Professional Documents

Culture Documents

Ê Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷

Uploaded by

RussiaLeaks0 ratings0% found this document useful (0 votes)

8 views3 pagesOriginal Title

D-31(1)

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesÊ Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷

Uploaded by

RussiaLeaksCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

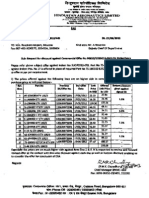

An AS 9100C and

ISO 14001-2004 Company

|r-=rr-r r -rr |c+=r |-r|-rc=

HINDUSTAN AERONAUTICS LIMITED

| || , , |-| .|||| / Sukhoi Engine Division

,A Govt of India Undertaking Under Ministry of Defence)

| -||| | o.,, ||-|| : +| ||, ~| | ||, |||

Sunabeda 763 002 Dist. Koraput ,Odisha,India

Phone : +916853 221200, Fax : +916853 222292

Fax : +91891-2755464 (Vizag)

| ||-|| ++/+, +|-| | , | |-| +. +, +| -| +||| +., o+, , , ++|: +., o+.

Corporate Office: 15/1, Cubbon Road, Bangalore-560 001 Phone: Office: 91-80-2232 0701, 2232 0903 Fax : 91-80-2232 0758

||||, / Website: www.hal-india.com

HAL/KPT/SED/D/2014/31 Date : 30-01-2014

To

1. Mr. V V Kiryukhin,

Chief Designer,

Lyulka SATURN, Moscow.

13,Kasatkin Street, Moscow-

129301

Fax: 007-495-6867566.

2. Mr. Igor Chechikov,

JSC OBORONPROM, MOSCOW,

29/141, Vereiskaya Street

p/o: #26, , 121357 Moscow, Russia

Fax: 007-495-2236414, 7975548.

3. Mr. A N Permyakov

Director License Programme

UMPO, UFA

2 Ferina Street, 45003

Russia

Telex: 162340RICA RU

Fax: 007-3472-383655.

4. Rpt: RM, Moscow

Sub: Improvements in Bearing Design to preclude recurrent failures of

AL31FP engines.

Operational confidence level of the Indian Air Force has significantly

reduced due to recurrent premature failures of AL-31FP Engines and increasing

trend of single engine emergency landings. Details of 41 cases of single engine

emergency landings were discussed in various forums such as IRSA and Tripartite

Meeting at Air HQ with OEM representatives. Of the total 41 cases, 11 cases were

due to Bearing failures (Inter Rotor and Inter Shaft Bearing).

Failure of both these Bearings could be the manifestations of various serious

Design deficiencies in the present Design for AL-31FP engines which are to be

identified explicitly on the highest priority, and the Design modifications are to be

incorporated in a time bound manner in order to boost the diminishing confidence

level of the Indian Air Force.

Contd 2

--2--

As a way forward Russian side has proposed 20 recommendations (11 for

Manufacturing and 9 for Exploitation) after Joint Investigation was carried out

along with Indian side. Recommendation is given for modification of Inter Rotor

bearing (Part No: 5-272822P2Y) with improved cooling of the Bearing by

introduction of additional Lubrication oil supply holes.

Indian side is of the opinion that this recommendation is a short term solution

to the Bearing failure problem. Other critical design aspects such as Material

characteristics of the Bearing races and Rollers, Micro-structural changes leading to

plastic deformation during operation, Material erosion and Load characteristics need

to be introspected and validated.

Preliminary findings/Analysis of the Cat-A Bearings vis a vis failed Engine

Bearing reveal the following:

1. Inter-shaft bearing (55-2672919P5):

a. Abrasive wear and moisture corrosion observed on raceway with

discoloration of outer ring.

b. Plastic deformation of inner ring with discoloration and abrasive and

adhesive wear on raceway.

c. Crack initiation on almost all cage pockets.

d. Spalling observed in cage pockets at roller contact.

e. High ovality noticed on inner and outer rings.

f. Signs of overheating seen with micro-structural changes leading to

deformation.

g. Hardness profiles of outer ring showed low hardness values from

raceway to core rather than from outer diameter to core which

confirms heat generation is high on raceway compared to outer

diameter.

2. Inter-rotor bearing (5-272822P2Y):

a. Outer ring and inner ring raceways shows false brinelling marks, spalling

and plastic deformation. Also fretting and micro cracks were observed

on one side of face end of outer ring.

