Build mockups in the location indicated or, if not indicated, as directed by LAWA. Use materials indicated for the completed Work. 1. Piping Mockups: a. b. c. d. e. f. g. h. i. 2. 3. 4. 5. 6. One 10-foot section of NPS 2 straight pipe. One each of a 90-degree threaded, welded, and flanged elbow. One each of a threaded, welded, and flanged tee fitting. One NPS 2 or smaller valve, and one NPS 2-1/2 or larger valve. Four support hangers including hanger shield and insert. One threaded strainer and one flanged strainer with removable portion of insulation. One threaded reducer and one welded reducer. One pressure temperature tap. One mechanical coupling.

7. 8. 1.5

Equipment Mockups: One tank or vessel. For each mockup, fabricate cutaway sections to allow observation of application details for insulation materials, adhesives, mastics, attachments, and jackets. Notify LAWA seven days in advance of dates and times when mockups will be constructed. Obtain LAWA's approval of mockups before starting insulation application. Approval of mockups does not constitute approval of deviations from the Contract Documents contained in mockups unless LAWA specifically approves such deviations in writing. Maintain mockups during construction in an undisturbed condition as a standard for judging the completed Work. Demolish and remove mockups when directed.

WARRANTY A. Furnish one-year minimum. B. Furnish five year manufacturer warranty for man made fiber.

PART 2 - PRODUCTS 2.1 MANUFACTURER A. Manufacturers for Glass Fiber and Mineral Fiber Insulation Products: 1. 2. 3. CertainTeed. Johns Manville. Owens-Corning.

PLUMBING INSULATION 22 07 00 - 3

Plumbing Systems

Guide Specification

2.2

PIPE INSULATION A. TYPE P-1: ASTM C547, molded glass fiber pipe insulation. Conform to ASTM C795 for application on Austenitic stainless steel. 1. 2. 3. 4. B. Thermal Conductivity: 0.23 at 75 degrees F. Operating Temperature Range: 0 to 850 degrees F. Vapor Barrier Jacket: ASTM C1136, Type I, factory applied reinforced foil kraft with self-sealing adhesive joints. Jacket Temperature Limit: minus 20 to 150 degrees F.

TYPE P-2: ASTM C547, molded glass fiber pipe insulation. Conform to ASTM C795 for application on Austenitic stainless steel. 1. 2. Thermal Conductivity: 0.23 at 75 degrees F. Operating Temperature Range: 0 to 850 degrees F.

C.

TYPE P-3: ASTM C612; semi-rigid, fibrous glass board noncombustible, end grain adhered to jacket. Conform to ASTM C795 for application on Austenitic stainless steel. 1. 2. 3. 4. Thermal Conductivity: 0.27 at 75 degrees F. Operating Temperature Range: 0 to 650 degrees F. Vapor Barrier Jacket: ASTM C1136, Type II, factory applied reinforced foil kraft with self-sealing adhesive joints. Jacket Temperature Limit: minus 20 to 150 degrees F.

D. TYPE P-4: ASTM C612; semi-rigid, fibrous glass board noncombustible. Conform to ASTM C795 for application on Austenitic stainless steel. 1. E. Thermal Conductivity: 0.27 at 75 degrees F.

TYPE P-5: ASTM C534, Type I, flexible, closed cell elastomeric insulation, tubular. 1. 2. Thermal Conductivity: 0.27 at 75 degrees F. Operating Temperature Range: Range: Minus 70 to 180 degrees F.

F.

TYPE P-6: ASTM C534, Type I, flexible, closed cell elastomeric insulation, tubular. 1. 2. 3. Thermal Conductivity: 0.30 at 75 degrees F. Maximum Service Temperature: 300 degrees F. Operating Temperature Range: Range: Minus 58 to 300 degrees F.

G. TYPE P-7: ASTM C534, Type I, flexible, nonhalogen, closed cell elastomeric insulation, tubular. 1. 2. 3. Thermal Conductivity: 0.27 at 75 degrees F. Maximum Service Temperature: 250 degrees F. Operating Temperature Range: Range: Minus 58 to 250 degrees F.

PLUMBING INSULATION 22 07 00 - 4

Plumbing Systems

Guide Specification

H. TYPE P-8: ASTM C547, Type I or II, mineral fiber preformed pipe insulation, noncombustible. 1. 2. 3. I. Thermal Conductivity: 0.23 at 75 degrees F. Maximum Service Temperature: 1200 degrees F. Canvas Jacket: UL listed, 6 oz/sq yd, plain weave cotton fabric treated with fire retardant lagging adhesive.

TYPE P-9: ASTM C591, Type IV, polyisocyanurate foam insulation, formed into shapes for use as pipe insulation. 1. 2. 3. 4. Density: 4.0 pounds per cubic foot. Thermal Conductivity: 180 day aged value of 0.19 at 75 degrees F. Operating Temperature Range: Range: Minus 297 to 300 degrees F. Vapor Barrier Jacket: ASTM C1136, Type I, factory applied film of 4 mils thickness and water vapor permeance of 0.02 perms.

J.

TYPE P-10: ASTM C578, Type XIII, extruded polystyrene insulation, formed into shapes for use as pipe insulation. 1. 2. 3. Thermal Conductivity: 180 day aged value of 0.259 at 75 degrees F. Operating Temperature Range: Range: Minus 297 to 165 degrees F. Vapor Barrier Jacket: ASTM C1136, Type I, factory applied film of 4 mils thickness and water vapor permeance of 0.02 perms.

K. TYPE P-11: ASTM C533; Type I, hydrous calcium silicate pipe insulation, rigid molded white; asbestos free. 1. 2. 2.3 Thermal Conductivity: 0.45 at 200 degrees F. Operating Temperature Range: 140 to 1200 degrees F.

PIPE INSULATION JACKETS A. Vapor Retarder Jacket: 1. 2. B. ASTM C921, white Kraft paper with glass fiber yarn, bonded to aluminized film. Water Vapor Permeance: ASTM E96/E96M; 0.02 perms.

PVC Plastic Pipe Jacket: 1. 2. 3. Product Description: ASTM D1785, one piece molded type fitting covers and sheet material, off-white color. Thickness: 30 mil. Connections: Brush on welding adhesive with VOC content of 50 g/l according to CFR 59, Subpart D (EPA Method 24).

C.

ABS Plastic Pipe Jacket: 1. Jacket: One piece molded type fitting covers and sheet material, off-white color.

PLUMBING INSULATION 22 07 00 - 5

Plumbing Systems

Guide Specification

2. 3. 4. 5. 6. 7.

Minimum service temperature: -40 degrees F. Maximum service temperature of 180 degrees F. Water Vapor Permeance: ASTM E96/E96M; 0.02 perms. Thickness: 30 mil. Connections: Brush on welding adhesive. Connections: Brush on welding adhesive with VOC content of 50 g/l according to CFR 59, Subpart D (EPA Method 24).

D. Aluminum Pipe Jacket: 1. 2. 3. 4. 5. 6. E. ASTM B209. Thickness: 0.020 inch thick sheet. Finish: Smooth Embossed. Joining: Longitudinal slip joints and 2 inch laps. Fittings: 0.2 inch thick die shaped fitting covers with factory attached protective liner. Metal Jacket Bands: 1/2 inch wide; 0.015 inch thick aluminum. 0.020 inch thick stainless steel.

Stainless Steel Pipe Jacket: 1. 2. 3. 4. ASTM A240/A240M OR ASTM 666 Type 304 stainless steel. Thickness: 0.016 inch thick. Finish: Smooth. Metal Jacket Bands: 1/2 inch wide; 0.020 inch thick stainless steel.

F.

Field Applied Glass Fiber Fabric Jacket System: 1. 2. Insulating Cement/Mastic: ASTM C195; hydraulic setting on mineral wool. Glass Fiber Fabric: a. b. 3. Cloth: Untreated; 9 oz/sq yd weight. Blanket: 1.0 lb/cu ft density.

Indoor Vapor Retarder Finish: a. b. Cloth: Untreated; 9 oz/sq yd weight. Vinyl emulsion type acrylic, compatible with insulation, white color.

2.4

PIPE INSULATION ACCESSORIES A. Vapor Retarder Lap Adhesive: Compatible with insulation. B. C. Covering Adhesive Mastic: Compatible with insulation. Piping 1-1/2 inches diameter and smaller: Galvanized steel insulation protection shield. MSS SP-69, Type 40. Length: Based on pipe size and insulation thickness.

D. Piping 2 inches diameter and larger: Wood insulation saddle, hard maple. Inserts length: not less than 6 inches long, matching thickness and contour of adjoining insulation. PLUMBING INSULATION 22 07 00 - 6

Plumbing Systems

Guide Specification

E. F.

Closed Cell Elastomeric Insulation Pipe Hanger: Polyurethane insert with aluminum single piece construction with self adhesive closure. Thickness to match pipe insulation. Tie Wire: 0.048 inch stainless steel with twisted ends on maximum 12 inch centers.

G. Mineral Fiber Hydraulic-Setting Thermal Insulating and Finishing Cement: ASTM C449/C449M. H. Insulating Cement: ASTM C195; hydraulic setting on mineral wool. I. 2.5 Adhesives: Compatible with insulation.

EQUIPMENT INSULATION A. TYPE E-1: ASTM C553; glass fiber, flexible or semi-rigid, noncombustible. 1. 2. 3. B. Thermal Conductivity: 0.24 at 75 degrees F. Operating Temperature Range: 0 to 450 degrees F. Density: 1.65 pound per cubic foot.

TYPE E-2: ASTM C612; glass fiber, rigid board, noncombustible with factory applied kraft reinforced aluminum foil jacket. 1. 2. 3. 4. Thermal Conductivity: 0.24 at 75 degrees F. Operating Temperature Range: 0 to 450 degrees F. Density: 3.0 pound per cubic foot. Jacket Temperature Limit: minus 20 to 150 degrees F.

C.

TYPE E-3: ASTM C612; semi-rigid, fibrous glass board noncombustible, end grain adhered to jacket. 1. 2. 3. 4. Thermal Conductivity: 0.27 at 75 degrees F. Operating Temperature Range: 0 to 650 degrees F. Vapor Barrier Jacket: ASTM C1136, Type II, factory applied reinforced foil kraft with self-sealing adhesive joints. Jacket Temperature Limit: minus 20 to 150 degrees F.

D. TYPE E-4: ASTM C612; semi-rigid, fibrous glass board noncombustible. 1. 2. E. Thermal Conductivity: 0.27 at 75 degrees F. Operating Temperature Range: 0 to 650 degrees F.

TYPE E-5: ASTM C612, man made mineral fiber, noncombustible, Classes 1-4. 1. 2. 3. Thermal Conductivity: 0.25 at 100 degrees F. Maximum Service Temperature: 1200 degrees F. Density: 4 pound per cubic foot.

PLUMBING INSULATION 22 07 00 - 7

Plumbing Systems

Guide Specification

2.6

EQUIPMENT INSULATION JACKETS A. PVC Plastic Equipment Jacket: 1. 2. 3. 4. 5. 6. B. Product Description: ASTM D1785, sheet material, off-white color. Minimum Service Temperature: -40 degrees F. Maximum Service Temperature: 150 degrees F. Water Vapor Permeance: ASTM E96/E96M; 0.02 perms. Thickness: 30 mil. Connections: Brush on welding adhesive with VOC content of 50 g/l according to CFR 59, Subpart D (EPA Method 24).

Aluminum Equipment Jacket: 1. 2. 3. 4. 5. 6. ASTM B209. Thickness: 0.020 inch thick sheet. Finish: Embossed. Joining: Longitudinal slip joints and 2 inch laps. Fittings: 0.02 inch thick die shaped fitting covers with factory attached protective liner. Metal Jacket Bands: 3/8 inch wide; 0.015 inch thick aluminum. 0.020 inch thick stainless steel.

C.

Canvas Equipment Jacket: UL listed, 6 oz/sq yd, plain weave cotton fabric with fire retardant lagging adhesive compatible with insulation.

D. Vapor Retarder Jacket: 1. 2. E. ASTM C921, white Kraft paper with glass fiber yarn, bonded to aluminized film. Water Vapor Permeance: ASTM E96/E96M; 0.02 perms.

Field Applied Glass Fiber Fabric Jacket System: 1. 2. Insulating Cement/Mastic: ASTM C195; hydraulic setting on mineral wool. Glass Fiber Fabric: a. b. 3. Cloth: Untreated; 9 oz/sq yd weight. Blanket: 1.0 lb/cu ft density.

Indoor Vapor Retarder Finish: a. b. Cloth: Untreated; 9 oz/sq yd weight. Vinyl emulsion type acrylic, compatible with insulation, black white color.

2.7

EQUIPMENT INSULATION ACCESSORIES A. Vapor Retarder Lap Adhesive: Compatible with insulation. B. C. Covering Adhesive Mastic: Compatible with insulation. Tie Wire: 0.048 inch stainless steel with twisted ends on maximum 12 inch centers.

Plumbing Systems

PLUMBING INSULATION 22 07 00 - 8

Guide Specification

D. Mineral Fiber Hydraulic-Setting Thermal Insulating and Finishing Cement: ASTM C449/C449M. E. 2.8 Adhesives: Compatible with insulation.

ADHESIVES A. Materials shall be compatible with insulation materials, jackets, and substrates and for bonding insulation to itself and to surfaces to be insulated, unless otherwise indicated. B. Calcium Silicate Adhesive: Fibrous, sodium-silicate-based adhesive with a service temperature range of 50 to 800 deg F. 1. Manufacturers: a. b. c. 2. C. Childers Products, Division of ITW; CP-97. Foster Products Corporation, H. B. Fuller Company; 81-27/81-93. Marathon Industries, Inc.; 290.