Contd 3

You might also like

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Root Cause Analysis of Bridle Roll Shaft Failure at Continuous Process IndustryDocument15 pagesRoot Cause Analysis of Bridle Roll Shaft Failure at Continuous Process IndustryPuja BhandarkarNo ratings yet

- Fitness For Service Assessment of Ageing Pressure Vessel Experiencing External Corrosion: A Case StudyDocument5 pagesFitness For Service Assessment of Ageing Pressure Vessel Experiencing External Corrosion: A Case StudyBhanwraa AawaraNo ratings yet

- Design and Analysis of A Tubular Space Frame Chassis of A High Performance Race CarDocument5 pagesDesign and Analysis of A Tubular Space Frame Chassis of A High Performance Race CaresatjournalsNo ratings yet

- RJ 32 14Document7 pagesRJ 32 14EvgenNo ratings yet

- Casting Defects in Low-PressureDocument8 pagesCasting Defects in Low-PressureNishant Jain100% (2)

- WX 100Document17 pagesWX 100anon_967426204100% (1)

- Failure Analysis of An Automobile Coil SpringDocument8 pagesFailure Analysis of An Automobile Coil Springdarkace00000No ratings yet

- Fatigue Analysis PDFDocument6 pagesFatigue Analysis PDFPallavit NigamNo ratings yet

- Norma FiatDocument15 pagesNorma FiatmirosekNo ratings yet

- High Temperature Solid LubricantDocument19 pagesHigh Temperature Solid Lubricantgcytd65e756c56e765rNo ratings yet

- Life and Failure of Aircraft Wheels - A ReviewDocument6 pagesLife and Failure of Aircraft Wheels - A ReviewIca IcaNo ratings yet

- Modeling and Static Analysis of Alloy Wheel Using Different MaterialsDocument6 pagesModeling and Static Analysis of Alloy Wheel Using Different MaterialsVAISHNAVI KOHALENo ratings yet

- Air 5065Document11 pagesAir 5065niky186No ratings yet

- MAHACY80ENGINEDocument13 pagesMAHACY80ENGINEIlham grix SanjayaNo ratings yet

- National Transportation Safety Board: Docket No. SA-542 Exhibit No. 15-ADocument41 pagesNational Transportation Safety Board: Docket No. SA-542 Exhibit No. 15-AGFNo ratings yet

- AC 20-97 Amdt 0Document13 pagesAC 20-97 Amdt 0Harry NuryantoNo ratings yet

- ENI - Casing Design ManualDocument134 pagesENI - Casing Design Manualwelltest2012100% (14)

- Designofthe Aircraft Groundingand Mooring SystemDocument77 pagesDesignofthe Aircraft Groundingand Mooring SystemEvrenNo ratings yet

- PROJECT STANDARDS and SPECIFICATIONS Inspection of Rotating Equipment Rev01webDocument4 pagesPROJECT STANDARDS and SPECIFICATIONS Inspection of Rotating Equipment Rev01webhiyeonNo ratings yet

- HKKJR LJDKJ Jsy Ea KyDocument18 pagesHKKJR LJDKJ Jsy Ea KymailbkraoNo ratings yet

- Oisd STD-141Document31 pagesOisd STD-141Jyotsana Rawat83% (6)

- Sae Ams S 13165Document27 pagesSae Ams S 13165sabrunoNo ratings yet

- Rolling Element Bearing Failure AnalysisDocument4 pagesRolling Element Bearing Failure AnalysisYanuar KrisnahadiNo ratings yet

- Ceramic Rolling Element Damage Sensitivity and Gearbox System ResponseDocument9 pagesCeramic Rolling Element Damage Sensitivity and Gearbox System ResponseAnonymous lEX5U51wOANo ratings yet

- Document Wta 501 2 PDFDocument37 pagesDocument Wta 501 2 PDFTibin ThomasNo ratings yet

- Pt6-42a Comp Turbine WashDocument8 pagesPt6-42a Comp Turbine WashSky SoccerNo ratings yet

- Análisis de Fallos de Fundición de Aleaciones de Aluminio en Cuatro RuedasDocument8 pagesAnálisis de Fallos de Fundición de Aleaciones de Aluminio en Cuatro Ruedasjohnny oreNo ratings yet

- NHA General Specification Dec-1998Document541 pagesNHA General Specification Dec-1998Saad Ullah87% (46)

- Subject: Aircraft Tire Maintenance and Operational Practices Date: 4/18/05 Initiated By: AFS-306 AC No.: 20-97B ChangeDocument10 pagesSubject: Aircraft Tire Maintenance and Operational Practices Date: 4/18/05 Initiated By: AFS-306 AC No.: 20-97B ChangeDavid Samaniego PánchezNo ratings yet

- Nasa Rolling-Element Bearings - A Review of State of ArtDocument87 pagesNasa Rolling-Element Bearings - A Review of State of Artchetan_thakur4278100% (1)

- 32 Samss 005Document33 pages32 Samss 005naruto256100% (1)

- 2018 - Experimental Research in Automobile NPT Force Heterogeneity - Matecconf - Icmtmte2018 - 02019Document5 pages2018 - Experimental Research in Automobile NPT Force Heterogeneity - Matecconf - Icmtmte2018 - 02019gkarohikaNo ratings yet

- 32 Samss 005Document34 pages32 Samss 005ரமேஷ் பாலக்காடுNo ratings yet

- Chassis ModificationDocument46 pagesChassis ModificationJawahar Raj0% (1)

- STD 125Document18 pagesSTD 125Joydev GangulyNo ratings yet

- Engineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunDocument10 pagesEngineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunBima SorayaNo ratings yet

- Selectively Reinforced Squeeze Cast PistonsDocument6 pagesSelectively Reinforced Squeeze Cast PistonsAswath RamNo ratings yet