For indoor applications, use adhesive that has a VOC content of 80 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

Cellular-Glass, Phenolic, Polyisocyanurate, and Polystyrene Adhesive: Solvent-based resin adhesive, with a service temperature range of minus 75 to plus 300 deg F. 1. Products: Subject to compliance with requirements, provide one of the following available products that may be incorporated into the Work include, but are not limited to, the following: a. b. 2. Childers Products, Division of ITW; CP-96. Foster Products Corporation, H. B. Fuller Company; 81-33.

calculated according to 40 CFR 59, Subpart D (EPA Method 24).

D. Flexible Elastomeric and Polyolefin Adhesive: Comply with MIL-A-24179A, Type II, Class I. 1. Manufacturers: a. b. c. 2. E. Aeroflex USA Inc.; Aeroseal. Armacell LCC; 520 Adhesive. Foster Products Corporation, H. B. Fuller Company; 85-75.

For indoor applications, use adhesive that has a VOC content of 50 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

Mineral-Fiber Adhesive: Comply with MIL-A-3316C, Class 2, Grade A. 1. Manufacturers:

PLUMBING INSULATION 22 07 00 - 9

Plumbing Systems

Guide Specification

a. b. c. 2. F.

Childers Products, Division of ITW; CP-82. Foster Products Corporation, H. B. Fuller Company; 85-20. Marathon Industries, Inc.; 225.

For indoor applications, use adhesive that has a VOC content of 80 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

ASJ Adhesive, and FSK and PVDC Jacket Adhesive: Comply with MIL-A-3316C, Class 2, Grade A for bonding insulation jacket lap seams and joints. 1. Manufacturers: a. b. c. 2. Childers Products, Division of ITW; CP-82. Foster Products Corporation, H. B. Fuller Company; 85-20. Marathon Industries, Inc.; 225.

For indoor applications, use adhesive that has a VOC content of 50 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

G. PVC Jacket Adhesive: Compatible with PVC jacket. 1. Manufacturers: a. b. c. 2. Dow Chemical Company (The); 739, Dow Silicone. Johns-Manville; Zeston Perma-Weld, CEEL-TITE Solvent Welding Adhesive. Speedline Corporation; Speedline Vinyl Adhesive.

For indoor applications, use adhesive that has a VOC content of 50 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

2.9

MASTICS A. Materials shall be compatible with insulation materials, jackets, and substrates; comply with MIL-C-19565C, Type II. 1. For indoor applications, use mastics that have a VOC content that meets the requirement of the South Coast Air Quality Management District Rule #1168. VOC limits to be per amendment date 1/7/05.

B.

Vapor-Barrier Mastic: Water based; suitable for indoor and outdoor use on below ambient services. 1. Manufacturers: a. b. c. 2. Childers Products, Division of ITW; CP-35. Foster Products Corporation, H. B. Fuller Company; 30-90. Marathon Industries, Inc.; 590.

Water-Vapor Permeance: ASTM E 96, Procedure B, 0.013 perm at 43-mil dry film thickness.

Plumbing Systems

PLUMBING INSULATION 22 07 00 - 10

Guide Specification

3. 4. 5. C.

Service Temperature Range: Minus 20 to plus 180 deg F. Solids Content: ASTM D 1644, 59 percent by volume and 71 percent by weight. Color: White.

Vapor-Barrier Mastic: Solvent based; suitable for indoor use on below ambient services. 1. Manufacturers: a. b. c. 2. 3. 4. 5. Childers Products, Division of ITW; CP-30. Foster Products Corporation, H. B. Fuller Company; 30-35. Marathon Industries, Inc.; 501.

Water-Vapor Permeance: ASTM F 1249, 0.05 perm at 35-mil dry film thickness. Service Temperature Range: 0 to 180 deg F. Solids Content: ASTM D 1644, 44 percent by volume and 62 percent by weight. Color: White.

D. Vapor-Barrier Mastic: Solvent based; suitable for outdoor use on below ambient services. 1. Manufacturers: a. b. c. 2. 3. 4. 5. 6. Childers Products, Division of ITW; Encacel. Foster Products Corporation, H. B. Fuller Company; 60-95/60-96. Marathon Industries, Inc.; 570.

Water-Vapor Permeance: ASTM F 1249, 0.05 perm at 30-mil dry film thickness. Service Temperature Range: Minus 50 to plus 220 deg F. Solids Content: ASTM D 1644, 33 percent by volume and 46 percent by weight. Color: White. For outdoor aluminum finish, use 60-39 mastic.

2.10 SEALANTS A. Joint Sealants: 1. Joint Sealants for Cellular-Glass, Phenolic, and Polyisocyanurate Products Manufacturers: a. b. c. 2. Childers Products, Division of ITW; CP-76. Foster Products Corporation, H. B. Fuller Company; 30-45. Marathon Industries, Inc.; 405.

Joint Sealant for Polystyrene Products - Manufacturers: a. b. c. Childers Products, Division of ITW; CP-70. Foster Products Corporation, H. B. Fuller Company; 30-45/30-46. Marathon Industries, Inc.; 405.

3. 4.

Materials shall be compatible with insulation materials, jackets, and substrates. Permanently flexible, elastomeric sealant.

Plumbing Systems

PLUMBING INSULATION 22 07 00 - 11

Guide Specification

5. 6. 7. B.

Service Temperature Range: Minus 100 to plus 300 deg F. Color: White or gray. For indoor applications, use sealants that have a VOC content of 250 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

FSK and Metal Jacket Flashing Sealants: 1. Manufacturers: a. b. c. 2. 3. 4. 5. 6. Childers Products, Division of ITW; CP-76-8. Foster Products Corporation, H. B. Fuller Company; 95-44. Marathon Industries, Inc.; 405.

Materials shall be compatible with insulation materials, jackets, and substrates. Fire- and water-resistant, flexible, elastomeric sealant. Service Temperature Range: Minus 40 to plus 250 deg F. Color: Aluminum. For indoor applications, use sealants that have a VOC content of 250 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

C.

ASJ Flashing Sealants, and Vinyl, PVDC, and PVC Jacket Flashing Sealants: 1. Manufacturers: a. 2. 3. 4. 5. 6. Childers Products, Division of ITW; CP-76.

Materials shall be compatible with insulation materials, jackets, and substrates. Fire- and water-resistant, flexible, elastomeric sealant. Service Temperature Range: Minus 40 to plus 250 deg F. Color: White. For indoor applications, use sealants that have a VOC content of 250 g/L or less when calculated according to 40 CFR 59, Subpart D (EPA Method 24).

2.11 FIELD APPLIED FABRIC REINFORCING MASH A. Woven Glass-Fiber Fabric for Pipe Insulation: Approximately 2 oz./sq. yd. with a thread count of 10 strands by 10 strands/sq. inch for covering pipe and pipe fittings. 1. Manufacturers: a. B. Vimasco Corporation; Elastafab 894.

Woven Glass-Fiber Fabric for Equipment Insulation: Approximately 6 oz./sq. yd. with a thread count of 5 strands by 5 strands/sq. inch for covering equipment. 1. Manufacturers: a. Childers Products, Division of ITW; Chil-Glas No. 5.

PLUMBING INSULATION 22 07 00 - 12

Plumbing Systems

Guide Specification

C.

Woven Polyester Fabric: Approximately 1 oz./sq. yd. with a thread count of 10 strands by 10 strands/sq. inch, in a Leno weave, for equipment and pipe. 1. Manufacturers: a. b. Foster Products Corporation, H. B. Fuller Company; Mast-A-Fab. Vimasco Corporation; Elastafab 894.

2.12 FIELD-APPLIED CLOTHS A. Woven Glass-Fiber Fabric: Comply with MIL-C-20079H, Type I, plain weave, and presized a minimum of 8 oz./sq. yd.. 1. Manufacturers: a. Alpha Associates, Inc.; Alpha-Maritex 84215 and 84217/9485RW, Luben 59.

2.13 SECUREMENTS A. Bands: 1. Manufacturers: a. b. c. 2. 3. 4. 5. B. Childers Products; Bands. PABCO Metals Corporation; Bands. RPR Products, Inc.; Bands.

Stainless Steel: ASTM A 167 or ASTM A 240/A 240M, Type 304 or Type 316; 0.015 inch thick, 3/4 inch wide with closed seal. Aluminum: ASTM B 209, Alloy 3003, 3005, 3105, or 5005; Temper H-14, 0.020 inch thick, 3/4 inch wide with closed seal. Springs: Twin spring set constructed of stainless steel with ends flat and slotted to accept metal bands. Spring size determined by manufacturer for application. Copper clad annealed steel wire having a minimum 16 gauge thickness.

Insulation Pins and Hangers: 1. Capacitor-Discharge-Weld Pins: Copper- or zinc-coated steel pin, fully annealed for capacitor-discharge welding, 0.135-inch- diameter shank, length to suit depth of insulation indicated. a. Manufacturers: 1) 2) 3) AGM Industries, Inc.; CWP-1. GEMCO; CD. Midwest Fasteners, Inc.; CD.

PLUMBING INSULATION 22 07 00 - 13

Plumbing Systems

Guide Specification

2.

Cupped-Head, Capacitor-Discharge-Weld Pins: Copper- or zinc-coated steel pin, fully annealed for capacitor-discharge welding, 0.135-inch- diameter shank, length to suit depth of insulation indicated with integral 1-1/2-inch galvanized carbon-steel washer. a. Manufacturers: 1) 2) 3) AGM Industries, Inc.; CWP-1. GEMCO; Cupped Head Weld Pin. Midwest Fasteners, Inc.; Cupped Head.

3.

Insulation-Retaining Washers: Self-locking washers formed from 0.016-inch- thick, stainless-steel sheet, with beveled edge sized as required to hold insulation securely in place but not less than 1-1/2 inches in diameter. a. Manufacturers: 1) 2) 3) b. AGM Industries, Inc.; RC-150. GEMCO; R-150. Midwest Fasteners, Inc.; WA-150.

Protect ends with capped self-locking washers incorporating a spring steel insert to ensure permanent retention of cap in exposed locations.

4.

Nonmetal Insulation-Retaining Washers: Self-locking washers formed from 0.016-inchthick nylon sheet, with beveled edge sized as required to hold insulation securely in place but not less than 1-1/2 inches in diameter. a. Manufacturers: 1) 2) GEMCO. Midwest Fasteners, Inc.

C.

Staples: Outward-clinching insulation staples, nominal 3/4-inch- wide, stainless steel or Monel.

D. Wire: 0.080-inch nickel-copper alloy. 1. Manufacturers: a. b. c. C & F Wire. Childers Products. PABCO Metals Corporation.

2.14 CORNER ANGLES A. PVC Corner Angles: 30 mils thick, minimum 1 by 1 inch, PVC according to ASTM D 1784, Class 16354-C. White or color-coded to match adjacent surface. B. Aluminum Corner Angles: 0.040 inch thick, minimum 1 by 1 inch, aluminum according to ASTM B 209, Alloy 3003, 3005, 3105 or 5005; Temper H-14.

Plumbing Systems

PLUMBING INSULATION 22 07 00 - 14

Guide Specification

C.

Stainless-Steel Corner Angles: 0.024 inch thick, minimum 1 by 1 inch, stainless steel according to ASTM A 167 or ASTM A 240/A 240M, Type 304 or 316.

PART 3 - EXECUTION 3.1 INSTALLATION - PIPING SYSTEMS A. Piping Exposed to View in Finished Spaces: Locate insulation and cover seams in least visible locations. B. Continue insulation through penetrations of building assemblies or portions of assemblies having fire resistance rating of one hour or less. Provide intumescent firestopping when continuing insulation through assembly. Finish at supports, protrusions, and interruptions. For penetrations of assemblies with fire resistance rating greater than one hour. See all sections in Division. Piping Systems Conveying Fluids Below Ambient Temperature: 1. 2. Insulate entire system including fittings, valves, unions, flanges, strainers, flexible connections, pump bodies, and expansion joints. Furnish factory-applied or field-applied vapor retarder jackets. Secure factory-applied jackets with pressure sensitive adhesive self-sealing longitudinal laps and butt strips. Secure field-applied jackets with outward clinch expanding staples and seal staple penetrations with vapor retarder mastic. Insulate fittings, joints, and valves with molded insulation of like material and thickness as adjacent pipe. Finish with glass cloth and vapor retarder adhesive or PVC fitting covers.

C.

3.

D. Glass Fiber Board Insulation: 1. 2. 3. E. Apply insulation close to equipment by grooving, scoring, and beveling insulation. Fasten insulation to equipment with studs, pins, clips, adhesive, wires, or bands. Fill joints, cracks, seams, and depressions with bedding compound to form smooth surface. On cold equipment, use vapor retarder cement. Cover wire mesh or bands with cement to a thickness to remove surface irregularities.

Polyisocyanurate Foam Insulation Extruded Polystyrene Insulation: 1. 2. Wrap elbows and fitting with vapor retarder tape. Seal butt joints with vapor retarder tape.

F.

Hot Piping Systems 140 degrees F or less: 1. Furnish factory-applied or field-applied standard jackets. Secure with outward clinch expanding staples or pressure sensitive adhesive system on standard factory-applied jacket and butt strips or both. Insulate fittings, joints, and valves with insulation of like material and thickness as adjoining pipe. Finish with glass cloth and adhesive or PVC fitting covers.

2.

PLUMBING INSULATION 22 07 00 - 15

Plumbing Systems

Guide Specification

3.