- Sae J518 1993 PDFDocument14 pagesSae J518 1993 PDFdinesh panchal67% (3)

- Main Landing Gear Wheel Failure Involving A Boeing 737, ZK-ZQBDocument7 pagesMain Landing Gear Wheel Failure Involving A Boeing 737, ZK-ZQBTimothy IsholaNo ratings yet

- 4-Spalling Investigation of Connecting RodDocument10 pages4-Spalling Investigation of Connecting RodHakimNo ratings yet

- TurbineDocument12 pagesTurbineMMPAPNo ratings yet

- Machinery Failure Analysis Troubleshooting Fourth Edition1Document7 pagesMachinery Failure Analysis Troubleshooting Fourth Edition1Juanma GarcíaNo ratings yet

- Hyd DamperDocument12 pagesHyd DampermailbkraoNo ratings yet

- Worm Gearbox Bearing Life PredictionDocument6 pagesWorm Gearbox Bearing Life Predictionhangmann169No ratings yet

- 32 Samss 005Document34 pages32 Samss 005jagp_24No ratings yet

- On The Design of Rear Uprights For A Race Car: Research On Engineering Structures and Materials November 2020Document19 pagesOn The Design of Rear Uprights For A Race Car: Research On Engineering Structures and Materials November 2020Aswin P SubhashNo ratings yet

- Ford Y-Block Engines: How to Rebuild & ModifyFrom EverandFord Y-Block Engines: How to Rebuild & ModifyRating: 4.5 out of 5 stars4.5/5 (3)

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- DMA December 12, 2013Document44 pagesDMA December 12, 2013RussiaLeaksNo ratings yet

- DMA December 09, 2013Document52 pagesDMA December 09, 2013RussiaLeaksNo ratings yet

- DMA December 09, 2013Document52 pagesDMA December 09, 2013RussiaLeaksNo ratings yet

- DMA December 12, 2013Document44 pagesDMA December 12, 2013RussiaLeaksNo ratings yet

- DMA December 12, 2013Document44 pagesDMA December 12, 2013RussiaLeaksNo ratings yet

- DMA December 09, 2013Document52 pagesDMA December 09, 2013RussiaLeaksNo ratings yet

- Dispatch Contract 1261Document1 pageDispatch Contract 1261RussiaLeaksNo ratings yet

- Department 1124Document3 pagesDepartment 1124RussiaLeaksNo ratings yet

- Digambar Adhar BagulDocument3 pagesDigambar Adhar BagulRussiaLeaksNo ratings yet

- Details of ReceiptsDocument4 pagesDetails of ReceiptsRussiaLeaksNo ratings yet

- Department 1125Document4 pagesDepartment 1125RussiaLeaksNo ratings yet

- Sukhoi Engine Division, Koraput 31 IRSA - DEPARTMENT: 0630/0631/0632/0633Document3 pagesSukhoi Engine Division, Koraput 31 IRSA - DEPARTMENT: 0630/0631/0632/0633RussiaLeaksNo ratings yet

- Department 3907Document12 pagesDepartment 3907RussiaLeaksNo ratings yet

- Department - 3907Document8 pagesDepartment - 3907RussiaLeaksNo ratings yet

- Deepak Budha SuryawanshiiDocument3 pagesDeepak Budha SuryawanshiiRussiaLeaksNo ratings yet

- Covering LetterDocument1 pageCovering LetterRussiaLeaksNo ratings yet

- Critical PartsDocument6 pagesCritical PartsRussiaLeaksNo ratings yet

- Critical Issues 27.01.14Document6 pagesCritical Issues 27.01.14RussiaLeaksNo ratings yet

- Ê Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷Document3 pagesÊ Þxnöùºiééxé B®Úéäxééìê) Õcºé Ê Éê É) Äõb÷RussiaLeaksNo ratings yet

- Critical IssuesDocument6 pagesCritical IssuesRussiaLeaksNo ratings yet

- Critical Issues-1 30.12.13Document5 pagesCritical Issues-1 30.12.13RussiaLeaksNo ratings yet

- Critical Issues As On 17th Dec 2013Document2 pagesCritical Issues As On 17th Dec 2013RussiaLeaksNo ratings yet

- Comments On CO of JSC ROEDocument1 pageComments On CO of JSC ROERussiaLeaksNo ratings yet

- Corst JensDocument2 pagesCorst JensRussiaLeaksNo ratings yet

- Coorrected - Consent Letter From JV PartnersDocument1 pageCoorrected - Consent Letter From JV PartnersRussiaLeaksNo ratings yet

- Contract 67 CorrectDocument1 pageContract 67 CorrectRussiaLeaksNo ratings yet

- Comments On CO of JSC ROEDocument1 pageComments On CO of JSC ROERussiaLeaksNo ratings yet

- Comments On CO of JSC ROEDocument1 pageComments On CO of JSC ROERussiaLeaksNo ratings yet

- Comments On CO of JSC ROEDocument1 pageComments On CO of JSC ROERussiaLeaksNo ratings yet