Do not insulate unions and flanges at equipment, but bevel and seal ends of insulation at such locations.

G. Inserts and Shields: 1. 2. Piping 1-1/2 inches Diameter and Smaller: Install galvanized steel shield between pipe hanger and insulation. Piping 2 inches Diameter and Larger: Install insert between support shield and piping and under finish jacket. a. b. 3. Insert Configuration: Minimum 6 inches long, of thickness and contour matching adjoining insulation; may be factory fabricated. Insert Material: Compression resistant insulating material suitable for planned temperature range and service.

Piping Supported by Roller Type Pipe Hangers: Install galvanized steel shield between roller and inserts.

H. Insulation Terminating Points: 1. 2. I. Branch Piping 1 inch and Smaller: Terminate hot water piping at union upstream of the control valve. Condensate Piping: Insulate entire piping system and components to prevent condensation.

Closed Cell Elastomeric Insulation: 1. 2. 3. 4. 5. Push insulation on to piping. Miter joints at elbows. Seal seams and butt joints with manufacturers recommended adhesive. When application requires multiple layers, apply with joints staggered. Insulate fittings and valves with insulation of like material and thickness as adjacent pipe.

J.

Pipe Exposed in Mechanical Equipment Rooms or Finished Spaces (less than 10 feet above finished floor): Finish with canvas jacket sized for finish painting.

K. Piping Exterior to Building: Provide vapor retarder jacket. Insulate fittings, joints, and valves with insulation of like material and thickness as adjoining pipe, and finish with glass mesh reinforced vapor retarder cement. Cover with aluminum jacket with seams located at 3 or 9 oclock position on side of horizontal piping with overlap facing down to shed water or on bottom side of horizontal piping. L. Buried Piping: Insulate only where insulation manufacturer recommends insulation product may be installed in trench, tunnel or direct buried. Install factory fabricated assembly with inner all-purpose service jacket with self-sealing lap, and asphalt impregnated open mesh glass fabric, with 1 mil thick aluminum foil sandwiched between three layers of bituminous compound; outer surface faced with polyester film.

M. Heat Traced Piping Interior to Building: As recommended by Heat Trace System Manufacturer. PLUMBING INSULATION 22 07 00 - 16

Plumbing Systems

Guide Specification

N. Heat Traced Piping Exterior to Building: As recommended by Heat Trace System Manufacturer. O. Prepare pipe insulation for finish painting. 3.2 INSTALLATION - EQUIPMENT A. Factory Insulated Equipment: Do not insulate. B. C. Exposed Equipment: Locate insulation and cover seams in least visible locations. Fill joints, cracks, seams, and depressions with bedding compound to form smooth surface. On cold equipment, use vapor retarder cement.

D. Equipment Containing Fluids Below Ambient Temperature: 1. 2. 3. Insulate entire equipment surfaces. Apply insulation close to equipment by grooving, scoring, and beveling insulation. Fasten insulation to equipment with studs, pins, clips, adhesive, wires, or bands. Furnish factory-applied or field-applied vapor retarder jackets. Secure factory-applied jackets with pressure sensitive adhesive self-sealing longitudinal laps and butt strips. Secure field-applied jackets with outward clinch expanding staples and seal staple penetrations with vapor retarder mastic. Finish insulation at supports, protrusions, and interruptions.

4. E.

Equipment Containing Fluids 140 degrees F Or Less: 1. 2. 3. Do not insulate flanges and unions, but bevel and seal ends of insulation. Install insulation with factory-applied or field applied jackets, with or without vapor barrier. Finish with glass cloth and adhesive. Finish insulation at supports, protrusions, and interruptions.

F.

Equipment in Mechanical Equipment Rooms or Finished Spaces: Finish with canvas jacket sized for finish painting.

G. Equipment Located Exterior to Building: Install vapor barrier jacket or finish with glass mesh reinforced vapor barrier cement. Cover with aluminum jacket with seams located on bottom side of horizontal equipment. H. Cover insulation with aluminum jacket. I. J. Nameplates and ASME Stamps: Bevel and seal insulation around; do not cover with insulation. Equipment Requiring Access for Maintenance, Repair, or Cleaning: Install insulation for easy removal and replacement without damage.

K. Prepare equipment insulation for finish painting.

PLUMBING INSULATION 22 07 00 - 17

Plumbing Systems

Guide Specification

3.3

PENETRATIONS A. Insulation Installation at Roof Penetrations: Install insulation continuously through roof penetrations. 1. 2. Seal penetrations with flashing sealant. For applications requiring only indoor insulation, terminate insulation above roof surface and seal with joint sealant. For applications requiring indoor and outdoor insulation, install insulation for outdoor applications tightly joined to indoor insulation ends. Seal joint with joint sealant. Extend jacket of outdoor insulation outside roof flashing at least 2 inches below top of roof flashing. Seal jacket to roof flashing with flashing sealant.

3. 4. B. C.

Insulation Installation at Underground Exterior Wall Penetrations: Terminate insulation flush with sleeve seal. Seal terminations with flashing sealant. Insulation Installation at Aboveground Exterior Wall Penetrations: Install insulation continuously through wall penetrations. 1. 2. Seal penetrations with flashing sealant. For applications requiring only indoor insulation, terminate insulation inside wall surface and seal with joint sealant. For applications requiring indoor and outdoor insulation, install insulation for outdoor applications tightly joined to indoor insulation ends. Seal joint with joint sealant. Extend jacket of outdoor insulation outside wall flashing and overlap wall flashing at least 2 inches. Seal jacket to wall flashing with flashing sealant.

3. 4.

D. Insulation Installation at Interior Wall and Partition Penetrations (That Are Not Fire Rated): Install insulation continuously through walls and partitions. E. Insulation Installation at Fire-Rated Wall and Partition Penetrations: Install insulation continuously through penetrations of fire-rated walls and partitions. 1. F. Comply with requirements for firestopping and fire-resistive joint sealers.

Insulation Installation at Floor Penetrations: 1. 2. Pipe: Install insulation continuously through floor penetrations. Seal penetrations through fire-rated assemblies.

3.4

SCHEDULES A. Water Supply Services Piping Insulation Schedule:

PLUMBING INSULATION 22 07 00 - 18

Plumbing Systems

Guide Specification

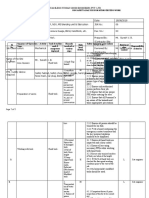

INSULATION PIPING SYSTEM Domestic Hot Water Supply and Recirculation Domestic Hot Water Supply and Recirculation systems with domestic water temperature maintenance cable Domestic Cold Water (Exposed) Deionized Water B. TYPE P-1 PIPE SIZE 1-1/4 inches and smaller 1-1/2 inches and larger P-1 1 inch and smaller 1-1/4 inches to 2 inches 2-1/2 inches and larger P-1 or P-5 1-1/4 inches and smaller 1-1/2 inches and larger P-1 or P-5 All sizes

INSULATION THICKNESS inches 1.0 2.0 1.0 1.5 2.0 0.75 1.0 1.0

Drainage Services Piping Insulation Schedule: INSULATION

PIPING SYSTEM

INSULATION TYPE

PIPE SIZE

THICKNESS inches

Storm Piping (horizontal above ground within building) Sanitary Sewer Piping (Exposed) C.

P-1 or P-5 P-1 or P-5

All sizes All sizes

1.0 1.0

Equipment Insulation Schedule: INSULATION

EQUIPMENT

INSULATION TYPE

THICKNESS inches 1.0 2.0 2.0 1.0 2.0

Roof Drain Bodies Domestic Hot Water Storage Tanks Domestic Water Storage Tanks Domestic Water Booster Pump Bodies Water Softeners and Tanks

E-2 E-1 E-2 E-1, E-2, E-5 E-1, E-2,

PLUMBING INSULATION 22 07 00 - 19

Plumbing Systems

Guide Specification

3.5

DOMESTIC WATER HEAT EXCHANGER INSULATION SCHEDULE A. Round, exposed breeching and connector insulation shall be the following: 1. 2. 3. B. Calcium Silicate: 4 inches thick. High-Temperature Mineral-Fiber Blanket: 3 inches thick and 3-lb/cu. ft. nominal density. High-Temperature Mineral-Fiber Board: 3 inches thick and 6-lb/cu. ft. nominal density.

Round, concealed breeching and connector insulation shall be the following: 1. 2. 3. Calcium Silicate: 4 inches thick. High-Temperature Mineral-Fiber Blanket: 3 inches thick and 3-lb/cu. ft. nominal density. High-Temperature Mineral-Fiber Board: 3 inches thick and 6-lb/cu. ft. nominal density.

C.

Rectangular, exposed breeching and connector insulation shall be the following: 1. 2. 3. Calcium Silicate: 4 inches thick. High-Temperature Mineral-Fiber Blanket: 3 inches thick and 3-lb/cu. ft. nominal density. High-Temperature Mineral-Fiber Board: 3 inches thick and 6-lb/cu. ft. nominal density.

D. Rectangular, concealed breeching and connector insulation shall be the following: 1. 2. 3. 3.6 Calcium Silicate: 4 inches thick. High-Temperature Mineral-Fiber Blanket: 3 inches thick and 3-lb/cu. ft. nominal density. High-Temperature Mineral-Fiber Board: 3 inches thick and 6-lb/cu. ft. nominal density.

OUTDOOR, UNDERGROUND PIPING INSULATION SCHEDULE A. Grease Waste Piping, All Sizes, Where Heat Tracing Is Installed: Cellular glass, 2 inches thick.

3.7

UNDERGROUND, FIELD-INSTALLED INSULATION JACKET A. For underground direct-buried piping applications, install underground direct-buried jacket over insulation material.

END OF SECTION 22 07 00

PLUMBING INSULATION 22 07 00 - 20

Plumbing Systems

You might also like

- Piping & Equipt Insulation - RevDocument7 pagesPiping & Equipt Insulation - RevLuis Gabriel BautistaNo ratings yet

- C610 PDFDocument4 pagesC610 PDFGLADYS2714No ratings yet

- Fact Sheet - Tornadoes PDFDocument2 pagesFact Sheet - Tornadoes PDFcelcarenupierdeNo ratings yet

- TM Underground ShelterDocument58 pagesTM Underground ShelterTom Jubert0% (1)

- Installation Manual HVAC Pipework and Ductwork 2012 PDFDocument24 pagesInstallation Manual HVAC Pipework and Ductwork 2012 PDFsasan490% (1)

- 0015-2 GL Guidelines For Approval of Construct, Towage and InstallDocument22 pages0015-2 GL Guidelines For Approval of Construct, Towage and InstalldamnagedNo ratings yet

- Pipe Insulation Section OverviewDocument8 pagesPipe Insulation Section OverviewManjunath ShettyNo ratings yet

- 224 19 Static Vaccum Insulated Cryogenic Vessels Operation and InspectionDocument48 pages224 19 Static Vaccum Insulated Cryogenic Vessels Operation and InspectionZasaliveNo ratings yet

- ASTM C1696-15 Standard Guide For Industrial Thermal Insulation SystemsDocument36 pagesASTM C1696-15 Standard Guide For Industrial Thermal Insulation SystemsGOPALJI SINGH100% (4)

- Quality Control System Fabrication Heat ExchangersDocument5 pagesQuality Control System Fabrication Heat ExchangersCorine CaracasNo ratings yet

- Advance Level EngineerDocument28 pagesAdvance Level EngineerBoni MagtibayNo ratings yet

- Seminar of Underwater Welding & Inspection: Ali Malik Saadoon University of Baghdad Engineering Affairs DepartmentDocument44 pagesSeminar of Underwater Welding & Inspection: Ali Malik Saadoon University of Baghdad Engineering Affairs Departmentpraphul gamangoNo ratings yet

- Vibrations: Consulting ServicesDocument20 pagesVibrations: Consulting ServicesAgung Pramu AjiNo ratings yet

- Thermal Power PlantDocument16 pagesThermal Power Plantmprasad_veena100% (1)

- The Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Document4 pagesThe Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Rushan Lakdimuthu100% (1)

- Plumbing Piping InsulationDocument9 pagesPlumbing Piping InsulationMY PCNo ratings yet

- ASME BPV Code Section VIII Divisions: Requirements for Pressure Vessel Design and ConstructionDocument5 pagesASME BPV Code Section VIII Divisions: Requirements for Pressure Vessel Design and ConstructionDiana CarolinaNo ratings yet

- Best Home Insulators for Ice CubesDocument10 pagesBest Home Insulators for Ice Cubesrianne180% (1)

- FM Approval 4924Document18 pagesFM Approval 4924Thành Đại GiaNo ratings yet

- Gupta Santosh K - Optimization For EngineersDocument22 pagesGupta Santosh K - Optimization For Engineerseasy BooksNo ratings yet

- Thermal Insulation Application GuideDocument7 pagesThermal Insulation Application GuideAbhishek KumarNo ratings yet

- MineralWoolInsulation Data SheetDocument18 pagesMineralWoolInsulation Data SheetAnonymous MB5YbaLrBENo ratings yet

- Equipment Insulation SpecificationDocument7 pagesEquipment Insulation Specificationadel rihanaNo ratings yet

- RES6 Rules For Pleasure Yachts 2023 - Part B 1.1.2023Document297 pagesRES6 Rules For Pleasure Yachts 2023 - Part B 1.1.2023Emanuele ButtàNo ratings yet

- Mechanical Insulation Standards at UT AustinDocument8 pagesMechanical Insulation Standards at UT Austinrizviabbas2012No ratings yet

- MSG Flood Risk Assessment WSP - 70038867-r04 Fra01 v5 PDFDocument36 pagesMSG Flood Risk Assessment WSP - 70038867-r04 Fra01 v5 PDFabhay dubeyNo ratings yet

- Peak of Flight Newsletter Rocket PlansDocument97 pagesPeak of Flight Newsletter Rocket PlansPierre LalsingNo ratings yet

- 2013 Container Information BulletinDocument13 pages2013 Container Information BulletinAaron Huaynate EspinozaNo ratings yet

- Afi SC03 QRBN Ci 00233Document1 pageAfi SC03 QRBN Ci 00233حسن كاظم ريسان B-4No ratings yet

- Vendor Approval Compliance Sheet for GFRC WorksDocument16 pagesVendor Approval Compliance Sheet for GFRC WorksRavi Shankar KolluruNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- MSDS Portland Cement PDFDocument5 pagesMSDS Portland Cement PDFMohamad TaufikNo ratings yet

- NAHAD Design Handbook SampleDocument10 pagesNAHAD Design Handbook SampleAnoop G PillaiNo ratings yet

- Ab-522 Standard Pneumatic Test Procedure Requirements PDFDocument17 pagesAb-522 Standard Pneumatic Test Procedure Requirements PDFMarizta Perdani PutriNo ratings yet

- CES Business PresentationDocument50 pagesCES Business PresentationGary David CrowhurstNo ratings yet

- Hydrotest Welding and NDTDocument11 pagesHydrotest Welding and NDTALFA ENGINEERINGNo ratings yet

- Hydrotesting Job Safety AnalysisDocument5 pagesHydrotesting Job Safety Analysissakthi venkatNo ratings yet

- TDS Link Ears and Pins MPIDocument1 pageTDS Link Ears and Pins MPIRanjithNo ratings yet

- 2015 Container Exam BulletinDocument14 pages2015 Container Exam BulletinAndrés Falla VictoriaNo ratings yet

- Sky Stage Ultra Boiler Platform (UM 36 100)Document14 pagesSky Stage Ultra Boiler Platform (UM 36 100)Scherloscobit CGNo ratings yet

- Contoh Pengisian Enrollment FormDocument3 pagesContoh Pengisian Enrollment FormAbu Akhtar Aira AlthafNo ratings yet

- QC 64247-1 Contact Plate Inspection ReportDocument2 pagesQC 64247-1 Contact Plate Inspection ReportSenthil KumarNo ratings yet

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocument5 pagesSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNo ratings yet

- Anchor Bolt and Setting TemplateDocument5 pagesAnchor Bolt and Setting Templatemadhu_bgrNo ratings yet

- 5-Valve Manifold - Butt WeldDocument1 page5-Valve Manifold - Butt Weldhaisam sarwarNo ratings yet

- Burea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFDocument236 pagesBurea Veritas - Rules On Materials Ans Welding For The Classification On Marine Units PDFAnonymous 7tBrl8No ratings yet

- Part K MATERIALS 430 - Erstl - K - Egstl - K-CV - 2013Document209 pagesPart K MATERIALS 430 - Erstl - K - Egstl - K-CV - 2013Dave DumontNo ratings yet

- Monica ChiDocument2 pagesMonica ChikarthikawarrierNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- 1 Identification of The Substance/preparation and of The Company/undertakingDocument7 pages1 Identification of The Substance/preparation and of The Company/undertakingShadin Asari ArabaniNo ratings yet

- Clarkson C-Valve Iom ManualDocument102 pagesClarkson C-Valve Iom Manualpca9750% (2)

- Microsoft Project 2000 Foundation Level Training ManualDocument149 pagesMicrosoft Project 2000 Foundation Level Training Manualfal_engNo ratings yet

- Ingress Protection (IP)Document2 pagesIngress Protection (IP)nileshb1985No ratings yet

- 23 07 00 HVAC InsulationDocument17 pages23 07 00 HVAC InsulationAhmed AzadNo ratings yet

- 230719Document10 pages230719Jothimanikkam SomasundaramNo ratings yet

- 07 2100 - Building InsulationDocument7 pages07 2100 - Building InsulationAngelo Carlo MalabananNo ratings yet

- Project Standard Specification: Pipe Insulation 15083 - Page 1/15Document15 pagesProject Standard Specification: Pipe Insulation 15083 - Page 1/15adel rihanaNo ratings yet

- Armaflex Insulation + Fire Rated DuctworkDocument7 pagesArmaflex Insulation + Fire Rated DuctworkGiải Pháp Cơ ĐiệnNo ratings yet

- HVAC Piping Insulation-Fiberglas InsulationDocument7 pagesHVAC Piping Insulation-Fiberglas Insulationbudi budihardjoNo ratings yet

- Afico Pipe Insulation PDFDocument4 pagesAfico Pipe Insulation PDFHusni HayathNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationuddinnadeemNo ratings yet

- 092900Document5 pages092900Manuela AvendañoNo ratings yet

- Section 07210 Building InsulationDocument7 pagesSection 07210 Building InsulationMØhãmmed ØwięsNo ratings yet

- 23 07 19 HVAC Piping InsulationDocument24 pages23 07 19 HVAC Piping InsulationSoumojit SamantaNo ratings yet

- InsulationDocument3 pagesInsulationjituahirNo ratings yet

- RegulationDocument15 pagesRegulationLuzhengyeNo ratings yet

- 1 RoofingDocument6 pages1 RoofingEfz EfzNo ratings yet

- C-9302C Interposing Relay Module Issue4.03Document2 pagesC-9302C Interposing Relay Module Issue4.03Agung Pramu AjiNo ratings yet

- 50031161662011fa PDFDocument88 pages50031161662011fa PDFAgung Pramu AjiNo ratings yet

- Trafo Temp ControllerDocument8 pagesTrafo Temp ControllerNey VelNo ratings yet

- Liquid Level IndicatorDocument6 pagesLiquid Level IndicatorSantiago PeñuelaNo ratings yet

- 993331G CAT Accessories Catalog LoRDocument32 pages993331G CAT Accessories Catalog LoRAgung Pramu AjiNo ratings yet

- GSTDocument2 pagesGSTAgung Pramu AjiNo ratings yet

- C-9503 Loop Isolator Features and InstallationDocument2 pagesC-9503 Loop Isolator Features and InstallationAgung Pramu AjiNo ratings yet

- Multi-Objective Optimization Design of Cycloid Pin Gear Planetary ReducerDocument10 pagesMulti-Objective Optimization Design of Cycloid Pin Gear Planetary ReducerAgung Pramu AjiNo ratings yet

- Earthmoving Materials and Operations PDFDocument27 pagesEarthmoving Materials and Operations PDFAgung Pramu AjiNo ratings yet

- 053Document10 pages053Agung Pramu AjiNo ratings yet

- YX-DL Integrated Sulfur Analyzer (Indonesia)Document1 pageYX-DL Integrated Sulfur Analyzer (Indonesia)Agung Pramu AjiNo ratings yet

- Pulsa Series 680 IomDocument26 pagesPulsa Series 680 IomAgung Pramu AjiNo ratings yet

- Newsletter 1 2013 EnglishDocument16 pagesNewsletter 1 2013 EnglishAgung Pramu AjiNo ratings yet

- Seamless Mechanical Steel Tubing Specification & SizesDocument6 pagesSeamless Mechanical Steel Tubing Specification & Sizespasanac77No ratings yet

- Leakness TestDocument8 pagesLeakness TestAndra MirrleesNo ratings yet

- De-Mystifying AutoCAD Plant 3D IsometricsDocument71 pagesDe-Mystifying AutoCAD Plant 3D IsometricsJorge Andrés PovedaNo ratings yet

- Interaction Between Sootblower Jet and Superheater Platens in Recovery BoilersDocument4 pagesInteraction Between Sootblower Jet and Superheater Platens in Recovery BoilersAgung Pramu AjiNo ratings yet

- 06-010504.012 Compressed Air Storage PDFDocument8 pages06-010504.012 Compressed Air Storage PDFAgung Pramu AjiNo ratings yet

- 9 Specification For Mechanical Pipework Insulation PDFDocument4 pages9 Specification For Mechanical Pipework Insulation PDFAgung Pramu AjiNo ratings yet

- 0752 ARMAFLEX in Mechanical Piping InsulationDocument15 pages0752 ARMAFLEX in Mechanical Piping InsulationAgung Pramu AjiNo ratings yet

- PARCOL HB ControlValve Sizing 2013Document24 pagesPARCOL HB ControlValve Sizing 2013gion_ro401100% (1)

- Engineering Analysis of An Offshore Pipeline On An Escarpment in A Seismically Active Zone A Case Study in The CaspianDocument8 pagesEngineering Analysis of An Offshore Pipeline On An Escarpment in A Seismically Active Zone A Case Study in The CaspianD Toño ToroNo ratings yet

- PARCOL HB ControlValve Sizing 2013Document24 pagesPARCOL HB ControlValve Sizing 2013gion_ro401100% (1)

- 007 TubingandpipeDocument48 pages007 TubingandpipejaytronizerNo ratings yet

- Vent Silencer - PulscoDocument13 pagesVent Silencer - PulscodigecaNo ratings yet

- Msds 440 Butyl Gasket PDFDocument2 pagesMsds 440 Butyl Gasket PDFAgung Pramu AjiNo ratings yet

- 1Document30 pages1Agung Pramu Aji0% (1)

- استخدامات العزلDocument38 pagesاستخدامات العزلroseNo ratings yet

- AS 1530.4 Fire-Resistance Tests of Elements of Building ConstructionDocument47 pagesAS 1530.4 Fire-Resistance Tests of Elements of Building ConstructionIbrahim KNo ratings yet

- DETAILED SYLLABUS FOR ASSISTANT PROFESSOR (CHEMICAL ENGINEERINGDocument10 pagesDETAILED SYLLABUS FOR ASSISTANT PROFESSOR (CHEMICAL ENGINEERINGanu molNo ratings yet

- Heat Transfer Coefficient Composite WallDocument44 pagesHeat Transfer Coefficient Composite WallNaveen luckyNo ratings yet

- 3 +shawcor+ (Pipeline+Performance+Group)Document29 pages3 +shawcor+ (Pipeline+Performance+Group)kikorrasNo ratings yet

- Segment Brochure Elotex BermocollDocument16 pagesSegment Brochure Elotex BermocollVictor ZuñigaNo ratings yet

- Steam consumption specifications for single corrugatorDocument2 pagesSteam consumption specifications for single corrugatorV U P RaoNo ratings yet

- Floor Heating CalculationDocument6 pagesFloor Heating CalculationБаасанхүү ЛхагвачулуунNo ratings yet

- Electric Vehicle Battery Pack Design For Mitigating Thermal Runaway PropagationDocument6 pagesElectric Vehicle Battery Pack Design For Mitigating Thermal Runaway PropagationSanket AmbadagattiNo ratings yet

- FCL y Un50 13Document7 pagesFCL y Un50 13DuskoNo ratings yet

- VIESSMANN DHW Calculation VitocellTechnicalGuideDocument52 pagesVIESSMANN DHW Calculation VitocellTechnicalGuideaakoglanisNo ratings yet

- Physical Performance of Industrial and EPS and Cork 2019 Construction and BuDocument10 pagesPhysical Performance of Industrial and EPS and Cork 2019 Construction and Bujmaurício_161194No ratings yet

- Drain Pipe Insulation BrochureDocument2 pagesDrain Pipe Insulation BrochureTeoxNo ratings yet

- Pre QualificationDocument146 pagesPre QualificationriyasNo ratings yet

- Price List For Painting Works: 2450 0000 PS 2300 03 A Mangalore Pta Plant JBF Petrochemicals LimitedDocument24 pagesPrice List For Painting Works: 2450 0000 PS 2300 03 A Mangalore Pta Plant JBF Petrochemicals LimitedSoumitra GuptaNo ratings yet

- Chapter 5 - Lecture NotesDocument18 pagesChapter 5 - Lecture NotesAAANo ratings yet

- LIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONDocument3 pagesLIGHTWEIGHT, NON-SAGGING BUILDING INSULATIONAnwar SyedNo ratings yet

- AP Armaflex Sheet & RollDocument4 pagesAP Armaflex Sheet & RollabbasithNo ratings yet

- Circular Building Process Reuse of Insulators From Construction and Demolition Waste To Produce Lime MortarsBuildings PDFDocument25 pagesCircular Building Process Reuse of Insulators From Construction and Demolition Waste To Produce Lime MortarsBuildings PDFGonzalo Fuentes GuimetNo ratings yet

- Actividad 2 AraujoDocument10 pagesActividad 2 AraujoAngel AraujoNo ratings yet

- Instructions:: University of Pune Polymer/Petroleum/Petrochemical) Momentum TransferDocument42 pagesInstructions:: University of Pune Polymer/Petroleum/Petrochemical) Momentum TransferEkugum Pascal ChinedumNo ratings yet

- Childers PDS CP 70 R0719Document2 pagesChilders PDS CP 70 R0719Maikol Cedeño CerdasNo ratings yet

- CSEC PHYSICS HEAT TRANSFERDocument6 pagesCSEC PHYSICS HEAT TRANSFEROsmany MadrigalNo ratings yet

- Norsok C-002 Architectural Components and EquipmentDocument64 pagesNorsok C-002 Architectural Components and EquipmentNam Un KimNo ratings yet

- Polyisocyanurate InsulationDocument2 pagesPolyisocyanurate Insulationalfreddieick1No ratings yet

- Md. Alamgir Hossain: Lecturer (ME) Department of Textile Engineering Green University of Bangladesh (GUB)Document14 pagesMd. Alamgir Hossain: Lecturer (ME) Department of Textile Engineering Green University of Bangladesh (GUB)saimunNo ratings yet